Peru FoodNews 2010 - GBR

Peru FoodNews 2010 - GBR

Peru FoodNews 2010 - GBR

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

20 A Global Business Reports publication<br />

A Global Business Reports publication<br />

21<br />

you need to give something different to the<br />

client. We are betting strongly on valueadded<br />

products, and on solutions rather than<br />

just commodities”.<br />

Carranza asserts that its main clients are<br />

in the dairy and bakery, carbonated drinks<br />

and juices sectors. In a highly specialised<br />

world of flavours, colours and fragrances,<br />

the challenge is to make sure the formula<br />

fits exactly the idea that the clients want to<br />

materialise: “The development process of a<br />

product can take a year. We incur a lot of<br />

risk, therefore it is very important to monitor<br />

the process very closely. Having a plant<br />

where we can do pretty much everything,<br />

from bread to ice creams, we can carry<br />

out tests together with the client to ensure<br />

that we are going in the right direction”,<br />

Carranza adds.<br />

For Federico Bauer, President of Montana,<br />

this characteristic of the flavours business<br />

places some limitations on how much the<br />

companies in this field can export: “We sell<br />

natural colorants to 40 countries and expect<br />

exports to represent 20% of our sales by<br />

2011. In the flavours market, however, we<br />

need to be close to the customers with our<br />

own laboratories. We cannot really develop<br />

the export market from Lima as we need to<br />

carry out tests and we cannot send samples<br />

in and out”.<br />

Giving a hand,<br />

worldwide<br />

A food product may be ready to be<br />

consumed, but it will have no value for the<br />

producer unless it reaches the customer in<br />

perfect shape and on time. While problems<br />

in this final link of the value chain may be<br />

addressable in products like conserves, in<br />

the case of perishables a mistake can be very<br />

expensive, even disastrous. That is why the<br />

companies taking care of this need to be<br />

world-class. As Andrés Muñoz of Interbank<br />

puts it: “I strongly believe that fresh<br />

products offer great added value. If a final<br />

consumer can buy a fruit in a supermarket<br />

knowing that it has been recently taken<br />

from the field, that’s fantastic technology<br />

and logistics”.<br />

The logistics process does not depend<br />

solely on the efficiency of the provider,<br />

but on external factors such as the state<br />

of the country’s infrastructure and the<br />

availability of cargo spaces in airplanes<br />

and boats. Alberto Uribe, Director of<br />

DHL’s Perishables Division, explains:<br />

“In air transportation, <strong>Peru</strong> relies on the<br />

connections made by passenger planes.<br />

From Lima there are direct flights to<br />

Miami, Los Angeles, New York, Madrid<br />

and Amsterdam; there are no direct flights<br />

to the other main markets. It is thanks to<br />

the excellent quality of the different agro<br />

products exported that they can reach final<br />

markets in perfect condition in places like<br />

South Africa, Australia or China after four<br />

days of transit”.<br />

Eduardo Rey, Managing Director of<br />

Schenker, further develops on this issue:<br />

“The Asian market is incredibly big and has<br />

enormous potential, but right now there are<br />

no direct flights. The four airlines currently<br />

connecting Lima with Europe are sometimes<br />

not enough for certain cargo requirements.<br />

I addition to this, we are really behind in<br />

ports: the Callao port has experienced some<br />

critical moments”.<br />

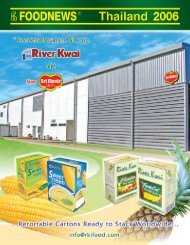

One thing is clear: logistics companies<br />

need to be solid enough to overcome these<br />

challenges. Emilio Fantozzi, General<br />

Manager of Ransa, a <strong>Peru</strong>vian logistics<br />

company operating since 1939, describes<br />

the basics of success in this field: “If you do<br />

not want the clients to do the job themselves,<br />

you need to have better processes than<br />

them; to offer more competitive costs that<br />

they could have; and to make life simpler<br />

for them”. No wonder having the latest<br />

technology, software and a well-trained<br />

workforce (Ransa employs over 4 000<br />

people in Latin America) needs to be part<br />

of the equation.<br />

From machinery to logistics, food producers need the support of efficient providers.<br />

(Photo courtesy of Ransa)