AUTOMOTIVE ELECTRICAL CIRCUITS AND WIRING

AUTOMOTIVE ELECTRICAL CIRCUITS AND WIRING

AUTOMOTIVE ELECTRICAL CIRCUITS AND WIRING

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

A common problem arises when a CARBON TRACE (small line of carbonlike<br />

substance that conducts electricity) forms on the inside of the distributor cap or outer<br />

edge of the rotor. The carbon trace will short coil voltage to ground or to a wrong<br />

terminal lug in the distributor cap. A carbon trace will cause the spark plugs to either<br />

fire poorly or not at all.<br />

Using a droplight, check the inside of the distributor cap for cracks and carbon trace.<br />

Carbon trace is black which makes it hard to see on a black-colored distributor cap. If<br />

carbon trace or a crack is found, replace the distributor cap or rotor.<br />

CONTACT POINT DISTRIBUTOR SERVICE.- In a contact point distributor,<br />

there are two areas of concern- the contact points and the condenser.<br />

Bad contact points cause a variety of engine performance problems. These problems<br />

include high-speed missing, no-start problem, and many other ignition troubles.<br />

Visually inspect the surfaces of the contact points to determine their condition. Points<br />

with burned and pitted contacts or with a worn rubbing block must be replaced.<br />

However, if the points look good, point resistance should be measured. Turn the<br />

engine over until the points are closed and then use an ohmmeter to connect the meter<br />

to the primary point lead and to ground. If resistance reading is too high, the points are<br />

burned and must be replaced.<br />

A faulty condenser may leak (allow some dc current to flow to ground), be shorted<br />

(direct electrical connection to ground), or be opened (broken lead wire to the<br />

condenser foils). If the condenser is leaking or open, it will cause point arcing and<br />

burning. If the condenser is shorted, primary current will flow to ground and the<br />

engine will NOT start. To test a condenser using an ohmmeter, connect the meter to<br />

the condenser and to ground. The meter should register slightly and then return to<br />

infinity (maximum resistance). Any continuous reading other than infinity indicates<br />

that the condenser is leaking and must be replaced.<br />

Installing contact points is a relatively simple procedure but must be done with<br />

precision and care in order to achieve good engine performance and economy. Make<br />

sure the points are clean and free of any foreign material.<br />

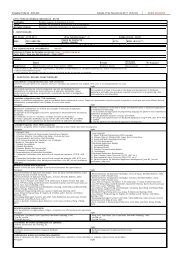

Proper alignment of the contact points is extremely important (fig. 2-52). If the faces<br />

of the contact points do not touch each other fully, heat generated by the primary<br />

current cannot be dissipated and rapid burning takes place. The contacts are aligned by<br />

bending the stationary contact bracket only. NEVER BEND THE MOVABLE<br />

CONTACT ARM. Ensure the contact arm-rubbing block rests flush against the<br />

distributor cam. A small amount of an approved lubricate should be placed on the<br />

distributor cam to reduce friction between the cam and rubbing block. Once the points<br />

are installed, they can be adjusted using either a feeler gauge or dwell meter.<br />

To use a feeler gauge to set the contact points, turn the engine over until the points are<br />

FULLY OPEN. The rubbing block should be on top of a distributor cam lobe. With<br />

the points open, slide the specified thickness feeler gauge between them. Adjust the<br />

points so that there is a slight drag on the blade of the feeler gauge. Depending upon<br />

<strong>AUTOMOTIVE</strong> <strong>ELECTRICAL</strong> <strong>CIRCUITS</strong> <strong>AND</strong> <strong>WIRING</strong> 69/ 101