Chip Blaster manual - Salvex

Chip Blaster manual - Salvex

Chip Blaster manual - Salvex

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Chip</strong>BLASTER, Inc. 99<br />

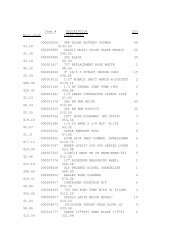

27.0. OPTIONAL EQUIPMENT (Cont.):<br />

27.1. Magelis Human Interface Unit (HMI) (Cont.)<br />

27.1.6. The order of screens are:<br />

27.1.6.1. Machine run time.<br />

27.1.6.2. Circuit breaker or overload trip.<br />

27.1.5.3.Pressure below 300 PSIG (requires optional pressure switch).<br />

27.1.5.4.Tank low limit.<br />

27.1.5.5.Drive fault.<br />

27.1.5.6.Filter “A” dirty.<br />

27.1.5.7.Filter “B” dirty.<br />

27.1.5.8.Post filter dirty.<br />

27.1.7. Also included as part of the HMI programming is the “Super Users Group” In this<br />

screens it possible to modify certain control parameters. The parameters are:<br />

27.1.7.1. Coolant #1 off delay set point adjustable from 0 to 2.5 seconds (default<br />

is 2.5 seconds).<br />

27.1.7.2. Coolant #2 off delay set point adjustable from 0 to 2.5 seconds (default<br />

is 2.5 seconds).<br />

27.1.7.3. Skimmer off set point adjustable from 5 to 30 minutes (default is 10<br />

minutes).<br />

27.1.7.4. Skimmer on set point adjustable from 1 to 20 minutes (default is 5<br />

minutes).<br />

27.1.7.5. Slow coolant return delay before warning set point adjustable from 2 to<br />

4 minutes (default is 2 minutes).<br />

27.1.7.6. Low pressure switch enable. This will enable the use of an optional<br />

pressure switch to monitor outlet number 1. An alarm will be sounded if<br />

the pressure falls below 300 PSIG (20.6 bar).<br />

27.1.7.7. Autocross enable. This will enable automatic change over from filter A<br />

to filter B when filter A becomes dirty. This requires factory installed<br />

filters, solenoid valves and additional inputs/outputs from the PLC.<br />

THIS NOT A RECOMMENDED FIELD MODIFICATION.<br />

27.1.7.8. Run relay enable. This option sets the <strong>Chip</strong>BLASTER to run<br />

continuous with high pressure controlled by the “Call for coolants” only.<br />

This option would be used for machine tools that have multiple fast tool<br />

changes with short cycle times.<br />

27.1.7.9. Pulsed “M” code enable. This option sets the <strong>Chip</strong>BLASTER to operate<br />

using a pulsed “M” code in lieu of a maintained “M” code. When this<br />

option is enabled a “FIN” / “ACH” signal is available as an output to<br />

machine tool. Also available is a input to the <strong>Chip</strong>BLASTER for a<br />

machine tool door open switch.<br />

27.1.7.10. Low pressure hose wash down enable. This option allows the use of a<br />

“garden” style hose to be used to with low pressure filtered coolant to<br />

wash off the mill table or tomb stone during a part change.<br />

THIS NOT A RECOMMENDED FIELD MODIFICATION.<br />

27.1.7.11. Low pressure flood coolant enable. This will enable the<br />

<strong>Chip</strong>BLASTER to supply low pressure filtered coolant through coolant<br />

number 1 outlet to the machine tool.<br />

THIS NOT A RECOMMENDED FIELD MODIFICATION.<br />

27.1