Chip Blaster manual - Salvex

Chip Blaster manual - Salvex

Chip Blaster manual - Salvex

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Chip</strong>BLASTER, Inc. 40<br />

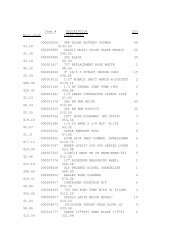

14.0. PREVENTATIVE MAINTENANCE: (Cont.):<br />

14.25. TANK - CLEANING:<br />

14.25.1. Coolant in the tank should be drained yearly so that the tank may be properly<br />

14.17-14.23<br />

cleaned.<br />

14.25.2. Dispose of fluid per local regulations.<br />

14.25.3. Clean all baffles and replace.<br />

14.25.4. After tank has been cleaned, all filters should be replaced.<br />

14.25.5. The <strong>Chip</strong>BLASTER should be stated as a new unit. Refer to SECTION 10.0.<br />

14.27. PUMP MOUNTING BOLTS – CHECK:<br />

14.27.1. The filter pump mounting bolts should be checked for tightnes. The<br />

recommended torque is 210 IN LB (24 Newton-meters).<br />

14.27.2. The bolts for the main high pressure prussure pump to mounting rails should be<br />

torqued to 200 IN LB (23 Newton-meters).<br />

14.29. RETURN PUMP (<strong>Chip</strong>BLASTER supplied) – CHECK FLOW RATE:<br />

14.29.1. This pump should be checked every six months to insure the correct flow rate. If<br />

the flow rate has decreased, the pump should be rebuilt or replaced.<br />

14.29.2. An indication the return pump may be clogged will be constant “SLOW<br />

COOLANT RETURN” warnings.<br />

14.29.3. The <strong>Chip</strong>BLASTER must be powered down and the disconnect placed in the<br />

OFF position and locked out.<br />

14.29.4. Remove the inlet and outlet hoses by loosening the hose clamps. Inspect the inlet<br />

and outlet for chips that may have accumulated, remove chips as required.<br />

14.29.5. Remove the four (4) bolts using a 7/16” wrench that hold the casting in place.<br />

14.29.6. Clean all chips from the casting and impeller. Be careful not to damage the back<br />

of the casting where it mates to the adapter as this is a metal to metal seal.<br />

14.29.7. Re-assemble the casting and replace the four (4) bolts. Insure the casting is<br />

snugly in place. Check the shaft to insure it rotates freely. (Use the screwdriver<br />

slot in the motor to turn the shaft).<br />

14.29.8. Re-install the inlet and outlet hoses and tighten the hose clamps securely.<br />

14.29.9. Re-power the <strong>Chip</strong>BLASTER unit and check for leaks.<br />

14.30. RETURN PUMP (<strong>Chip</strong>BLASTER supplied) – CHECK FOR LEAKS:<br />

14.30.1. Check for leaks around the casting where it mates with the adapter.<br />

14.30.2. If pump is leaking around casting, tighten the four (4) bolts. DO NOT OVER<br />

TIGHTEN.<br />

14.31. RETURN PUMP (<strong>Chip</strong>BLASTER supplied) – INLET and OUTLET:<br />

14.31.1. Check for leaks around the inlet and outlet connections.<br />

14.31.2. If the hoses are cracked or cut replace hoses.