RM - SONDERMANN Pumpen + Filter GmbH & Co. KG

RM - SONDERMANN Pumpen + Filter GmbH & Co. KG

RM - SONDERMANN Pumpen + Filter GmbH & Co. KG

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Product range<br />

Magnetically coupled centrifugal pumps<br />

Submersible pumps<br />

<strong>Filter</strong>s and filter equipment<br />

<strong>Co</strong>mpetence in<br />

pump and filter<br />

technologies

SONDE<strong>RM</strong>ANN makes the difference –<br />

with excellent product quality, decades<br />

of experience and reliable service.<br />

Excellent products<br />

Ask any expert or specialist company which<br />

pump technology they use, the answer will<br />

mostly be SONDE<strong>RM</strong>ANN. That’s something<br />

we are rightly proud of! All our products and<br />

devices are of highest quality, from simple<br />

submersible pumps to magnetically coupled<br />

pumps that are absolutely safe to run dry. So<br />

our pumps will work reliably and impeccably<br />

in any place for a long time.<br />

Reliable service<br />

We have an especially dense network of customer<br />

advisors: only in Germany, well-trained<br />

technical advisors in 14 distribution companies<br />

are at your disposal. So we are everywhere<br />

in close contact with the users of our<br />

products. Whatever challenge of fluid pumping<br />

or filtering you face, the job will be done<br />

best by a SONDE<strong>RM</strong>ANN pump or filter. Just<br />

try us!<br />

Decades of experience<br />

The SONDE<strong>RM</strong>ANN brand stands for decades<br />

of experience and continuous development<br />

of products. For more than 50 years now, our<br />

pumps and pumping systems have been used<br />

in various industries all over the world. And<br />

up to this day, we have been able to consolidate<br />

our technological lead. This unique<br />

technological know-how enables us to solve<br />

almost every pump-related problem of our<br />

clients.<br />

Much more than standard issue<br />

As standard models are often inadequate<br />

for a specific application, we have been prepared,<br />

from the beginning, to manufacture<br />

customized designs. Tell us your specific<br />

type of problem in detail and we will be able<br />

to help you solve it in no time. This is also<br />

what SONDE<strong>RM</strong>ANN stands for.<br />

Quality made in Germany<br />

Wherever SONDE<strong>RM</strong>ANN is written on, quality<br />

made in Germany is inside. All our products<br />

are entirely manufactured in Germany<br />

and certified according to the ISO 9001 standard.<br />

This is only one of the reasons why our<br />

products are of superior quality. Since we are<br />

very serious about each new pump and filter,<br />

every single one is thoroughly checked in<br />

several stages before it leaves the company.<br />

SONDE<strong>RM</strong>ANN is a member of<br />

the German Surface Engineering<br />

Industries Association.<br />

2

Table of <strong>Co</strong>ntents<br />

SONDE<strong>RM</strong>ANN pumps and filters 2<br />

Overview of pumps 4<br />

Choose the right pump 5<br />

Pumps 5<br />

of the <strong>RM</strong> series 5<br />

of the <strong>RM</strong>-TS series 9<br />

of the <strong>RM</strong>-MS series 10<br />

of the <strong>RM</strong>-MF series 12<br />

of the GM-N series 16<br />

of the GM-P series 19<br />

of the RT series 22<br />

<strong>Filter</strong>s 25<br />

Universal filter vessels 25<br />

Quick-change filters 26<br />

<strong>Filter</strong>s combined with pumps 27<br />

<strong>Filter</strong> elements and cartridges, accessories 28<br />

RPR-<strong>Co</strong>ntrol units 29<br />

Sales representations in<br />

Germany and abroad 30<br />

3

Choosing the right pump is a guarantee<br />

of safe and reliable operation.<br />

<strong>Co</strong>rrect installation<br />

Choosing the right pump for each type of<br />

application is a crucial factor in trouble-free<br />

operation for a long time.<br />

It doesn’t matter if the inflow is below the<br />

liquid level or a self-priming pump has to<br />

be used above liquid level or the pump<br />

operates in submersible applications, we<br />

can always offer you the right pump.<br />

Vertically mounted<br />

submersible centrifugal<br />

pump of the RT series<br />

(wet-pit installation)<br />

Self-priming<br />

side-channel pump<br />

of the <strong>RM</strong>S series<br />

Self-priming<br />

magnetically coupled<br />

centrifugal pump<br />

of the <strong>RM</strong>B series<br />

Non-self-priming<br />

magnetically coupled<br />

centrifugal <strong>RM</strong> pump<br />

with extrapriming tank<br />

Non-self-priming<br />

magnetically coupled<br />

centrifugal pump<br />

of the <strong>RM</strong> series<br />

Vertically mounted<br />

submersible<br />

centrifugal pump<br />

of the RTA series<br />

(dry-well installation)<br />

Other applications<br />

Non-self-priming centrifugal <strong>RM</strong><br />

pump with extra priming tank<br />

Pump mounted to a transport<br />

vehicle<br />

Non-self-priming centrifugal<br />

<strong>RM</strong> pump with heat exchanger<br />

Submersible centrifugal pump<br />

4

<strong>RM</strong><br />

Magnetically coupled centrifugal<br />

pumps without shaft seal<br />

A wide range of applications<br />

<strong>RM</strong> pumps are always used when perfect<br />

leakproofness and freedom from maintenance<br />

are indispensable. They are especially<br />

used to deliver aggressive acids and bases,<br />

degreasing baths, chemicals, highly corrosive<br />

liquids and fluids tending to cristallize.<br />

Manufacturers of printed-circuit boards, the<br />

solar industry and purification plants also<br />

profit from <strong>RM</strong> pumps by SONDE<strong>RM</strong>ANN.<br />

These arrangements are cost-intensive and<br />

require a lot of maintenance. What is more,<br />

the necessary maintenance intervals considerably<br />

reduce the availability of the<br />

pump.<br />

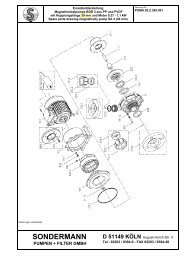

<strong>Co</strong>nstructional design<br />

Our magnetically coupled centrifugal pumps<br />

of the <strong>RM</strong> series do not have a shaft seal<br />

but use permanent magnets to transmit the<br />

motor drive to the pump impeller without<br />

Motor<br />

Rear casing<br />

Lantern<br />

Inner magnet<br />

Driving magnet<br />

Impeller<br />

Housing<br />

Advantages of <strong>RM</strong> pumps are:<br />

<br />

<br />

<br />

<br />

<br />

<br />

No mechanical sealing<br />

of the shaft.<br />

Mechanical separation of<br />

motor and pump from<br />

each other.<br />

Absolute leakproofness.<br />

Free from maintenance.<br />

<strong>Co</strong>mpact and space-saving<br />

design.<br />

Easy installation.<br />

Ball bearings<br />

Starting ring of of<br />

rear casing<br />

Sleeve<br />

bearings<br />

Starting ring of<br />

impeller<br />

Starting ring of<br />

pump housing<br />

Mechanical shaft seals have always been<br />

the weak points of conventional centrifugal<br />

pumps because they wear out with time. So<br />

when you deliver aggressive or toxic fluids,<br />

the leakage of fluid, for example, may result<br />

in a hazardous situation.<br />

When delivering non-lubricating fluids or<br />

fluids tending to crystallize in particular, the<br />

use of mechanical shaft seals requires very<br />

complex arrangements like sealing chambers<br />

with double-acting mechanical seals.<br />

any contact. A shaft exit requiring expensive<br />

sealing is no longer necessary, since<br />

the wet part and the dry part of the pump<br />

are hermetically separated from each other<br />

by the rear casing. Thus, leakages through<br />

worn shaft sealings are definitely ruled out<br />

and <strong>RM</strong> pumps are absolutely free from<br />

maintenance. The metal-free and all-plastic<br />

making of our pumps is standard since this<br />

design is a guarantee for best protection<br />

from corrosion.<br />

5

<strong>RM</strong><br />

Our pumps of the <strong>RM</strong> series feature<br />

high operational reliability and minimum<br />

maintenance<br />

Characteristic curves<br />

Discharge head [in m.Wg]<br />

60<br />

55<br />

50<br />

45<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

0 100 200 300 400 500 600 700 800 900 1000<br />

0 6 12 18 24 30 36 42 48 54 60<br />

Delivery rate [in l/min. or m 3 /h]<br />

<strong>RM</strong> 1<br />

<strong>RM</strong> 1.5<br />

<strong>RM</strong> 2<br />

<strong>RM</strong> 3<br />

<strong>RM</strong> 4<br />

<strong>RM</strong> 4.5<br />

<strong>RM</strong> 4.5<br />

<strong>RM</strong> 5<br />

l/min<br />

m 3 /h<br />

The metal-free and all-plastic design of our<br />

pumps is the best way to prevent corrosion.<br />

Housings may be also made of special stainless<br />

steel. We offer the right combination of<br />

materials for any fluid to be delivered, depending<br />

on its temperature.<br />

Characteristics of <strong>RM</strong> pumps<br />

The characteristic curves of <strong>RM</strong> 1 to <strong>RM</strong> 5<br />

pumps show for each type of pump its delivery<br />

rates at given discharge heads (back<br />

pressure). Discharge heads are in meters,<br />

water gauge. If the fluid delivered has a<br />

density of more than 1.0, the generated<br />

pressure (in bars) rises accordingly.<br />

Simple and sturdy design<br />

with maintenance-free<br />

sleeve bearings.<br />

6

<strong>RM</strong><br />

Magnetically coupled centrifugal<br />

pumps without shaft seal<br />

Non-self-priming pumps<br />

Non-self-priming centrifugal pumps<br />

Pumps of type 1<br />

Delivery rate:<br />

1–36 L/min<br />

Discharge head:<br />

up to 5 m.Wg<br />

Pumps of type 1.5<br />

Delivery rate:<br />

1–83 L/min<br />

Discharge head:<br />

up to 7 m.Wg<br />

Pumps of type 2<br />

Delivery rate:<br />

5–130 L/min<br />

Discharge head:<br />

up to 9 m.Wg<br />

Pumps of type 2D<br />

Delivery rate:<br />

5–60 L/min<br />

Discharge head:<br />

up to 16 m.W<br />

Pumps of type 3<br />

Delivery rate:<br />

8–230 L/min<br />

Discharge head:<br />

up to 23 m.Wg<br />

Pumps of type 4<br />

Delivery rate:<br />

10–400 L/min<br />

Discharge head:<br />

up to 36 m.Wg<br />

Pumps of type 4.5<br />

Delivery rate:<br />

20–900 L/min<br />

Discharge head:<br />

up to 35 m.Wg<br />

Pumps of type 5<br />

Delivery rate:<br />

30–1250 L/min<br />

Discharge head:<br />

up to 60 m.Wg<br />

7

<strong>RM</strong><br />

Magnetically coupled centrifugal<br />

pumps without shaft seal<br />

Self-priming centrifugal pumps and <strong>RM</strong> <strong>Co</strong>ol-mini pump<br />

Self-priming centrifugal pumps<br />

Pumps of type 2.1<br />

Delivery rate:<br />

1–22 L/min<br />

Discharge head:<br />

up to 54 m.Wg<br />

Suction head<br />

up to 7 m.Wg<br />

Pumps of type 3.1<br />

Delivery rate:<br />

8–240 L/min<br />

Discharge head:<br />

up to 18 m.Wg<br />

Suction head<br />

up 3,5 m.Wg<br />

<strong>RM</strong> <strong>Co</strong>ol<br />

magnetically coupled<br />

centrifugal mini-pump<br />

The magnetically coupled centrifugal mini-pump of<br />

the <strong>RM</strong>-<strong>Co</strong>ol type is the perfect high-performance<br />

cooling system to remove heat from laser devices,<br />

computers, plasma-arc cutters, etc. (available in PP,<br />

PPS or PVDF).<br />

<strong>RM</strong> pumps are vailable in<br />

the following materials<br />

Material<br />

temperature range<br />

of components in contact with the fluid<br />

Polypropylene (PP) 0 bis +80 °C<br />

Polyvinylidene fluoride (PVDF) –20 bis +95 °C<br />

Polyphenylene sulphide (PPS) –20 bis +100 °C<br />

Stainless steel (1.4305, 1.4571) –20 bis +100 °C<br />

Oxide ceramic<br />

(aluminium oxide 99.7 %) –20 bis +100 °C<br />

PTFE graphite –20 bis +100 °C<br />

Gaskets<br />

Ethylene-propylene-diene<br />

rubber (EPDM) –20 bis +100 °C<br />

Fluorinated rubber (FKM) –20 bis +100 °C<br />

FKM with coating of fluorinated<br />

ethylene-propylene-diene<br />

(FEP coated) –20 bis +100 °C<br />

Nitrile-butadiene rubber (NBR) –20 bis +100 °C<br />

<strong>RM</strong> <strong>Co</strong>ol mini-pump<br />

Delivery rate: up to 5 L/min<br />

Discharge head: up to 2 m.Wg<br />

8

<strong>RM</strong>-TS<br />

Magnetically coupled<br />

centrifugal pumps safe<br />

to run dry<br />

Absolutely safe to run dry<br />

<strong>Co</strong>nventional magnetically coupled pumps<br />

can hardly cope with dry running. In fact,<br />

their sleeve bearings need continuous<br />

liquid-film lubrication to keep bearing<br />

friction and the resulting frictional heat as<br />

low as possible and also to provide the<br />

bearing with sufficient cooling. With their<br />

Since the pump does not have a shaft seal,<br />

it is hermetically sealed off and, because of<br />

this unique design, leakages through worn<br />

shaft sealings are definitely ruled out.<br />

Simple and reliable design:<br />

<br />

<br />

<br />

<br />

<br />

<br />

Absolutely safe to run dry.<br />

Magnetically coupled, no sleeve bearings.<br />

Extremely high resistance to chemicals.<br />

All present pumps of the <strong>RM</strong>-type can be<br />

adapted to the new system safe to run dry.<br />

The pumps may be also used at high speeds<br />

without any problems.<br />

Increased efficiency by using bearings with<br />

an extremely small coefficient of friction.<br />

pumps of the <strong>RM</strong>-TS series, SONDE<strong>RM</strong>ANN<br />

offer the first magnetically coupled centrifugal<br />

pumps in the world that are absolutely<br />

safe to run dry.<br />

Suction and discharge ports<br />

with O-ring sealings<br />

Inner magnet<br />

Driving magnet<br />

The pumps of this new series include all<br />

advantages of our longstanding experience<br />

with pumps of the <strong>RM</strong> series and the<br />

additional certainty that they will not be<br />

damaged by dry running. The coefficient<br />

of friction of the new bearing system is so<br />

small that only a minimum of heat is<br />

generated. Therefore, the bearing does not<br />

require any liquid lubrication.<br />

Motor<br />

Fully ceramic roller bearing of<br />

the impeller magnet<br />

9

<strong>RM</strong>-MS<br />

Multi-stage magnetically<br />

coupled centrifugal pumps<br />

Definitely more power:<br />

<br />

<br />

<br />

<br />

<br />

<br />

Highly energy-efficient<br />

at high pressures: The<br />

pump’s best efficiency<br />

point is at high discharge<br />

heads and small quantities<br />

delivered.<br />

<strong>Co</strong>mpact, flexible and<br />

modular construction in<br />

monobloc design.<br />

One, two or three stages<br />

available.<br />

Extremely high resistance<br />

to chemicals.<br />

Torque transmission by<br />

means of magnetic coupling.<br />

Made of metal-free plastic<br />

in PP or PVDF.<br />

A lot more efficiency<br />

at high pressures<br />

<strong>RM</strong>-MS pumps are perfectly suited to deliver<br />

aggressive fluids at high pressures.<br />

As single-stage centrifugal pumps are not<br />

very efficient at high pressures, we designed<br />

this multi-stage centrifugal pump.<br />

Instead of several centrifugal pumps<br />

working one after the other, an <strong>RM</strong>-MS<br />

pump consists of several impellers connected<br />

in series within one volute. Thus,<br />

the discharge heads of all impellers add up.<br />

Suction and discharge ports<br />

with O-ring sealings<br />

Inner magnet<br />

As a result, <strong>RM</strong>-MS pumps are much more<br />

efficient in delivering higher flow rates at<br />

high pressures than single-stage centrifugal<br />

pumps that work within a less favourable<br />

operating range.<br />

One to three impellers,<br />

depending on the type<br />

of pump<br />

Driving magnet<br />

Motor<br />

10

<strong>RM</strong>-MS<br />

Multi-stage magnetically<br />

coupled centrifugal pumps<br />

Characteristic curves<br />

Discharge head [in m.Wg]<br />

80<br />

75<br />

70<br />

65<br />

60<br />

55<br />

50<br />

45<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

0<br />

50 100 150 200 250 300<br />

0 3 6 9 12 15 18<br />

Delivery rate [in l/min. or m 3 /h]<br />

<strong>RM</strong>-MS, 3 stages<br />

<strong>RM</strong>-MS, 2 stages<br />

<strong>RM</strong>-MS, 1 stage<br />

l/min<br />

m 3 /h<br />

High performance<br />

Centrifugal pumps of the <strong>RM</strong>-MS series are<br />

of modular design. Magnetically driven<br />

impellers are connected in series. The<br />

pumps are available with one, two or three<br />

impellers (stages).<br />

Because of the impellers connected in<br />

series, one <strong>RM</strong>-MS pump is considerably<br />

more efficient at higher pressures than<br />

comparable single-stage centrifugal<br />

pumps would be.<br />

Fields of application<br />

The specific features and technical data of<br />

the <strong>RM</strong>-MS pumps make them most suitable<br />

to deliver aggressive chemicals at higher<br />

pressures but medium pump performance,<br />

such as in industrial booster stations for<br />

aggressive chemicals, demineralized water<br />

supply systems, spraying processes,<br />

scrubbers and washers as well as in dosing<br />

chemicals at system pressures of more than<br />

3 bars.<br />

11

<strong>RM</strong>-MF<br />

Magnetically coupled<br />

centrifugal pumps with<br />

variable-speed drive<br />

NEW!<br />

The innovative MF drive concept<br />

The <strong>RM</strong> 4.5-MF pump with variable-speed<br />

drive knows how to make intelligent use<br />

of its power.<br />

SONDE<strong>RM</strong>ANN’s new magnetically coupled<br />

centrifugal pumps have an innovative,<br />

energy-efficient and compact drive system<br />

with variable speed. This assures you of<br />

an optimum and need-based fluid control<br />

that does not waste any energy.<br />

Fields of application<br />

<strong>RM</strong> pumps are always used when perfect<br />

leakproofness and maintenance-free<br />

operation are indispensable. In particular,<br />

they are used to deliver aggressive acids<br />

and bases, degreasing baths, chemicals,<br />

highly corrosive liquids and fluids tending<br />

to cristallize.<br />

Advantages of <strong>RM</strong>-MF pumps are:<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

The efficiency rate of the pump<br />

is optimized to the operating<br />

point.<br />

Integrated speed control.<br />

Exceptionally high efficieny<br />

within the whole range of speed.<br />

Wide range of flexible applications<br />

as the centrifugal pumps are<br />

operated by frequency converters.<br />

Small and compact design.<br />

Since the frequency converter is<br />

directly mounted to the motor,<br />

there is no need of long, shielded<br />

and expensive cables to connect<br />

the motor to the electrical cabinet.<br />

More space available in the<br />

electrical cabinet and no need of<br />

cooling it.<br />

Adjusting the head capacity curve<br />

of the pump to the operating point<br />

required saves energy.<br />

Only one type of pumps to cover<br />

all voltages and frequencies<br />

throughout the world.<br />

The pumps already meet the IE3<br />

energy efficiency class standards<br />

that will be applicable as of 2015<br />

and 2017.<br />

Saving of energy results in less<br />

operating costs.<br />

Reduction of CO 2 emissions<br />

because of less power<br />

consumption.<br />

12

<strong>RM</strong>-MF<br />

Magnetically coupled<br />

centrifugal pumps with<br />

variable-speed drive<br />

Delivery rates (3,500 rpm)<br />

Discharge head [in m.Wg]<br />

45<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

0 100 200 300 400 500 600 700 800 900<br />

0 6 12 18 24 30 36 42 48 54<br />

Delivery rate [in l/min. or m 3 /h]<br />

<strong>RM</strong>-MF 4.5<br />

<strong>RM</strong>-MF 4<br />

<strong>RM</strong>-MF 3<br />

l/min<br />

m 3 /h<br />

Frequency converter<br />

for more flexibility<br />

Depending on modern operational requirements,<br />

a pump often has to deliver various<br />

volume flow rates or offer different operating<br />

points. Speed-changing frequency converters<br />

enable the <strong>RM</strong>-MF pumps to control<br />

fluid delivery on demand in an extremely<br />

easy and energy-saving way.<br />

The frequency converter also allows you to<br />

use all pumps of the <strong>RM</strong>-MF series with any<br />

power supply voltage and any frequency all<br />

over the world. This means that you may<br />

use an <strong>RM</strong>-MF pump in any kind of machinery<br />

and plant world-wide – a fact that substantially<br />

simplifies your site planning and<br />

spare parts logistics.<br />

Enormous potential for saving<br />

Very often, pumps are designed far too big<br />

and powerful, just to „play it safe“. But the<br />

various safety factors resulting from such<br />

hypothetical layout of the system add up<br />

considerably so that extremely powerful<br />

pumps are installed that later on are operated<br />

only in part load.<br />

In part-load operation, however, the efficiency<br />

of a centrifugal pump is extremely<br />

low and energy-wasting. On the other hand,<br />

the delivery rate of oversized centrifugal<br />

pumps is often reduced by means of throttle<br />

valves. <strong>Co</strong>ntrolling the delivery rate by a frequency<br />

converter has the unique advantage<br />

that when the speed is reduced by half, the<br />

electric power consumption is not more<br />

than one eighth!<br />

13

<strong>RM</strong>-MF<br />

Magnetically coupled<br />

centrifugal pumps with<br />

variable-speed drive<br />

Motor performance (at 3,500 rpm)<br />

8000<br />

7000<br />

6000<br />

<strong>RM</strong>4.5-MF<br />

<strong>RM</strong>4-MF<br />

<strong>RM</strong>3-MF<br />

Motor performance [W]<br />

5000<br />

4000<br />

3000<br />

2000<br />

1000<br />

0<br />

0 100 200 300 400 500 600 700 800 900<br />

0 6 12 18 24 30 36 42 48 54<br />

l/min<br />

m 3 /h<br />

Delivery rate [in l/min. or m 3 /h]<br />

Pump of type <strong>RM</strong>4.5-MF<br />

Pump of type <strong>RM</strong>4-MF<br />

Pump of type <strong>RM</strong>3-MF<br />

An <strong>RM</strong>-MF pump allows you to precisely<br />

adjust its performance to the volume flow<br />

required so that the power consumption<br />

of the pump is just as high as needed.<br />

SONDE<strong>RM</strong>ANN pumps of the <strong>RM</strong>-MF series<br />

are highly efficient centrifugal pumps<br />

whose motor efficiency more than fulfills<br />

the requirements of the IE2 efficiency class<br />

standard. What is more, our pumps already<br />

meet the IE3 energy efficiency class standards<br />

that will be applicable as of 2015 and<br />

2017.<br />

14

<strong>RM</strong>-MF<br />

Magnetically coupled<br />

centrifugal pumps with<br />

variable-speed drive<br />

<strong>Co</strong>mparison in size<br />

The multi-frequency<br />

drive technique<br />

The motors of our <strong>RM</strong>-MF pumps are especially<br />

designed asynchronous motors. When<br />

nominally loaded, they operate at a frequency<br />

of 120 Hz and a rated speed of 3,450 rpm.<br />

As these motors have been optimized to<br />

operate with a frequency converter, they<br />

cannot run without such frequency converter.<br />

As a standard feature, the frequency<br />

converter is directly mounted to the motor<br />

and thus combines a compact drive unit<br />

with the motor. SONDE<strong>RM</strong>ANN frequency<br />

converters adjust the magnetizing current<br />

to the load required and thus considerably<br />

increase the motors’ efficiency in part-load<br />

operation. It is also possible to control such<br />

motor by an external frequency converter<br />

that is installed in the electrical cabinet or<br />

at the wall (optionally available).<br />

Another substantial advantage of the motors<br />

of <strong>RM</strong>-MF pumps is that they are much<br />

smaller and lighter than any other standard<br />

asynchronous motor of the same power<br />

<strong>Co</strong>mparison of two magnetically coupled centrifugal pumps of 7.5 kW<br />

clearly shows that the <strong>RM</strong>-MF pump is distinctly more compact than the<br />

pump with a conventional IE2 class motor.<br />

within the IE2 energy efficiency class. That’s<br />

why the new <strong>RM</strong>-MF pumps are efficient and<br />

compact centrifugal pumps for precise fluid<br />

control on demand.<br />

<strong>Co</strong>mparison of sizes<br />

Nominal power<br />

motor size<br />

kW IE2 motor MF motor<br />

0,75 80 63<br />

1,1 90 71<br />

1,5 90 71<br />

2,2 90 80<br />

3,0 100 80<br />

4,0 100 90<br />

5,5 112 100<br />

7,5 132 100<br />

11,0 160 112<br />

15,0 160 132<br />

18,5 180 132<br />

22,0 180 132<br />

15

GM-N<br />

Magnetically coupled<br />

standard chemical pumps<br />

Pumps of the GM-N series<br />

<strong>Co</strong>nstructional design<br />

Magnetically coupled centrifugal pumps of<br />

the GM-N series are centrifugal chemical<br />

pumps with PTFE/PFA lining. Their dimensions<br />

and nominal duty points comply with<br />

the DIN EN 22858 standard. They are available<br />

as GM-NP pump in pull-out design<br />

with free shaft end or as GM-NB pump in<br />

monobloc design with flange-mounted drive<br />

motor.<br />

The pumps are resistant to almost all kinds<br />

of corrosion because the fluids delivered<br />

will be only in contact with PTFE/PFA, oxide<br />

ceramic, zirconium oxide or silicon carbide.<br />

GM-N pumps are magnetically driven singlestage<br />

pumps with annular casing that do not<br />

have a shaft seal. The rear casing hermetically<br />

closes the pump which is absolutely<br />

leak-proof. This rear casing is either made<br />

of composite carbon fibre material and lined<br />

with PTFE or made of zirconium oxide. The<br />

closed impeller made of PTFE is mounted to<br />

a hollow ceramic shaft with double sleeve<br />

bearings made of silicon carbide. Due to this<br />

hollow shaft, the sleeve bearings are always<br />

impeccably lubricated and cooled, even<br />

under difficult operating conditions. So the<br />

pump is less sensitive to incomplete lubrication<br />

and/or dry running.<br />

Vacuum-proof<br />

case lining of PFA,<br />

4 mm thick.<br />

Thrust bearings of<br />

optimum dimensions<br />

take the axial thurst.<br />

PTFE impeller with<br />

curved blades for<br />

more efficiency.<br />

Special parallel<br />

keys for power<br />

transmission.<br />

Shafts with bore holes<br />

ensure for forced internal<br />

circulation to<br />

improve lubrication of<br />

the bearings.<br />

Metal-free rear casing<br />

made of carbon<br />

fibre to prevent eddy<br />

losses.<br />

16

GM-N<br />

Magnetically coupled<br />

standard chemical pumps<br />

The driving mechanism<br />

Fields of application<br />

The permanent-magnetic transmission<br />

system consists of a PTFE coated inner<br />

magnet and a flywheel with outer magnets.<br />

The permanent magnets are made of cobalt<br />

and samarium. A rear casing with PTFE<br />

lining or made of zirconium oxide hermetically<br />

closes the pump which is absolutely<br />

leak-proof.<br />

As they are absolutely leak-proof, GM pumps<br />

are perfectly suited to deliver highly<br />

aggressive or hazardous liquids. Thus, users<br />

in all fields of the chemical and pharmaceutical<br />

industries have relied on our pumps<br />

for a long time past. The standard chemical<br />

pumps are available either in pull-out design<br />

or in compact monobloc design with flangemounted<br />

motor.<br />

Advantages of GM-N pumps are:<br />

<br />

<br />

<br />

<br />

<br />

<br />

Ceramic shaft with bore holes<br />

for internal split-stream<br />

circulation.<br />

Less sensitive to incomplete<br />

lubrication.<br />

Impellers with curved blades<br />

for more efficiency.<br />

No eddy losses due to metal-free<br />

rear casings.<br />

PTFE parts are free of metallic<br />

framework.<br />

Silicon-carbide thrust bearings<br />

of optimum dimensions take the<br />

axial thrust.<br />

The standard chemical pumps<br />

are available as GM-NP pump<br />

in pull-out design with free<br />

shaft end or as GM-NB pump in<br />

compact monobloc design with<br />

flange-mounted motor.<br />

Safe and environmentally friendly<br />

Our pumps allow you to safely and environmentally friendly deliver highly<br />

aggressive liquids like, for example, monochloroacetic acid, sulphuric acid<br />

and hydrofluoric acid, because they are made of highly corrosion-resistant<br />

materials.<br />

17

GM-N<br />

Magnetically coupled<br />

standard chemical pumps<br />

Characteristic curves of GM-N pumps (n= 2,900min -1 , 50Hz)<br />

100<br />

90<br />

80<br />

50-250<br />

Discharge head [in m.Wg]<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

25-160<br />

32-160<br />

50-200<br />

32-200<br />

40-200<br />

80-200<br />

0<br />

0 1 2 4 6 8 10<br />

20 30 40 50 60 70 80 100 120 140 160 180<br />

Delivery rate [in m 3 /h]<br />

Characteristic curves of GM-N pumps (n= 1,450min -1 , 50Hz)<br />

24<br />

22<br />

50-250<br />

Discharge head [in m.Wg]<br />

20<br />

16<br />

12<br />

8<br />

4<br />

25-160<br />

32-160<br />

50-200<br />

32-200 40-200<br />

80-200<br />

0<br />

0 1 2 4 6 8<br />

10 20 30 40 50 60 70 80 100 120<br />

Delivery rate [in m 3 /h]<br />

18

GM-P<br />

Magnetically driven<br />

peripheral chemical pumps<br />

made of PTFE<br />

Fields of application<br />

Pumps of the GM-P series<br />

GM-P pumps are peripheral or side-channel<br />

pumps that are best suited to deliver small<br />

to medium volume flows at high pressures<br />

of up to 8 bars. Like pumps of the GM-N<br />

series, these pumps are also resistant to<br />

almost all kinds of corrosion. Thus, they<br />

are best suited for absolutely leak-proof<br />

delivery of highly aggressive and hazardous<br />

liquids that are free of abrasive or crystalline<br />

components.<br />

GM-P pumps are peripheral pumps in<br />

monobloc design with PTFE/PFA lining.<br />

As these magnetically coupled pumps do<br />

not have a shaft seal, they are hermetically<br />

closed and do not need any packing at all.<br />

The pumps are resistant to almost all kinds<br />

of corrosion because the fluids delivered<br />

will be only in contact with PTFE/PFA, oxide<br />

ceramic, zirconium oxide or silicon carbide.<br />

The pumps are just as suitable to deliver<br />

liquids with low boiling points because they<br />

are absolutely insensitive to cavitation. The<br />

volume flow may even contain up to 30<br />

percent of gas.<br />

Advantages of GM-P pumps are:<br />

<br />

<br />

<br />

<br />

<br />

Insensitive to cavitation.<br />

Delivery of fluids with a<br />

gas content of up to 30%.<br />

Ceramic casing inserts<br />

for constant delivery<br />

rates, even at varying<br />

temperatures.<br />

No eddy losses due to<br />

metal-free rear casing.<br />

PTFE parts are free of<br />

metallic framework.<br />

Vacuum-proof case<br />

lining of PFA,<br />

4 mm thick.<br />

Ceramic casing<br />

inserts for free<br />

impeller rotation.<br />

Special parallel<br />

keys for power<br />

transmission.<br />

Metal-free rear<br />

casing made of<br />

carbon fibre to<br />

prevent eddy<br />

losses.<br />

19

GM-P<br />

Magnetically driven<br />

peripheral chemical pumps<br />

made of PTFE<br />

<strong>Co</strong>nstructional design<br />

A special technology<br />

GM-P pumps are magnetically driven singlestage<br />

peripheral pumps that do not have<br />

a shaft seal. The annular casing is either<br />

made of spheroidal graphite cast iron and<br />

lined with PFA or of PTFE. The impeller<br />

made of PTFE is floating on a ceramic<br />

shaft and supported at both sides by sleeve<br />

bearings of silicon carbide. The rear casing<br />

hermetically closes the pump which is<br />

absolutely leak-proof. This rear casing is<br />

either made of composite carbon fibre<br />

material and lined with PTFE or of zirconium<br />

oxide. The magnetic coupling consists<br />

of a PTFE coated inner magnet and a flywheel<br />

with driving magnets.<br />

It is important to keep to various parameters<br />

in order to guarantee a constant performance<br />

throughout the overall operating<br />

time.<br />

On the one hand, the performance of a<br />

peripheral pump depends on the size of<br />

its discharge channel and the width of<br />

the gap between impeller and discharge<br />

channel walls. On the other hand, corrosionresistant<br />

materials (like PTFE or PFA) built<br />

into the pump tend to creep or cold-flow<br />

when pressure or temperature varies so<br />

that pump performance would change in<br />

the course of time.<br />

20

GM-P<br />

Magnetically driven<br />

peripheral chemical pumps<br />

made of PTFE<br />

Characteristic curves of GM-P pumps (n= 2,900min -1 , 50Hz)<br />

Discharge head [in m.Wg]<br />

100<br />

80<br />

60<br />

40<br />

25-140<br />

25-100<br />

15-90<br />

20<br />

0<br />

0<br />

16<br />

32<br />

66<br />

100 133 166 200 233 266 300 l/min.<br />

1<br />

2<br />

4<br />

6 8 10 12 14 16 18 m 3 /h<br />

Delivery rate [in l/min. or m 3 /h]<br />

A corrosion-resistant ceramic insert inside<br />

the casing helps to avoid this and always<br />

grants a constant width of this gap.<br />

The metal-free rear<br />

casing of GM-P pumps<br />

is made of carbon<br />

fibre to prevent<br />

eddy losses.<br />

Advantages for the user are:<br />

All operating parameters are kept for<br />

the entire service period of the pump.<br />

A defined width of gap allows for easy<br />

inspection without expensive<br />

adjustments required.<br />

Trouble-free operation at temperatures<br />

of up to 150°C and operating pressures<br />

of up to 16 bars.<br />

21

RT<br />

Submersible centrifugal pumps for<br />

wet-pit and dry-well installation<br />

Advantages of RT pumps:<br />

<br />

<br />

<br />

<br />

<br />

<br />

Non-corroding plastic pump<br />

without any metal part in<br />

contact with the fluid.<br />

Patented shaft-sealing<br />

ceramic labyrinth that is<br />

free of wear.<br />

The pump is available in PP,<br />

PVDF and stainless steel.<br />

High efficiency by using<br />

a volute.<br />

Flanges may be dimensioned<br />

according to our clients’<br />

specifications.<br />

Drive unit with mounted<br />

frequency converter is<br />

available upon request.<br />

Innovative technology<br />

makes the difference<br />

The search for better and nearer to perfect<br />

solutions resulted in an all-time technological<br />

standard from which our clients in this<br />

field of application benefit as well.<br />

SONDE<strong>RM</strong>ANN’s submersible centrifugal<br />

pumps distinguish themselves by their<br />

practical design and sturdy construction.<br />

All components being in contact with the<br />

fluid are made of materials that are resistant<br />

to corrosion and chemicals.<br />

The pumps’ construction also offers the advantages<br />

that they are safe to run dry (without<br />

requiring intermediate bearings), do not<br />

require much space and can be adjusted to<br />

specific requirements of our clients.<br />

SONDE<strong>RM</strong>ANN’s submersible centrifugal<br />

pumps are used for vertical wet-pit operation<br />

in pressureless containers, open basins<br />

and pits. They have excellent performance<br />

in the delivery and circulation of clean,<br />

slightly contaminated and abrasive fluids,<br />

aqueous solutions, suspensions and liquid<br />

mixtures.<br />

Our submersible centrifugal pumps are best<br />

suited to deliver acids and bases, acid and<br />

alkaline mixtures, solvents, alkaline degreasing<br />

and electroplating baths, photochemicals<br />

and many other low-viscosity<br />

fluids of up to 160 mPa s (or 160 cP).<br />

22

RT<br />

Submersible centrifugal pumps for<br />

wet-pit and dry-well installation<br />

<strong>Co</strong>nstructional features<br />

of RT pumps<br />

Fixed connection,<br />

90° offset<br />

Protection class<br />

Our motors are of protection class<br />

IP55 (ventilation cowl with protective<br />

canopy). Explosion-proof motors<br />

available upon request.<br />

Sound-pressure level<br />

Because of the motor’s precisionbalanced<br />

running, the sound-pressure<br />

level is below 70dB (A), according to<br />

DIN EN 12639 standard.<br />

Electric drive<br />

by a surface-cooled single-phased or<br />

three-phase low-voltage cage motor.<br />

Upon request, motors with<br />

integrated frequency<br />

converter are also<br />

available.<br />

<strong>Co</strong>ating<br />

Two-compoment acidproof protective<br />

varnishing. Special colours are available<br />

upon request.<br />

Fixed connection,<br />

vertical up<br />

The discharge pipe<br />

(left picture) may be<br />

replaced by a filter<br />

(right picture).<br />

Discharge port<br />

Screw neck according<br />

to DIN 8063 standard (or<br />

optional version of flange<br />

connection according to<br />

DIN 2501 standard, PN 10/16).<br />

Flange dimensions<br />

are made at short<br />

notice according to<br />

customer specifications.<br />

Shaft gland<br />

For every kind of application, a specific<br />

gland sealing is used. Especially for the<br />

delivery of highly crystallizing fluids,<br />

SONDE<strong>RM</strong>ANN pumps are equipped with<br />

a patented sealing system.<br />

Non-corroding<br />

plastic pump without any<br />

metal part in contact with<br />

the fluid. The motor shaft is<br />

entirely coated with plastic<br />

material.<br />

Sturdy construction<br />

Pump housing, mounting<br />

flange, standpipe and<br />

discharge pipe are<br />

welded together to a<br />

complete unit.<br />

This unit is also available<br />

as flexible assembly<br />

screwed together.<br />

High efficiency<br />

because of the<br />

volute used.<br />

Performance data<br />

SONDE<strong>RM</strong>ANN pumps have the right impeller<br />

for every delivery rate required.<br />

Suction port<br />

The suction port is equipped with a<br />

strainer to protect the pump from<br />

coarse contaminations. An extension<br />

tube is optionally available.<br />

23

RT<br />

Centrifugal immersion pumps for<br />

wet-pit and dry-well installation<br />

(Our RTA pumps for dry-well installation<br />

have the same features)<br />

Pumps for wet-pit installation<br />

Pumps of type 1<br />

Delivery rate of<br />

up to 32 L/min<br />

Discharge head of<br />

up to 7 m.Wg<br />

Submergence of<br />

up to 400mm<br />

Pumps of type 2<br />

Delivery rate of<br />

up to 130 L/min<br />

Discharge head of<br />

up to 12 m.Wg<br />

Submergence of<br />

up to 500mm<br />

Pumps of type 3<br />

Delivery rate of<br />

up to 280 L/min<br />

Discharge head of<br />

up to 25 m.Wg<br />

Submergence of<br />

up to 500mm<br />

Pumps of type 4<br />

Delivery rate of<br />

up to 550 L/min<br />

Discharge head of<br />

up to 32 m.Wg<br />

Submergence of<br />

up to 500mm<br />

Pumps of type 5<br />

Delivery rate of<br />

up to 1,000 L/min<br />

Discharge head of<br />

up to 42 m.Wg<br />

Submergence of<br />

up to 500mm<br />

Pumps of type 6<br />

Delivery rate of<br />

up to 1,700 L/min<br />

Discharge head of<br />

up to 43 m.Wg<br />

Submergence of<br />

up to 850mm<br />

24

Solid, reliable and efficient:<br />

Universal filter housings by SONDE<strong>RM</strong>ANN<br />

available in sizes 1 to 32 to meet every reqirement<br />

All advantages at a glance:<br />

Our universal filter<br />

housings come in<br />

different sizes with<br />

1 to 32 slots for<br />

filter cartridges and<br />

a height of 4 to 40<br />

inches. Thus we can<br />

exactly dimension<br />

every filter to your<br />

specific demands.<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Great choice of filters.<br />

All-purpose filter chambers<br />

can take a wide range<br />

of various filter elements.<br />

Housings are entirely<br />

made of plastic.<br />

All filters can be combined<br />

with all of our pumps.<br />

Splash-guard built into<br />

the filter cap.<br />

Thanks to their quick-release<br />

fastener, the quick-change<br />

filter types are extremely<br />

easy to handle.<br />

Pressure losses are very low.<br />

A filter of size 1, for example, has a<br />

filtration rate of up to 3,000 L/h.<br />

A filter of size 32, for example, has a<br />

filtration rate of up to 72,000 L/h.<br />

SONDE<strong>RM</strong>ANN filters are used to remove<br />

both organic and inorganic contaminations<br />

from aggressive and neutral liquids, by<br />

means of high-pass or surface filtration.<br />

Main fields of application include electroplating,<br />

etching and cleaning plants,<br />

sewage and water treatment installations<br />

as well as solar, textile and food industries.<br />

The following filter elements can be<br />

inserted into our filter housings:<br />

– wound cartridge, cloth and membrane<br />

filters;<br />

– paper disks, filter bags and sieves;<br />

– activated carbon as granular bed or<br />

filter cartridge.<br />

As they are entirely made of plastic, these<br />

filter housings are especially suited to filter<br />

aggressive fluids, such as<br />

– acids, bases and mixtures;<br />

– solvents;<br />

– alkaline degreasing baths;<br />

– electroplating baths;<br />

– photochemicals;<br />

– radioactive, aseptic and precious liquids;<br />

– other low-viscosity fluids.<br />

Apart from standard filters that can be<br />

combined with every SONDE<strong>RM</strong>ANN<br />

pump, we also design and produce, in close<br />

cooperation with our clients, customized<br />

functional modules ready to be installed.<br />

25

Solid, reliable and powerful:<br />

<strong>Filter</strong>technology by SONDE<strong>RM</strong>ANN is top quality<br />

and best performance<br />

Quick-change and belt filters<br />

Quick-change filters of the SF series<br />

SF 1 filter<br />

Made of PP or PVDF.<br />

Suitable for woundcartridge<br />

filter<br />

elements and sieves.<br />

Quick-release lock<br />

by means of a hand<br />

lever.<br />

Double safety<br />

cap switch.<br />

SF 3 filter<br />

Made of PP or PVDF.<br />

Suitable for woundcartridge<br />

filter elements,<br />

sieves, filter<br />

bags and activated<br />

carbon filters.<br />

Quick-release lock by<br />

means of a hand lever.<br />

Double safety<br />

cap switch.<br />

Belt filter<br />

Inclined-bed belt<br />

filter made of<br />

plastic, with<br />

variable-speed<br />

drive.<br />

This filter is espcially<br />

suitable for<br />

aggressive fluids<br />

with high contanmination<br />

levels.<br />

Flow indicators to ensure safety<br />

Flow indicators built into pipelines are a simple and<br />

cost-effective way to monitor the flow of the fluid<br />

delivered. Our flow indicators come in two designs:<br />

Indicators made of PP are suited for low-viscosity<br />

fluids resembling water with densities of 0.8 to 1.5,<br />

those made of PVDF are also suited for low-viscosity<br />

fluids resembling water but with densities of 0.8 to 1.84.<br />

26

The right combination of filters and pumps<br />

for more efficiency and reliability<br />

Exemplifying combinations of filters and magnetically coupled pumps<br />

<strong>Filter</strong>s combined with magnetically coupled pumps<br />

Size 1<br />

<strong>Filter</strong> of size 1<br />

combined with<br />

a magnetically<br />

coupled pump of<br />

the <strong>RM</strong> 1.5 series,<br />

used with one<br />

filter candle for a<br />

filtration rate of<br />

up to 3,000 L/h.<br />

Size 4<br />

<strong>Filter</strong> of size 4<br />

combined with a<br />

magnetically<br />

coupled pump of<br />

the <strong>RM</strong> 3 series,<br />

used with four<br />

filter candles for<br />

a filtration rate of<br />

up to 12,000 L/h.<br />

<strong>Filter</strong> with magnetically coupled pump<br />

and activated-carbon element<br />

Size 8<br />

<strong>Filter</strong> of size 8<br />

combined with<br />

a magnetically<br />

coupled pump of<br />

the <strong>RM</strong> 4 series,<br />

used with eight<br />

filter candles and<br />

an activated-carbon<br />

chamber for<br />

a filtration rate of<br />

up to 30,000 L/h.<br />

<strong>Filter</strong> plant with a filter of size<br />

32 for a filtration rate of up to<br />

72,000 L/min.<br />

The unit integrates into a tailormade<br />

functional module ready<br />

to be installed that was<br />

designed and produced in close<br />

cooperation with our<br />

client.<br />

Activated carbon<br />

Activated carbon filters are especially<br />

used with electroplating baths, but also<br />

to absorb organic substances, remove<br />

foreign metals and regain precious<br />

metals from flushing water.<br />

27

A wise decision: <strong>Filter</strong> housing, pump and filter<br />

material made by one and the same company<br />

Exemplifying combinations of filters, submersible pumps,<br />

filter elements and accessories<br />

<strong>Co</strong>mbinations of filters and submersible pumps<br />

Submersible pump<br />

of the RT series<br />

combined with a<br />

filter of size 1 for a<br />

filtration rate of<br />

up to 6,000 L/min<br />

and a submergence<br />

of 200 to 500mm.<br />

RT pump combined<br />

with a quick-change<br />

filter of the SF 1<br />

series for a<br />

filtration rate of<br />

up to 18,000 L/min<br />

and a submergence<br />

of 270 to 500mm.<br />

<strong>Filter</strong> elements and accessories<br />

Wound or extruded filter<br />

candles for high-pass filtration<br />

Their advantages are high<br />

intake of contaminations<br />

and easy handling. Optionally<br />

available are membrane filter<br />

candles, filter candles with<br />

activated carbon or made of<br />

stainless steel.<br />

<strong>Filter</strong> bags<br />

made of different materials<br />

such as PP, needled felt, cotton,<br />

etc.<br />

Their advantages are absolute<br />

filtration, washability and easy<br />

handling.<br />

Wound filter cartridge<br />

<strong>Filter</strong> bag element<br />

<strong>Filter</strong> plates<br />

for absolute filtration with<br />

(surface) filter plates made<br />

of paper or needled felt, for<br />

example.<br />

Their advantages are highest<br />

separation accuracy and<br />

low-priced consumables.<br />

Accessories<br />

Differential pressure<br />

switch to monitor pump<br />

and filter, with hose<br />

connectors or flanges<br />

according to DIN 2501<br />

standard.<br />

<strong>Filter</strong> plate element<br />

28

RPR-<strong>Co</strong>ntrol 100<br />

The active-power meter integrated<br />

to the RPR-<strong>Co</strong>ntrol 100 system has<br />

four user-programmable switching<br />

thresholds that are assigned to the<br />

operating conditions of<br />

– dry running;<br />

– overheating;<br />

– overload;<br />

– flow rate falling below<br />

the minimum value.<br />

All advantages at a glance:<br />

<br />

<br />

<br />

<br />

<br />

<br />

Safe and efficient<br />

monitoring of pumps of<br />

up to 20kW.<br />

<strong>Co</strong>st-saving avoidance<br />

of expensive damages<br />

to the pump.<br />

Increased availability of<br />

your installation.<br />

No pipeline fixtures required.<br />

Unproblematic retrofitting<br />

to existing installations.<br />

Integrated operating-hours<br />

meter to indicate due<br />

maintenance inspection of<br />

the installation.<br />

Electronic monitoring of motor currents<br />

reliably protects pumps from dry running,<br />

overheating and overload. If the above mentioned<br />

malfunctions cannot be completely<br />

ruled out with your installation, you should<br />

use an electronic protector to switch off the<br />

pump before it is damaged. Such protectors<br />

will not only prevent damage to the pump,<br />

but also avoid breakdowns of the installation<br />

and costs resulting thereof. Once the<br />

cause of the malfunction is eliminated, the<br />

pump is immediately ready to continue operation.<br />

RPR-<strong>Co</strong>ntrol 100 1<br />

to be built into electrical<br />

cabinets and plug in the<br />

separate programming unit.<br />

RPR-<strong>Co</strong>ntrol 100 2<br />

to be built into control<br />

cabinets and with integrated<br />

programming unit.<br />

The protector can also be used to monitor<br />

a set minimum volume flow rate in order to<br />

automatically detect and signal a clogged<br />

filter or scheduled replacement of filters.<br />

RPR-<strong>Co</strong>ntrol 100 3<br />

Portable monitoring device<br />

with indicating lamps and<br />

push-buttons but without<br />

programming unit.<br />

Separate programming unit<br />

Hand-held programmer with<br />

cable and plug to programme<br />

switching thresholds to<br />

RPR-<strong>Co</strong>ntrol 100 1 and<br />

RPR-<strong>Co</strong>ntrol 100 3.<br />

29

Sales areas in Germany<br />

Thanks to our wide distribution network all over<br />

Germany, you will always find one of our experts<br />

at close range.<br />

4<br />

BREMEN<br />

MÜNSTER<br />

KIEL<br />

ROSTOCK<br />

HAMBURG<br />

HANNOVER<br />

3<br />

2<br />

MAGDEBURG<br />

1<br />

BERLIN<br />

1 Berlin/Brandenburg<br />

Sondermann <strong>Pumpen</strong> + <strong>Filter</strong><br />

<strong>GmbH</strong> & <strong>Co</strong>. <strong>KG</strong><br />

August-Horch-Straße 2, 51149 Köln<br />

Tel.: 0 22 03/93 94-0<br />

Fax: 0 22 03/93 94-48<br />

info@sondermann-pumpen.de<br />

2 Hamburg/SH/MV<br />

Dieter Roy<br />

Dorfstraße 23, 21514 Kleinpampau<br />

Tel.: 0 41 55/82 38 10 0<br />

Fax: 0 41 55/82 38 10 1<br />

mobil: 0172/628 77 82<br />

d.roy@flux-pumpen.de<br />

3 Hannover/Kassel<br />

Dipl.-Ing. (FH) Ulrich Pöhls<br />

Alte Bemeroder Straße 122,<br />

30539 Hannover<br />

Tel.: 05 11/51 71 51<br />

Fax: 05 11/54 45 92 9<br />

mobil: 0172/628 77 83<br />

u.poehls@flux-pumpen.de<br />

4 Bremen/Münster<br />

Dipl.-Ing. (FH) Mathias Reimer<br />

Zwickenbach 18, 49324 Melle<br />

Tel.: 0 54 22/92 27 48 0<br />

Fax: 0 54 22/92 27 48 6<br />

mobil: 0170/180 25 46<br />

m.reimer@flux-pumpen.de<br />

5.1 Nordrhein-Westfalen Süd<br />

Waldemar Wostmann<br />

Mattlener Weg 12, 50769 Köln<br />

Tel.: 02 21/70 88 19 2<br />

Fax: 02 21/70 04 09 6<br />

mobil: 0177/708 81 92<br />

pumpeninfo@wostmann.de<br />

5.2 Nordrhein-Westfalen Nord<br />

Stephan Hill<br />

Wilensteinweg 10, 50739 Köln<br />

Tel.: 02 21/29 01 14 22<br />

Fax: 0 22 03/93 94-48<br />

mobil: 0173/716 28 44<br />

s.hill@sondermann-pumpen.de<br />

6 Hessen<br />

Robert Höfling<br />

Odenwaldring 25,<br />

63500 Seligenstadt<br />

Tel.: 0 61 82/15 83<br />

Fax: 0 61 82/96 19 27<br />

mobil: 0177/583 49 69<br />

r.hoefling@flux-pumpen.de<br />

KÖLN<br />

7.1 Baden-Württemberg Nord<br />

Martin Reichert<br />

Talweg 12, 75433 Maulbronn<br />

Tel.: 0 70 43/10 1-420<br />

Fax: 0 70 43/10 1-444<br />

mobil: 0174/166 57 62<br />

m.reichert@flux-pumpen.de<br />

7.2 Baden-Württemberg Süd<br />

Dipl.-Ing. (FH) Dieter Röder<br />

Hans-Thoma-Str. 16,<br />

75015 Bretten<br />

Tel.: 0 72 52/50 49 79 2<br />

Fax: 0 72 52/50 49 79 3<br />

mobil: 0172/101 42 17<br />

d.roeder@flux-pumpen.de<br />

5.1<br />

8 Bayern Süd<br />

Markus Werner<br />

Hauptstraße 5a, 82544 Egling<br />

Tel.: 0 81 76/15 45<br />

Fax: 0 81 76/99 70 23<br />

mobil: 0172/831 15 96<br />

m.werner@flux-pumpen.de<br />

9 Bayern Nord<br />

Dipl.-Ing. (FH) W. Schauer<br />

Joseph-Otto-Kolb-Str. 31,<br />

91088 Bubenreuth<br />

Tel.: 0 91 31/82 97 75 0<br />

Fax: 0 91 31/97 46 38 2<br />

mobil: 0172/628 77 81<br />

w.schauer@flux-pumpen.de<br />

10<br />

5.2<br />

SAARBRÜCKEN<br />

6<br />

ERFURT<br />

FRANKFURT<br />

WÜRZBURG<br />

NÜRNBERG<br />

9<br />

MANNHEIM<br />

MAULBRONN<br />

STUTTGART<br />

7.2<br />

FREIBURG<br />

7.1<br />

15 16<br />

8<br />

MÜNCHEN<br />

10 Rheinland-Pfalz/Saarland<br />

Frank Schorn<br />

Fliederstraße 19,<br />

66773 Schwalbach<br />

Tel.: 0 68 34/56 72 50<br />

Fax: 0 68 34/56 72 62<br />

mobil: 0172/625 92 23<br />

f.schorn@flux-pumpen.de<br />

DRESDEN<br />

15 Thüringen/Sachsen-Anhalt<br />

Dipl. Ing. (FH) Hendrik Müller<br />

Angerstraße 4, 06193 Petersberg<br />

Tel.: 0 34 60 6/29 03 21<br />

Fax: 0 34 60 6/29 03 22<br />

mobil: 0172/132 46 74<br />

h.mueller@flux-pumpen.de<br />

16 Sachsen<br />

Dipl.-Ing. Gerd Hanauska<br />

Südstraße 37,<br />

09212 Limbach-Oberfrohna<br />

Tel.: 0 37 22/50 25 75<br />

Fax: 0 37 22/50 56 03<br />

mobil: 0172/628 77 84<br />

g.hanauska@flux-pumpen.de<br />

30

Sales representations abroad<br />

SONDE<strong>RM</strong>ANN pumps and filters<br />

are present all over the world. Are<br />

you looking for an opportunity to<br />

buy our products in your country?<br />

Just give us a call at our <strong>Co</strong>logne<br />

headquarters or send us an email.<br />

We will be pleased to help you.<br />

SONDE<strong>RM</strong>ANN<br />

<strong>Pumpen</strong> + <strong>Filter</strong> <strong>GmbH</strong> & <strong>Co</strong>. <strong>KG</strong><br />

August-Horch-Straße 2<br />

D-51149 <strong>Co</strong>logne<br />

Phone: +49 22 03/93 94-0<br />

Fax: +49 22 03/93 94-48<br />

info@sondermann-pumpen.de<br />

www.sondermann-pumpen.de<br />

For more than 50 years, SONDER-<br />

MANN’s specialist consultants have<br />

also advised you on the comprehensive<br />

range of FLUX pumps. FLUX’s<br />

pumps have always been known for<br />

their excellent quality. Now, they<br />

offer a wide range of products from<br />

barrel and container pumps to submersible<br />

centrifugal and eccentric<br />

screw pumps to pneumatic diaphragm<br />

pumps, mixers, liquid-flow<br />

meters and lots of accessories.<br />

You will find more information at<br />

www.flux-pumpen.de.<br />

31

SPU 12/2012 - PDF_GB<br />

SONDE<strong>RM</strong>ANN<br />

<strong>Pumpen</strong> + <strong>Filter</strong> <strong>GmbH</strong> & <strong>Co</strong>. <strong>KG</strong><br />

August-Horch-Straße 2<br />

D-51149 <strong>Co</strong>logne<br />

PO Box 920101<br />

D-51151 Köln<br />

Phone: +49 22 03/93 94-0<br />

Fax: +49 22 03/93 94-48<br />

info@sondermann-pumpen.de<br />

www.sondermann-pumpen.de<br />

Subject to technical modifications.