BID DOCUMENT - IDCO

BID DOCUMENT - IDCO

BID DOCUMENT - IDCO

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

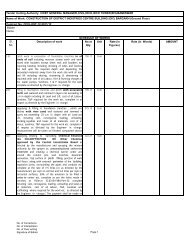

(f)<br />

be made to allow the form work to be removed without shock or damage to the concrete its contains or to<br />

adjacent work.<br />

Opening sufficient in size and number to permit convenient access to clean properly and inspect the inside<br />

of the forms shall provide. All dirt, chips sawdust and other foreign matter shall be removed from within the<br />

form before any concrete is deposited therein. Forms shall be kept wet for at least 10 minutes before<br />

concrete is placed.<br />

(g) With in one week of the acceptance of his tender the contractor shall submit for the approval of the<br />

engineer drawing and descriptions should in the methods he proposes to use for the creation and support of<br />

the form work.<br />

1.12 STRIKING OF FORM WORK<br />

(a)<br />

No form work shall be struck without the prior approval of the engineer form work shall be removed in<br />

accordance with a programme agreeably the engineer without such shock or vibration as would damage the<br />

concrete and without interruption to the curing of the concrete.<br />

Concrete exposed by the removal of formwork shall be left untouched till the Engineer inspects it.<br />

1.13 PREPARATION OF SURFACES TO RECEIVE CONCRETE<br />

Before new concrete is deposited against the surface of set concrete at construction Joints the surface of<br />

the set concrete shall be thoroughly scrubbed or roughened and cleaned by means of compressed air and<br />

sand or other approved means to such an extent that on smooth skin of concrete that may be left from the<br />

previous concrete is placed. These scrubbed surfaces shall be thoroughly cleaned, brushed and watered<br />

and if so instructed by the engineer be coated with neat cement grout well brushed into the surface.<br />

1.14 STEEL OF REINFORCEMENT<br />

(a)<br />

(b)<br />

(c)<br />

The steel for normal reinforced concrete shall be high yield strength deformed round bars conforming to IS<br />

1786 and IS 1139. Corrosion resistance rod shall be exclusively used in piles provided in the foundation.<br />

Mild steel rod conforming to IS 432 shall be used wherever required by the engineer. The engineer shall<br />

perform tests to be made on samples of steel reinforcement stored at the site before use. . In the event of<br />

any sample not meeting the requirement of Bureau of Indian standard, the whole consignment of bars from<br />

which the samples were taken will be rejected by the engineer not withstanding any previous acceptance on<br />

the strength of the manufacturers certificate. Any reinforcement rejected by the engineer shall be removed<br />

from the site.<br />

The steel shall be kept clean and shall be free from mill scales, loose dust oil earth or other harmful<br />

materials before being placed in the forms. The steel at site shall be stored under roof with non-porous<br />

enclosure around.<br />

The steel shall only be procured from the authorized outlets of the manufacturer approved by the engineer.<br />

1.15 BENDING OF REINFORCEMENT<br />

All reinforcement shall be bent cold using bar bending machines and appliance approved by the engineer.<br />

Unless otherwise specified in the drawings, the bending dimension tolerances and the dimensions of<br />

anchors, hooks binders stirrups and the like shall comply with the IS standards. Only experienced steel<br />

benders and fixer shall be employed. Bending shall be accurately carried out and no steel blocks or wooden<br />

wedges will be permitted for keeping reinforcement in place.<br />

1.16 PLACING OF REINFORCEMENT<br />

(a) The number size from and position of all steel bars shall be in accordance with the drawings and in the placing<br />

and fixing of them the function of each bar is to be kept in mind. The reinforcement shall be accurately<br />

assembled and firmly secured by wire ties made form no. 16 soft annealed wire so that the whole assembly<br />

is rigid and will not be misplaced while concrete is being compacted around it. The ends of the wire ties<br />

shall be turned inward away from and shall not be left projecting beyond the reinforcing bar. The engineer<br />

due to valid reasons may order change in shape size and spacing of bars at contractor’s cost.<br />

(b) The cover of concrete to steel shall be maintained by spacing blocks securely wired to the bars or by other<br />

means approved by the engineer. Spacing blocks for the various cover dimensions shall be cast from<br />

cement mortar made from I part of cement and II parts of sand. The blocks shall be well compacted and<br />

shall be fully cured before being used. Temporary bracing shall be provided to prevent movement of all<br />

steel projecting from the concrete in the course of construction.<br />

29