AUTOMOTIVE ELECTRICAL CIRCUITS AND WIRING

AUTOMOTIVE ELECTRICAL CIRCUITS AND WIRING

AUTOMOTIVE ELECTRICAL CIRCUITS AND WIRING

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

point design, use a screwdriver or Allen wrench to open and close the points. Tighten<br />

the hold-down screws and recheck the point gap. Typically point gap settings average<br />

around .015 inch for eight-cylinder engines and .025 inch for six-and four-cylinder<br />

engines. For the gap set of the engine you are working on, consult the manufacturer's<br />

service manual.<br />

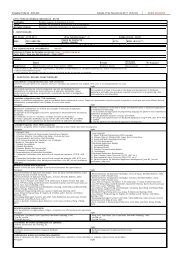

Figure 2-52.- Contact point alignment.<br />

CAUTION<br />

Ensure the feeler gauge is clean before inserting it between the points. Oil and grease<br />

will reduce the service life of the points.<br />

To use a dwell meter for adjusting contact points, connect the red lead of the dwell<br />

meter to the distributor side of the ignition coil (wire going to the contact points).<br />

Connect the black lead to ground.<br />

If the distributor cap has an adjustment window, the points should be set with the<br />

engine running. With the meter controls set properly, adjust the points through the<br />

window of the distributor cap using a Allen wrench or a special screwdriver. Turn the<br />

point adjustment screw until the dwell meter reads within manufacturer's specification.<br />

However, if the distributor cap does not have an adjustment window, remove the<br />

distributor cap and ground the ignition coil wire. Then crank the engine; this action<br />

will simulate engine operation and allow point adjustment with the dwell meter.<br />

Dwell specifications vary with the number of cylinders. An eight-cylinder engine<br />

requires 30 degrees of dwell. An engine with few cylinders requires more dwell time.<br />

Always consult the manufacturer's service manual for exact dwell values.<br />

Dwell should remain constant as engine speed increases or decreases. However, if the<br />

distributor is worn, you can have a change in the dwell meter reading. This is known<br />

as DWELL VARIATION. If dwell varies more than 3 degrees, the distributor should<br />

either be replaced or rebuilt. Also, a change in the point gap or dwell will change<br />

ignition timing. For this reason, the points should always be adjusted before ignition<br />

timing.<br />

<strong>AUTOMOTIVE</strong> <strong>ELECTRICAL</strong> <strong>CIRCUITS</strong> <strong>AND</strong> <strong>WIRING</strong> 70/ 101