AUTOMOTIVE ELECTRICAL CIRCUITS AND WIRING

AUTOMOTIVE ELECTRICAL CIRCUITS AND WIRING

AUTOMOTIVE ELECTRICAL CIRCUITS AND WIRING

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

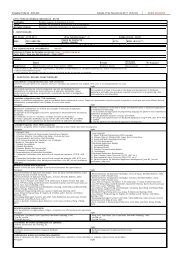

A faulty spark wire can either have a burned or broken conductor, or it could have<br />

deteriorated insulation. Most spark plugs wires have a resistance conductor that can be<br />

easily separated. If the conductor is broken, voltage and current cannot reach the spark<br />

plug. If the insulation is faulty, sparks may leak through to ground or to another wire<br />

instead of reaching the spark plugs. To test the wires for proper operation, you can<br />

perform the following:<br />

A SPARK PLUG WIRE RESISTANCE TEST<br />

will check the spark plug conductor or coil wire conductor. To perform a wire<br />

resistance test, connect an ohmmeter across each end of the wire. The meter will read<br />

internal wire resistance in ohms. Typically resistance should NOT be over 5,000 ohms<br />

per inch or 100.000 ohms total. Since specifications vary, compare your readings to<br />

the manufacturer's specifications.<br />

A SPARK PLUG WIRE INSULATION TEST<br />

checks for sparks arcing through the insulation to ground. To perform an insulation<br />

test with the hood up, block out as much light as possible, start the engine, and move a<br />

grounded screwdriver next to the insulation. If a spark jumps through the insulation to<br />

the screwdriver, the wire is bad. Spark plug leakage is a condition in which electric<br />

arcs pass through the wire insulation.<br />

Installing new spark plug wire is a simply task, especially when one wire at a time is<br />

replaced. Wire replacement is more complicated if all of the wires have been removed.<br />

Then you must use engine firing order and cylinder numbers to route each wire<br />

correctly. Service manuals can be used to trace the wires from each distributor cap<br />

tower to the correct spark plug.<br />

Distributor Service<br />

The distributor is critical to the proper operation of the ignition system. The distributor<br />

senses engine speed, alters ignition timing, and distributes high voltage to the spark<br />

plugs. If any part of the distributor is faulty, engine performance suffers.<br />

DISTRIBUTOR CAP <strong>AND</strong> ROTOR.- When problems point to possible distributor<br />

cap or rotor troubles, remove and inspect them. The distributor cap should be carefully<br />

checked to see that sparks have not been arcing from point to point. Both interior and<br />

exterior must be clean. The firing points should not be eroded, and the interior of the<br />

towers must be clean.<br />

The rotor tip, from which the high-tension spark jumps to each distributor cap<br />

terminal, should not be worn. It also should be checked for excessive burning, carbon<br />

trace, looseness, or other damage. Any wear or irregularity will result in excessive<br />

resistance to the high-tension spark. Make sure that the rotor fits snugly on the<br />

distributor shaft.<br />

<strong>AUTOMOTIVE</strong> <strong>ELECTRICAL</strong> <strong>CIRCUITS</strong> <strong>AND</strong> <strong>WIRING</strong> 68/ 101