Submerged Arc Welding Technical Handbook - Esab

Submerged Arc Welding Technical Handbook - Esab

Submerged Arc Welding Technical Handbook - Esab

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

If the welding speed is decreased beyond a<br />

certain point, the penetration will also<br />

decrease. This is because a good portion of<br />

the molten weld pool will be beneath the<br />

welding wire and the pool will cushion the<br />

penetrating force of the arc.<br />

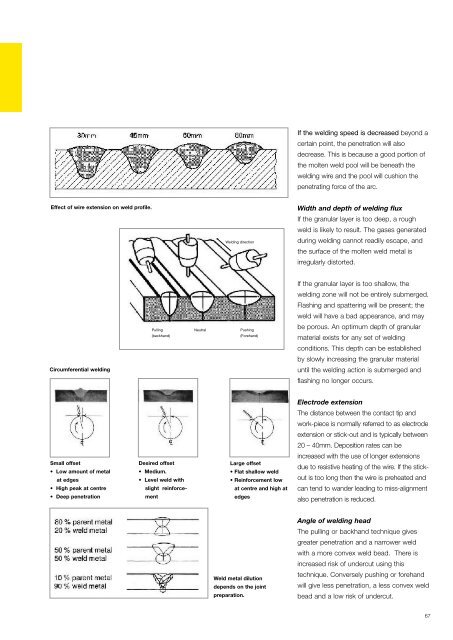

Effect of wire extension on weld profile.<br />

<strong>Welding</strong> direction<br />

Width and depth of welding flux<br />

If the granular layer is too deep, a rough<br />

weld is likely to result. The gases generated<br />

during welding cannot readily escape, and<br />

the surface of the molten weld metal is<br />

irregularly distorted.<br />

If the granular layer is too shallow, the<br />

welding zone will not be entirely submerged.<br />

Flashing and spattering will be present; the<br />

weld will have a bad appearance, and may<br />

Pulling<br />

(backhand)<br />

Neutral<br />

Pushing<br />

(Forehand)<br />

be porous. An optimum depth of granular<br />

material exists for any set of welding<br />

conditions. This depth can be established<br />

by slowly increasing the granular material<br />

Circumferential welding<br />

until the welding action is submerged and<br />

flashing no longer occurs.<br />

Electrode extension<br />

The distance between the contact tip and<br />

work-piece is normally referred to as electrode<br />

extension or stick-out and is typically between<br />

<br />

Small offset<br />

<br />

at edges<br />

<br />

<br />

Desired offset<br />

<br />

<br />

slight reinforcement<br />

Large offset<br />

<br />

<br />

at centre and high at<br />

edges<br />

increased with the use of longer extensions<br />

due to resistive heating of the wire. If the stickout<br />

is too long then the wire is preheated and<br />

can tend to wander leading to miss-alignment<br />

also penetration is reduced.<br />

Angle of welding head<br />

The pulling or backhand technique gives<br />

greater penetration and a narrower weld<br />

with a more convex weld bead. There is<br />

increased risk of undercut using this<br />

Weld metal dilution<br />

depends on the joint<br />

preparation.<br />

technique. Conversely pushing or forehand<br />

will give less penetration, a less convex weld<br />

bead and a low risk of undercut.<br />

67