we keep things moving - STÃBER ANTRIEBSTECHNIK GmbH + Co ...

we keep things moving - STÃBER ANTRIEBSTECHNIK GmbH + Co ...

we keep things moving - STÃBER ANTRIEBSTECHNIK GmbH + Co ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Fundamentals of PROFIBUS<br />

Operation manual<br />

5<br />

5.3 Data transmission via PROFIBUS DP<br />

5.3.1 Possible communication<br />

Devices of the 5 th generation of STÖBER inverters support cyclic and acyclic<br />

services with the DP-V1 option. This provides a wide variety of possible ways to<br />

communicate:<br />

C2 - Master<br />

C2 - Master<br />

C1 - Master<br />

HMI<br />

1<br />

3<br />

2<br />

4<br />

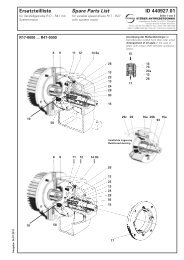

Fig. 5-2: Different communication options<br />

1: Cyclic communication<br />

2 - 4: Acyclic communication<br />

Cyclic communication (1) is the simple exchange of user data via the data<br />

exchange telegram. Time critical process data (PZD) are exchanged bet<strong>we</strong>en a<br />

class-1 master (C1) and the drive controller with cyclic communication. Such data<br />

include, for example, reference and actual values, and control and status<br />

information. A routine for parameter communication (of the familiar PKW channel<br />

as with the FDS 4000) can be implemented within the cyclic communication.<br />

There is always exactly one C1 master in each PROFIBUS setup. This master<br />

reads the GSD file, configures the drives, starts PROFIBUS and runs the cyclic<br />

communication. The C1 master is usually the controller (arrow 1).<br />

The acyclic services (2-4) are available in DP-V1 for the transmission of new<br />

parameter jobs for controlling and monitoring the drives, parallel to true cyclic<br />

communication.<br />

WE KEEP THINGS MOVING<br />

ID 441687.03<br />

21