Installation service by Step-Four Tips from the experts

Installation service by Step-Four Tips from the experts

Installation service by Step-Four Tips from the experts

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

No. 28 | March 2010<br />

www.step-four.at<br />

Maga zine<br />

<strong>Installation</strong> without renovation:<br />

<strong>Installation</strong> <strong>service</strong><br />

<strong>by</strong> <strong>Step</strong>-<strong>Four</strong><br />

Enormous:<br />

The Fairey Rotodyne<br />

model<br />

<strong>Tips</strong> <strong>from</strong> <strong>the</strong> <strong>experts</strong>:<br />

Professional know-how<br />

Face-lift for <strong>the</strong> hot wire cutting system | <strong>Tips</strong> & Tricks | Trade Fair Schedule

Editorial<br />

Dear readers!<br />

Ernst Ramberger<br />

Director<br />

<strong>Step</strong>-<strong>Four</strong> GmbH<br />

Spring awakening<br />

Just as nature will soon be in full bloom,<br />

we also want to break some ground and<br />

rise to <strong>the</strong> coming challenges with renewed<br />

zest and lots of energy, after a pretty<br />

turbulent year. In times such as <strong>the</strong>se,<br />

not only is it particularly important to manufacture<br />

products of <strong>the</strong> highest quality,<br />

but also to provide additional benefits. Although<br />

we have cultivated close customer<br />

relationships and followed a customer-oriented<br />

policy for many years, for 2010<br />

we intend to concentrate even more on <strong>the</strong><br />

areas of customer care, <strong>service</strong> and support.<br />

Because satisfied customers are and<br />

will always be <strong>the</strong> foundation of a prospering<br />

company.<br />

We find solutions<br />

Focussing on customer requirements<br />

has to begin even before machines are<br />

installed. With regard to this, we are<br />

able to provide our customer with solution<br />

proposals, even for <strong>the</strong> most tricky<br />

or cramped space conditions. More information<br />

can be ga<strong>the</strong>red <strong>from</strong> <strong>the</strong> inside<br />

pages. I am particularly pleased about <strong>the</strong><br />

delivery of <strong>the</strong> hi<strong>the</strong>rto largest <strong>Step</strong>-<strong>Four</strong><br />

system, an Xpert CUT 5000 with a cutting<br />

length of up to 8 metres!<br />

New look<br />

Here it is! The new <strong>Step</strong>-<strong>Four</strong> Magazine.<br />

After long and numerous brainstorming<br />

sessions, reams of ideas and a variety of<br />

layouts, we are very happy with <strong>the</strong> result.<br />

We not only revised <strong>the</strong> look of <strong>the</strong> new<br />

<strong>Step</strong>-<strong>Four</strong> Magazine, but we also decided<br />

to revise <strong>the</strong> content and perform a “relaunch”.<br />

After ten successful years of publishing<br />

our customer newsletter, you now<br />

hold a magazine in your hands that is more<br />

comprehensive than ever before. We hope<br />

that you like <strong>the</strong> new magazine. We would<br />

be pleased to receive your feedback.<br />

Shape <strong>the</strong> future with us<br />

Ano<strong>the</strong>r inspiring suggestion! Due to <strong>the</strong><br />

fact that we have enjoyed a pleasurable<br />

and successful collaboration with our customers<br />

over <strong>the</strong> many years, we would like<br />

to invite you to take part in launching new<br />

projects. Shape <strong>the</strong> future with us <strong>by</strong> informing<br />

us about your requirements and<br />

ideas. Perhaps this will lead to a joint<br />

project.<br />

Yours sincerely, Ernst Ramberger<br />

CONTENT<br />

3 Newsticker<br />

New at <strong>Step</strong>-<strong>Four</strong><br />

4 INTRODUCING<br />

Ascending Technologies<br />

5 TRAINING<br />

A visit at <strong>the</strong> HTBLA Ried<br />

6 Service<br />

<strong>Installation</strong> solutions<br />

<strong>by</strong> <strong>Step</strong>-<strong>Four</strong><br />

7 OFFERS<br />

Save cost-effectively<br />

10 Reportage<br />

The creation of a scale model<br />

12 Know-how<br />

<strong>Tips</strong> <strong>from</strong> our <strong>experts</strong><br />

Mas<strong>the</strong>ad: STEP-FOUR GmbH, Bayernstrasse 77, 5071 Wals-Siezenheim, Austria, Phone: +43<br />

(0)662/45 93 78-0 Fax: +43 (0)662/45 93 78-20, E-mail: office@step-four.at: www.step-four.at;<br />

Editorial staff: Ernst Ramberger, Reinhard Leithner, Dieter König; layout and production: JAGER<br />

PR, www.jager-pr.at<br />

10<br />

2 STEP-FOUR | March 2010

News<br />

Face-lift for <strong>the</strong><br />

PC-CUT Standard<br />

After many years of success, <strong>the</strong> tried and<br />

tested PC-CUT Standard hot wire cutting<br />

system has now been given an advantageous<br />

face-lift. The ingenious yet simple<br />

construction itself didn’t actually need to<br />

be modified, but <strong>the</strong> spindles and shafts<br />

were given larger dimensions, which will<br />

provide higher speeds with <strong>the</strong> lowest level<br />

of vibration.<br />

With immediate effect, 16 mm steel shafts<br />

and spindles with an increase of 3 mm are<br />

applied. The spindle motor couplings are<br />

made of aluminium <strong>from</strong> now on. Thanks<br />

to <strong>the</strong> application of cable carriers, cable<br />

spaghetti is also a thing of <strong>the</strong> past. Even<br />

though we have performed <strong>the</strong>se improvements,<br />

<strong>the</strong> prices remain unchanged.<br />

Railway<br />

histories<br />

On <strong>the</strong> occasion of <strong>the</strong> 25th year jubilee<br />

celebrations of <strong>the</strong> Model Railway Club in<br />

Eferding, Mr. Loidl, a faithful <strong>Step</strong>-<strong>Four</strong><br />

customer <strong>from</strong> Fraham in Upper Austria,<br />

proudly presented <strong>the</strong> model of <strong>the</strong> first<br />

locomotive of <strong>the</strong> Linz local railway, <strong>the</strong><br />

E22 002, model 1912. This particular locomotive<br />

travelled along <strong>the</strong> Linz – Eferding<br />

– Weizenkirchen line at that time. The<br />

construction and completion time for <strong>the</strong><br />

model amounted to 200 hours.<br />

New: Safe-Coat in<br />

500 g containers<br />

SAFE-COAT, <strong>the</strong> coating for EPS, XPS,<br />

wood, plastic, and lots more, is now also<br />

available in 500 g containers, as well as<br />

<strong>the</strong> hi<strong>the</strong>rto available 5 kg containers. The<br />

sales price lies at € 12.60 incl. VAT. The<br />

base colour of <strong>the</strong> coating is transparent<br />

and can be coloured according to choice<br />

<strong>by</strong> simply adding pigments. The material<br />

is applied <strong>by</strong> means of a brush or roller.<br />

Drying is performed without shrinking effects.<br />

The surface is smooth and even and<br />

can be painted. The Safe-Coat coating can<br />

be used as a base coating on EPS and XPS,<br />

so that a more “aggressive” coating (solvent-containing<br />

paint) can be subsequently<br />

applied. SAFE-COAT can be used without<br />

<strong>the</strong> necessity of breathing protection.<br />

Xpert Cut: Think<br />

big, cut bigger!<br />

At <strong>the</strong> end of February, we were able to<br />

deliver <strong>the</strong> hi<strong>the</strong>rto biggest system of <strong>the</strong><br />

new Xpert CUT series. With an operational<br />

range of 5000 x 2600 x 8000 mm, enormous<br />

parts, which previously had to be<br />

manufactured in painstaking detail work<br />

with several individual elements, can now<br />

be produced in one piece.<br />

Featured in <strong>the</strong> picture: Michael Schmalzer<br />

in <strong>the</strong> enormous Xpert CUT 5000 with<br />

a cutting length of 8 metres.<br />

STEP-FOUR | March 2010<br />

3

INTRODUCING<br />

Ascending Technologies: The specialist for<br />

multi-rotor aircraft systems<br />

We take particular pleasure in observing<br />

<strong>the</strong> success of young companies working<br />

with <strong>Step</strong>-<strong>Four</strong> systems. The two Achtelik<br />

bro<strong>the</strong>rs <strong>from</strong> Stockdorf near Munich acquired<br />

<strong>the</strong>ir milling machine in 2002 – at<br />

which time <strong>the</strong>y were still students-. Innovative<br />

ideas combined with diligence and<br />

perseverance finally led to <strong>the</strong> founding of<br />

a successful company.<br />

Ascending Technologies – <strong>the</strong> name of<br />

<strong>the</strong> company stands for innovative multi-rotor<br />

aircraft systems. Many years of<br />

experience, based on <strong>the</strong> award-winning<br />

“Jugend forscht” (Young Scientists) work<br />

performed <strong>by</strong> <strong>the</strong> managing partners and<br />

employees, as well as a great enthusiasm<br />

for flying systems, are a guarantee for sophisticated<br />

and innovative concepts, which<br />

have created one or ano<strong>the</strong>r revolution on<br />

<strong>the</strong> “quadrocopter skies”.<br />

The high-tech devices have been used for<br />

a number of special assignments, such as<br />

<strong>the</strong> examination of large-area coal fires in<br />

China, which was performed for research<br />

A quadrocopter<br />

<strong>from</strong> astec<br />

institutes, to fly over archaeological excavation<br />

sites in Mongolia, and to observe<br />

whales in Argentina. Many photographers<br />

use <strong>the</strong> robots for high-quality aerial photographs.<br />

Are you looking for a robust, light and manoeuvrable<br />

quadrocopter, with which you<br />

can impress your friends <strong>by</strong> letting it hover<br />

around your living room or soar across <strong>the</strong><br />

skies outdoors with a breathtaking aero-<br />

batic programme? Or do you need a<br />

means <strong>by</strong> which you can shoot aerial<br />

photographs and videos? Do you perhaps<br />

need a flying sensor carrier for<br />

research projects? Then visit <strong>the</strong> website<br />

www.asctec.de.<br />

By <strong>the</strong> way: Both <strong>the</strong> prototypes and<br />

<strong>the</strong> serial models are still being produced<br />

today with <strong>the</strong> aid of <strong>Step</strong>-<strong>Four</strong><br />

products.<br />

<strong>Step</strong>-<strong>Four</strong> system requirements<br />

Operating system<br />

CPU power<br />

Memory - RAM<br />

CD Rom drive<br />

Free hard disc<br />

storage<br />

Interfaces<br />

Graphic board<br />

Milling software S4PROV4<br />

Cutting software S4CUTV4<br />

Milling software XpertMill<br />

V2.xx<br />

MS DOS 6.0, Windows<br />

95, 98<br />

MS DOS 6.0, Windows<br />

95, 98<br />

Windows 2000,<br />

XP, Vista, Win7<br />

Wing Designer Windows 95, 98,<br />

2000, XP, Vista,<br />

Win7<br />

LiftOff Windows 2000,<br />

XP, Vista, Win7<br />

<strong>from</strong> 500 MHz 32 MB YES 20 MB LPT 1, LPT 2 VGA screen<br />

<strong>from</strong> 500 MHz 32 MB YES 20 MB LPT 1, LPT 2 VGA screen<br />

<strong>from</strong> 1,4 GHz 256 MB YES 100 MB USB <strong>from</strong> 1.1 Standard graphic<br />

board, open GL<br />

<strong>from</strong> 500 MHz 32 MB YES 20 MB LPT 1, LPT 2<br />

USB <strong>from</strong> 1.1<br />

<strong>from</strong> 1,4 Ghz 256 MB YES 20 MB LPT 1, LPT 2<br />

USB <strong>from</strong> 1.1<br />

Standard graphic<br />

board, open GL<br />

Standard graphic<br />

board<br />

Here you can see an overview of <strong>the</strong> system requirements needed for <strong>the</strong> various <strong>Step</strong>-<strong>Four</strong> software products. You can request drivers<br />

for <strong>the</strong> Windows 7. 64 Bit version, which you require for <strong>the</strong> WING designer V2 USB Dongle and <strong>the</strong> XpertMILL 2.PC USB Dongle,<br />

directly <strong>from</strong> <strong>Step</strong>-<strong>Four</strong>.<br />

4 STEP-FOUR | March 2010

Training<br />

HTBLA Ried in <strong>the</strong> Innkreis district<br />

Practical training for budding engineers<br />

On <strong>the</strong> 22 of January 2010, <strong>the</strong> brand new<br />

HTBLA State Polytechnic Institute in Ried,<br />

in <strong>the</strong> Innkreis district of <strong>the</strong> Upper Austrian<br />

Innviertel, presented <strong>the</strong>ir “Open Day”.<br />

The HTBLA Ried provides <strong>the</strong> students<br />

with <strong>the</strong> best possible foundation training<br />

for career entry of academic studies<br />

through hands-on, practical training. This<br />

is achieved <strong>by</strong> a collaboration between industry,<br />

commerce, and school, which is<br />

unique in Austria. A part of <strong>the</strong> training<br />

takes place as workshop tuition directly<br />

on <strong>the</strong> premises of <strong>the</strong> participating companies.<br />

Construction lessons are also provided<br />

directly in <strong>the</strong> companies or are “online<br />

connected”.<br />

<strong>Step</strong>-<strong>Four</strong> Head of Marketing Reinhard<br />

Leithner was able to assure himself, during<br />

his visit at <strong>the</strong> polytechnic, that <strong>the</strong> students<br />

are not only in good hands under <strong>the</strong><br />

supervision of Head Instructor Franz Liebl.<br />

The excellently equipped school provides<br />

<strong>the</strong> young ladies (yes, <strong>the</strong>re are a number<br />

of enthusiastic female engineers) and gentlemen<br />

with <strong>the</strong> best training for <strong>the</strong>ir futures.<br />

The <strong>Step</strong>-<strong>Four</strong> milling machine is,<br />

of course, an essential feature.<br />

<strong>Step</strong>-<strong>Four</strong> is pleased to have experienced<br />

a successful day at <strong>the</strong> school and wishes<br />

<strong>the</strong> students and teachers all <strong>the</strong> best for<br />

<strong>the</strong> future. Fur<strong>the</strong>r details can be ga<strong>the</strong>red<br />

under www.htl-ried-innviertel.at.<br />

A focus on manufacturing technology<br />

Under consideration of economic thinking,<br />

<strong>the</strong> field of manufacturing technology<br />

imparts knowledge on <strong>the</strong> <strong>the</strong>oretical<br />

and practical principles in<br />

<strong>the</strong> field of mechanics, construction<br />

of machines and systems, and manufacturing<br />

technology, supplemented<br />

<strong>by</strong> knowledge in electrical engineering,<br />

measurement, control and regulation<br />

technology, as well as operational<br />

sequences with particular consideration<br />

of quality management and product<br />

management.<br />

Learning is fun with <strong>the</strong> top equipment.<br />

Reinhard Leithner <strong>from</strong> <strong>Step</strong>-<strong>Four</strong> and Franz Liebl <strong>from</strong> <strong>the</strong><br />

HTBLA Ried.<br />

Content students working on <strong>the</strong>ir <strong>Step</strong>-<strong>Four</strong> system.<br />

Young ladies are also enthusiastic about technology.<br />

STEP-FOUR | March 2010<br />

5

Service<br />

How does <strong>the</strong> sailing ship get inside<br />

<strong>the</strong> bottle?<br />

You will perhaps ask yourself<br />

what this age-old<br />

question has to do with<br />

<strong>Step</strong>-<strong>Four</strong>. Quite a lot. Due<br />

to <strong>the</strong> needs and requirements<br />

of our customers,<br />

<strong>the</strong> <strong>Step</strong>-<strong>Four</strong> systems have<br />

become increasingly<br />

larger over <strong>the</strong> last few years.<br />

The Xpert series is a<br />

perfect example.<br />

Just as with <strong>the</strong> demands that our company<br />

has to meet, <strong>the</strong> machines get bigger<br />

all <strong>the</strong> time. Unfortunately, however, <strong>the</strong><br />

doors of our customers‘ workshops don’t<br />

grow at <strong>the</strong> same rate as <strong>the</strong> dimensions<br />

that are required of <strong>the</strong> milling machines.<br />

What’s <strong>the</strong> solution? Well, some providers<br />

leave this problem to <strong>the</strong> customer. <strong>Step</strong>-<br />

<strong>Four</strong> doesn’t.<br />

A tight fit. The <strong>Step</strong>-<strong>Four</strong> system is bigger than <strong>the</strong> workshop door.<br />

<strong>Installation</strong> without renovation<br />

We not only build high quality systems, but<br />

also ensure that <strong>the</strong>y can be installed without<br />

<strong>the</strong> need to perform extensive renovations.<br />

If necessary, we will bring out own<br />

marquee in order to protect <strong>the</strong> system<br />

and our experienced assembly fitters <strong>from</strong><br />

<strong>the</strong> whims of wea<strong>the</strong>r during <strong>the</strong> on-site<br />

unloading or assembly work. A high level<br />

of flexibility regarding <strong>the</strong> installation of<br />

machines is an integral part of our corporate<br />

maxims of customer care, <strong>service</strong> and<br />

support. We have meanwhile managed to<br />

ga<strong>the</strong>r a lot of experience in installing <strong>the</strong><br />

large Xpert systems. Even customers with<br />

very limited space conditions can safely<br />

assume that we are able to find a solution<br />

to (practically) every space problem.<br />

Just ask us.<br />

We’ll find a way.<br />

Xpert 2600P<br />

We install whatever <strong>the</strong> wea<strong>the</strong>r.<br />

Xpert 3D<br />

6 STEP-FOUR | March 2010

Shop<br />

Spring awakening offer<br />

Engraving unit<br />

15 % discount<br />

Suction clamp collar<br />

Toge<strong>the</strong>r with <strong>the</strong> appropriate<br />

gravers, this accessory<br />

provides constant engraving<br />

widths of less than 1/10<br />

mm. Whe<strong>the</strong>r applied for<br />

prototype production of circuit<br />

boards or for engraving<br />

light systems, <strong>the</strong> <strong>Step</strong>-<strong>Four</strong><br />

engraving unit works with<br />

<strong>the</strong> highest level of precision<br />

and reliability.<br />

If you mention <strong>the</strong> codeword “Spring Awakening” when<br />

placing an order, you will receive a 15% discount up until<br />

<strong>the</strong> 30th of April for this accessory.<br />

Whe<strong>the</strong>r you want to perform<br />

rough milling or fine<br />

engraving, your working<br />

space always remains clean<br />

with <strong>the</strong> <strong>Step</strong>-<strong>Four</strong> suction<br />

clamp collar. The plastic<br />

bristles enclose <strong>the</strong> milling<br />

area well without impeding<br />

<strong>the</strong> tool change. Simply<br />

state <strong>the</strong> codeword “Spring<br />

Awakening” when placing<br />

an order – and you save yourself 15%. Simply state <strong>the</strong><br />

codeword “Spring Awakening” when placing an order –<br />

and you save yourself 15%.<br />

Engraving unit for 43 mm milling motors:<br />

Suction clamp collar for 43 mm milling motors:<br />

price reduction <strong>from</strong> € 372.00 to € 316,20 price reduction <strong>from</strong> € 138.00 to € 117,30<br />

Offer<br />

Milling cutter type 2100<br />

Spring discount<br />

Plotting knife<br />

VHM milling cutter type 2100, 1/8“ shaft<br />

10 piece set with 2 pieces each measuring<br />

0.8 mm, 1.0 mm, 1.8 mm, 2.2 mm,<br />

and 3 mm<br />

2 flute routers, micro-spiralled toothing<br />

with chip breakers, fishtail tip, right cutting,<br />

right helix, fulfil <strong>the</strong> highest quality<br />

demands with regard to chip transport,<br />

clean cut edges.<br />

Particularly suitable for contour milling of<br />

circuit boards and fibrous composite materials,<br />

such as glass fibre reinforced plastic<br />

(GRP) and carbon fibre reinforced plastic<br />

(CRP). Also suitable for Depron with very<br />

high feed rates. Unsuitable for soft <strong>the</strong>rmoplastics,<br />

such as ABS, PE, PS, as well<br />

as wood and metal.<br />

price reduction <strong>from</strong> € 55.00 to € 28,00<br />

Plotting knife complete set:<br />

Retrofit your milling machine<br />

as a transparency<br />

plotter! Both self-adhesive<br />

and heat shrink films<br />

can be easily cut with <strong>the</strong><br />

aid of <strong>the</strong> <strong>Step</strong>-<strong>Four</strong> plotting<br />

knife unit. Included within<br />

<strong>the</strong> scope of delivery is<br />

<strong>the</strong> precision knife holder,<br />

a hard metal plotting knife,<br />

a sample disc, and a set of<br />

transparencies. Save 15 %<br />

with <strong>the</strong> codeword “Spring<br />

Awakening”.<br />

price reduction <strong>from</strong> € 264.00 to € 224,40<br />

Inclusive VAT. Valid until 30th of April 2010.<br />

STEP-FOUR | March 2010<br />

7

Seminare<br />

Friday, 6th of August, 2010<br />

Workshop: Milling novices<br />

Please register <strong>by</strong> phone<br />

under +43/(0)662/45<br />

93 78 or via e-mail to<br />

office@step-four.at<br />

Workshop target audience: This workshop<br />

is aimed at interested model makers<br />

who have not yet ga<strong>the</strong>red any experience<br />

with a PC controlled milling machine,<br />

but are considering using such a machine<br />

to build <strong>the</strong>ir models. The objective of <strong>the</strong><br />

workshop is to demonstrate <strong>the</strong> basics of<br />

milling technology.<br />

Content:<br />

• Basic functions and features of a contour<br />

milling machine<br />

• Material science<br />

• Selecting <strong>the</strong> right tool<br />

• Definition of <strong>the</strong> milling parameter<br />

• Differences in <strong>the</strong> 2, 2.5 and 3D milling<br />

process<br />

• <strong>Tips</strong> & tricks in milling<br />

Participant prerequisites: PC skills and<br />

possibly some experience with a CAD programme,<br />

such as CorelDraw or TurboCAD.<br />

Attendance fee: € 220,00<br />

Friday, 16th of April, 2010, and Friday, 1st of October, 2010<br />

Workshop: Model aircraft construction made easy<br />

Please register <strong>by</strong> phone<br />

under +43/(0)662/45<br />

93 78 or via e-mail to<br />

office@step-four.at<br />

Workshop target audience: Dedicated aircraft<br />

constructors who want to learn lots<br />

of new things and profit <strong>from</strong> <strong>the</strong> extensive<br />

experience and store of knowledge provided<br />

<strong>by</strong> our model making expert, Hannes<br />

Schmaltzer.<br />

Content: For an already existing glass fibre<br />

reinforced plastic (GRP) fuselage, wings<br />

are constructed with <strong>the</strong> aid of <strong>the</strong> Wing<br />

designer and rudders constructed with<br />

aid of Turbo-CAD. These constructions<br />

are <strong>the</strong>n milled and assembled. In addi-<br />

tion to profile removal techniques, profile<br />

digitalisation, and wing construction, participants<br />

will also learn how to prepare a<br />

rib set for CNC milling and <strong>the</strong> final assembly<br />

of a wing.<br />

Participant prerequisites: PC skills and<br />

possibly some experience with a CAD programme,<br />

such as CorelDraw or TurboCAD.<br />

Attendance fee: € 220,00<br />

Friday, 18th of June, 2010, and Friday, 10th of December, 2010<br />

Workshop: From 3D construction to <strong>the</strong> finished work piece<br />

Workshop target audience: For interested<br />

model makers, who are already familiar<br />

with 3 D construction programmes and<br />

now want to realise <strong>the</strong>ir constructions<br />

with <strong>the</strong> aid of milling technology. Experience<br />

with 3 D construction is essential<br />

and is, <strong>the</strong>refore, a precondition.<br />

SolidWorks etc. or a CAD programme,<br />

such as CorelDraw or TurboCAD.<br />

Attendance fee: € 260,00<br />

Please register <strong>by</strong> phone<br />

under +43/(0)662/45<br />

93 78 or via e-mail to<br />

office@step-four.at<br />

Participant prerequisites: PC skills and<br />

experience with a 3D CAD programme,<br />

such as TurboCAD, Rhinoceros, SolidEdge,<br />

8 STEP-FOUR | March 2010

Events<br />

Event and trade fair<br />

schedule 2010<br />

<strong>Step</strong>-<strong>Four</strong> is represented at a number of<br />

events in 2010. We look forward to seeing<br />

you <strong>the</strong>re!<br />

Date Event Venue<br />

6.3. - 7.3.2010 Rotor live Baden/Baden Baden/Baden<br />

25.3. - 28.3.2010 Faszination Modellbau Karlsruhe (Model Karlsruhe/DE<br />

Making Expo)<br />

24.4. - 25.4.2010 Salzburger Hangflugtournee RC/H2 Hochreith/Kuchl/AT<br />

(Slope Soaring)<br />

1.05.2010 Flugtag Lienz East Tyrol (Flight Day) Lienz Osttirol/AT<br />

15.5. - 16.5.2010 Wasserflugtreffen (Water Flight Venue) Grundlsee/AT<br />

29.5. - 30.5.2010 Salzburger Hangflugtournee RC/H2 Abtenau/AT<br />

(Slope Soaring)<br />

19.6. - 20.6.2010 Großseglerbewerb Trattberg (Large-Scale Trattberg/AT<br />

Glider Competition)<br />

3.7. - 4.7.2010 Großseglerbewerb Hochreith (Large- Hochreith/AT<br />

Scale Glider Competition)<br />

10.7. - 11.7.2010 Hangstreckenfliegen RC/H1 (Slope Soaring)<br />

Abtenau/AT<br />

16.7. - 18.7.2010 Oldtimer-Treffen (Vintage Glider Venue) Hochreith/AT<br />

14.8. - 15.8.2010 Flugtag Lehrte bei Hannover (Flight Day) Lehrte/DE<br />

11.9. - 12.9.2010 Salzburger Hangflugtournee RC/H2 Kaiserbuche/AT<br />

(Slope Soaring)<br />

17.9. - 19.9.2010 Jet Power Bad Neuenahr/DE<br />

25.9. - 26.9.2010 Salzburger Hangflugtournee RC/H2 Abtenau/AT<br />

(Slope Soaring)<br />

8.10. - 10.10.2010 Spielemesse und Modellbauwelt (Games Salzburg/AT<br />

and Model Making Expo)<br />

15./16.10.2010 <strong>Step</strong> <strong>Four</strong> in-house exhibition 2010 Salzburg/AT<br />

29.10. - 1.11.2010 Faszination Modellbau Friedrichshafen<br />

(Model Making Expo)<br />

Friedrichshafen/DE<br />

Intermodellbau 2010 without <strong>Step</strong>-<strong>Four</strong><br />

For <strong>the</strong> first time in 15 years, we will not<br />

participate as an exhibitor at this year’s<br />

“Intermodellbau” in Dortmund. You probably<br />

ask yourself: Why not?<br />

Well, during <strong>the</strong> last few years we have<br />

observed significant changes regarding<br />

<strong>the</strong> number of visitors and <strong>the</strong>matic focus,<br />

which, in our opinion, are anything<br />

but positive. Therefore, we had to ask ourselves<br />

whe<strong>the</strong>r or not a participation justifies<br />

<strong>the</strong> enormous expenditure of time<br />

and effort.<br />

New role model<br />

The “Intermodellbau” was once <strong>the</strong> leading<br />

trade fair for model building in Germany,<br />

but, in our opinion, this title has<br />

increasingly moved to <strong>the</strong> model mak-<br />

ing fairs “Faszination Modellbau” in Friedrichshafen<br />

and Sinsheim. By <strong>the</strong> way, this<br />

year’s “Spring - Faszination Modellbau”“<br />

exhibition will take place for <strong>the</strong> first time<br />

in Karlsruhe <strong>from</strong> <strong>the</strong> 25th till <strong>the</strong> 28th of<br />

March. Many discussions were held within<br />

our company and with fellow exhibitors,<br />

customers and prospective customers.<br />

The ultimate result was that we decided<br />

not to participate at <strong>the</strong> “Intermodellbau”<br />

2010. The future will show whe<strong>the</strong>r or not<br />

<strong>the</strong> “Intermodellbau” will again become<br />

what it once was. If so, <strong>the</strong>n we‘ll be happy<br />

to return.<br />

In order to still be able to reach as many<br />

customers and potential customers as<br />

possible in Germany, we will participate<br />

in numerous o<strong>the</strong>r events that focus on <strong>the</strong><br />

subject of model aircraft construction. We<br />

are convinced that those events will bring<br />

us closer to <strong>the</strong> real model makers. Fur<strong>the</strong>rmore,<br />

it would be our pleasure to be<br />

able to welcome you at our company base<br />

in <strong>the</strong> beautiful district of Salzburg, where<br />

we can give you a personal presentation of<br />

our products. Come and visit us!<br />

We would like to hear your opinion<br />

I hope for your understanding regarding<br />

our decision not to exhibit at <strong>the</strong> “Intermodellbau”<br />

this year, and hope that this<br />

causes you no inconvenience. We would<br />

very much like to hear your opinion on this<br />

matter. Simply write me an e-Mail to reinhard.leithner@step-four.at.<br />

STEP-FOUR | March 2010<br />

9

Rubrik<br />

The “Fairey Rotodyne” is ready for its maiden flight.<br />

An extraordinary scale model is created with<br />

<strong>the</strong> “Basic 540”<br />

Phillipp Gardemin <strong>from</strong> Baden-Württember,<br />

Germany,<br />

reports about building<br />

this helicopter model with<br />

<strong>the</strong> aid of a <strong>Step</strong>-<strong>Four</strong> Basic<br />

540. With a rotor diameter<br />

of almost three metres,<br />

this is a mighty big chopper.<br />

I dreamt for years about building a “Fairey<br />

Rotodyne” scale model. I flew this extraordinary<br />

helicopter in <strong>the</strong> late 50s, in England<br />

– but unfortunately this project didn’t<br />

get past <strong>the</strong> prototype status. This helicopter<br />

was extraordinary due to <strong>the</strong> fact that<br />

<strong>the</strong> almost 30 m main rotor was tip-driven.<br />

The tips were powered <strong>by</strong> a mixture<br />

of fuel and compressed air bled <strong>from</strong> two<br />

wing-mounted turboprops.<br />

The model was constructed at a scale of<br />

1:10. In order to be able to <strong>by</strong>pass <strong>the</strong> mechanical<br />

complexity of <strong>the</strong> tip drive, <strong>the</strong><br />

plan was to operate <strong>the</strong> model as an autogyro<br />

aircraft. This means that <strong>the</strong> rotor<br />

is driven <strong>by</strong> <strong>the</strong> airflow, thus, allowing <strong>the</strong><br />

model to take off. The first drawings were<br />

created on <strong>the</strong> CAD. The dimensions were<br />

<strong>the</strong>n taken over <strong>from</strong> a plastic model <strong>by</strong> <strong>the</strong><br />

Airfix company.<br />

Realisation with <strong>Step</strong>-<strong>Four</strong><br />

The fulfilment of <strong>the</strong> dream, however,<br />

could only take form with <strong>the</strong> acquisition<br />

of <strong>the</strong> “Basic 540” milling machine.<br />

The general layout drawings in <strong>the</strong> CAD<br />

gradually became a tangible plan. Thus,<br />

<strong>the</strong> individual parts separately drawn, exported<br />

to <strong>the</strong> milling software, and <strong>the</strong>n<br />

be directly milled. Only poplar plywood in<br />

thicknesses of four and three millimetres<br />

was used. The sheeting was made <strong>from</strong><br />

1,5 mm balsa.<br />

Ten month construction period<br />

During a construction period of over ten<br />

months, <strong>the</strong> milling machine became a<br />

best friend. Even <strong>the</strong> smallest of parts<br />

were drawn, exported to <strong>the</strong> milling software,<br />

and subsequently milled. The large<br />

cockpit, for instance, was quasi drawn<br />

<strong>from</strong> nothing in <strong>the</strong> CAD, <strong>the</strong> parts exported<br />

and milled. After a total construction<br />

period of twelve months, <strong>the</strong> model<br />

stood on <strong>the</strong> meadow, ready for flight.<br />

Two Hyperion external rotors with 4 blade<br />

airscrews <strong>from</strong> Varioprop and a 6s LiPo<br />

6500 mAh served for propulsion. The rotor<br />

blades – consisting of a Styrofoam cores<br />

with carbon reinforced plastic spars and<br />

plywood sheeting – rotated in a four-blade<br />

rotor hub <strong>from</strong> Varioprop and a self-built<br />

swivel mechanism. The entire model now<br />

weighed 10.5 kg.<br />

Test flights<br />

The “Fairey Rotodyne” was unfortunately<br />

unable to perform its maiden flight, which<br />

was due to <strong>the</strong> fact that <strong>the</strong> self-built autogyro<br />

mechanism wasn’t powerful enough<br />

for <strong>the</strong> enormous rotor diameter of almost<br />

three metres. The model is currently undergoing<br />

modifications, where<strong>by</strong> mechanical<br />

details are being improved upon, as<br />

well as <strong>the</strong> mechanic of <strong>the</strong> swivelling vertical<br />

tail fins. New test flights are planned<br />

for spring 2010. The “Basic 540” will certainly<br />

provide me with many more good<br />

<strong>service</strong>s until <strong>the</strong>n.<br />

Philipp Gardemin<br />

10 STEP-FOUR | March 2010

Model making<br />

The original „Fairey Rotodyne“ of <strong>the</strong><br />

50s unfortunately never quite past <strong>the</strong><br />

prototype status.<br />

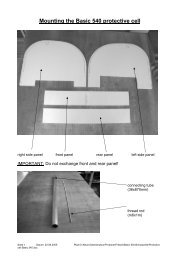

The frames and spar caps were milled<br />

<strong>from</strong> 4 mm poplar plywood.<br />

The rotor tower with <strong>the</strong> mounted mechanism.<br />

The tail with <strong>the</strong> swivelling vertical tail<br />

fins consist of a spar-ribbed construction<br />

made <strong>from</strong> milled 3 mm poplar plywood<br />

parts.<br />

Thanks to CAD and CNC, retrospectively<br />

constructed parts also fit perfectly,<br />

such as <strong>the</strong> servo holder above.<br />

Many parts of <strong>the</strong> cockpit construction<br />

were designed as a basis on <strong>the</strong> CAD<br />

and <strong>the</strong>n milled.<br />

The wings are also rib constructions<br />

with standing crest spar.<br />

The engine nacelles consist of inner<br />

parts constructed and mounted as housings<br />

– all drawn and milled, of course.<br />

After a construction period of eight<br />

months, <strong>the</strong> body shell was practically<br />

complete.<br />

The rotor mechanism unfortunately<br />

proved to be insufficiently stable<br />

enough for flight.<br />

STEP-FOUR | March 2010<br />

11

PRACTICE TIPS<br />

<strong>Tips</strong> <strong>from</strong> our specialists<br />

Our modelling expert<br />

Hannes<br />

Schmalzer advises:<br />

Wing Designer: Show left wing and print<br />

out!<br />

In order to be able to show and print out <strong>the</strong><br />

wing in Wing Designer, proceed as follows.<br />

• Move <strong>the</strong> cursor on to <strong>the</strong> intersection of<br />

<strong>the</strong> two lines and click <strong>the</strong> right mouse<br />

button.<br />

• Select <strong>the</strong> line tab in <strong>the</strong> opened characteristics<br />

window.<br />

• Mark in <strong>the</strong> checkbox of <strong>the</strong> left pointing<br />

X arrow.<br />

• Confirm <strong>by</strong> pressing “accept” and <strong>the</strong><br />

left wing will be shown.<br />

• The wing can also be mirrored in <strong>the</strong> Y<br />

direction. Printing out is performed as<br />

with <strong>the</strong> left wing.<br />

S4CUT V4 cutting software:<br />

In order to ensure that <strong>the</strong> cutting software<br />

can be used with <strong>the</strong> second PC dongle<br />

on a Windows XP computer, <strong>the</strong> CON-<br />

FIG.NT has to be entered at <strong>the</strong> end of <strong>the</strong><br />

files=50 list.<br />

DXF import:<br />

The object dimensions are not correct after<br />

importing <strong>from</strong> CorelDraw. Important!<br />

CorelDraw draws metrically, but exports<br />

imperially. The unit 1 :25.4 must be entered<br />

in <strong>the</strong> import filter of <strong>the</strong> milling software.<br />

TurboCAD:<br />

Before exporting a drawing in <strong>the</strong> DXF<br />

format, ungroup all items, also known as<br />

exploding in TurboCAD. Text excepts and<br />

written items also have to be exploded.<br />

Thus, <strong>the</strong>y can be exported in DXF format<br />

and <strong>the</strong>n be opened or imported in <strong>the</strong><br />

milling and cutting software.<br />

Our design engineer<br />

Roman Tutschka advises:<br />

XpertMILL:<br />

What a lot of people don’t know: When<br />

moving <strong>the</strong> machine to set zero point or<br />

tool change point via <strong>the</strong> keyboard, one<br />

can move between XY and Z with <strong>the</strong> aid<br />

of <strong>the</strong> space key.<br />

Milling aluminium:<br />

Type F2422 milling cutters are particularly<br />

suitable for milling aluminium. Do not immerse<br />

too slowly into <strong>the</strong> material, o<strong>the</strong>rwise<br />

a built-up edge can form, which leads<br />

to premature wear of <strong>the</strong> milling cutter.<br />

And don’t forget <strong>the</strong> cooling agents! Recommended<br />

parameters:<br />

• Milling cutter diameter: 2 mm<br />

• Advance: 2 mm<br />

• Speed: 24000 r/min<br />

• Forward feed XY: 220 mm/min<br />

• Forward feed Z: 200 mm/min<br />

• Cooling: Atomised spray with n-paraffin<br />

Spring offer<br />

Precise 760<br />

Now till <strong>the</strong> 30th of<br />

April 2010!<br />

• Precise 760 ready assembled, operational range 750 x 458 x 100 mm<br />

• SF-C2 control electronics with XpertLINK Windows adapter<br />

• XpertMILL V2 professional milling software<br />

• Xpert[DRAW] software expansion module<br />

• Xpert[CAM] software expansion module<br />

• Maintenance set<br />

• Kress surface milling machine 800 FME<br />

Instead of € 6978.00 now only € 5500.00 incl. VAT<br />

Order now!<br />

Phone: +43 (0) 662/45 93 78-0 or e-mail: office@step-four.at<br />

You can save<br />

over € 1400.00<br />

Offer only applies in Germany and Austria. Plus shipping costs.<br />

12 STEP-FOUR | March 2010