AUTOMOTIVE ELECTRICAL CIRCUITS AND WIRING

AUTOMOTIVE ELECTRICAL CIRCUITS AND WIRING

AUTOMOTIVE ELECTRICAL CIRCUITS AND WIRING

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

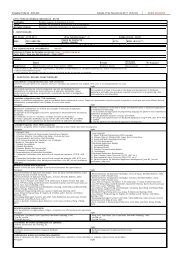

GENERATOR MAINTENANCE<br />

The dc generator requires periodic cleaning, lubrication, inspection of brushes and<br />

commutator, and testing of brush spring tension. In addition, the electrical connections<br />

need attention to ensure clean metal-to-metal contact and tightness.<br />

Some generators have hinged cap oilers. Lubricate these with a few drops of medium<br />

weight oil at each maintenance cycle. Do not overlubricate, because as excessive<br />

amount of oil can get on the commutator and prevent the brushes from functioning<br />

properly.<br />

Visually and manually inspect the condition of all cables, clamps, wiring, and terminal<br />

connections. See that the generator drive pulley is tight on the shaft and that the belt is<br />

in good condition and adjusted properly. Also, ensure that the generator is securely<br />

mounted and has a good ground.<br />

Remove the cover band, on generator so equipped, and inspect the inner surface of the<br />

generator cover band for tiny globules of solder. If any solder is found, the generator is<br />

producing excessive current and has melted the solder used in connecting the armature<br />

wires to the commutator bars. This condition requires removal of the generator to<br />

repair or replace the armature.<br />

If no solder is found, inspect the commutator, brushes, and electrical connections. If<br />

the commutator is dirty or slightly rough, using 00 sandpaper can smooth it. NEVER<br />

use emery cloth on the commutator.<br />

Once the commutator has been sanded, blow compressed air through the interior of the<br />

generator to remove any excess dirt and brush particles. Lift the brushes in the brush<br />

holder to see that they are free to operate and have sufficient tension to prevent arcing<br />

and burning of the commutator and brushes. If brushes are worn down to one half of<br />

their original length, replace them.<br />

<strong>AUTOMOTIVE</strong> <strong>ELECTRICAL</strong> <strong>CIRCUITS</strong> <strong>AND</strong> <strong>WIRING</strong> 24/ 101