AUTOMOTIVE ELECTRICAL CIRCUITS AND WIRING

AUTOMOTIVE ELECTRICAL CIRCUITS AND WIRING

AUTOMOTIVE ELECTRICAL CIRCUITS AND WIRING

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

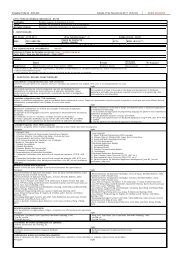

Figure 2-28.- Typical diode.<br />

Since the engine speed varies in a vehicle, the frequency also varies with the change of<br />

speed. Likewise, increasing the number of pairs of magnetic north and south poles will<br />

increase the frequency by the number pair of poles. A four-pole generator can generate<br />

twice the frequency per revolution of a two-pole rotor.<br />

ALTERNATOR OUTPUT CONTROL<br />

A voltage regulator controls alternator output by changing the amount of current flow<br />

through the rotor windings. Any change in rotor winding current changes the strength<br />

of the magnetic field acting on the stator windings. In this way, the voltage regulator<br />

can maintain a preset charging voltage. The three basic types of voltage regulators are<br />

as follows:<br />

Contact point voltage regulator, mounted away from the alternator in the engine<br />

compartment<br />

Electronic voltage regulator, mounted away from the alternator in the engine<br />

compartment<br />

Electronic voltage regulator, mounted on the back or inside the alternator<br />

The contact point voltage regulator uses a coil, set of points, and resistors that limits<br />

system voltage. The electronic or solid-state regulators have replaced this older type.<br />

For operation, refer to the "Regulation of Generator Output" section of this chapter.<br />

<strong>AUTOMOTIVE</strong> <strong>ELECTRICAL</strong> <strong>CIRCUITS</strong> <strong>AND</strong> <strong>WIRING</strong> 34/ 101