guidelines for conservation of energy on pump irrigation system

guidelines for conservation of energy on pump irrigation system

guidelines for conservation of energy on pump irrigation system

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ewe '-.b-.~<br />

GUIDELINES FOR<br />

CONSERVATION OF ENERGY ON<br />

PUMP IRRIGATION SYSTEM<br />

~ \iR1 3Wlrrr<br />

CENTRAL WATER COMMISSION<br />

NEW DELHI<br />

APRIL 1988

CWC PUBLICATION NO.26/88<br />

CENTRAL WATER· COMMISSION<br />

NAVGAM DESIGN CELL<br />

GUIDELINES FOR<br />

CONSERVATION OF ENERGY' ON<br />

PUMP IRRIGATION SYSTEM<br />

NEW DELHI<br />

WIIRl~~ "-«t~<br />

PU"""

Page No.<br />

1<br />

1<br />

3<br />

5<br />

System 'B' at delivery end and System 'A' at<br />

delivery end<br />

6<br />

7<br />

Method <str<strong>on</strong>g>of</str<strong>on</strong>g> measurement <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>energy</str<strong>on</strong>g> c<strong>on</strong>sumpti<strong>on</strong> and<br />

efficiency <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>pump</strong>ing <strong>system</strong><br />

8<br />

9<br />

10<br />

Method <str<strong>on</strong>g>of</str<strong>on</strong>g> discharge measurement from the<br />

trajectory <str<strong>on</strong>g>of</str<strong>on</strong>g> the jet <str<strong>on</strong>g>of</str<strong>on</strong>g> water<br />

11<br />

12

GUIDELINES FOR CONSERVATION OF<br />

ENERGY ON PUMP IRRIGATION SYSTEM<br />

[;.~<br />

In India there are about 64 lakh electric pt~pS and about 56 A diesel<br />

<strong>pump</strong>s used by farmers <str<strong>on</strong>g>for</str<strong>on</strong>g> irrigati<strong>on</strong> purposeso Such agricultural <strong>pump</strong>s c<strong>on</strong>sume<br />

electricity and diesel worth Rs. 4000 croreJd~,

Find out the gross head <strong>on</strong> the <strong>pump</strong>ing <strong>system</strong> by adding the static<br />

head, the losses in the pipes and valves and the exit velocity<br />

head.<br />

STATIC HEAD is the difference in water level in the well and the<br />

level <str<strong>on</strong>g>of</str<strong>on</strong>g> the centre line <str<strong>on</strong>g>of</str<strong>on</strong>g> the exit end <str<strong>on</strong>g>of</str<strong>on</strong>g> the delivery pipeo<br />

Losses in the pipes and valves can be measured by means <str<strong>on</strong>g>of</str<strong>on</strong>g> pressure<br />

and vacuum gauges provided at (i) the top end <str<strong>on</strong>g>of</str<strong>on</strong>g> the sucti<strong>on</strong><br />

pipe near the <strong>pump</strong> and (ii) the delivery pipe near the <strong>pump</strong>o The<br />

total losses in the <strong>system</strong> can be calculated as per the details<br />

given in Annexure III.<br />

The <str<strong>on</strong>g>energy</str<strong>on</strong>g> c<strong>on</strong>sumpti<strong>on</strong> and efficiency <str<strong>on</strong>g>of</str<strong>on</strong>g> the <strong>pump</strong>i;lg <strong>system</strong> can be<br />

measured by adopting the method given in Annexure I. The minimum<br />

efficiency <str<strong>on</strong>g>of</str<strong>on</strong>g> the <strong>pump</strong>ing <strong>system</strong> shall be as specified in th~ relevant<br />

IS Code (I.S. Code No. 6595-1980-Specificati<strong>on</strong> <str<strong>on</strong>g>for</str<strong>on</strong>g> horiz<strong>on</strong>tal<br />

centrifugal <strong>pump</strong>s <str<strong>on</strong>g>for</str<strong>on</strong>g> clear, cold, fresh water <str<strong>on</strong>g>for</str<strong>on</strong>g> agricultural<br />

purposes". IS Code No. 9079-1979-"Specificati<strong>on</strong> <str<strong>on</strong>g>for</str<strong>on</strong>g> m<strong>on</strong>oset <strong>pump</strong>s<br />

<str<strong>on</strong>g>for</str<strong>on</strong>g> clear, cold, fresh water <str<strong>on</strong>g>for</str<strong>on</strong>g> agricultural purposes."<br />

Alternately, the actual <str<strong>on</strong>g>energy</str<strong>on</strong>g> c<strong>on</strong>sumed as read from the <str<strong>on</strong>g>energy</str<strong>on</strong>g><br />

meter may be compared with the maximum <str<strong>on</strong>g>energy</str<strong>on</strong>g> that should have<br />

been c<strong>on</strong>sumed by the <strong>pump</strong>ing <strong>system</strong>. If the actual <str<strong>on</strong>g>energy</str<strong>on</strong>g> c<strong>on</strong>sumed<br />

is higher than the maximum <str<strong>on</strong>g>energy</str<strong>on</strong>g> that should have been c<strong>on</strong>sumed<br />

by the <strong>system</strong> then remedial measures are necessary to improve the<br />

efficiency <str<strong>on</strong>g>of</str<strong>on</strong>g> the <strong>system</strong> to save <str<strong>on</strong>g>energy</str<strong>on</strong>g>.<br />

4) Check from the manufacturer's per<str<strong>on</strong>g>for</str<strong>on</strong>g>mance c~art <str<strong>on</strong>g>of</str<strong>on</strong>g> the <strong>pump</strong> and<br />

motor, the rated discharge <str<strong>on</strong>g>of</str<strong>on</strong>g> the <strong>pump</strong> <str<strong>on</strong>g>for</str<strong>on</strong>g> the gross head calculated<br />

at Sl.No.2 at the rated voltage. Check the voltage <str<strong>on</strong>g>of</str<strong>on</strong>g> the<br />

power line by a voltmeter to see whether the voltage is the rated<br />

voltage. The discharge <str<strong>on</strong>g>of</str<strong>on</strong>g> the <strong>pump</strong> shall be measured <strong>on</strong>ly when the<br />

voltage is equal to the rated voltage.<br />

The actuaL discharge measured at Sl.No. 1 shall be equal to the<br />

rated discharge <str<strong>on</strong>g>of</str<strong>on</strong>g> the <strong>pump</strong>. If the actual discharge is less than<br />

the rated discharge then it means that the <strong>pump</strong>ing <strong>system</strong> is not<br />

working at the optimum efficiency and thus it c<strong>on</strong>sumes more <str<strong>on</strong>g>energy</str<strong>on</strong>g><br />

than required. It plso means that the loss <str<strong>on</strong>g>of</str<strong>on</strong>g> head or <str<strong>on</strong>g>energy</str<strong>on</strong>g> in -<br />

the pipe line and valves and/or the <strong>pump</strong> is high.

Even if the actual discharge is equal to the rated discharge in a <strong>pump</strong>ing<br />

<strong>system</strong> c<strong>on</strong>taining G.I. pipes and ordinary footvalve , the <strong>system</strong><br />

efficiency can be improved by following method~<br />

1) If the foot valve is covered by plastic sheet or gunny cloth, remove<br />

the same. Cover the footvalve by suitable strainer, if necessary,<br />

to prevent leaves and weeds entering the valve. Do not allow<br />

silt to accumulate near the foot valve. Periodical checking is<br />

necessary <str<strong>on</strong>g>for</str<strong>on</strong>g> the same.<br />

2) a) If the footvalve is not a fricti<strong>on</strong>less footvalve, replace the<br />

same by a fricti<strong>on</strong>less or minus fricti<strong>on</strong> footvalve, <str<strong>on</strong>g>of</str<strong>on</strong>g> standard<br />

make c<strong>on</strong><str<strong>on</strong>g>for</str<strong>on</strong>g>ming to the r.S •.Code, No. 10805-1986. Kirloskar'<br />

Minus Fricti<strong>on</strong> footvalves, Pant Nagar footvalves or equivalent<br />

available in the market can be used.<br />

b) As the diameter <str<strong>on</strong>g>of</str<strong>on</strong>g> the minus fricti<strong>on</strong> footvalve increases, it<br />

is found that the head loss through the footvalve decreases.<br />

There<str<strong>on</strong>g>for</str<strong>on</strong>g>e, a footvalve <str<strong>on</strong>g>of</str<strong>on</strong>g> bigger, diameter than the diameter<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> the sucti<strong>on</strong> pipe may b~ used al<strong>on</strong>gwith a taper piece.<br />

3) Check whether proper size <str<strong>on</strong>g>of</str<strong>on</strong>g> pipe <str<strong>on</strong>g>for</str<strong>on</strong>g> sucti<strong>on</strong> & delivery as recommended<br />

by the I.S. Code No. 9694 (Part I) - 1980. Code <str<strong>on</strong>g>of</str<strong>on</strong>g> practice<br />

<str<strong>on</strong>g>for</str<strong>on</strong>g> the selecti<strong>on</strong>, installati<strong>on</strong>, operati<strong>on</strong> and maintenance <str<strong>on</strong>g>of</str<strong>on</strong>g> horiz<strong>on</strong>tal<br />

centrifugal <strong>pump</strong>s <str<strong>on</strong>g>for</str<strong>on</strong>g> agricultural applicati<strong>on</strong>s - Part I -<br />

Selecti<strong>on</strong>, is used in the <strong>pump</strong>ing <strong>system</strong>.<br />

Table No. 4 <str<strong>on</strong>g>for</str<strong>on</strong>g> Nominal pipe size <str<strong>on</strong>g>for</str<strong>on</strong>g> sucti<strong>on</strong> and delivery lines<br />

as given in the I.S. Code is reproduced in Annexure II.<br />

4) Check the G.I. pipe line with Rigid PVC pipes <str<strong>on</strong>g>of</str<strong>on</strong>g> proper size which<br />

gives less fricti<strong>on</strong> loss in turn reducing the <str<strong>on</strong>g>energy</str<strong>on</strong>g> c<strong>on</strong>sumpti<strong>on</strong>.<br />

HOPE pipes can also be used but they are costlier than RPVC pipes.<br />

The fC' valve fo~ G.I. pipe is 100 against 150 <str<strong>on</strong>g>for</str<strong>on</strong>g> Rigid PVC or<br />

HOPE pipes.<br />

5) Check whether proper size <str<strong>on</strong>g>of</str<strong>on</strong>g> footvalve and sluice valve has been<br />

provided as shown in the table given in Annexure II. Otherwise<br />

change the same al<strong>on</strong>gwith the pipes.<br />

6) Sucti<strong>on</strong> head should not be more than 4.5m. Otherwise the <strong>pump</strong> will<br />

operate at low efficiency and the discharge will be less. L<strong>on</strong>g<br />

time operati<strong>on</strong> with high sucti<strong>on</strong> lift will result in damage to the<br />

impeller <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>pump</strong>. There<str<strong>on</strong>g>for</str<strong>on</strong>g>e the <strong>pump</strong> shall be installed in such<br />

a manner that the sucti<strong>on</strong> head is lesp than 4.5m. Sucti<strong>on</strong> head<br />

should be measured from time to time to check whether the same is<br />

within 4.5m and suitable meaSures as discussed under Sl.No. 1,2,3<br />

and 4 should be taken necessary, to keep the sucti<strong>on</strong> head within<br />

4.5m.<br />

7) In the sucti<strong>on</strong> side <str<strong>on</strong>g>of</str<strong>on</strong>g> a <strong>pump</strong>ing <strong>system</strong>, if the G.I. pipe and ordinary<br />

footvalve are replaced by R. P.V.C. pipe and frictioi,less

footvalve, then it is observed that the saving in <str<strong>on</strong>g>energy</str<strong>on</strong>g> can be<br />

nearly 32% <str<strong>on</strong>g>for</str<strong>on</strong>g> a discharge <str<strong>on</strong>g>of</str<strong>on</strong>g> 11.7 litres/sec. and a lift <str<strong>on</strong>g>of</str<strong>on</strong>g> 3.5m<br />

(See Figure 3).<br />

8) a) A horiz<strong>on</strong>tal delivery pipe provided at about 1.5 M above the<br />

water level in the channel or sump as shown in Fig.1 causes<br />

unnecessary loss <str<strong>on</strong>g>of</str<strong>on</strong>g> <str<strong>on</strong>g>energy</str<strong>on</strong>g>. This <strong>system</strong> can be improved by<br />

providing 2 Nos. <str<strong>on</strong>g>of</str<strong>on</strong>g> 45 0 bends and a horiz<strong>on</strong>tal pipe at a lower<br />

level just about 15 em above the water level as shown i.nFig. 2<br />

will save head loss by 97.5% <strong>on</strong> delivery side and save <str<strong>on</strong>g>energy</str<strong>on</strong>g><br />

c<strong>on</strong>sumpti<strong>on</strong>.<br />

b) A diffuser provided at the delivery end can further reduce the<br />

loss <str<strong>on</strong>g>of</str<strong>on</strong>g> head due to exit velocity by about 50% in a 63 mm diameter<br />

pipe and above 87% in a 110 mm diameter pipe.<br />

The improved <strong>system</strong> as<br />

saving in <str<strong>on</strong>g>energy</str<strong>on</strong>g>. For<br />

<str<strong>on</strong>g>energy</str<strong>on</strong>g> can be saved in<br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> a motor-<strong>pump</strong> giving<br />

110 mm dia RPVC pipes •.<br />

or 0.47 H .P.<br />

shown in Fig. 2 will give substantial<br />

example, nearly 260 units <str<strong>on</strong>g>of</str<strong>on</strong>g> electrical<br />

800 hours <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>pump</strong>ing per annum in case<br />

a discharge <str<strong>on</strong>g>of</str<strong>on</strong>g> 12.5 l/sec. through<br />

The saving in power is nearly 0.350 Kw<br />

d) If the c<strong>on</strong>venti<strong>on</strong>al <strong>pump</strong>ing <strong>system</strong> as shown In Fig. 3 having<br />

G.I. pipes and ordinary foot valve is improv€d by providing<br />

RPVC pipes diffuser and fricti<strong>on</strong>less footval~es and the delivery<br />

end <str<strong>on</strong>g>of</str<strong>on</strong>g> pipe is bent down to have the exit end <str<strong>on</strong>g>of</str<strong>on</strong>g> pipe<br />

to be in the same line as the centre line <str<strong>on</strong>g>of</str<strong>on</strong>g> the <strong>pump</strong>, then<br />

saving in <str<strong>on</strong>g>energy</str<strong>on</strong>g> to the extent <str<strong>on</strong>g>of</str<strong>on</strong>g> 47% can be obtained, when<br />

the discharge is 11.7 l/sec. and the static lift <str<strong>on</strong>g>of</str<strong>on</strong>g> water is<br />

3.5 m.<br />

9) Check whether the <strong>pump</strong> and motor are made as per relevant I.S.<br />

standards. M<strong>on</strong>o-block <strong>pump</strong>sets having combined efficiency not<br />

less than 60-65% should be used. Replace the <strong>pump</strong> and motor if it<br />

is found to give less efficiency. "Also check whether the motor<br />

is <str<strong>on</strong>g>of</str<strong>on</strong>g> proper size. Oversized motor with higher H.P. rating than<br />

r~quired will operate at lower efficiency and c<strong>on</strong>sume more <str<strong>on</strong>g>energy</str<strong>on</strong>g>.<br />

There<str<strong>on</strong>g>for</str<strong>on</strong>g>e correct size <str<strong>on</strong>g>of</str<strong>on</strong>g> motor should be determined <str<strong>on</strong>g>for</str<strong>on</strong>g> the given<br />

discharge and gross head from the per<str<strong>on</strong>g>for</str<strong>on</strong>g>mance chart <str<strong>on</strong>g>of</str<strong>on</strong>g> the manufacturer<br />

and the same should be installed. A good guide can be had<br />

from the "Guidelines <str<strong>on</strong>g>for</str<strong>on</strong>g> selecti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> agricultural <strong>pump</strong>sets -<br />

Field staff and farmers guide" prepared by the Nati<strong>on</strong>al Bank <str<strong>on</strong>g>for</str<strong>on</strong>g><br />

Agriculture and Rural Development, Bombay (Page 12, 13 and Table<br />

VIII) <str<strong>on</strong>g>for</str<strong>on</strong>g> the selecti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> motor.<br />

10) A capacitor fitted to the motor reduce <str<strong>on</strong>g>energy</str<strong>on</strong>g> c<strong>on</strong>sumpti<strong>on</strong>. There<str<strong>on</strong>g>for</str<strong>on</strong>g>e,<br />

capacitor should be got c<strong>on</strong>nected to the motor, if it is not<br />

already provided with the motor.<br />

11) Power meters may be got checked frequently <str<strong>on</strong>g>for</str<strong>on</strong>g> its proper functi<strong>on</strong>ing.<br />

12) If it is not possible to replace the <strong>pump</strong> and motor, due to high<br />

cost, at least the valves and pipes must be changed. It is found

to improve the efficiency <str<strong>on</strong>g>of</str<strong>on</strong>g> the <strong>system</strong>, by about 15% to<br />

2~.<br />

~<br />

13) The <strong>pump</strong> and motor should be installed <strong>on</strong> firm foundati<strong>on</strong> with<br />

anchor belts etc. to avoid vibrati<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> the <strong>pump</strong>.<br />

~le farmer will require the services <str<strong>on</strong>g>of</str<strong>on</strong>g> a c<strong>on</strong>sulting agency or an<br />

Engineer to check the efficiency <str<strong>on</strong>g>of</str<strong>on</strong>g> the <strong>pump</strong>ing <strong>system</strong> and to suggest remedial<br />

measures to be adopted to improve the efficiency. If the above said measures<br />

are taken, the resultant saving in <str<strong>on</strong>g>energy</str<strong>on</strong>g> will go a l<strong>on</strong>g way in helping the<br />

progress <str<strong>on</strong>g>of</str<strong>on</strong>g> the nati<strong>on</strong>. The saving in <str<strong>on</strong>g>energy</str<strong>on</strong>g> will more than compensate the<br />

capital cost invested in a very short time. After that it is all pr<str<strong>on</strong>g>of</str<strong>on</strong>g>it <str<strong>on</strong>g>for</str<strong>on</strong>g><br />

the farmer.

•<br />

00 lEND<br />

~ __ 2.5M<br />

{M<br />

II.'~EL/VERY<br />

PIPE (RPVCl<br />

FiG.1 SYSTEM 'B' AT DELIVERY END<br />

DELIVERY PIPE _'_M-+ IM. ---1<br />

(RPVCl<br />

I<br />

90·BE~O ~5 REND<br />

1MI<br />

MOTOR<br />

PUMP<br />

I O~M.I<br />

------T~~~~MI<br />

CHANNEL

FIG.3<br />

I<br />

---1I<br />

_.._....- _.1'-<br />

.-...:...__--.All: _ _ _<br />

-<br />

- - -- --<br />

SKETCH FOR ORIGINAL PUMPING SYSTEM<br />

SKETCH FOR NEW IMPROVED<br />

PUMPING SYSTE M<br />

(NOT TO SCALE)

METHOD OF MEASUREMENT OF ENERGY CONSUMPTION<br />

AND EFFICIENCY OF PUMPING SYSTEM<br />

a~ Input power to the <strong>pump</strong>ing <strong>system</strong> can be measured by means <str<strong>on</strong>g>of</str<strong>on</strong>g> a watt meter<br />

in the power lines c<strong>on</strong>nected to the motor. For 3 phase A.C. motor two watt<br />

meters have to be c<strong>on</strong>nected to the terminals <str<strong>on</strong>g>of</str<strong>on</strong>g> the motor and the total <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

the two watt meter readings will give the total power.<br />

b) Alternatively input power can be calculated by measuring the number <str<strong>on</strong>g>of</str<strong>on</strong>g> units<br />

c<strong>on</strong>sumed by the motor in the <str<strong>on</strong>g>energy</str<strong>on</strong>g> meter <str<strong>on</strong>g>for</str<strong>on</strong>g> a particular amount <str<strong>on</strong>g>of</str<strong>on</strong>g> time.<br />

The power input to the motor<br />

Energy in Kwh<br />

Time in hours<br />

c) Output power <str<strong>on</strong>g>of</str<strong>on</strong>g> the <strong>pump</strong>ing <strong>system</strong> can be determined by measurement <str<strong>on</strong>g>of</str<strong>on</strong>g> discharge<br />

by provisi<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> a V-notch in the irrigati<strong>on</strong> channel carrying water<br />

to the fields from the <strong>pump</strong> delivery. The gross head <strong>on</strong> the <strong>pump</strong>ing <strong>system</strong><br />

can be calculated by adding the static head, .the losses in the pipes and<br />

valves and exit velocity head.<br />

Static head is the difference in w-ater level in the well and the level <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

the centre line <str<strong>on</strong>g>of</str<strong>on</strong>g> the delivery pipe. Losses in the pipes and valves can<br />

be calculated as per the,I.S. Code No. 9694 (Part I) - 1980 - (Code <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

Practice <str<strong>on</strong>g>for</str<strong>on</strong>g> the selecti<strong>on</strong>, installati<strong>on</strong>, operati<strong>on</strong> and maintenance <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

horiz<strong>on</strong>tal centrifugal <strong>pump</strong>s <str<strong>on</strong>g>for</str<strong>on</strong>g> Agricultural Applicati<strong>on</strong>s - Part I Se.1ecti<strong>on</strong>).<br />

The output power can be calculated by using the following <str<strong>on</strong>g>for</str<strong>on</strong>g>mula:<br />

WQH<br />

Power output = 75 - x 746 watts.<br />

3<br />

where w - 1000 Kg/m Unit weight <str<strong>on</strong>g>of</str<strong>on</strong>g> water<br />

Output power <str<strong>on</strong>g>of</str<strong>on</strong>g> <strong>pump</strong>s<br />

(in watts)<br />

Input to motor<br />

(in watts)<br />

WQHt<br />

75 M x<br />

0.746 kwh<br />

P<br />

Minimum efficiency <str<strong>on</strong>g>of</str<strong>on</strong>g> the <strong>pump</strong>ing <strong>system</strong> as per<br />

1.S. Code.

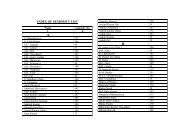

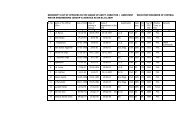

Volume Rate <str<strong>on</strong>g>of</str<strong>on</strong>g> Nominal Pipe Size <str<strong>on</strong>g>of</str<strong>on</strong>g> Nominal Pipe Size <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

Flow Sucti<strong>on</strong> Pipe Delivery Pipe<br />

~ rom rom<br />

1 2 3<br />

0.50 20 20<br />

1.00 30 25<br />

1.25 40 32<br />

1.60 40 40<br />

2.00 40 40<br />

2.50 50 40<br />

3.20 65 50<br />

4.00 65 50<br />

5.00 65 65<br />

8.00 80 80<br />

10.00 100 80<br />

12.50 100 100<br />

16.00 125 100<br />

20.00 125 125<br />

25.00 150 125<br />

32.00 150 150<br />

40.00 200 150<br />

50.00 200 200<br />

60.00 250 200<br />

80.00 250 250<br />

100.00 300 250<br />

125.00 350 300<br />

Note -- The above values have been calculated <strong>on</strong> the basis <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

velocity <str<strong>on</strong>g>of</str<strong>on</strong>g> flow <str<strong>on</strong>g>of</str<strong>on</strong>g> 1.5 Mis (approx) and 2.0 mls (approx)<br />

in the sucti<strong>on</strong> and delivery pipes respe~tively.

Pressure at the top end <str<strong>on</strong>g>of</str<strong>on</strong>g> the sucti<strong>on</strong><br />

pipe near the <strong>pump</strong>.<br />

P1<br />

Kg/em<br />

2<br />

Pressure in the deli.very pipe near the<br />

<strong>pump</strong>.<br />

P2 Kg/em<br />

2<br />

Difference in level between the gauges<br />

at inlet and outlet <str<strong>on</strong>g>of</str<strong>on</strong>g> the <strong>pump</strong>s.<br />

Total head loss in the <strong>pump</strong>ing <strong>system</strong><br />

(in ems) (P2 )<br />

-P1 - ~50 em + hg<br />

w

i<br />

Horiz<strong>on</strong>tal and vertical co-ordinates <str<strong>on</strong>g>of</str<strong>on</strong>g> any point <strong>on</strong><br />

the jet <str<strong>on</strong>g>of</str<strong>on</strong>g> water leaving out <str<strong>on</strong>g>of</str<strong>on</strong>g> the delivery pipe in<br />

Metres.<br />

Velocity <str<strong>on</strong>g>of</str<strong>on</strong>g> water at the exit point <str<strong>on</strong>g>of</str<strong>on</strong>g> delivery pipe<br />

in rn/sec.<br />

. 1 . d .. / 2<br />

Acce erat~<strong>on</strong> ue to grav~ty ~n rn see •

1. Selecti<strong>on</strong> <str<strong>on</strong>g>of</str<strong>on</strong>g> Agricultural Pumpsets - Field Staff and Farmers Guide by<br />

Nati<strong>on</strong>al Bank <str<strong>on</strong>g>for</str<strong>on</strong>g> Agriculture and Rural Development Bombay.<br />

Guidance to Farmers - Selecting, Operating and Maintaining Centrifugal<br />

Pump by Dr. Sakthi Vadivel, Anna University, Madras - 25.<br />

3. Techno-Ec<strong>on</strong>omic Aspects <str<strong>on</strong>g>of</str<strong>on</strong>g> Different Types <str<strong>on</strong>g>of</str<strong>on</strong>g> Pump Rectificati<strong>on</strong> Measur~s<br />

by Dr. S.M. Patel, Director, Institute <str<strong>on</strong>g>of</str<strong>on</strong>g> Co-operative Management<br />

prep.ared <str<strong>on</strong>g>for</str<strong>on</strong>g> Gujarat Energy Development Agency.<br />

4. Proceedings <str<strong>on</strong>g>of</str<strong>on</strong>g> the Nati<strong>on</strong>al Seminar <strong>on</strong> Use <str<strong>on</strong>g>of</str<strong>on</strong>g> Plastics in Agriculture<br />

held at Vigyan Bhavan, Feb. 6, 1987, organised by the Directorate <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

Extensi<strong>on</strong> (Ministry <str<strong>on</strong>g>of</str<strong>on</strong>g> Agriculture Govt. <str<strong>on</strong>g>of</str<strong>on</strong>g> India).<br />

5. 1.S. Code No. 6595-1980 "specificati<strong>on</strong> <str<strong>on</strong>g>for</str<strong>on</strong>g> horiz<strong>on</strong>tal centrifugal <strong>pump</strong>s<br />

<str<strong>on</strong>g>for</str<strong>on</strong>g> clear, cold, fresh water <str<strong>on</strong>g>for</str<strong>on</strong>g> Agricultural Purposes".<br />

6. I.S. Code No.9079-1979 - "Specificati<strong>on</strong> <str<strong>on</strong>g>for</str<strong>on</strong>g> m<strong>on</strong>oset <strong>pump</strong>s <str<strong>on</strong>g>for</str<strong>on</strong>g> clear,<br />

cole, fresh wat€:r <str<strong>on</strong>g>of</str<strong>on</strong>g> Agricultural purposes".<br />

7. 1.S. Code No.9694 (Part I) - 1980 "Code <str<strong>on</strong>g>of</str<strong>on</strong>g> practice <str<strong>on</strong>g>for</str<strong>on</strong>g> the Selecti<strong>on</strong>,<br />

Installati<strong>on</strong>, Operati<strong>on</strong> and Maintenance <str<strong>on</strong>g>of</str<strong>on</strong>g> Horiz<strong>on</strong>tal Centrifugal<br />

Pumps <str<strong>on</strong>g>for</str<strong>on</strong>g> Agricultural Applicati<strong>on</strong>s - Part I - Selecti<strong>on</strong>".<br />

8. 1.5. Code No.10805-1986 "Specificati<strong>on</strong> <str<strong>on</strong>g>for</str<strong>on</strong>g> Footvalves" Reflux Valves or<br />

N<strong>on</strong>-Return valves and Bore Valves to be used in Sucti<strong>on</strong> lines <str<strong>on</strong>g>of</str<strong>on</strong>g> Agricultural<br />

Pumping System".<br />

,<br />

9. I.S. Code No. 2951 (Part I & II) - 1965 "Recommendati<strong>on</strong> <str<strong>on</strong>g>for</str<strong>on</strong>g> Estimati<strong>on</strong><br />

<str<strong>on</strong>g>of</str<strong>on</strong>g> Flow <str<strong>on</strong>g>of</str<strong>on</strong>g> Liquids in closed c<strong>on</strong>duit".

Designed and Printed at ewc Offset Press, R.K.Puram, New Delhi-110066<br />

ewc Publicati<strong>on</strong> No:26/88 1500Copies