Bidder Name : Tender Inviting Authority: CHIEF GENERAL ... - IDCO

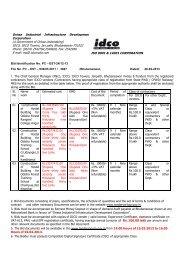

Bidder Name : Tender Inviting Authority: CHIEF GENERAL ... - IDCO

Bidder Name : Tender Inviting Authority: CHIEF GENERAL ... - IDCO

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

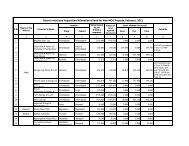

<strong>Tender</strong> <strong>Inviting</strong> <strong>Authority</strong>: <strong>CHIEF</strong> <strong>GENERAL</strong> MANAGER,CIVIL,<strong>IDCO</strong>,<strong>IDCO</strong> TOWER,BHUBANESWAR<br />

<strong>Name</strong> of Work: CONSTRUCTION OF DISTRICT INDISTRIES CENTRE BUILDING (DIC) BARGARH (Ground Floor)<br />

Contract No: CIVIL-EST-12-2011/12<br />

<strong>Bidder</strong><br />

<strong>Name</strong> :<br />

Sl.<br />

No.<br />

Description of work<br />

SCHEDULE OF WORKS<br />

No.or Unit Rate (in<br />

Qty.<br />

Figures)<br />

Rate (in Words)<br />

AMOUNT<br />

1.0 Earth work in excavation of foundation trenches in all<br />

kinds of soil including moorum stoney earth and earth<br />

mixed with boulders except sheet rock and boulders not<br />

requiring blasting including dressing of sides and leveling<br />

the bed upto the required depth and depositing the<br />

excavated materials away from the work site with all lead<br />

and lift including shoring, shuttering & dewatering (if<br />

required) with cost of all Labour, Hire & Running charges of<br />

the water pumps, Sundries, T & P required for the work<br />

complete as directed by the Engineer- in- charge.<br />

2.0 Filling in foundation trenches and plinth with excavated<br />

earth well watered and rammed in layers not exceeding 23<br />

c.m in depth including all Lead and Lift, cost of all Labour,<br />

Sundries, T&P required for the work etc. complete in all<br />

respect as directed by the Engineer- in- charge.<br />

3.0 Supplying & Filling in foundation trenches , plinth and<br />

ditches with river sand well watered and rammed in<br />

layers not exceeding 23 c.m in depth with all Lead and<br />

Lift, including cost, conveyance, loading, unloading,<br />

stacking,royalties and taxes of all materials, cost of all<br />

labour, sundries, T&P required for the work etc. complete in<br />

all respect as directed by the Engineer- in -charge.<br />

(Measurement will be taken on finished compacted section<br />

only)<br />

4.0 Supplying, Diluting & Spreading Chemical Emulsion<br />

like CHLORPYRIPHOS OR Other Chemical<br />

approved by the Central Insecticides Board as<br />

directed by the manufacturer and spraying the mixture<br />

uniformly by the sprayer as preconstructional antitermite<br />

treatment and creating a chemical barrier under and<br />

around the column pits, wall trenches, basement<br />

excavation, top surface of plinth filling, junction of walls<br />

and floors along with external perimeter of the building,<br />

expansion joints, surrounding the pipes and conduits etc.<br />

complete at the rate of 7.5 litres (or as directed by the<br />

manufacturer) per sqm on vertical and 5.0 litres per sqm on<br />

horizontal surfaces, 50% of the emulsion to be filled in<br />

center to center etc. complete as per the holes made in<br />

trenches at 150m.m IS:6313/1981(Part-II) complete<br />

including cost, conveyance, loading, unloading and taxes of<br />

all materials, cost of all labour, T&P, sundries and<br />

scaffolding where required for the work etc. as directed by<br />

the Engineer -in -charge.( The payment shall be made on<br />

190.11 Cum<br />

190.11 Cum<br />

375.13 Cum<br />

222.21 Sqm<br />

No. of Corrections<br />

No. of Interpolation<br />

No. of Over writing<br />

Signature of <strong>Bidder</strong> Page 1

Sl.<br />

No.<br />

Description of work<br />

No.or<br />

Qty.<br />

Unit<br />

Rate (in<br />

Figures)<br />

Rate (in Words)<br />

AMOUNT<br />

4.0 Note- The contractor shall have to furnish ten years<br />

Guarantee to maintain the Anti-termite treated area/<br />

structure free from termite.In addition to the 10 years<br />

Guarantee furnished as above, the contractor shall have to<br />

furnish ten years (after a certificate of final completion)<br />

Bank Guarantee Bond issued by any Nationalised Bank<br />

executed in favour of O.I.I.D.C (<strong>IDCO</strong>)/ Client as directed<br />

in the prescribed format available in the tender document<br />

for an amount of 10% (ten percent) of cost of this item of<br />

work, to attend the defects if any.<br />

5.0 Providing Plinth Protection of 600 m.m Width all<br />

around the plinth area of the proposed building<br />

with an<br />

under layer of 75m.m thick Plain Cement Concrete of<br />

proportion (1:4:8) using 40mm size hard crusher broken<br />

black granite<br />

stone metal compacted over a consolidated<br />

rigid ground and top of 50 m.m thick Cement Concrete of<br />

proportion<br />

(1:2:4) with 12mm size hard crusher broken<br />

black granite stone chips laid to proper slope and gradient<br />

and top to be finished smooth with 12mm thick cement<br />

plaster in C.M(1:4) and protected the edges with 1st class<br />

K.B.brick massonary walls ( using the K.B Bricks of<br />

crushing strength not less than 75Kg/Sqcm) (half brick<br />

masonry 125mm deep) in Cement Mortar (1:6) including<br />

excavation of required earth , cost , conveyance, loading,<br />

unloading, stacking,royalities & taxes of all Materials,<br />

cost<br />

all Labour,Sundries, T&P, watering, curing etc complete in<br />

all respect as directed by the Engineer-in-charge. (Pament<br />

will be made on the finished item of composite works<br />

only,no separate pament will be made for any indivisual<br />

part portion of item of work).<br />

6.0 Providing and laying Plain Cement Concrete of<br />

proportion (1:4:8) in foundation and floors (i.e. below<br />

the base course of the flooring) using 40 mm size crusher<br />

broken H.G Stone Metal free from weathered skins ,cement<br />

and screened & washed sharp river sand for mortar of<br />

approved quality & from approved quarry including hoisting,<br />

lowering and laying concrete to the required level, ramming,<br />

watering & curing etc complete to required levels, laid in<br />

layers not exceeeding 15cm thick in each layer including<br />

cost, conveyance , loading,unloading,royalties and taxes of<br />

all materials, cost of all labour, Sundries, T&P required for<br />

the work including shoring, shuttering and dewatering ( if<br />

required) including hire and running charges of water pump<br />

required for the work etc complete in all respect as directed<br />

by the Engineer-in-charge.<br />

48.52 Sqm<br />

30.91 Cum<br />

No. of Corrections<br />

No. of Interpolation<br />

No. of Over writing<br />

Signature of <strong>Bidder</strong> Page 2

Sl.<br />

No.<br />

Description of work<br />

No.or<br />

Qty.<br />

Unit<br />

Rate (in<br />

Figures)<br />

Rate (in Words)<br />

AMOUNT<br />

7.0 First Class Kiln Burnt Brick Masonry in cement mortar of 45.15 Cum<br />

mix (1:6) using K.B. bricks of size 25 c.m x 12 c.m x 8 c.m<br />

having crushing strength not less than 75 kg per square<br />

c.m. with cement and screened & washed sharp sand for<br />

mortar after immersing the K.B bricks for 6 (Six) hours in<br />

water before use in works in Foundation & Plinth and<br />

similar such type of works with all necessary projections,<br />

splays cutting, circular moulding, corbelling, chamfering,<br />

watering and curing etc. including cost, coveyance,stacking,<br />

loading, unloading, royalties and taxes of all materials,cost<br />

of all labour,scaffolding, sundries and T&P required for the<br />

works etc. complete in all respect as directed by the<br />

Engineer-in-charge.<br />

8.0 First Class Kiln Burnt Brick Masonry in cement mortar of 77.35 Cum<br />

mix (1:6) using K.B. bricks of size 25 c.m. x 12 c.m. x 8<br />

c.m. having crushing strength not less than 75 kg per<br />

square c.m. with cement and screened & washed sharp<br />

sand for mortar after immersing the bricks for 6 (Six) hours<br />

in water before use in works in superstructure and<br />

similar such type of works with all necessary projections,<br />

splays cutting, circular moulding, corbelling, chamfering,<br />

watering and curing etc. including cost, coveyance, loading,<br />

unloading,stacking, royalties and taxes of all materials, cost<br />

of all labour,scaffolding, sundries and T&P required for the<br />

works etc. complete in all respect as directed by the<br />

Engineer-in-charge.<br />

9.0 First Class Kiln Burnt Brick Masonry for 125 m.m width 7.08 Cum<br />

brick masonry wall in cement mortar of mix (1:4) using<br />

K.B. bricks of size 25 c.m x 12 c.m x 8 c.m having crushing<br />

strength not less than 75 kg per square c.m with provision<br />

of 2 ( Two nos ) of 6 m.m dia M.S. Round Reinforcement<br />

Bars at each 4th layers) with cement and screened &<br />

washed sharp river sand for mortar after immersing the<br />

bricks for 6 (Six) hours in water before use in works in<br />

superstructure and similar such type of works with all<br />

necessary projections, splays cutting, circular moulding,<br />

corbelling, chamfering, watering and curing etc. including<br />

cost, coveyance, loading, unloading, stacking, royalties and<br />

taxes of all materials ,cost of all labour, sundries, T&P<br />

required for the works etc. complete in all respect as<br />

directed by the Engineer-in-charge.<br />

10.0 Providing ,Lifting, Hoisting & Laying Reinforced Cement<br />

Concrete of M-200 grade in Column Base, Column<br />

Footings, Stem of the Columns up to plinth level<br />

and Raft Foundation as per approved designs and<br />

drawings having a minimum compressive strength ( in work<br />

test) 200Kg. / Square cm. in 15 cm. cubes at 28 days<br />

after mixing and test conducted in accordance with I.S. 456<br />

and I.S. 516 using screened & washed sharp river sand for<br />

mortar and 10 mm. to 20 mm. size black hard crusher<br />

broken granite stone chips( of required quantities) from<br />

weathered skins of approved quality & from approved<br />

quarry, washed and cleaned to be mixed in concrete<br />

mixture with approved quality of cement including<br />

hoisting, lowering, laying and compacting concrete by using<br />

vibrators, watering and curing for 28 days, centering and<br />

shuttering then after dismantling and removing the<br />

debrises away from the work site and finishing the exposed<br />

surface smooth providing grooves or beads wherever<br />

necessary including cost, conveyance, loading,<br />

No. of Corrections<br />

No. of Interpolation<br />

No. of Over writing<br />

Signature of <strong>Bidder</strong> Page 3

Sl.<br />

No.<br />

Description of work<br />

No.or<br />

Qty.<br />

Unit<br />

Rate (in<br />

Figures)<br />

Rate (in Words)<br />

AMOUNT<br />

10.1 a) Footing & Pedestal 35.72 Cum<br />

10.2 b) Column upto Plinth 6.66 Cum<br />

11.0 Providing ,Lifting, Hoisting & Laying Reinforced Cement 11.44 Cum<br />

Concrete of M-200 grade in PLINTH BAND of<br />

approved designs and drawings having a minimum<br />

compressive strength ( in work test) 200 Kg. / Square<br />

cm. in 15 cm. cubes at 28 days after mixing and test<br />

conducted in accordance with I.S. 456 and I.S. 516 using<br />

screened & washed sharp river sand for mortar and 10 mm.<br />

to 20 mm. size black hard crusher broken granite stone<br />

chips of approved quality from approved quarry, washed<br />

and cleaned to be mixed in concrete mixture with<br />

approved quality of cement including hoisting, lowering,<br />

laying and compacting concrete by using vibrators, watering<br />

and curing for 28 days, centering and shuttering then after<br />

dismantling and removing the debrises away from the work<br />

site and finishing the exposed surface smooth providing<br />

grooves or beads wherever necessary including cost,<br />

conveyance, loading, unloading, royalties and taxes of all<br />

materials , cost of all labours, scaffolding, sundries, T&P<br />

11.0 required for the work etc. complete in all respect but excluding cost<br />

and conveyance of M.S. rods or Tor steel and binding wires<br />

and labour charges for straightening, cutting, bending etc.<br />

of M.S. rods or Tor steel and binding wires and tying the<br />

grills and placing in proper position as directed by Engineerin-charge.<br />

12.0 Providing ,Lifting, Hoisting & Laying Reinforced Cement 9.57 Cum<br />

Concrete of M-200 grade in all kinds Column in<br />

Superstructure as per approved designs and drawings<br />

having a minimum compressive strength ( in work test)<br />

200Kg. / Square cm. in 15 cm. cubes at 28 days after<br />

mixing and test conducted in accordance with I.S. 456 and<br />

I.S. 516 using screened & washed sharp river sand for<br />

mortar and 10 mm. to 20 mm. size black hard crusher<br />

broken granite stone chips( of required quantities) from<br />

weathered skins of approved quality & from approved<br />

quarry, washed and cleaned to be mixed in concrete<br />

mixture with approved quality of cement including<br />

hoisting, lowering, laying and compacting concrete by using<br />

vibrators, watering and curing for 28 days, centering and<br />

shuttering then after dismantling and removing the<br />

debrises away from the work site and finishing the exposed<br />

surface smooth providing grooves or beads wherever<br />

necessary including cost, conveyance, loading,<br />

unloading,stacking, royalties and taxes of all materials , cost<br />

12.0 T&P required for the work etc. complete in all respect but<br />

the excluding cost & conveyance of M.S. rods or Tor Steel<br />

and Binding wires and labour charges for straightening,<br />

cutting, bending etc. of M.S. rods or Tor steel and binding<br />

wires and tying the grills and placing in proper position as<br />

directed by the Engineer-in-charge.<br />

No. of Corrections<br />

No. of Interpolation<br />

No. of Over writing<br />

Signature of <strong>Bidder</strong> Page 4

Sl.<br />

No.<br />

Description of work<br />

No.or<br />

Qty.<br />

Unit<br />

Rate (in<br />

Figures)<br />

Rate (in Words)<br />

AMOUNT<br />

13.0 Providing ,Lifting, Hoisting & Laying Reinforced Cement<br />

Concrete of M-200 grade in all kinds BEAM as per<br />

approved designs and drawings having a minimum<br />

compressive strength ( in work test) 200Kg. / Square<br />

cm. in 15 cm. cubes at 28 days after mixing and test<br />

conducted in accordance with I.S. 456 and I.S. 516 using<br />

screened & washed sharp river sand for mortar and 10 mm.<br />

to 20 mm. size black hard crusher broken granite stone<br />

chips( of required quantities) from weathered skins of<br />

approved quality & from approved quarry, washed and<br />

cleaned to be mixed in concrete mixture with approved<br />

quality of cement including hoisting, lowering, laying and<br />

compacting concrete by using vibrators, watering and curing<br />

for 28 days, centering and shuttering then after dismantling<br />

and removing the debrises away from the work site and<br />

finishing the exposed surface smooth providing grooves or<br />

beads wherever necessary including cost, conveyance,<br />

loading, unloading,stacking, royalties and taxes of all<br />

materials , cost of all labours, scaffolding, sundries,<br />

13.0 T&P required for the work etc. complete in all respect but<br />

the excluding cost & conveyance of M.S. rods or Tor Steel<br />

and Binding wires and labour charges for straightening,<br />

cutting, bending etc. of M.S. rods or Tor steel and binding<br />

wires and tying the grills and placing in proper position as<br />

directed by the Engineer-in-charge.<br />

14.0 Providing ,Lifting, Hoisting & Laying Reinforced Cement<br />

Concrete of M-200 grade in all kinds ROOFSLAB as<br />

per approved designs and drawings having a minimum<br />

compressive strength ( in work test) 200Kg. / Square<br />

cm. in 15 cm. cubes at 28 days after mixing and test<br />

conducted in accordance with I.S. 456 and I.S. 516 using<br />

screened & washed sharp river sand for mortar and 10 mm.<br />

to 20 mm. size black hard crusher broken granite stone<br />

chips( of required quantities) from weathered skins of<br />

approved quality & from approved quarry, washed and<br />

cleaned to be mixed in concrete mixture with approved<br />

quality of cement including hoisting, lowering, laying and<br />

compacting concrete by using vibrators, watering and curing<br />

for 28 days, centering and shuttering then after dismantling<br />

and removing the debrises away from the work site and<br />

finishing the exposed surface smooth providing grooves or<br />

beads wherever necessary including cost, conveyance,<br />

loading, unloading,stacking, royalties and taxes of all<br />

materials , cost of all labours, scaffolding, sundries,<br />

14.0 T&P required for the work etc. complete in all respect but<br />

the excluding cost & conveyance of M.S. rods or Tor Steel<br />

and Binding wires and labour charges for straightening,<br />

cutting, bending etc. of M.S. rods or Tor steel and binding<br />

wires and tying the grills and placing in proper position as<br />

directed by the Engineer-in-charge.<br />

10.39 Cum<br />

20.69 Cum<br />

No. of Corrections<br />

No. of Interpolation<br />

No. of Over writing<br />

Signature of <strong>Bidder</strong> Page 5

Sl.<br />

No.<br />

Description of work<br />

No.or<br />

Qty.<br />

Unit<br />

Rate (in<br />

Figures)<br />

Rate (in Words)<br />

AMOUNT<br />

15.0 Providing ,Lifting, Hoisting & Laying Reinforced Cement<br />

Concrete of M-200 grade in all kinds LINTELS as<br />

per approved designs and drawings having a minimum<br />

compressive strength ( in work test) 200Kg. / Square<br />

cm. in 15 cm. cubes at 28 days after mixing and test<br />

conducted in accordance with I.S. 456 and I.S. 516 using<br />

screened & washed sharp river sand for mortar and 10 mm.<br />

to 20 mm. size black hard crusher broken granite stone<br />

chips( of required quantities) from weathered skins of<br />

approved quality & from approved quarry, washed and<br />

cleaned to be mixed in concrete mixture with approved<br />

quality of cement including hoisting, lowering, laying and<br />

compacting concrete by using vibrators, watering and curing<br />

for 28 days, centering and shuttering then after dismantling<br />

and removing the debrises away from the work site and<br />

finishing the exposed surface smooth providing grooves or<br />

beads wherever necessary including cost, conveyance,<br />

loading, unloading,stacking, royalties and taxes of all<br />

materials , cost of all labours, scaffolding, sundries,<br />

15.0 T&P required for the work etc. complete in all respect but<br />

the excluding cost & conveyance of M.S. rods or Tor Steel<br />

and Binding wires and labour charges for straightening,<br />

cutting, bending etc. of M.S. rods or Tor steel and binding<br />

wires and tying the grills and placing in proper position as<br />

directed by the Engineer-in-charge.<br />

16.0 Providing, lifting, hoisting and laying Reinforced Cement<br />

Concrete of M-200 grade in all kinds of STAIRCASES<br />

WITH RAILINGS as per approved designs and drawings<br />

having a minimum compressive strength ( in work test) 200<br />

Kg. / Square cm. in 15 cm. cubes at 28 days after mixing<br />

and test conducted in accordance with I.S. 456 and I.S. 516<br />

using screened & washed sharp river sand for mortar and<br />

10 mm. to 20 mm. size black hard crusher broken granite<br />

stone chips of approved quality from approved quarry,<br />

washed and cleaned to be mixed in concrete mixture with<br />

approved quality of cement including hoisting, lowering,<br />

laying and compacting concrete by using vibrators, watering<br />

and curing for 28 days, centering and shuttering then after<br />

dismantling and removing the debrises away from the work<br />

site and finishing the exposed surface smooth providing<br />

grooves or beads wherever necessary including cost,<br />

conveyance, loading, unloading, royalties and taxes of all<br />

materials , cost of all labours, scaffolding, sundries, T&P<br />

required for the work etc complete in all respect but excluding<br />

16.0 cost and conveyance of M.S. rods or Tor steel and binding<br />

wires and labour charges for straightening, cutting, bending<br />

etc. of M.S. rods or Tor steel and binding wires and tying<br />

the grills and placing in proper position as directed by<br />

Engineer-in-charge.<br />

5.04 Cum<br />

3.00 Cum<br />

No. of Corrections<br />

No. of Interpolation<br />

No. of Over writing<br />

Signature of <strong>Bidder</strong> Page 6

Sl.<br />

No.<br />

Description of work<br />

No.or<br />

Qty.<br />

Unit<br />

Rate (in<br />

Figures)<br />

Rate (in Words)<br />

AMOUNT<br />

17.0 Providing ,Lifting, Hoisting & Laying Reinforced Cement 13.71 Sqm<br />

Concrete of M-200 grade in all kinds CHAJJA AND<br />

SILL PROJECTION (of 6.5cm. Average thick) as per<br />

approved designs and drawings having a minimum<br />

compressive strength ( in work test) 200Kg. / Square<br />

cm. in 15 cm. cubes at 28 days after mixing and test<br />

conducted in accordance with I.S. 456 and I.S. 516 using<br />

screened & washed sharp river sand for mortar and 10 mm.<br />

to 20 mm. size black hard crusher broken granite stone<br />

chips( of required quantities) from weathered skins of<br />

approved quality & from approved quarry, washed and<br />

cleaned to be mixed in concrete mixture with approved<br />

quality of cement including hoisting, lowering, laying and<br />

compacting concrete by using vibrators, watering and curing<br />

for 28 days, centering and shuttering then after dismantling<br />

and removing the debrises away from the work site and<br />

finishing the exposed surface smooth providing grooves or<br />

beads wherever necessary including cost, conveyance,<br />

loading, unloading,stacking, royalties and taxes of all<br />

17.0 T&P required for the work etc. complete in all respect but<br />

the excluding cost & conveyance of M.S. rods or Tor Steel<br />

and Binding wires and labour charges for straightening,<br />

cutting, bending etc. of M.S. rods or Tor steel and binding<br />

wires and tying the grills and placing in proper position as<br />

directed by the Engineer-in-charge.<br />

18.0 Cutting, Straightening coiled or bent up HYSD / TMT 96.51 Qtl<br />

Reinforcement Bars welding or jointing if necessary,<br />

bending, binding, tying the grills as required for R.C.C.<br />

works, providing Fan Hooks where necessary and<br />

hoisting, lowering and placing the same in proper position<br />

according to the approved designs and drawings in all<br />

floors at all height including cost, coveyance, loading,<br />

unloading ,stacking & taxes of HYSD/ TMT Reinforcement<br />

Bars and Binding Wires of 18 to 20 Gauge as required for<br />

the work , cost of all Labour ,Sundries, T&P,Staging and<br />

Scaffolding complete in all respect as directed by Engineerin-charge.<br />

(Payment will be made according to the actual /<br />

proper weight of the HYSD / TMT Reinforcement Bars &<br />

Binding Wires consumed in the particular work only) .<br />

19.0 16 m.m thick cement plaster in cement mortar of 550.00 Sqm<br />

mix (1:6) in all floors at all height using screened &<br />

washed sharp river sand for mortar with approved quality of<br />

cement, finished smooth to the rough surface of the brick<br />

masonry walls after racking out the joints properly<br />

,providing grooves wherever necessary including cost,<br />

conveyance, loading, unloading,stacking, royalties and taxes<br />

of all Materials, cost of all Labour, T&P, Sundries ,<br />

Scaffolding, Watering, Curing,Rounding of corners etc.<br />

required for the work complete etc. as directed by the<br />

20.0<br />

Engineer- in -charge.<br />

12 m.m thick cement plaster in cement mortar of 330.00 Sqm<br />

mix (1:6) in all floors at all height using screened &<br />

washed sharp river sand for mortar with approved quality of<br />

cement, finished smooth to the even surface of the brick<br />

masonry walls after racking out the joints properly<br />

,providing grooves wherever necessary including cost,<br />

conveyance, loading, unloading,stacking, royalties and taxes<br />

of all Materials, cost of all Labour, T&P, Sundries ,<br />

Scaffolding, Watering, Curing,Rounding of corners etc.<br />

required for the work complete etc. as directed by the<br />

Engineer- in -charge.<br />

No. of Corrections<br />

No. of Interpolation<br />

No. of Over writing<br />

Signature of <strong>Bidder</strong> Page 7

Sl.<br />

No.<br />

Description of work<br />

No.or<br />

Qty.<br />

Unit<br />

Rate (in<br />

Figures)<br />

Rate (in Words)<br />

AMOUNT<br />

21.0 6 m.m thick cement plaster in cement mortar of mix<br />

(1:4) in all floors at all height using screened & washed<br />

sharp river sand for mortar with approved quality of<br />

cement to the ceiling of the Roof Slab, Staircase, Beams,<br />

Columns,Landings, Railings,Chajja ,Fins ,Walls ,Jally and<br />

Shelves etc. including roughening, scraping, chiseling,<br />

cleaning, closed deep chipping with slurry treatment and<br />

finished smooth to all R.C.C. Surface including cost,<br />

conveyance, loading, unloading, royalties ,stacking and<br />

taxes of all Materials, cost of all Labour,Sundries, T&P,<br />

Scaffolding,Watering, Curing etc. complete in all respect as<br />

directed by the Engineer- in- charge<br />

22.0 Providing ,Fitting and Fixing minimum 8 m.m to 10m.m<br />

thick Vitrified Tile in flooring using Vitrified Tile of<br />

approved quality, colour and size(600 m.m x 600 m.m<br />

coloured printed series homogeneous) in floors, treads on<br />

steps and landings in all floors at all height on 25 m.m<br />

thick bed of cement mortar of mix (1:1) laid in proper<br />

slope and gradient with screened & washed sharp river<br />

sand for mortar and grouted with neat white cement slurry<br />

joining the Vitrified Tile with neat white cement slurry<br />

mixed with required quantities of pigments of approved<br />

marks to match the shades of the Vitrified Tile if<br />

required (Tiles are to be immersed in the water for required<br />

time before use) including cost, conveyance, loading,<br />

unloading, stacking, royalties and taxes of all Materials, cost<br />

of all Labour, Sundries, T&P required for the work<br />

,Watering,Curing for required days including cleaning the<br />

flooring space manually etc. complete in all respect as<br />

directed by the Engineer-in-charge.<br />

23.0 Providing , Fitting & Fixing Anti-Skid Ceramic Floor<br />

Tiles in flooring using special plain / printed series Anti-<br />

Skid Ceramic Floor Tile of premium grade ( having<br />

minimum thickness 7 mm to 8 mm & size 300 m.m x 300<br />

m.m OR 400 m.m x400 m.m) confirming to I.S 13755 of<br />

approved quality and shade in floors, treads on steps and<br />

landings in all floors at all height on 25 m.m thick bed of<br />

cement mortar of mix (1:1) laid in proper slope and<br />

gradient with screened & washed sharp river sand for<br />

mortar and grouted with neat white cement slurry, joining<br />

the Anti-Skid Ceramic FloorTiles with neat white<br />

cement slurry,mixed with required (Tiles are to be<br />

immersed in the water for required time before use)<br />

quantities of pigments of approved marks to match the<br />

shades of the Anti-Skid Ceramic FloorTiles if required<br />

including cost, conveyance, loading, unloading, stacking,<br />

royalties and taxes of all Materials, cost of all Labour,<br />

Sundries, T&P required for the work , Watering , Curing for<br />

required days , cleaning the flooring space manually etc.<br />

209.87 Sqm<br />

196.91 Sqm<br />

14.00 Sqm<br />

No. of Corrections<br />

No. of Interpolation<br />

No. of Over writing<br />

Signature of <strong>Bidder</strong> Page 8

Sl.<br />

No.<br />

Description of work<br />

No.or<br />

Qty.<br />

Unit<br />

Rate (in<br />

Figures)<br />

Rate (in Words)<br />

AMOUNT<br />

24.0 Providing, Fitting & Fixing of 8 mm. to 10mm. thick<br />

Vitrified Tile ( of size 600 m.m x 600 m.m ) of NITCO or<br />

equivalent make confirming to IS specifications having<br />

minimum breaking strength 1400 kg/sq.cm in dados<br />

skirting and riser of steps in all floors at all heights on<br />

12m.m thick cement mortar (1:3) to proper slope, line and<br />

level including cutting to required size and shape, fixing at<br />

corners and splays etc. including filling the joints with<br />

silicon sealant to match the shade of Vitrified Tile as per<br />

the design & drawing including cost, conveyance, loading,<br />

unloading, stacking,royalties and taxes of all materials, cost<br />

of all labour, T & P, sundries, watering & curing etc.<br />

required for the work complete in all respect as directed by<br />

25.0<br />

the<br />

Supplying,<br />

Engineer-in-Charge.<br />

Fitting & Fixing Ceramic Glazed Wall Tiles<br />

in Dados Skirting and Riser of Steps using approved<br />

shade,quality and size of Ceramic Glazed Wall Tiles<br />

(having thickness of 6.5 m.m to 6.7 m.m & 300 m.m<br />

X.200.m.m or 200 m.m X.200.m.m size) confirming to<br />

IS.13753 in proper position in all floors at all heights on<br />

12 mm. thick cement plaster (1:3) using screened and<br />

washed sharp river sand for mortar with cement, grounted<br />

with neat cement slurry and jointed with neat cement mixed<br />

with required approved shade of pigment to match the<br />

shade of the Ceramic Glazed Wall Tiles (Tiles are to<br />

be immersed in the water for required time before use)<br />

including cost, conveyance, loading, unloading,stacking,<br />

royalties and taxes of all Materials, cost of all Labour,<br />

Curing, Sundries and T&P, etc. required for the work<br />

complete as directed by the Engineer-in-charge.<br />

26.0 Supplying, Fitting and Fixing well dressed and well<br />

seasoned Sal Wood Choukaths ( of different length<br />

and size i.e 75m.m x 100 m.m OR 62.5x125mm) in<br />

proper position & plumb including two coats of coaltaring<br />

to the wall and lintel faces of choukaths including cost of<br />

coaltar and all labour & T&P charges of coaltaring<br />

alongwith fixing required nos. of W.I. clamps to the<br />

choukaths with approved qualities of screws in all floors at<br />

all height including cost, coveyance, loading ,<br />

unloading,stacking and taxes of all Materials, cost of all<br />

Labour,Sundries, T&P required for the work etc. complete in<br />

all respect as directed by the Engineer- in- charge.<br />

27.0 Supplying, fitting and fixing of 32mm thick factory made<br />

one side laminated flush door shutters with as per IS-<br />

2202/92 with solid core block board from seasoned and<br />

treated 2nd class hard wood , Battern, bonded with phenol<br />

formal dehide synthetic resign pressed over suitable<br />

adhesive including providing stainless steel hinges, locking<br />

arrengement and other fittings & fixtures if required etc.<br />

complete as per direction of Engg.- in- charge.<br />

61.33 Sqm<br />

20.48 Sqm<br />

0.46 Cum<br />

18.90 Sqm<br />

No. of Corrections<br />

No. of Interpolation<br />

No. of Over writing<br />

Signature of <strong>Bidder</strong> Page 9

Sl.<br />

No.<br />

Description of work<br />

No.or<br />

Qty.<br />

Unit<br />

Rate (in<br />

Figures)<br />

Rate (in Words)<br />

AMOUNT<br />

28.0 Providing and fixing 30mm. thick Factory Made Solid Panel<br />

PVC. Door Shutter consisting of frame made out of<br />

M.S.tubes of 19 mm. gauge thickness and size of 19mmx<br />

19mm for stiles & 15mmx15mm for top and bottom rails.<br />

M.S. frame shall have a coat of steel primers of approved<br />

make and manufacturer. M.S. frame shall be covered with 5<br />

mm thick heat moulded " PVC. 'C' channel of size<br />

30x50mm. forming stiles, and 5mm. thick , 75mm wide,<br />

PVC sheet for top rail , lock rail & bottom rail on either<br />

side, and 10mm ( 5mmx2mm) thick,20mm wide cross PVC<br />

sheet as gap insert for top rail and bottom rail. panelling of<br />

5mm. thick PVC. sheet beading on either side, and joined<br />

together with solvent cement adhesive etc. An additional<br />

m5mm. thick PVC. strip of 20mm. width is to be stuck on<br />

the interior side of the 'C'channel using PVC. solvent<br />

adhesive.PVCdoor frame of size 50x47mm. with a wall<br />

thickness of 5mm,made out of extruded 5 mm rigid pvc<br />

foam sheet mitred at corners and joined with 2 nos of<br />

150mm. lond beackets of 15x15 mm. M.S. square tube of<br />

28.0 gasket weather seal to be provided through out the frame.<br />

The door frame is to be fixed ro the wall using M.S. scerws<br />

of 65/100 mm. size complete as per manufacturers<br />

specification and direction of Engg. in charge.<br />

29.0 Providing, fitting, fixing of fully glazed Aluminum openable<br />

ventilator / top hung ventilator using 15 micron anodized<br />

OEL Aluminum section 2082 as out section,9139 as mullion<br />

section, 4124 as a shutter section frame with tapered clip of<br />

section 4125, aluminum angle, rubber beading, friction stay<br />

and handle etc. with 5mmthick glass including all cost of<br />

labour, T&P, hire charges of drilling machine, labour<br />

charges etc complete.<br />

7.56 Sqm<br />

5.64 Sqm<br />

30.0 Providing, fitting, fixing Aluminum window (sliding type) 32.40 Sqm<br />

made up aluminium Section 151-154, 151-155 as window<br />

frame section No.151-155, 151-153 and 151-167 as shutter<br />

frame with 5mm thick black glass as panel fitted with<br />

rubber beading alomhwith locking arrangements and all<br />

requisite fitting including cost, conveyance, loading,<br />

unloading and taxes of all materials, cost of all labour, T&P<br />

etc complete as per direction of Engineer-in-charge.<br />

31.0 Providing, fitting, fixing of Aluminum door with OEL 6.12 Sqm<br />

anodized Al. door section of 9202 as vertical member, 9201<br />

as top member and 9200 as bottom and middle member &<br />

6mm. plain glass in top & bottom portion fixed on the<br />

door frame by means of tapered clip No.4660 and the frame<br />

to be completed by means of jointin angle No 1855 (partly<br />

openable and partly fixed) including all cost conveyance,<br />

loading, unloading, taxes of all materials, cost of all labour,<br />

T&P, sundries, hire charges of drilling machine alongwith<br />

labour charges etc complete in all respect as directed by the<br />

Engg.- in-charge.<br />

32.0 Applying Distempering 2 (Two) coats to the Interior 759.87 Sqm<br />

plastered surface of the walls using approved quality<br />

& shade of Distemper over a coat water based Acrylic<br />

putty making smooth to the surface to receive Distemper<br />

in all floors at all heights including cost,conveyance, loading,<br />

unloading,stacking, taxes of all Materials,cost of all<br />

Labour,Scaffoldings, Staging, Sundries, T&P etc.required for<br />

the work complete as directed by the Engineer -in -charge.<br />

No. of Corrections<br />

No. of Interpolation<br />

No. of Over writing<br />

Signature of <strong>Bidder</strong> Page 10

Sl.<br />

No.<br />

Description of work<br />

No.or<br />

Qty.<br />

Unit<br />

Rate (in<br />

Figures)<br />

Rate (in Words)<br />

AMOUNT<br />

33.0 Applying 2 (Two ) coats of Weather Coat Painting<br />

to the external plastered surface of the wall using<br />

approved quality & shade of Weather Coat Paint (I.S.I)<br />

as specified by the concerned Manufacturer to give an even<br />

shade over a coat of cement wash in all floors & at all<br />

height including cost, coveyance, loading ,<br />

unloading,stacking and taxes of all Materials, cost of all<br />

Labour,Sundries, Staging,Scaffolding, T&P required for the<br />

work , Watering & Curing the Exterior Weather Coat<br />

Painting surface properly for required period etc.<br />

complete in all respect as directed by the Engineer- incharge.<br />

34.0 Supplying, Fitting and Fixing Stainless Steel of 304<br />

grade in Handrail using 50mm dia of 2mm thick circular<br />

pipe with stainless steel balustrade of size 32 m.m x 32 m.m<br />

x 2 m.m @ 0.90mtr.centre to centre and stainless steel<br />

square pipe bracing of size 32m.m x 32m.m x 2m.m in 3<br />

(Three) rows in stair case and at required places as per<br />

approved Drawings, Design and Specification with welding,<br />

buffing, polishing etc in all floors at all height including<br />

cost, conveyance,loading,unloading ,stacking & taxes of all<br />

Materials,cost of all Labour, T&P etc. required for the work<br />

complete in all respect as directed by the Engineer-in<br />

charge<br />

35.0 Providing and Painting two coats with synthetic enamel<br />

paint of approved brand (ASIAN PAINTS, BERGER, DUCO,<br />

ICI etc make or equivalent) and shade on new Steel work /<br />

Wood work to give an even shade over an under coat of<br />

primer of approved brand and manufacturer including cost<br />

of all materials with taxes and transportation, all labour,<br />

scaffolding, sundries, T&P etc. complete as per the direction<br />

of the Engineer-in-charge.<br />

36.0 Supplying, fitting and fixing M.S. window grill made out of<br />

M.S. square bar / M.S. flats / M.S. angles as per approved<br />

drawing and design, cutting to required size and welding<br />

properly, finished smooth and sand papering, including cost,<br />

conveyance, taxes of all materials, required screws, cost of<br />

all labour, T&P etc. as required for the work complete as<br />

per direction of the Engineer-in-charge in all floors.<br />

37.0 Providing and fixing 110mm dia schedule 80 PVC rain water<br />

pipes with spigot and socket and all necessary HDPE<br />

specials such as tees, bends, loops, socket, shoes, clamps<br />

etc. including jointing materials as per the manufacturer's<br />

specification, cutting holes in the walls and floors mending<br />

and making good the same, with fixing the vertical lines by<br />

HDPE clamps of approved design including providing<br />

seasoned hard wood wedge fixed to wall, cutting holes in<br />

walls, mending and making good the damage in cement<br />

mortar (1:4) including fixing the clamp to wooden wedges<br />

with brass screws using necessary scaffolding etc. complete<br />

for all heights including the cost of all materials, labour,<br />

taxes, royalties, transportation, loading and unloading,<br />

sundries T&P etc. complete as directed by the of E-I-C.<br />

38.0 ELECTRICAL PORTION<br />

330.00 Sqm<br />

8.00 Rmt<br />

70.00 Sqm<br />

650.00 Kg<br />

20.00 Sqm<br />

No. of Corrections<br />

No. of Interpolation<br />

No. of Over writing<br />

Signature of <strong>Bidder</strong> Page 11

Sl.<br />

No.<br />

Description of work<br />

No.or<br />

Qty.<br />

Unit<br />

Rate (in<br />

Figures)<br />

Rate (in Words)<br />

AMOUNT<br />

38.0 Internal wiring to light, exhaust fan, call bell ceiling fan &<br />

5A plug points with 1.5 Sqm PVC insulated 1100 Volt grade<br />

multi standared copper conductor wire for phase , neutral &<br />

earth continuty conductor and loop earth to fitting & fixture<br />

run inside 2mm thick PVC conduit pipe recessed in wall/<br />

column/ ceiling of the building including supply of materials<br />

such as flush type switches sheet metal switch board with<br />

bakelite cover, wire ceiling rose angle/batten holder,<br />

38.1<br />

junction box etc complete with making good the damages<br />

caused as required as as per direction of Engineer-incharge.<br />

Light point 44.00 Nos<br />

38.2 Ceiling fan point with supply & fixing of ceiling fan hook 14.00 Nos<br />

made of 10mm steel round bar (space shall be provided for<br />

installation of electronic type fan regulator<br />

38.3 Exhaust fan point 3.00 Nos<br />

38.4 Call bell point 4.00 Nos<br />

38.5 5A plug on same board 10.00 Nos<br />

38.6 5A plug on saparate board 4.00 Nos<br />

39.0 Supply installation and testing of 25A 3 pin industrial scrap 3.00 Nos<br />

pin earth type socket out let with 25A (100MA)RCCB<br />

complete as required and as per direction of Engineer-incharge.<br />

40.0 Wiring for circuit & submain with following number & size of<br />

PVC insulated 1100 Volt grade multistandard copper<br />

conductor wire run inside 2mm thick PVC conduit pipe<br />

recessed in ceiling/ column/walls of building including<br />

supply of all materials such as wires, conduit junction box<br />

etc complete with making good the damages caused as<br />

required and as per direction of Engineer-in-charge.<br />

40.1 2 nos single core 2.5 sqmm copper wire for phase & neutral 450.00 Mtr<br />

and 1 no single core 1.5 sqmm copper wire for earth<br />

continuity conductor<br />

40.2 2 nos single core 6.0 sqmm copper wire for phase & neutral 150.00 Mtr<br />

and 1 no single core 4.0 sqmm copper wire for earth<br />

continuity conductor (MDB to BDB & AC point)<br />

41.0 Suply, delivery, laying & testing of following size of PVC<br />

insulated PVC sheathed, round. Strip armoured aluminium<br />

conductor power cable of 1100 volt grade laid derectly in<br />

ground/ on surface of wall / column/ esxisting RCC/stone<br />

ware/ through existing G.I pipe/ hume pipe as case may be<br />

including excavation of earth in all kinds of soil & rock, sand<br />

cushing, protective covering refilling the trench with sand,<br />

brick covering but excluding the cost of G.I pipe/ hume pipe<br />

and cable end termination, damages caused as required<br />

and as per direction of Engineer-in-cgarge.<br />

41.1 3 1/2 C x 95mm2 AYFY L.T pole to MDB 50.00 Mtr<br />

41.2 31/2 C x50mm2 MDB to FDB 20.00 Mtr<br />

41.3 4Cx10mm2 FDB to BDB (P) 20.00 Mtr<br />

42.0 Supply of materials and making end termination with brass<br />

double compression cable glands and bimetalic crimping<br />

type cable lugs for following size of PVC insulated & PVC<br />

sheathed aluminium conductor armoured power cable of<br />

1100 Volts grade of the following sizes complete as required<br />

and as per direction of Engineer-in-charge.<br />

42.1 3 1/2 C x 95mm2 2.00 Nos<br />

42.2 31/2Cx50mm2 2.00 Nos<br />

42.3 4Cx10 mm2 2.00 Nos<br />

No. of Corrections<br />

No. of Interpolation<br />

No. of Over writing<br />

Signature of <strong>Bidder</strong> Page 12

Sl.<br />

No.<br />

Description of work<br />

No.or<br />

Qty.<br />

Unit<br />

Rate (in<br />

Figures)<br />

Rate (in Words)<br />

AMOUNT<br />

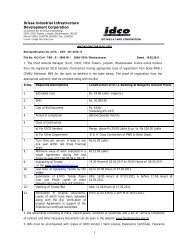

43.0 Distribution Board supply, delivery, installation, testing and<br />

commissioning of L.T indoor. Floor wall mounted type<br />

distribution boards made out of 2mm thick CR sheet metal<br />

cubicle fixed on MS chanel base, duly acid treated for<br />

derusting, primered and painted with 2 coats of enamel<br />

paint of approved shade, dust damp & vermin proof having<br />

hinged door and compartmental arrangement for each<br />

equipment & busbar chamber on the top of the panel<br />

running horizentally, having provision for cable/conduit<br />

entry earthing studs as per specification mentioned below<br />

duly factory wired confirmed to the relevant ISS as per<br />

approved G.A drawing and as per special condition of<br />

contract make good damages caused as required complete<br />

as per direction of EIC.<br />

43.1 Meter Board- supply, delivery, installation & testing of 1.00 Set<br />

tamper proof encloser containing, 1 no 3 phase 4 wire CT<br />

operated KWH meter (20-100A) with all connection and as<br />

per direction of engineer-in-charge.<br />

43.2 Main Distribution Board (MDB)<br />

43.2 Incoming100 A TPN MCCB ISO- 1.00 Nos<br />

43.2 Bus bar- 4nos 200A Electrelytic copper bus bar<br />

43.2 Out going<br />

43.2 2 Nos 63 A FP MCB<br />

43.2 4 nos 40A DPMCB<br />

43.2 4 nos 25A SPMCB<br />

43.2 Instruments<br />

43.2 3 nos phase indicating lamp with control fuses & 0.500 V<br />

voltameter with selector switch-1 no<br />

43.3 Floor distribution board (FDB)<br />

43.3 Incoming<br />

43.3 63A FPMCB-1 no<br />

43.3 Bus bar- 4 nos 100A electrelytic coper bus bar<br />

43.3 Out going<br />

43.3 4 nos 40 A DPMCB<br />

43.3 2 nos 40 A FPMCB<br />

43.3<br />

Instrument- 3 nos phase indicating lamp with control fuse<br />

1.00 Set<br />

43.4 Branch Distribution Board BDB - L<br />

43.4 Incoming- 32A DP MCB- 1no<br />

43.4 Out going 6 /10A SP MCB- 06 nos 6.00 Set<br />

43.5 Branch distribution Board-BDB-P<br />

43.5 Incoming<br />

43.5 40A FP MCB-1 no<br />

43.5 Out going<br />

43.5 25A SPMCB-6 nos 1.00 Set<br />

44.0 Earthing<br />

44.1 Supply of materials and installation of pipe earth electrode 2.00 Nos<br />

made out of 50mm dia class "B" G.I pipe of 3.0 mtr long<br />

with arrangements for fitting/ termination of G.I flat/ wire<br />

with G.I nut bolts and washers including cost of charcoal,<br />

salt, foreign soil, water pouring arrangements, brick<br />

masonry enclosue on top with removals RCC cover complete<br />

with labour for excavation of pit in all kinds of soil and rock<br />

44.2<br />

as required and as per direction of EIC.<br />

Supply oif materials and laying under ground/ floor/wall<br />

including making end termination and jointing, the cut<br />

portion by welding and testing for continuty and resistance<br />

of following size G.I flat for earthing of main distribution<br />

board complete as required as per direction of EIC.<br />

No. of Corrections<br />

No. of Interpolation<br />

No. of Over writing<br />

Signature of <strong>Bidder</strong> Page 13

Sl.<br />

No.<br />

Description of work<br />

No.or<br />

Qty.<br />

Unit<br />

Rate (in<br />

Figures)<br />

Rate (in Words)<br />

AMOUNT<br />

44.2 25x5mm G.I. flat 30.00 Mtr<br />

44.3 Supply of materials and laying under ground/ floor/wall 50.00 Mtr<br />

including making end termination and testing of 6 SWG G.I<br />

wire for loop earthing of equipments switch boards and<br />

panels as required complete as per direction of Egineer-incharge.<br />

45.0 Fitting & Fixtures<br />

45.0 Supply, delivery, installation and testing of following type<br />

fluorescent tube fixtures directly on wall/ceiling of building<br />

with all accessories such a copper ballast, glow starter,<br />

power factor improvement condenser, flourescent tube<br />

45.1<br />

light, stove enameled box perpex sheet cover etc complete<br />

assembly including supply and fixing on teak wood round<br />

block and making connection from the suitable point outlet<br />

as per direction of the EIC.<br />

1x4x40W box type fitting similar to philips Cat No TMC 21.00 Nos<br />

501/136 HPF with tube suspended/ directly fixed<br />

45.2 2x4x40W box type TL fitting similar to philips cat no- 6.00 Nos<br />

PMC/50/236 HPF with tubes suspended from ceiling by<br />

providing two nos 18SWG M.S conduit down rod 19mm OD<br />

with bulb & socket complete with all accessories and<br />

connection.<br />

45.3 4x18 WTL fitting similar to philips cat No-TBS 369/418 1.00 Nos<br />

MDGN HPF with tube directly fixed on ceiling<br />

46.0 Supply, delivery, installation and testing of following type of<br />

incandescent bulb fitting on wall/ ceiling/ column of building<br />

including supply of 60 Watt/ 100 Watt GLS lamps complete<br />

fitting and making connection from the suitable point outlet<br />

complete as required and as per direction of the Engineer-incharge.<br />

46.1 Incandescent bulb of required wattage not exceeding 100<br />

Watt on existing angle holder/ batten holder of point wiring.<br />

13.00 Nos<br />

47.0 Supply fixing & testing of 150 W HPSV fittings with lamp<br />

similar to philips Cat no-SRX086/150-1xSON/SON-T &<br />

bracket connection as per direction of E.I.C.<br />

48.0 S/F of computer point consisting of 5 Amp plug 3 nos,<br />

indicator & DPMCB as per direction of Engineer-in-charge.<br />

3.00 Nos<br />

4.00 Nos<br />

49.0 Supply, delivery, installation and testing of following sweeps<br />

of a.c ceiling fan of approved make complete with fan<br />

blades, down rod canpies capacitor etc including making<br />

connection from the suitable point outlet with 3 core 1.5<br />

mm2 copper cord and cost of electronic type step up fan<br />

regulator complete as required and as per direction of<br />

Engineer-in-charage.<br />

49.1 1200 mm SWEEP 14.00 Nos<br />

50.0 Supply, delivery, installation and testing of 300mm<br />

sweep,1400rpm exhaust fan suitable for operation at 250<br />

Volt, 50Hz, a.c supply complete with a set of propeller<br />

blade, tripod leg for mounting of mortor, ring frame, blades<br />

gravity louver complete assembly including making hole of<br />

suitable size for housing exhaust fan making connection<br />

from point outlet, making good the damages caused<br />

complete as required and as per direction of EIC.<br />

50.1 300mm sweep 900 RPM Heavy Duty type. 3.00 No<br />

51.0 Supply, Installation & testing of Ding Dong type Call Bell<br />

suitable for operation in 230V AC supply, mounted on M.S<br />

sheet metal board with bakelite cover including cost of<br />

making connection from point outlet complete as required<br />

as per direction of Engineer-in-charge.<br />

4.00 No<br />

No. of Corrections<br />

No. of Interpolation<br />

No. of Over writing<br />

Signature of <strong>Bidder</strong> Page 14

Sl.<br />

No.<br />

Description of work<br />

No.or<br />

Qty.<br />

Unit<br />

Rate (in<br />

Figures)<br />

Rate (in Words)<br />

AMOUNT<br />

52.0 Supply and fixing of flush type telephone socket outlet on<br />

cocealed metal box with bakelite cover including laying of<br />

0.6mm dia twin pair telephone wire laid inside 2mm wall<br />

thickness PVC pipe recessed in wall/ roof etc complete as<br />

per direction of Engineer-in-charge.<br />

53.0 Supply, Installation & Testing of 1.5 Ton split Air<br />

Conditioner with 5KVA voltage stablizer copper wound &<br />

M.S.Grill for house the out door unit of Air conditioner<br />

complition as required & as per direction of Engineer-incharge.<br />

54.0 Supply& fixing of GI pipe medium gage of size 100mm B-<br />

class for mechanical protection of cable & as per direction of<br />

Engineer-in-charge.<br />

55.0 Supply & laying of RCC hume pipe for mechanical protection<br />

of cable including necessary fittings & jointing materials as<br />

required & as per direction of Engineer-in-charge.<br />

1.00 No<br />

2.00 No<br />

3.00 Mtr<br />

55.1 150mm RCC hume pipe 10.00 Mtr<br />

56.0 P.H PROTION<br />

56.0 INTERNAL (P.H)<br />

56.0 Supplying all materials, labour, taxes, T&P for fitting &<br />

fixing of CPVC flow guard pipes SDR-13.50 of 100% lead<br />

free & confirming to ASTM F 442 specific to CPVC with<br />

N.S.F. & C.B.R.I. approved with good quality including<br />

fittings, and mending good the damages after laying as<br />

per site requirement etc. all complete including testing as<br />

per specification and direction of Engineer-in-charge.Make :<br />

ASTRAL / SUPREME / EQUIVALENT<br />

56.1 25mm dia 32.00 Mtr.<br />

56.2 20mm dia 6.00 Mtr.<br />

57.0 Supplying all labour, T&P and materials and making 30.00 Mtr.<br />

grooves in brick/stone walls vertically and horizontally to the<br />

required depth & width for fixing pipes and fittings in the<br />

grooves ,testing the pipe line against leakage and filling the<br />

grooves with cement motar(1:4) to bring the surface to<br />

orginal level including cost of materials, curing &<br />

conveyance of materials etc. all complete as per the<br />

58.0<br />

direction of Engineer-in-charge.<br />

Supplying all labour ,T&P and cutting holes in bricks or<br />

stone masonry wall in all floors for taking pipes through<br />

and mending good the damages with supply of all required<br />

materials etc. complete as per the direction of the Engineerin-charge.<br />

58.1 a) For 15mm to 50mm PVC pipe to pass in 250mm thick 5.00 Each<br />

wall<br />

58.2 b) For 75mm to 150mm PVC pipe to pass in 250mm thick 7.00 Each<br />

wall<br />

59.0 Supplying all labour ,T&P and cutting holes in RCC chajja or<br />

roof crnice & beams in all floors for taking pipes through<br />

and mending good the damages with supply of all required<br />

materials etc. complete as per the direction of the Engineerin-charge.<br />

59.1 a) For 15mm to 50mm PVC pipe to pass in 125mm to 3.00 Each<br />

250mm thick wall.<br />

59.2 b) 75mm to 110mm PVC pipe to pass 300mm thick RCC 6.00 Each<br />

beam.<br />

No. of Corrections<br />

No. of Interpolation<br />

No. of Over writing<br />

Signature of <strong>Bidder</strong> Page 15

Sl.<br />

No.<br />

Description of work<br />

No.or<br />

Qty.<br />

Unit<br />

Rate (in<br />

Figures)<br />

Rate (in Words)<br />

AMOUNT<br />

60.0 Supplying all materials, labour. T&P for fitting and fixing<br />

white glazed vitreous china porcelain Orissa pattern water<br />

closet 580 x 410 x 290mm of approved make, confirming to<br />

IS-2556 and top inlet for sinking into floor with 100mm PVC<br />

'P' trap etc. including supply of necessary cement concrete<br />

for fitting the closet etc. comlete in all respect in all floors<br />

including cost, conveyance and taxes of all materials etc.<br />

complet eas per specification all complete as per direction of<br />

Engineer-in-charge.Make : PARRY<br />

WARE/NEYCER/CERA with ISI mark.<br />

60.1 Orissa pattern WC (580x440x290mm) 1.00 Nos.<br />

61.0 Supplying all materials and labour, T&P for fitting and fixing<br />

white glazed vitreous china porcelain wash down water<br />

closet (European pattern water closet 580 x 440 x 290mm)<br />

of approved make, ISI marked, including supply of matching<br />

'P' trap to the floor with wooden plug and chromium plated<br />

screws including jointing the trap with soil pipe in cement<br />

mortar (1:1) etc. all comlete including cost of W.C. Pan, PVC<br />

seat cover with CP brass hinges & rubber, buffers etc. all<br />

complete including cost, taxes and conveyance as per<br />

61.1<br />

specification all complete as per direction of Engineer-incharge.<br />

Make : PARRY WARE /Nycer/Cerawith ISI<br />

mark<br />

EWC (580x440x290mm) 2.00 Nos.<br />

62.0<br />

62.1<br />

Supply all materials, labour,taxes and T&P for fitting and<br />

fixing of 10 liter capacity PVC low level cistern complete<br />

with all parts and internal fittings of approved make with ISI<br />

mark and supplying of necessary brackets, screws etc.,<br />

32mm dia flush bend, 15mm dia x 450mm long PVC water<br />

connecting pipe with CP on brass union nuts at each end as<br />

per specification all complete as per direction of Engineer-incharge.<br />

Make : PARRY WARE/NEYCER/CERA with ISI<br />

mark.<br />

a) 10 ltr. Capacity low level Cistern 3.00 Nos.<br />

63.0 Supplying all materials , labour & T&P for construction of 1.00 Set<br />

platform for counter basin with brick masonary wall using<br />

1st class KB bricks having crushing strength not less than<br />

75/Kg/Cm 2 in CM (1:4), RCC (1.1.5:3) slab of size 1500<br />

x600x 40mm using 20mm dia down size graded HG chips<br />

with two nos. of oval shape basin hole including cladding<br />

the tops as well as edge of the slab with granite plate<br />

including cutting to size and moulding complete as per<br />

64.0<br />

requirement and direction of EIC.<br />

Supply all materials and labour for fitting and fixing of white<br />

glazed vitreous china ware porcelain wash hand basin,<br />

confirming to IS-2556 part-iv), 1981 ISI marked and of<br />

approved make with supply of CI bracket (one pair) built in<br />

type, painted, including 32mm dia CP on brass waste of<br />

approved quality including supply of 15mm dia PVC heavy<br />

duty water connection pipe 450mm long with CP on brass<br />

coupling nut at each end and supply of 32mm dia PVC<br />

waste pipe with heavy duty coupling nut, including cutting<br />

the walls, making good the damages with cement contrete<br />

(1:2:4) in hard granite chips all complete as per direction of<br />

Engineer-in-charge. (Make : PARRY WARE<br />

/NEYCER/CERA with ISI mark.)<br />

64.1 610x500mm oval shpae counter top wash hand basin 4.00 Nos<br />

No. of Corrections<br />

No. of Interpolation<br />

No. of Over writing<br />

Signature of <strong>Bidder</strong> Page 16

Sl.<br />

No.<br />

Description of work<br />

No.or<br />

Qty.<br />

Unit<br />

Rate (in<br />

Figures)<br />

Rate (in Words)<br />

AMOUNT<br />

65.0 Supplying all materials and labour, T&P for fitting and fixing<br />

of large standing type (Magnum) white glazed vitreous<br />

china ware flat back, lipped front urinal basin of size (590 x<br />

390 x 375mm) confirming to IS and of approved make<br />

along with supply of necessary component parts like supply<br />

of 32mm dia CP dome waste pipe, 15mm CP spreaders<br />

including connection from the inside supply pipe, CP pipe of<br />

15x450mm long and all complete as per specification &<br />

direction of the Engineer-in-charge.<br />

Make : PARRY WARE/NEYCER/CERA WITH ISI MARK<br />

65.1 590 x 390 x 375mm magnum type flat back standing urinal 2.00 Nos.<br />

66.0 Supplying all materials, labour & fitting and fixing 125mm<br />

dia CP on brass grating on top of floor traps with cement<br />

mortar (1:4) all complete as per specification & direction of<br />

Engineer-in-charge.<br />

66.1 125mm gratting 4.00 Nos.<br />

67.0 Supplying all materials , labour ,T&P and fittings and fixing<br />

of different water supply NP or CP on Brass or GM fixtures<br />

of ISI approved make of following sizes and specification<br />

with leak proof threaded joints tightened with spun yarn<br />

and white zinc or any other method as required and<br />

directed including testing and rectification of defects after<br />

testing complete as per direction of Engineer-incharge.Make<br />

: JAQUAR / (continental)/mark<br />

67.1<br />

(oriental) /Equivalent<br />

15mm dia CP Bibcock with wall flange short body 2.00 Nos.<br />

67.2 CP 15mm dia angle stop cock with wall flange 8.00 Nos.<br />

67.3 C.P on brass15mm dia C.P. Pillar Cock 4.00 Nos.<br />

67.4 C.P. Soap dish. 3.00 Nos<br />

67.5 C.P. Towel Ring with bracket. 4.00 Nos<br />

67.6 15mm dia CP Urinal auto Flush cock. 3.00 Nos.<br />

67.7 C.P. glass shelf with bracket and hinged guard rail of Size 1.00 Nos<br />

600mmx125mm with 5mm thick Glass Plane.<br />

67.8 CP 15mm dia extension piece 20.00 Nos<br />

67.9 32mm dia CP Bottle trap 7.00 Nos<br />

67.1 C.P Robe hook. 3.00 Nos<br />

68.0 Supplying all materials, labour, T&P, fitting and fixing UPVC<br />

SWR (Type-A) pipes & fittings of approved make confirming<br />

to IS-13592, both below & above ground level/floor & on<br />

walls including supply of bobbins, nains, screws, wooden<br />

cleats, MS/PVC clamps, pipe clips as per requirement,<br />

including earth work in excavation & fitting, including<br />

68.1<br />

cutting walls & floor & making good the damages with<br />

cement concrete (1:2:4) with hard granite chips, including<br />

scaffolding wherever necessary all complete as per direction<br />

of the Engineer-in-charge. Make : ORIPLAST / SUPREME<br />

/ EQUIVALENT<br />

i) 110mm Nominal dia pipe(S.W.R. Type-A) 25.00 Mtr.<br />

69.0 Supplying all materials, labour, T&P, fitting and fixing of<br />

UPVC SWR fittings of standard make duly approved by EIC<br />

complete with requisite testing as directed.Make :<br />

ORIPLAST / SUPREME / EQUIVALENT<br />

69.1 110mm dia "P" trap 6.00 Nos.<br />

69.2 110mm dia single junction with Door 5.00 Nos.<br />

69.3 110mm dia Door bend 5.00 Nos.<br />

69.4 110mm dia Plain bend 2.00 Nos.<br />

69.5 110mm dia terminal guard. 2.00 Nos.<br />

69.6 110 mmpipe clamp 20.00 Nos<br />

No. of Corrections<br />

No. of Interpolation<br />

No. of Over writing<br />

Signature of <strong>Bidder</strong> Page 17

Sl.<br />

No.<br />

Description of work<br />

No.or<br />

Qty.<br />

Unit<br />

Rate (in<br />

Figures)<br />

Rate (in Words)<br />

AMOUNT<br />

70.0 Supplying all materials, labour, T&P & fitting and fixing (600<br />

x 450mm) size bevelled edge plate gass mirror of superior<br />

glass minimum 5 mm thick & of approved make mounted<br />

on 6mm thick AC sheet or masonite sheet & fixed to<br />

wooden plugs with CP brass cup screws, washers etc. all<br />

complete including cost, conveyance, taxes of all materials<br />

complete as per specification and direction of the Engineerin-charge.<br />

70.1 (a)600mm x 450mm x 5 mm size bevelled edge plate glass<br />

mirror with A.C sheet backing<br />

2.00 Nos<br />

70.2 b) Aluminum frame mirror of 6.5 mm thick plain glass of 1.00 Nos<br />

size 1500mm x 600 mm with clamp hook and thermocoal<br />

backing.<br />

71.0 Supplying, fitting and fixing of 20mm and above thick white<br />

marble urinal partition plate of following sizes for separating<br />

the standing and squatting urinals including cost,<br />

conveyance, taxes for all materials, labour, T & P including<br />

cutting and moulding the edge etc. complete as per<br />

direction of the Engineer-in-charge.<br />

71.1 Standing Urinal partition of size ( 900x600x20mm) 2.00 No<br />

72.0 Supplying all materials, labour, taxes, T&P and fixing of 5.00 Mtr.<br />

100mm dia half round W.G.V.C.W porcelain channel etc.all<br />

complete as per the P.H specification and direction of the<br />

Engineer-in-charge.<br />

Make : PARRY WARE/NEYCER/CERA WITH ISI MARK.<br />

73.0 EXTERNAL WATER SUPPLY & SEWERAGE<br />

73.0 Supplying all material, labour , Taxes,T&P for fitting &<br />

fixing of following different water supply fittings conforming<br />

UPVC pipe 100% lead free & conforming to ASTM D<br />

2846/ASTM F 442 specifric toCPVC with N.S.F & CBRI<br />

approved with good quality including fitting, excavation of<br />

trenches in all kinds of soil & refilling the trenches after<br />

laying & testing of pipe line as per specification & direction<br />

of EIC. (Make- ASTRAL/ ASHIRBAD/ Equivalent.<br />

73.1 25mm dia.CPVC Ball Valve 3.00 Nos.<br />

73.2 50mm dia CPVC Ball Valve 5.00 Nos<br />

73.3 50mm dia PVC Ball cock 2.00 Nos<br />

74.0 Supplying & laying in trenches UPVC rain water pipes&<br />

fittings and specials of the following outside dia for all<br />

classes including jointing with supply of approved solvent<br />

cement by non heat application method including testing as<br />

per standard specification including earthwork in excavation<br />

of trenches in all kinds of soil in required depth & refilling of<br />

pipe line trenches in 0.3048 Mtrs or fixing to walls, floors<br />

with supply of necessary clamps, nails, wall plugs etc. all<br />

complete as per direction of Engineer in Charge.<br />

Make : ORIPLAST/SUPREME/EQUIVALENT<br />

74.1 a) 110mm dia UPVC rain water pipe 25.00 Mtr.<br />

74.2 b) 110mm dia UPVC rain water pipe bend/Shoe 10.00 No.<br />

74.3 c) 110mm dia UPVC Clamp 20.00 Nos.<br />

No. of Corrections<br />

No. of Interpolation<br />

No. of Over writing<br />

Signature of <strong>Bidder</strong> Page 18

Sl.<br />

No.<br />

Description of work<br />

No.or<br />

Qty.<br />

Unit<br />

Rate (in<br />

Figures)<br />

Rate (in Words)<br />

AMOUNT<br />

75.0 Supplying all materials, labour, T&P for construction of 4.00 No<br />

300mm x 300mm size Gulley trap chamber by K.B. bricks<br />

masonry having crushing strength 75 to 99 Kg/sqcm with<br />

250 x 250 mm CI grating including labour & materials for<br />

fitting & fixing 100mm dia square mouth HCI gulley trap<br />

with supply of all jointing materials and encasing the gulley<br />

trap with a block of C.C (1:3:6) with 25mm size hard stone<br />

metal all complete with providing & fixing of 300mm x<br />

300mm precast SFRC cover with frame as per approved<br />

design & specification and as per instruction of the EIC<br />

including cost, conveyance, taxes of all materials to site<br />

76.0<br />

complete as per direction of EIC.<br />

Providing, fitting, fixing of polythine moulded water storage<br />

76.1<br />

tank of capacity 1000 ltr. including construction of RCC (M-<br />

20) base slab, beam of approved design and 2/3 height (all<br />

round) cover with brick masonry wall in C.M. 1:4 and 12mm<br />

thick cement plaster 1:4 over brick work etc. providing<br />

laying and fixing of medium grade G.I./AUPVC pipe of<br />

approved size for filling, over flow, wash out and delivery<br />

line etc. all completeup to supply main as per specification<br />

and direction of EIC<br />

a) 1000 ltr.x2nos. polythene moulded water tank( Make :- 2000.00 Ltr<br />

Sintex)<br />

77.0 Supplying all material, labour, T&P and construction 20<br />

users septic tank with 2 years cleaning interval of inner size<br />

2.3 x1.1x 1.3 mtr (liquid depth) as per the approved<br />

drawing & specification with 500mm, 375mm & 250mm<br />

thick 1st class K.B. brick in C.M.(1:6), over a bed of 100mm<br />

thick P.C.C.(1:4:8) , 150mm thick PCC (1:2:4) & 40mm<br />

thick (Avg.) A.S flooring inside wall plastering with 12mm<br />

thick C.P. in C.M. (1:4) including neat cement punning,<br />

outside wall plastering with 16mm thick CP in C.M.(1:4),<br />

RCC slab of 125 mm thick (Avg.) with M-20 concrete using<br />

20mm down graded chips with necessary reinforcement,<br />

centering and shuttering including two nos of SFRC manhole<br />

cover with frame of approved quality with inlet & outlet<br />

chamber of size 750x750x450mm , two baffle walls, supply,<br />

fitting and fixing of necessary specials & fittings Tee,H.C.I<br />

vent pipe, PVC foot rest including excavation of earth, in all<br />

kind of soil including bailing out water and shoring,<br />

77.1<br />

shuttering etc. as necessary and back filling the sides of<br />

tank removing and filling all foreign up the chamber materials with fromwater insideafter.<br />

the chambers 1.00 No.<br />

complete as per direction of E.I.C.<br />

78.0 Supplying all material, labour, T&P and constructing<br />

manhole chamber / inspection chamber of size as<br />

mentioned below with 250mm nominal size K.B. Brick<br />

having crushing strength 75kg to 99kg / sqcm in CM 1:4<br />

over a bed of 150mm thick C.C. (1:3:6) using 40mm size<br />

HG metal, plastering with 12mm thick cement mortar 1:4 on<br />

internal and 16mm thick cement mortar (1:4) on external<br />

surface, inside finish with neat cement, providing & fixing<br />

PVC steps of appropriate quality & size, RCC (1:1.5:3) cover<br />

slab using 20m & down size graded HG chips along with<br />

factory made SFRC cover with frame , moulding and<br />

shaping the channel & benching with C.C (1:2:4) with hard<br />

granite chips 12mm size including breaking of pipe line<br />

where ever necessary and earth work in excavation in all<br />

kind of soil & rock and refilling the cavity around the<br />

chamber by selective soil, levelling the surface around the<br />

chamber with disposal of surplus earth, if any, to a distance<br />

of 50mt as per specification, design & drawing including<br />

cost of curing and all taxes , royality , cost , conveyance etc.<br />

No. of Corrections<br />

No. of Interpolation<br />

No. of Over writing<br />

Signature of <strong>Bidder</strong> Page 19

Sl.<br />

No.<br />

Description of work<br />

No.or<br />

Qty.<br />

Unit<br />

Rate (in<br />

Figures)<br />

Rate (in Words)<br />

AMOUNT<br />

78.1 a) Man Hole of size 1200mm x900mm x 900mm with<br />

125mm (avg) thick RCC slab.<br />

78.2 b) Inspection chamber of size 750mm x750mm x 600mm<br />

with 125mm (avg) thick RCC slab.<br />

79.0 Supplying & laying in trenches unplasticized UPVC- U drain<br />

SN-4 pipes and specials of the following outside dia for all<br />

classes including jointing with supply of approved solvent<br />

cement by non-heat application method including testing as<br />

per standard specification including earth work in excavation<br />

of trenches in all kind of soil in proper slope with type -C<br />

standard bedding CC 1:4:8 the required depth & refilling of<br />

pipe line trenches in 0.3048 Mtrs layer after laying and<br />

testing of pipe line etc. all complete as per direction of<br />

Eingineering in Charges.<br />

2.00 Nos<br />

2.00 Nos<br />

79.1 a) 110mm dia UPVC SWR Pipe (Type-A). 20.00 Mtr<br />

79.2 b) 160mm dia UPVC SWR Pipe (Type-A). 15.00 Mtr<br />

80.0 Supplying all materials, labour taxes T&P for construction of<br />

brick masonry soak way pit using K.B brick(1:4)having<br />

crushing strenght not less than 75kg/Sqm for the remaining<br />

height ( not less than 0.5m) 12mm thick cement plaster<br />

(1:4) both inside and outside of top brick work, RCC 125mm<br />

thick(avg) cover slab in CC(1:1/2:3) using 12mm size H.G<br />

chips,fitted with factory made SFRC Manhole cover(medium<br />

duty) of size 500mm dia including earthwork in excavation<br />

in hard soil,filling inside of the pit with 40mm size H.B.G<br />

metals for 150mm thick back filling the remaining portion<br />

including top 0.5mtr. with excavated selected earth,<br />

levelling the surface around the chamber with the disposal<br />

of surplus earth ,if any to a distance of 50m as per the<br />

specification design and drawing including cost of curing<br />

and all tax,royality , cost,conveyance etc. all complete as<br />

of size 1.50 mtr internal dia & 2.00 mtr depth with RCC<br />

cover slab as per approved drawing & specification all<br />

complete as per P.H. specification and the direction of EIC.<br />

80.1 1.5x3.0m deep soak way pit. 1.00 No<br />

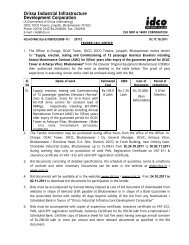

Total in Figures<br />

Total in Words<br />

No. of Corrections<br />

No. of Interpolation<br />

No. of Over writing<br />

Signature of <strong>Bidder</strong> Page 20