AUTOMOTIVE ELECTRICAL CIRCUITS AND WIRING

AUTOMOTIVE ELECTRICAL CIRCUITS AND WIRING

AUTOMOTIVE ELECTRICAL CIRCUITS AND WIRING

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Battery terminals<br />

Electrolyte<br />

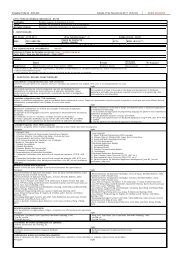

BATTERY ELEMENT.- The battery element is made up of negative plates, positive<br />

plates, separators, and straps (fig. 2-3). The element fits into a cell compartment in the<br />

battery case. Most automotive batteries have six elements.<br />

Figure 2-3.- Battery element.<br />

Each cell compartment contains two kinds of chemically active lead plates, known as<br />

positive and negative plates. The battery plates are made of GRID (stiff mesh<br />

framework) coated with porous lead. These plates are insulated from each other by<br />

suitable separators and are submerged in a sulfuric acid solution (electrolyte).<br />

Charged negative plates contain spongy (porous) lead (Pb) which is gray in color.<br />

Charged positive plates contain lead peroxide (PbO2 ) which has a chocolate brown<br />

color. These substances are known as the active materials of the plates. Calcium or<br />

antimony is normally added to the lead to increase battery performance and to<br />

decrease gassing (acid fumes formed during chemical reaction). Since the lead on the<br />

plates is porous like a sponge, the battery acid easily penetrates into the material. This<br />

aids the chemical reaction and the production of electricity.<br />

Lead battery straps or connectors run along the upper portion of the case to connect the<br />

plates. The battery terminals (post or side terminals) are constructed as part of one end<br />

of each strap.<br />

To prevent the plates from touching each other and causing a short circuit, sheets of<br />

insulating material (microporous rubber, fibrous glass, or plastic-impregnated<br />

material), called separators, are inserted between the plates. These separators are thin<br />

and porous so the electrolyte will flow easily between the plates. The side of the<br />

separator that is placed against the positive plate is grooved so the gas that forms<br />

during charging will rise to the surface more readily. These grooves also provide room<br />

for any material that flakes from the plates to drop to the sediment space below.<br />

<strong>AUTOMOTIVE</strong> <strong>ELECTRICAL</strong> <strong>CIRCUITS</strong> <strong>AND</strong> <strong>WIRING</strong> 6/ 101