Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

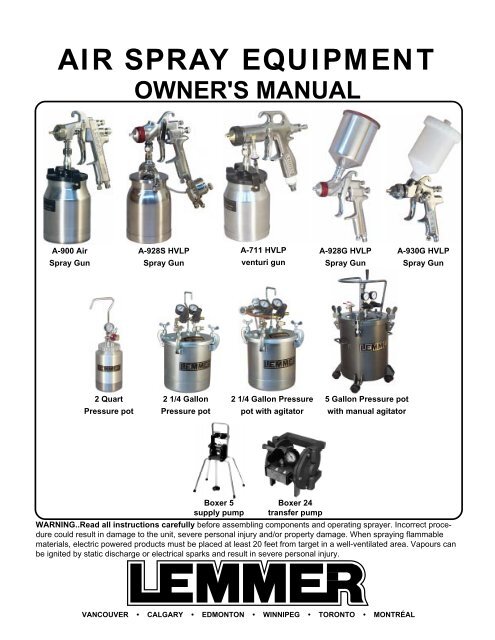

AIR SPRAY EQUIPMENT<br />

OWNER'S MANUAL<br />

A-900 <strong>Air</strong><br />

Spray Gun<br />

A-928S HVLP<br />

Spray Gun<br />

A-711 HVLP<br />

venturi gun<br />

A-928G HVLP<br />

Spray Gun<br />

A-930G HVLP<br />

Spray Gun<br />

2 Quart<br />

2 1/4 Gallon<br />

2 1/4 Gallon Pressure<br />

5 Gallon Pressure pot<br />

Pressure pot<br />

Pressure pot<br />

pot with agitator<br />

with manual agitator<br />

Boxer 5<br />

supply pump<br />

Boxer 24<br />

transfer pump<br />

WARNING..Read all instructions carefully before assembling components and operating <strong>spray</strong>er. Incorrect procedure<br />

could result in damage to the unit, severe personal injury and/or property damage. When <strong>spray</strong>ing flammable<br />

materials, electric powered products must be placed at least 20 feet from target in a well-ventilated area. Vapours can<br />

be ignited by static discharge or electrical sparks and result in severe personal injury.<br />

VANCOUVER • CALGARY • EDMONTON • WINNIPEG • TORONTO • MONTRÉAL<br />

1

TABLE OF CONTENTS<br />

SAFETY PRECAUTIONS ................................................................................... 2 CLEANING INSTRUCTIONS:<br />

INTRODUCTION ................................................................................................ 3<br />

PRESSURE POTS ....................................................................................... 11<br />

AIR SPRAY GUNS - CONVENTIONAL: ....................................................... 3<br />

BOXER SYSEMS ........................................................................................ 12<br />

AIR SPRAY GUNS - HVLP: .......................................................................... 3<br />

ALL AIR GUNS ............................................................................................ 13<br />

PRESSURE FEEDING THE AIR GUNS: ...................................................... 3 MAINTENANCE:<br />

COMPRESSOR REQUIREMENTS .............................................................. 3<br />

A-711 HVLP GUN ........................................................................................ 14<br />

LEMMER WARRANTY ................................................................................. 3<br />

PRESSURE POT ........................................................................................ 14<br />

SPECIFICATIONS:<br />

A-900 & A-928 GUN .................................................................................... 15<br />

PRESSURE POTS ........................................................................................ 4 TROUBLESHOOTING GUIDE ................................................................. 16 & 17<br />

BOXER 5 & 24 .............................................................................................. 5 OTHER QUALITY LEMMER PRODUCTS ....................................................... 18<br />

A-711 ............................................................................................................. 6 HOSES & COMPONENTS FOR AIR SPRAY EQUIPMENT ............................. 19<br />

PRESSURE POT .......................................................................................... 6 PARTS LIST & DIAGRAM:<br />

A-900 ............................................................................................................. 6<br />

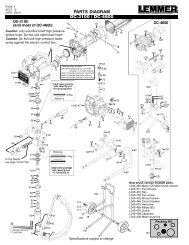

A-700 SERIES HVLP GUN ................................................................. 20 & 21<br />

A-928 ............................................................................................................. 7<br />

A-900 AIR GUN ........................................................................................... 22<br />

A-930 ............................................................................................................. 7<br />

A-928 AIR GUN ........................................................................................... 23<br />

SETTING UP OF UNIT - BOXER 5 .................................................................... 8<br />

A-930 HVLP GRAVITY GUN ....................................................................... 24<br />

SETTING UP OF UNIT - 2.25 GALLON PRESSURE POT ................................ 8<br />

2-1/4 GALLON PRESSURE POT ............................................................... 25<br />

PAINT PREPARATION & SELECTING THE PROPER FLUID SET ................... 9<br />

5 G PRESSURE POT W/MANUAL AGI ...................................................... 26<br />

PROPER SPRAYING TECHNIQUES ................................................................. 9<br />

2 QUART ..................................................................................................... 27<br />

OPERATING INSTRUCTIONS ................................................................. 10 & 11<br />

BOXER 5 ..................................................................................................... 27<br />

BOXER 24 ................................................................................................... 28<br />

DISTRIBUTION CENTRES ACROSS CANADA .............................................. 28<br />

WARNING<br />

1) Do not <strong>spray</strong> paints or other inflammable fluids<br />

indoors which have a flash point below 21 degree<br />

C, 70 degree F. Keep <strong>spray</strong> area well ventilated.<br />

Before <strong>spray</strong>ing, turn off all pilot lights and open<br />

flames.<br />

2) Wear a respirator which is approved for the<br />

product being <strong>spray</strong>ed.<br />

3) Do not use halogenated hydrocarbon solvents<br />

in this system; it contains aluminium parts and<br />

may explode. Cleaning agents, coatings, paints,<br />

and adhesives may contain halogenated hydrocarbon<br />

solvents. Don't take chances, consult your<br />

material supplier to be sure. (ex: methylene<br />

chloride and 1,1,1 - Trichlorethane)<br />

4) Caution: When a flammable liquid is <strong>spray</strong>ed<br />

there may be danger of fire or explosion<br />

especially in a closed area.<br />

5) Caution: Arcing parts. Keep the compressor at<br />

least 20 feet away from explosive vapours.<br />

6) Caution: Static electricity can be developed by<br />

<strong>spray</strong>ing. Ground unit and object to be <strong>spray</strong>ed.<br />

On electric units, unit power cord must be connected<br />

to a grounded outlet. Use only three wire<br />

extension cords. Static explosion can occur with<br />

ungrounded unit.<br />

7) Always follow safety precautions and warnings<br />

printed on paint container.<br />

8) Do not pull on hoses to move <strong>equipment</strong>, DO NOT<br />

kink or bend the hose sharply.<br />

9) Keep children or anyone not familiar with air <strong>spray</strong><br />

systems away from <strong>equipment</strong> and work area.<br />

10) Conductive metal containers must be used when<br />

flushing flammable fluids through the system.<br />

Always flush at low pressure with <strong>spray</strong> tip removed. A<br />

metal part of the <strong>spray</strong> gun must be held firmly against<br />

the grounded metal pail when flushing or relieving<br />

pressure from the gun.<br />

SAFETY PRECAUTIONS<br />

ATTENTION<br />

1) Ne jamais pulvériser à l’interieur un produit inflammable qui a<br />

un point éclair inférieur à 21 degrés C,70 degrés F. L’endroit où<br />

vous peinturez doit toujours être bien aéré. Avant de pulvériser<br />

s’assurer qu’il n’y a aucune flamme ou pilot (veilleuse) de fournaise<br />

en marche dans l’appartement.<br />

2) Servez-vous d’un masque respiratoire qui est certifié pour le<br />

produit que vous pulvérisez.<br />

3) Ne pas utiliser de solvants contenant des hydrocarbures<br />

halogénés avec ce matériel. Il contient des particules d'aluminium<br />

et peut exploser. Les agents de nettoyage, enduits, peintures et,<br />

adhésifs, peuvent contenir des solvants contenant des<br />

hydrocarbures halogénés. Soyez prudents; consultez votre<br />

fournisseur pour les informations nécessaires. (ex: méthylène<br />

chloride and 1,1,1 - Trichloréthane)<br />

4) Attention: La pulvérisaton d'un liquide inflammable peut entraîner<br />

un risque d'incendie ou d'explosion, surtout dans les espaces<br />

fermés.<br />

5) Attention: Étincelles électriques. Ne pas placer la compresseur à<br />

moins de 6 mètres des vapeurs explosives.<br />

6) Attention: La pression du produit que l’on pulvérise peut produire<br />

une charge électrostatique. Mettre le matériel et l'objet à<br />

pulvériser à la terre. Sur les modèles électriques, le cordon<br />

électrique doit être attaché à une prise de courrant reliée à terre. Le<br />

cordon de rallonge doit être à 3 fils. Des décharges d'électricité<br />

statique peuvent se produire si le matériel n'est pas mis à la terre.<br />

7) Toujours prendre les précautions nécessaires et observer toutes<br />

les consignes de sécurité figurant sur le pot de peinture.<br />

8) Il ne faut jamais essayer de déplacer l'appareil en tirant sur le tuyau. Il faut<br />

aussi éviter tout tortillement du tuyau.<br />

9) Les enfants et le personnes n'ayant aucune expérience<br />

avec ce genre de pulvérisateur doivent êtres gardés à l'écart<br />

de l'appareil et du chantier de travail.<br />

10) Quand on décharge des liquides inflammables il<br />

faut utiliser des pots conducteurs en métal. Quand on<br />

relâche la pression avec le pistolet, une partie métallique du<br />

pistolet doit être en contact avec le pot en métal muni de<br />

mise à la terre.<br />

2

CONGRATULATIONS on choosing a new <strong>Lemmer</strong> Spray<br />

System! Your <strong>Lemmer</strong> Spray System is exceptionally<br />

rugged in construction and designed to operate with the<br />

best possible delivery efficiency. Like any fine precision<br />

tool, its most efficient operation depends on a thorough<br />

knowledge of its operation capabilities and maintenance.<br />

With proper material preparation and maintenance, your<br />

<strong>Lemmer</strong> will produce beautiful, uniform finishing results for<br />

years to come.<br />

This manual covers a variety of air <strong>spray</strong> <strong>equipment</strong> which can<br />

be categorized as follows:<br />

AIR SPRAY GUNS - CONVENTIONAL:<br />

The A-900 which atomizes paint at 40 - 60 psi. The higher<br />

operating pressure results in the best possible finish.<br />

AIR SPRAY GUNS - HVLP:<br />

The A-711 / A-928 / A-930 which atomize paint at 2 - 10 psi.<br />

The lower operating pressure provides lowest possible over<strong>spray</strong><br />

mist with high speed application rates.<br />

PRESSURE FEEDING THE AIR GUNS:<br />

Advantages:<br />

• The <strong>spray</strong> gun can operate in any position, and fit in<br />

smaller areas.<br />

• The weight of the material is off the <strong>spray</strong> gun for less<br />

operator fatique.<br />

• A wider range of viscosities may be used with the same<br />

fluid nozzle.<br />

• Generally can increase application rates and reduce paint<br />

mist.<br />

• Saves time by requiring less fills.<br />

Fluid supply method:<br />

<strong>Lemmer</strong> pressurized containers are available in 2 quart<br />

remote, or 2.25 gallon remote. They are inexpensive and<br />

simple to operate.<br />

<strong>Lemmer</strong> low pressure pumps are available in two styles.<br />

The Boxer 5 is perfect for supplying constant steady<br />

pressure to multiple air <strong>spray</strong> guns. The Boxer 24 is not<br />

recommended for air gun supply but is for use as a transfer<br />

pump.<br />

COMPRESSOR REQUIREMENTS FOR MOST OF THESE<br />

SYSTEMS:<br />

For optimum results the air compressor should maintain a<br />

constant minimum air flow of 7 cfm at a minimum of 50 psi. <strong>Air</strong><br />

supply must be clean, dry, and oil free.<br />

LEMMER PAINT SPRAYING EQUIPMENT LIMITED WARRANTY<br />

LEMMER Spray Systems Ltd. extends to the original purchaser of its paint<br />

<strong>spray</strong> <strong>equipment</strong> a limited one year warranty from the date of purchase<br />

against defects in material or workmanship provided that the <strong>equipment</strong><br />

is installed and operated in accordance with the recommendations and<br />

instructions written in the owners manual. LEMMER Spray Systems Ltd.<br />

will repair or replace, at its option, defective parts without charge if such<br />

parts are returned (still intact in the original <strong>equipment</strong>) with transportation<br />

charges prepaid to the nearest LEMMER Spray Systems Ltd. outlet. An<br />

original proof of purchase must be attached.<br />

THIS WARRANTY DOES NOT COVER:<br />

Normal wear and/or defects caused by or related to abrasion, corrosion,<br />

abuse, negligence, accident, faulty installation or tampering in a manner<br />

which impairs normal operation.<br />

Transportation costs and other incidental, direct, special, or consequential<br />

damages or loss.<br />

INTRODUCTION<br />

Your <strong>Lemmer</strong> system is capable of <strong>spray</strong>ing a wide<br />

variety of lacquer, some epoxies, industrial finishes, latex,<br />

oil-based and alkyd paints, as well as stains, preservatives<br />

and other architectural coatings. The material you<br />

are <strong>spray</strong>ing will have a direct effect on the amount of<br />

pressure required for the optimum pattern and coverage<br />

to be obtained. We recommend that before actually<br />

beginning your job, you carefully read this manual and<br />

practice with the system until you feel comfortable using it.<br />

COATING APPLICATIONS<br />

COATING EXCELLENT GOOD NOT REC.<br />

Multi-colour (HVLP) X<br />

Stain<br />

X<br />

Sealers (concrete) X<br />

Asphalt Coating<br />

Primer<br />

X<br />

Elastomerics<br />

Varnish<br />

X<br />

Lacquer<br />

X<br />

Sealers (wood)<br />

X<br />

Acrylic<br />

X<br />

Textured<br />

X<br />

Block Filler<br />

Ext. Latex X*<br />

Ext. Oil Base X*<br />

Latex (Int.) X*<br />

Enamel (alkyd) X*<br />

*Some thinning may be required. Follow manufacturer’s<br />

recommendations.<br />

X<br />

X<br />

X<br />

3

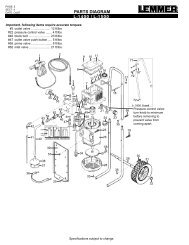

SPECIFICATIONS - PRESSURE POTS<br />

paint hose to<br />

<strong>spray</strong> gun. (black)<br />

WARNING: Make sure nuts<br />

and bolts are properly tightened<br />

before pressurizing the pot!<br />

fluid pressure<br />

regulator with<br />

guage.<br />

air <strong>spray</strong> gun<br />

fluid pressure<br />

regulator with<br />

guage.<br />

air cap pressure<br />

regulator with guage.<br />

line from air<br />

compressor.<br />

air hose to<br />

<strong>spray</strong> gun. (red)<br />

air <strong>spray</strong> gun<br />

line from air<br />

compressor.<br />

fluid<br />

paint hose<br />

to <strong>spray</strong><br />

gun. (black)<br />

air<br />

fluid<br />

air hose to<br />

<strong>spray</strong> gun. (red)<br />

air<br />

heavy<br />

duty<br />

clamps.<br />

safety<br />

valve,<br />

50 psi.<br />

safety<br />

valve,<br />

50 psi.<br />

teflon lined<br />

inner pot.<br />

Figure 1. - Typical 2 quart system<br />

DESCRIPTION:<br />

The following paragraphs refer to the 2 1/4 gallon system.<br />

The 2 quart system is basically the same other than size<br />

and not having a standard air regulator for the air cap air.<br />

The <strong>Lemmer</strong> pressure pot is designed for production line<br />

and decorator painting applications using internal or<br />

external mix <strong>spray</strong> guns. The pressure pot is capable of<br />

holding bulk quantities of paint or a one gallon paint can<br />

may be placed in the pressure pot without having to pour<br />

out can contents.<br />

Basic construction of the unit consists of a heavy deep<br />

drawn one piece galvanized steel pot, steel stamped pot<br />

lid, eyebolt clamp.<br />

The unit is equipped with a pressure regulator, gauge,<br />

safety relief and bleeder valve, paint line and air line<br />

connections. A convenient carrying handle allows attachment<br />

of the unit to the rung of a ladder or scaffolding to<br />

facilitate house or barn <strong>spray</strong>ing operations.<br />

Figure 2. - Typical 2 1/4 gallon system<br />

SPECIAL SAFETY PRECAUTIONS:<br />

• Do not pressurize pot over 50 PSI.<br />

• Make sure all feed line, eyebolts and <strong>spray</strong> guns are<br />

secured before turning air supply on.<br />

• Always shut off air pressure at source and bleed off<br />

all pressure in pressure pot by gently pulling safety<br />

valve ring before loosening knobs.<br />

• Regularly check to be sure gauge and regulator are<br />

functioning correctly. Also check that no paint nor<br />

other deposits are in safety valve inlet. In the event<br />

more than 50 PSI is applied to the pressure pot, and<br />

safety valve is clogged, the higher pressure could<br />

damage the pressure pot.<br />

• Only use original <strong>Lemmer</strong> replacement parts. These<br />

parts are safety performance engineered. Any substitutions<br />

may be counter-protective and dangerous.<br />

4

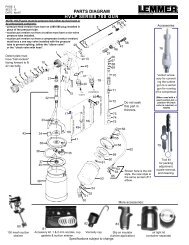

PUMP TYPE:<br />

These units are AIR POWERED DOUBLE DIAPHRAGM<br />

PUMPS. Top quality parts keep maintenance to a minimum. All<br />

paint valves are made of stainless steel for extra long abrasion<br />

resistance. The advantages of this type of pump is:<br />

- Minimal or no thinning of paint products<br />

- Pumps straight out of original paint container<br />

- Variable pressure<br />

- Boxer 5 is quiet running & and continues running even<br />

when <strong>spray</strong>ing stops to insure constant <strong>spray</strong> pressure<br />

- Boxer 24 is quiet running & and stops when flow stops. It is<br />

best suited for transfering liquids<br />

- Safe for hazardous locations - no electricity<br />

How Pneumatic pumps operate: A pneumatic pump consists<br />

of a reciprocating air motor and a fluid pump. Its speed and<br />

pressure are controled by air regulator. The pressure ratio<br />

(pump ratio) of the pump is determined by the square area of<br />

the air motor piston versus the square area of the piston in the<br />

fluid pump. The pumps maximum possible output pressure is<br />

determined by multiplying the ratio by the compressed air<br />

pressure fed into the air motor.<br />

Fluid pressure<br />

regulator<br />

Fluid outlet fliter<br />

Fluid outlet<br />

Fluid inlet<br />

Fluid inlet fliter<br />

<strong>Air</strong> pressure regulator<br />

<strong>Air</strong> shutoff<br />

valve<br />

<strong>Air</strong> motor<br />

piston<br />

<strong>Air</strong> logic valve<br />

<strong>Air</strong> valve shifter<br />

Figure 4. - Boxer 24 pump components<br />

SPECIFICATIONS - BOXER 5 & 24<br />

<strong>Air</strong> pressure<br />

regulator<br />

<strong>Air</strong> logic valve shft<br />

sensors (Boxer 5<br />

only)<br />

Fluid pump<br />

Figure 3. - Boxer 5 pump components<br />

Fluid outlet<br />

Outlet valve<br />

Fluid pump<br />

Inlet valve<br />

5<br />

Example:<br />

Pump ratio= 1:1<br />

<strong>Air</strong> pressure reading at air motor control= 71 psi<br />

Max. fluid pressure (1 x 71)= 71 psi<br />

The air is connected to the air motor of the pump. First, the<br />

pump is primed, then the pressure is set (lets say at 10 PSI for<br />

pumping latex). When the fluid pressure reaches 10 PSI in<br />

the hose, the:<br />

Boxer 5 pump cycles feely, waiting to deliver more fluid without<br />

delay. This uses about 2 cfm of air, but provides instant trigger<br />

response thus eliminating fan fluctuations.<br />

Boxer 24 fluid pump parts (including air motor) stop moving<br />

creating a stall position. When the flow valve is opened and the<br />

fluid pressure begins to drop, the air motor and fluid pump<br />

immediately begin to work to maintain pressure. The results are<br />

minimal air consumption and minimal all-around wear.<br />

PUMP COMPONENTS:<br />

Spray Gun: The <strong>spray</strong> gun is supplied separately and may be<br />

of a standard high pressure air design, or of the HVLP low<br />

pressure design.<br />

<strong>Air</strong> motor: These specially designed air motors convert the<br />

energy from compressed air into a double action stroke. Both<br />

the left and right power strokes are used by the fluid pump to<br />

create pressure and volume. The air motors are permanently<br />

lubricated and require minimal maintenance. Its air source must<br />

be regulated, clean, and free of oil.<br />

Fluid Pump: The fluid pump is a double diaphragm with inlet<br />

and outlet valves on each side. The diaphragm is made of a<br />

tough nylon resin blend and the housing of polyarilammide<br />

material for best chemical and abrasion resistance.<br />

Pressure regulator: The pressure regulator is on the top of the<br />

air motor. When the regulator handle is turned clockwise, air<br />

pressure is increased, when the handle is turned counterclockwise,<br />

air pressure is reduced.<br />

Always reduce the pressure (turn the handle all the way<br />

counterclockwise, or disconnect air supply) when cleaning or<br />

when switching the position of the dump valve (if so equipped).<br />

Dump Valve (if equipped): The dump valve is located on the<br />

side of the fluid pump. When turned to “prime” (handle in-line<br />

with body), it circulates fluid to vent the air trapped in the fluid<br />

pump out the return hose. It will continue to recirculate the fluid<br />

until the knob is manually turned to the “<strong>spray</strong>” position.<br />

When the dump valve is turned to “<strong>spray</strong>”, flow is shut off<br />

through the return hose and is routed to the fluid hose for<br />

<strong>spray</strong>ing or transferring.<br />

The dump valve also serves to relieve pressure on the system<br />

during shutdown and cleanup. The pressure is relieved by<br />

turning the prime valve to “dump”.<br />

COATINGS:<br />

Most types of paints and coatings are supplied ready to <strong>spray</strong><br />

(with the exception of possible thinning). In possible instances<br />

where a coating is contaminated with foreign particles, Boxer<br />

units are available with inlet filter screens, and a high pressure<br />

outlet filter to prevent possible plugging or damage.<br />

Viscosity alone is no measure for good pump priming,<br />

pumpability or <strong>spray</strong>ability. It may well be that a suction hose<br />

has to be exchanged for a straight suction tube, or a shorter<br />

tube to assist the priming action.<br />

Two-component materials generally have a short “pot life”. The<br />

unit must be properly flused and cleaned well before the curing<br />

time starts.<br />

Pumping coarse bodied or aggressive fluids is possible up to<br />

about 3mm maximum diameter particles.

Figure 5. - Typical pressure pot system<br />

Special safety precautions:<br />

• Do not pressurize tank over 50 PSI.<br />

• Make sure all feed line, eyebolts and <strong>spray</strong> guns are<br />

secured before turning air supply on.<br />

• Always shut off air pressure at source and bleed off<br />

all pressure in paint tank by gently pulling safety valve<br />

ring before loosening knobs.<br />

• Regularly check to be sure gauge and regulator are<br />

functioning correctly. Also check that no paint nor<br />

other deposits are in safety valve inlet. In the event<br />

more than 50 PSI is applied to the tank, and safety<br />

valve is clogged, the higher pressure could damage<br />

the tank.<br />

SPECIFICATIONS - A-711<br />

Fan width<br />

control.<br />

Spray pattern<br />

control air cap.<br />

Important: A pressure<br />

regulator must be used<br />

between the air<br />

compressor and the<br />

<strong>spray</strong> gun. The regulator<br />

wil also serve as the<br />

air control valve in<br />

controlling air flow<br />

through the <strong>spray</strong> gun.<br />

A-711 HVLP SPRAY GUN WITH PRESSURIZED CUP:<br />

As high speed compressed air passes through the venturi<br />

assembly, a low pressure field is created. Ambient air<br />

(outside room air) is pulled through the air filter/silencer,<br />

mixing with the compressed air, and creating a high<br />

volume of low pressure air. Operating at standard air line<br />

pressures the A-711 venturi gun creates less than 10 psi<br />

at the gun while maintaining 65 - 95% transfer efficiency.<br />

Special safety precautions:<br />

The A-711 venturi gun is a non bleeder type with continuous<br />

pressure in the cup, even after the air line has been<br />

disconnected! Do Not pull trigger after <strong>spray</strong>ing!<br />

Release pressure with the cup locking lever immediately<br />

after use. Wear eye protection!<br />

SPECIFICATIONS - PRESSURE POT<br />

DESCRIPTION:<br />

The <strong>Lemmer</strong> paint tank is designed for production line<br />

and decorator painting applications using internal or<br />

external mix <strong>spray</strong> guns. The tank is capable of holding<br />

bulk quantities of paint or a one gallon paint can may be<br />

placed in the tank without having to pour out can contents.<br />

Basic construction of the unit consists of a heavy deep<br />

drawn one piece galvanized steel tank, steel stamped<br />

tank lid, eyebolt clamp.<br />

The unit is equipped with a pressure regulator, gauge,<br />

safety relief and bleeder valve, paint line and air line<br />

connections. A convenient carrying handle allows attachment<br />

of the unit to the rung of a ladder or scaffolding to<br />

Material<br />

volume<br />

control knob.<br />

Venturi<br />

intake filter.<br />

<strong>Air</strong> hose inlet.<br />

Pressure cup.<br />

6<br />

facilitate house or barn <strong>spray</strong>ing operations.<br />

WARNING: Failure to follow instructions on proper<br />

assembly and use of a paint tank may possibly result<br />

in damage to property or personal injury. This unit<br />

must be assembled as indicated in these instructions.<br />

Only those parts supplied with this unit should<br />

be used. These parts are safety performance engineered.<br />

Any substitutions may be counter-protective<br />

and dangerous.<br />

SPECIFICATIONS - A-900<br />

<strong>spray</strong> pattern<br />

plane control.<br />

container<br />

anti-drip<br />

vent.<br />

fan width<br />

control knob.<br />

material volume<br />

control knob.<br />

air volume<br />

control knob.<br />

air hose inlet.<br />

A-900 AIR SPRAY GUN WITH SUCTION POT:<br />

The A-900 conventional <strong>spray</strong> gun is designed for furniture<br />

fine finishing, auto body shops, metal fabrication<br />

shops, contractors, and hobbyists. The metal gun is<br />

durable and has a large pot opening for easy cleaning.<br />

Spray fan control is adjusted at the top back, horizontal<br />

and vertical pattern is controlled at the air cap, and<br />

material flow is controlled at the back of the gun. Materials<br />

which can be <strong>spray</strong>ed include varnish, urethane,<br />

lacquer, automotive paint, epoxy, enamel, stain, latex, oil<br />

base, etc. The gun comes with a 1 quart container, and<br />

can also be used with an optional 2 quart or 2-1/4 gallon<br />

remote pressure pot. The fluid needle and seat are made<br />

of stainless steel, and the entire gun can be placed in a<br />

gun cleaning cabinet. The gun is supplied with a 1.5 mm<br />

general purpose nozzle for thin materials such as varnish,<br />

stain, and enamels (latex and oil base require some extra<br />

thinning). Other sizes available separately, see parts list<br />

in back of book.

SPECIFICATIONS - A-928<br />

<strong>spray</strong> pattern<br />

plane control.<br />

fan width<br />

control knob.<br />

material volume<br />

control knob.<br />

SPECIFICATIONS - A-930<br />

Nylon gravity pot<br />

with screw on lid.<br />

container air<br />

pressure hose.<br />

container<br />

pressure<br />

regulates up<br />

to 10 psi.<br />

air hose inlet.<br />

air volume<br />

control knob.<br />

<strong>spray</strong> pattern<br />

plane control.<br />

material volume<br />

control knob.<br />

fan width<br />

control knob.<br />

A-928 HVLP SPRAY GUN WITH PRESSURIZED CUP:<br />

The A-928 HVLP <strong>spray</strong> gun is designed for furniture fine<br />

finishing, auto body shops, metal fabrication shops,<br />

contractors, and hobbyists. The metal gun is durable and<br />

has a large pot opening for easy cleaning. Spray fan<br />

control is adjusted at the top back, horizontal and vertical<br />

pattern is controlled at the air cap, and material flow is<br />

controlled at the back of the gun. Materials which can be<br />

<strong>spray</strong>ed include varnish, urethane, lacquer, automotive<br />

paint, epoxy, enamel, stain, latex, oil base, multi-colour<br />

etc. The gun comes with a 1 quart container, and can<br />

also be used with an optional 2 quart or 2-1/4 gallon<br />

remote pressure pot. The fluid needle and seat are made<br />

of stainless steel, and the entire gun can be placed in a<br />

gun cleaning cabinet. The gun is supplied with a 1.4 mm<br />

general purpose nozzle for materials such as varnish,<br />

stain, and enamels (latex and oil base require some extra<br />

thinning). Other sizes available separately, see parts list<br />

in back of book.<br />

air volume<br />

control knob.<br />

air hose inlet.<br />

A-930 HVLP AIR SPRAY GUN WITH GRAVITY POT:<br />

The A-930 HVLP is designed for low over<strong>spray</strong> and high<br />

production. Low over<strong>spray</strong> is achieved by converting<br />

compressor air to High Volume Low Pressure in the air<br />

cap. Applications for this <strong>spray</strong> gun include furniture fine<br />

finishing, auto body, metal fabrication, and most other<br />

<strong>spray</strong> type jobs. The metal gun is durable and has a light<br />

weight nylon gravity container with a non-drip screw-on<br />

lid. Spray fan control is adjusted on the side of the gun,<br />

horizontal and vertical pattern is controlled at the air cap,<br />

and material flow is controlled at the back of the gun.<br />

Materials which can be <strong>spray</strong>ed include varnish,<br />

urethane, lacquer, automotive paint, metalics, epoxy,<br />

enamel, stain, latex, oil base, multi-colour, etc. The gun<br />

comes with a 1/2 litre container. The fluid needle and seat<br />

are made of stainless steel, and the entire gun can be<br />

placed in a gun cleaning cabinet. This gun is supplied<br />

with a 1.5 mm general purpose nozzle for thin materials<br />

such as lacquer, stain, and enamels (latex and oil base<br />

require some extra thinning). Nozzle sizes 1.0, 2.0 & 2.5<br />

are available separately, see parts list in back of book.<br />

7

TOOLS NEEDED:<br />

2 x 8" or larger crescent wrench<br />

PROCEDURE:<br />

1. Remove all system components from the box for<br />

assembly.<br />

2. Remove all protective caps from inlet and outlet<br />

connections of pump.<br />

3. Attach suction hose or sucton pipe to inlet of pump.<br />

Tighten securely.<br />

4. Attach return hose or dump valve to fluid outlet fitting<br />

to approximately 20 ft. lbs.<br />

5. Connect fluid hose to pump outlet. Tighten to approximately<br />

20 ft. lbs.<br />

6. Connect the fluid hose to the connection of the <strong>spray</strong><br />

gun. Tighten to 20 ft. lbs.<br />

7. Double check all connections, the unit is now ready<br />

for flushing.<br />

Note: The pump contains a preservative oil when you<br />

receive it, that may drip from the various connections<br />

when the protective caps are removed.<br />

ASSEMBLY:<br />

1. Assemble the regulator to the paint tank lid as shown<br />

in the exploded view drawing.<br />

NOTE: This regulator is a special pressure limiting<br />

regulator. Your paint tank should be used only with<br />

this regulator. NEVER ASSEMBLE A REGULATOR TO<br />

YOUR PAINT TANK IN ANY OTHER MANNER.<br />

2. Install the handle (13) in the threaded hole in the<br />

center of the tank lid (3) as shown.<br />

3. Attach the material hose to the material hose connector<br />

(15).<br />

4. Connect the material hose and the air hose to the<br />

<strong>spray</strong> gun and check all fittings to make sure they are<br />

tight.<br />

5. Turn both regulators to minimum pressure<br />

(counterclockwise) and connect air supply. Slowly<br />

increase fluid pressure while watching for any leaks.<br />

6. Read page 8 "operating instructions" for correct<br />

pressure settings.<br />

SETTING UP OF UNIT - BOXER 5<br />

air control assembly.<br />

paint filter.<br />

attach fluid<br />

hose here.<br />

paint suction<br />

hose.<br />

suction filter.<br />

Figure 6. - Boxer 5 system components.<br />

SETTING UP OF UNIT - 2.25 GALLON PRESSURE POT<br />

8<br />

9 7<br />

from air<br />

compressor.<br />

(some models)<br />

7<br />

3<br />

5<br />

from air<br />

compressor.<br />

(newer models)<br />

10<br />

4<br />

12<br />

11<br />

air hose to<br />

<strong>spray</strong> gun.<br />

boxer pump.<br />

air <strong>spray</strong> gun<br />

13<br />

14<br />

16<br />

paint hose to<br />

<strong>spray</strong> gun.<br />

17<br />

18<br />

CAUTION: Do not use wrench or pliers to tighten<br />

knobs. Hand tighten only.<br />

CAUTION: Make certain that all pressures within the<br />

system are relieved before attempting to remove any<br />

component or part of a component.<br />

2<br />

21<br />

19<br />

20<br />

WARNING: Failure to follow instructions on proper<br />

assembly and use of a paint tank may possibly result<br />

in damage to property or personal injury. This unit<br />

must be assembled as indicated in these instructions.<br />

Only those parts supplied with this unit should be<br />

used. These parts are safety performance engineered.<br />

Any substitutions may be counter-protective<br />

and dangerous.<br />

8<br />

1<br />

Figure 7. - Pressure pot components<br />

WARNING:<br />

Make sure<br />

nuts and bolts<br />

are properly<br />

tightened<br />

before<br />

pressurizing<br />

the tank!

PAINT PREPARATION & SELECTING THE PROPER FLUID SET<br />

FLUID SET SELECTION:<br />

Nozzle sets range in size to provide different fluid flow<br />

rates. For low flow rates or light viscosity fluid, select the<br />

smaller nozzle sizes. For high flow rates or high viscosity<br />

fluid, select the larger nozzle sizes. For the best atomization,<br />

use the fluid nozzle that will give the required flow<br />

with the needle fully triggered.<br />

Measuring paint viscosity:<br />

1. Thin paint according to paint can instructions. Be<br />

certain to use a thinner which is compatible with paint<br />

used. If no thinning instructions are given, a general<br />

rule of thumb is 5 to 15% thinners. (fine finish up to<br />

35%)<br />

Get professional looking results by following the <strong>spray</strong><br />

tips below.<br />

1. Adjust air line pressure to 50 psi to start. Test the<br />

<strong>spray</strong> pattern, atomization, and over<strong>spray</strong> mist and<br />

adjust pressure up or down to obtain desired results.<br />

2. Keep the gun perpendicular to the surface. Always<br />

hold the gun perpendicular to the surface with the tip<br />

approximately 6 to 8" from the surface. If held at an<br />

angle (up and down or side to side) paint will build up<br />

unevenly and leave the work splotchy. This also<br />

saves material and reduces mist.<br />

3. Move with a smooth arm stroke Move the gun at a<br />

steady even pace while keeping the gun perpendicular<br />

to the surface. (See figure 8) Do not move the gun<br />

by flexing your wrist. Fanning the gun will cause<br />

excessive over<strong>spray</strong> and uneven coverage. (See<br />

figure 9). If the rate of speed is not comfortable for<br />

you, select another nozzle/needle size according to<br />

the nozzle charts.<br />

PROPER SPRAYING TECHNIQUES<br />

2. Stir paint completely and strain.<br />

3. Use the viscosity cup to measure paint as follows:<br />

a) Submerge the <strong>Lemmer</strong> Viscosity cup in the paint.<br />

b) Lift the cup out of the paint and begin timing.<br />

c) Stop timing when the steady paint stream is first<br />

broken.<br />

d) The time recorded is the paint’s viscosity.<br />

4. Now read the nozzle chart included with the <strong>spray</strong><br />

guns parts list and choose the nozzle which lists the<br />

viscosity range your material falls into.<br />

Note: The nozzle chart has been made as accurately as<br />

possible. Not all paints will exactly comply due to paint<br />

ingredient variations. However, it is an excellent starting<br />

point for learning the basics <strong>spray</strong> painting.<br />

Thin Materials: Decrease air flow through gun to minimize<br />

mist.<br />

Heavy Materials: If flow rate is too slow, additional<br />

thinning will be needed or a larger fluid nozzle will be<br />

required.<br />

4. Start moving the gun before triggering To get<br />

smooth overlap and prevent initial paint buildup, start<br />

your stroke movement before pulling the trigger. At<br />

the end of the stroke release the trigger before<br />

stopping.<br />

NOTES:<br />

For a nice even finish, always overlap previous strokes<br />

by the same amount, generally 50%. Put on a full wet<br />

coat whenever possible.<br />

When blending spots, work from the outside in. Start one<br />

inch out, no dusting. This eliminates “chronic halo” .<br />

Figure 8. - Proper way to trigger <strong>spray</strong> gun.<br />

Figure 9. - Result of flexing wrist while <strong>spray</strong>ing.<br />

9

OPERATING INSTRUCTIONS<br />

Whenever the system is to be used, it must be prepared<br />

for the type of paint to be used. This requires the<br />

system to be flushed out with an appropriate solvent<br />

(water for latex, mineral spirits for oil base, etc.).<br />

Incorrect flushing can cause gumming and priming<br />

problems.<br />

Caution: Never aim <strong>spray</strong> gun at any part of the body.<br />

Even when air line is disconnected, the <strong>spray</strong> gun may<br />

retain fluid pressure.<br />

Note: if using agitator accessory, set air control valve<br />

to slowest speed that air motor will operate. This will<br />

ensure proper mixing without splashing and aerating.<br />

7. Set the vertical/horizontal <strong>spray</strong> pattern:<br />

On A-900, A-925, A-930: loosen the air cap ring,<br />

rotate the air cap, and re-tighten the ring.<br />

On A-711: just turn the air cap. The aircap adjusting<br />

ring only requires to be loosened if it is set to its<br />

widest pattern (srewed in tight).<br />

Caution: Never use metal implements to clean out<br />

holes in the air cap or fluid tip.<br />

Caution: Before servicing the gun always shut off air<br />

and fluid supply and relieve all pressure.<br />

Warning: Be certain that the air line supply line is at<br />

zero psi and pressure regulators are turned to minimum<br />

before connecting any air supply!<br />

1. Securely connect either suction pot, gravity pot, or<br />

pressure feed hose. If using the suction pot have the<br />

bent suction pipe aiming forward (or backward if<br />

<strong>spray</strong>ing upwards). Connect the "zero pressure" air<br />

line.<br />

2. Adjust the volume knob on gun counter clockwise<br />

until full trigger movement is achived.<br />

3. Prepare your paint and pour into the paint container.<br />

It is normal to thin products for air application 10-20%,<br />

depending on manufacturers recommendations and job<br />

particulars.Thicker products require more air pressure<br />

for atomization, larger nozzle sizes, and higher material<br />

pressures. Prepare the surface to be painted according<br />

to the paint suppliers instructions.<br />

4. Practice on scrap material before proceeding to <strong>spray</strong>.<br />

5. Set the atomizing air pressure. The best pressure for<br />

any type of <strong>spray</strong>ing is the lowest pressure that will<br />

give a good finish. This is because lower <strong>spray</strong>ing<br />

pressures have less over<strong>spray</strong>. Depending on the type<br />

of paint and its thickness, this pressure will range from<br />

40 - 80 psi.<br />

6. If using a pressure feed system, adjust the paint<br />

pressure to about 5 psi. The material or "pot" pressure<br />

determines how much paint comes from the gun, i.e.)<br />

how wet is the coat. Best material pressures are<br />

between 5- 20 psi. (The gun can be fed from any<br />

pressure pot, or from any transfer pump system with a<br />

1:1 ratio).<br />

Be careful not to overpower the ability of the gun to<br />

atomize properly by using too much fluid pressure. To<br />

test for proper fluid pressure, disconnect atomizing air<br />

to the gun (by use of separate regulator, shut off valve,<br />

or simply by kinking the hose if air is regulated at the<br />

compressor) and pull trigger of <strong>spray</strong> gun fully, the<br />

material stream should travel 12" to 18" in a downward<br />

arch. Increase or decrease the regulator pressure as<br />

necessary to obtain proper material flow.<br />

10<br />

Round jet (A-711 only) Horizontal Fan Vertical Fan<br />

Figure 10. - Spray pattern control (turn air cap).<br />

8. Set the <strong>spray</strong> fan width:<br />

On A-900, A-925, A-930: use the knob at the side of<br />

the <strong>spray</strong> gun head, or at the back of the gun. Turning<br />

the knob in reduces the <strong>spray</strong> fan size, turning it out<br />

increases fan. The practical limit is about an 8 - 10 "<br />

fan one foot from the gun (will also adjust down to very<br />

small round <strong>spray</strong> pattern). Note: The air consumption<br />

decreases as you reduce the fan width.<br />

On A-711: turn the control ring in (for wide) or out (for<br />

narrow). Smoother finishes can be obtained by using a<br />

narrow pattern. More material output can be gained by<br />

using a wide pattern.<br />

wider <strong>spray</strong> fan.<br />

normal <strong>spray</strong>fan.<br />

narrow <strong>spray</strong> fan.<br />

on A-711: turn ring in.<br />

on A-900/925/930: turn<br />

knob out.<br />

on A-711: turn ring<br />

until air cap is flush<br />

with fluid nozzle end.<br />

on A-900/925/930: turn<br />

knob to halfway point.<br />

on A-711: turn ring out.<br />

on A-900/925/930: turn<br />

knob in.<br />

Figure 11. - Spray fan width control (A-711 shown).<br />

9. Set the paint volume, use the knob at the back of the<br />

gun to limit the needle travel. As the knob is turned in,<br />

the needle travel is restricted, and material flow is<br />

reduced. (Keep in mind that this restriction will increase<br />

the needle and seat wear). This is for fine<br />

tuning only, the primary control of material flow is the<br />

nozzle size and material pressure.<br />

10. For best paint finish results keep the gun 8 - 12" from<br />

the work piece. Move your gun with a steady, constant<br />

motion to avoid runs, spots, and irregular finishes.

Note: To help prevent paint from entering the vent or<br />

the air hose on the pressurized cup models, refrain<br />

from overfilling the container or tipping the <strong>spray</strong> gun<br />

at extreme angles.<br />

OPERATING INSTRUCTIONS<br />

Warning for A-711 gun only: Paint cup is under continuous<br />

pressure, even after air line has been disconnected.<br />

Do Not pull trigger after <strong>spray</strong>ing! Release<br />

pressure with the cup locking lever immediately after<br />

use. Wear eye protection!<br />

maximum fill<br />

CLEANING INSTRUCTIONS - PRESSURE POTS<br />

fluid pressure regulator<br />

with gauge.<br />

line from air<br />

compressor.<br />

air <strong>spray</strong> gun<br />

air cap pressure<br />

regulator with gauge.<br />

fluid<br />

safety valve,<br />

50 psi.<br />

air<br />

WARNING: Make sure nuts<br />

and bolts are properly tightened<br />

before pressurizing the pot!<br />

teflon lined<br />

inner pot.<br />

heavy duty clamps.<br />

air hose to<br />

<strong>spray</strong> gun. (red)<br />

paint hose<br />

to <strong>spray</strong><br />

gun. (black)<br />

Typical pressure pot system components<br />

CLEAN PAINT POT AS FOLLOWS:<br />

IMPORTANT: It is very important that the fluid material<br />

hose and <strong>spray</strong> gun be cleaned as soon as the<br />

<strong>spray</strong> job is completed.<br />

1. Shut off air to the pot at air pressure regulator by<br />

turning adjusting screw counter clockwise.<br />

2. Gently pull safety valve ring to purge air from pot.<br />

Note: if equipped with agitator accessory, be sure to<br />

stop propeller before venting or opening lid.<br />

3. Completely cover <strong>spray</strong> gun nozzle with a soft rag<br />

and with air lines pressurized, pull trigger of the gun.<br />

This will force paint remaining in the material hose<br />

back into the pot.<br />

4. Remove pot lid and pour any remaining paint back<br />

into original containers for future use.<br />

5. Using a clean, dry cloth, wipe inside area of pot<br />

clean. A replacement plastic liner is #L011-586.<br />

6. Pour about 1/2 gallon of paint solvent into the pot.<br />

Use the correct type of solvent for the paint being<br />

used: mineral spirits for oil base paint, lacquer thinner<br />

for lacquer base paints, warm soap water for Latex,<br />

etc.<br />

7. Clamp lid onto pot and proceed to <strong>spray</strong> the proper<br />

solvent through <strong>spray</strong> gun and hose.<br />

8. Proceed to remove all thinner from hose in accordance<br />

with steps 1 thru 9 in this section.<br />

9. Clean lip of pot, groove pot cover, and gasket.<br />

CLEAN SAFETY VALVE AS FOLLOWS:<br />

Remove safety valve and clean port (orifice) periodically.<br />

Accumulations of paint in the port can prevent proper<br />

valve action. Do not disassemble valve or change settings.<br />

CAUTION: This component has been factory calibrated<br />

and sealed. Do not attempt to disassemble<br />

valve or alter calibration.<br />

11

CLEANING INSTRUCTIONS - BOXER SYSEMS<br />

As with all <strong>spray</strong> <strong>equipment</strong>, your <strong>spray</strong> system must<br />

be cleaned properly or it will not operate properly.<br />

Clogged valves and filters are the most common<br />

causes of problems. If followed, these guidelines will<br />

insure trouble free performance from your <strong>spray</strong><br />

system.<br />

CAUTION: Clean with water if latex is used. Clean<br />

with paint thinners for oil based paints. Both water<br />

and paint thinner will be refered to as "solvent" from<br />

here on in.<br />

CLEAN-UP:<br />

To get the best use and longest life from your <strong>spray</strong><br />

system, it is very important to clean it out properly. The<br />

procedure is simple and is very similar to the flushing<br />

procedure performed earlier. Cleaning and flushing would<br />

also be required when changing color, or type of paint, ie:<br />

latex changing to oil base.<br />

1. Turn pressure regulator to minimum, trigger gun into<br />

waste pail to release all system pressure.<br />

2. Lift both suction tube above the level of paint in the<br />

pail and turn pressure up to a slow cycle rate. Trigger<br />

gun to allow unit to pump out paint.<br />

Warning!<br />

Figure 14. Pump until clean solvent appears.<br />

Warning: conductive metal containers must be used<br />

when flushing flammable fluids through the system.<br />

Always flush at low pressure with atomizing air<br />

turned off. A metal part of the <strong>spray</strong> gun must be held<br />

firmly against the grounded metal pail when flushing<br />

or relieving pressure from the gun.<br />

6. Pump solvent out by lifting the suction hose out of the<br />

solvent. Turn pressure regulator to minimum and<br />

trigger gun to release system pressure and disconnect<br />

air supply.<br />

Figure 12. Pump fluid out.<br />

3. Place suction tube into pail with proper solvent to<br />

flush out paint and allow unit to prime in the solvent.<br />

Clean the outside of suction tube.<br />

Figure 13. Clean pump with suitable solvent .<br />

4. Turn pressure regulator to minimum and close<br />

gun.<br />

5. Spray with atomizing air still turned off and starting<br />

with minimum pressure, aim gun into paint container<br />

and hold trigger open until paint flow stops and<br />

solvent flow just begins. Release trigger. Aim gun into<br />

solvent pail and circulate solvent for about two<br />

minutes. To reduce splashing, direct the fluid stream<br />

along inside of bucket at a side angle and well above<br />

the fluid level.Release trigger. Point <strong>spray</strong> gun into an<br />

empty waste bucket and <strong>spray</strong> at least 1 gallon of<br />

fluid into it. (see figure 14).<br />

Figure 15. Fluid is pumped out.<br />

7. Follow above steps 1-6 using clean solvent to<br />

completely flush system. You may at this time, if you<br />

wish, blow compressed air into the tip (gun trigger<br />

open and air supply disconnected) to push the solvent<br />

all the way out the fluid nozzle.<br />

8. If changing paint types, ie: latex (water base) to oil<br />

base, you would have to flush system with clean<br />

mineral spirits using above steps 1-6. This would<br />

prepare the pump for the oil base paint. Water would<br />

have to be used as a last flush if changing from oil<br />

base paints to latex.<br />

9. Ensure pressure regulator is turned to minimum<br />

and all pressure is released. Turn pump air supply<br />

OFF.<br />

10. Brush gun clean with appropriate solvent. Inspect<br />

filters for pinholes, plugging, or other damage. Replace<br />

if required.<br />

11. Remove intake screen on suction tube and brush<br />

clean, re-install.<br />

12. Storing unit for more than 3 days. If system was<br />

cleaned with an oily paint thinner such as varsol, it is<br />

now ready for storage (after step 13). If system was<br />

cleaned with water or a strong thinner (ie. lacquer<br />

thinner) pump varsol (or mineral spirits) through the<br />

entire system by repeating step 7. If varsol is not<br />

available, drain all the solvent out of the hose, gun,<br />

and pump. (metal parts in the valves will corrode if<br />

left in water for long periods of time). With the<br />

pump running in the prime mode, place the suction<br />

tube in a container of light oil. Let the pump run until it<br />

spits oil drops out the gun nozzle. This will displace<br />

any remaining solvent and lubricate the valves for<br />

storage.<br />

13) Coil up <strong>spray</strong> hose, inspecting for signs of damage.<br />

12

CLEANING INSTRUCTIONS - ALL AIR GUNS<br />

As with any <strong>spray</strong> <strong>equipment</strong>, your <strong>spray</strong>er must be<br />

cleaned properly or it will not operate properly. If<br />

followed, the following guidelines will insure trouble<br />

free performance from your <strong>spray</strong>er.<br />

CAUTION: Clean with water if latex is used. Clean<br />

with paint thinners for oil based paints. Both water<br />

and paint thinner will be referred to as "solvent" from<br />

here on in.<br />

NOTE: We recommend running light oil or mineral<br />

spirits through the unit before storing. When using<br />

latex paints, make sure the unit has been completely<br />

cleaned before storing with mineral spirits. Mineral<br />

spirits react with latex paint to form a jelly-like substance.<br />

A-900, A-928, A-930, A-711:<br />

Solvent flushing gun (All models). Empty material from<br />

cup and add about 1" clean solvent. Attach cup to gun<br />

and swirl it around while <strong>spray</strong>ing. Remove cup and pull<br />

trigger to break air lock in material tube. Empty balance of<br />

solvent from cup and repeat process with clean solvent.<br />

Remove cup and wipe clean. Clean gun body with a<br />

solvent dampened cloth. Remove air cap and clean with<br />

solvent and brush. Do not use a hard metal object which<br />

might damage the air cap holes.<br />

A-928, clean<br />

the air hose<br />

CLEANING INSTRUCTIONS - A-711 AIR GUN<br />

A-711 ONLY:<br />

Back flush gun. Remove material cup and hold gun over<br />

a shop cloth. Connect air supply, hold finger over air cap,<br />

and pull the trigger. This will force all the air through the<br />

gun down the air check valve, blowing out any excess<br />

paint that may have been trapped.<br />

Cleaning the check valve and air hose is very important.<br />

Any blockage here prevents pressurization. To help<br />

prevent paint from entering hose, refrain from overfilling<br />

the container or tipping the <strong>spray</strong> gun at extreme angles.<br />

Warning: Paint cup is under continuous pressure,<br />

even after air line has been disconnected. Do Not pull<br />

trigger after <strong>spray</strong>ing! Release pressure with the cup<br />

locking lever immediately after use. Wear eye protection!<br />

Note: Back flushing<br />

is very important<br />

in keeping<br />

valve (1), hose (2),<br />

and tube (3) clean.<br />

Any blockage here<br />

prevents pressurization.<br />

To help<br />

prevent paint from<br />

entering tube (3),<br />

refrain from overfilling<br />

the container<br />

or tipping<br />

the <strong>spray</strong> gun at<br />

extreme angles.<br />

Warning: Paint cup is under<br />

continuous pressure, even after<br />

air line has been disconnedted.<br />

Do Not pull trigger after <strong>spray</strong>ing!<br />

Release pressure with the<br />

cup locking lever immediatly<br />

after use. Wear eye protection!<br />

3<br />

2<br />

1<br />

maximum fill<br />

A-711 HVLP<br />

gun.<br />

air cap<br />

check<br />

valve<br />

one<br />

way<br />

check<br />

valve<br />

13

nozzle<br />

needle<br />

MAINTENANCE - A-711 HVLP GUN<br />

adjustment drum<br />

needle packing<br />

lock nut<br />

packing nut<br />

spring<br />

spring cap<br />

adjusting<br />

screw<br />

1/16" spring travel, turbine<br />

3/8" spring travel, venturi<br />

Packing<br />

wrench<br />

Nozzle Tool<br />

Figure 16. - Trigger adjustment<br />

DISASSEMBLY:<br />

1. Remove air cap, detent plate, spring; spring cap,<br />

spring, & needle. Lastly remove nozzle using nozzle<br />

tool.<br />

ASSEMBLY:<br />

2. Lubricate needle with vaseline. Install needle, spring,<br />

and spring cap (loosely).<br />

3. Adjust packings by turning the packing wrench clockwise<br />

and triggering the needle while you tighten. When<br />

the needle binds, back off until the needle just moves<br />

freely.<br />

4. Install nozzle, spring, detent plate, and air cap.<br />

5. Check trigger free travel. Important: Ensure that the<br />

fluid adjusting screw is backed out all the way.<br />

If adjustment is required continue to step 6.<br />

Turbine gun.....1/16" spring travel (before needle moves)<br />

Venturi gun.....3/8" spring travel (before needle moves)<br />

6. Adjust trigger by removing the spring cap, loosening<br />

the lock nut and turning the drum until correct free<br />

travel is achieved. Tighten lock nut and install spring<br />

with cap.<br />

Figure 17. - Needle packing adjustment<br />

If tool kit is required, use order #L080-650 for 1 x<br />

packing wrench, 1 x nozzle tool, and 1 x cleaning brush.<br />

VENTURI ADJUSTMENT:<br />

Refer to parts diagram in back of manual. Be sure venturi<br />

is fully seated into the gun handle and that the locking<br />

screw is tight.<br />

1. If air fails to shut off when trigger is released, loosen<br />

locking nut (67) and turn adjustment cap (66) clockwise.<br />

This will allow venturi spindle to fully restore.<br />

2. If air flow fails to start before fluid needle moves,<br />

loosen locking nut (67) and turn adjustment cap (66)<br />

counterclockwise.<br />

FILTER/SILENCER MAINTENANCE:<br />

The filter must be in place while <strong>spray</strong>ing. This will<br />

prevent recirculating <strong>spray</strong> mist through the gun. The<br />

filter must be kept as clean as possible to allow full air<br />

flow through the <strong>spray</strong> gun. To clean, remove filter and<br />

brush with lacquer thinner.<br />

Caution: If the 2 quart remote cup is accidentally<br />

tipped over or held at too great an angle (or any other<br />

pressure pot), fluid might leak into the regulator. In<br />

the event this happens, clean immediately.<br />

MAINTENANCE - PRESSURE POT<br />

Periodically inspect the tank for leaks around the paint<br />

tank lid. If leakage is present, remove the paint tank lid<br />

and clean lip of tank and groove in tank lid. Replace<br />

gasket.<br />

14

MAINTENANCE - A-900 & A-928 GUN<br />

NEEDLE AND SEAT:<br />

1. Remove air cap.<br />

2 Pull and hold trigger. Remove nozzle using 8mm or<br />

5/16" open end wrench.<br />

3. Remove material control knob and spring.<br />

4. Pull needle out from back of gun.<br />

NEEDLE PACKING:<br />

1. Remove needle and nozzle as per above.<br />

2. Remove packing holder with 10mm wrench.<br />

3. Remove packing nut from holder and remove packing.<br />

Use great care to prevent damage if you plan to reuse<br />

the packing.<br />

Clean and inspect all parts for wear and replace as<br />

necessary. Reassemble in reverse order. Lightly oil<br />

needle where it passes through packing. Tighten packing<br />

gently, only enough to prevent seepage. Overtightening<br />

will cause needle & trigger to stick open.<br />

AIR VALVE:<br />

1. Remove the spring cap with screwdriver.<br />

ACCESSORIES<br />

2. Withdraw spring & valve from rear of gun.<br />

Clean as required.<br />

3. Replace valve if worn, lightly oil shaft &<br />

reassemble.<br />

CUP GASKET:<br />

Check for leaks by tipping with fluid inside. On the<br />

A-928 it is especially important to have a proper<br />

seal since the cup must pressurize in order for<br />

the <strong>spray</strong> gun to function.<br />

nozzle<br />

air cap<br />

packing<br />

holder<br />

packing<br />

packing<br />

nut<br />

trigger<br />

needle<br />

spring<br />

valve<br />

spring<br />

spring cap<br />

A-928 not exactly<br />

as shown.<br />

material<br />

control<br />

knob<br />

Spare 1 qt. cups & air tight lids<br />

The perfect pair for quick color change,<br />

easy clean up, and for storage of commonly<br />

used material (venturi gun only):<br />

1 - one quart cup .................... L080-580<br />

1 - air tight lid.......................... L080-648<br />

Extra cup gaskets:<br />

1 - package of 5 gaskets ........ L080-582<br />

Low pressure air and fluid hoses are rubber<br />

type for best life and flexibility. The fluid hose also<br />

has a nylon inner lining to withstand all paints<br />

including lacquers and 2 components. The inner<br />

tube's smooth surface also makes cleaning easier<br />

and quicker.<br />

5' x 1/4 twin line hose ............. L080-727<br />

15' x 1/4 twin line hose ........... L080-728<br />

25' x 1/4 twin line hose ........... L080-662<br />

50' x 1/4 twin line hose ........... L080-725<br />

25' x 3/8 twin line hose(1/4air) L080-729<br />

50' x 3/8 twin line hose(1/4air) L080-661<br />

Cotton overalls<br />

Small overalls ......................... L034-220<br />

Medium overalls ..................... L034-221<br />

Large overalls ........................ L034-222<br />

Extra large overalls ................ L034-223<br />

Viscosity cup<br />

Takes the guess work out of reducing<br />

your material. ......................... L075-106<br />

Spray hoods<br />

Spray hoods (pack of 3) ......... L034-205<br />

Suction strainers<br />

Slip on strainers for cup gun or paint<br />

tank, eliminates surface blemishes and<br />

plugged tips. 100 mesh screen.<br />

........................................ L080-587<br />

Strainer bags<br />

1 Gallon strainer w/elastic ...... L034-208<br />

5 Gallon strainer w/elastic ...... L034-209<br />

15<br />

Respirator<br />

North respirator (complete) .... L034-200

TROUBLESHOOTING GUIDE<br />

Provided you have followed the instructions, the <strong>spray</strong> system will operate efficiently and give trouble-free service.<br />

Should any unexpected problem arise you can, in most cases, remedy the problem by following the chart below. If you<br />

find that you cannot correct the problem, then take the <strong>spray</strong>er to your nearest authorized service agency. Many of the<br />

“causes” listed are unlikely to happen. However, all are included in an attempt to cover every possibility.<br />

IT IS ABSOLUTELY ESSENTIAL FOR TROUBLE-FREE OPERATION THAT YOUR SPRAY SYSTEM BE KEPT<br />

CLEAN AND FREE OF RESIDUAL PAINT BUILD-UP ON THE INTERNAL PARTS. IT MUST BE CLEANED AND<br />

LUBRICATED AFTER EVERY USE.<br />

Problem<br />

1 Will not <strong>spray</strong><br />

2 Poor Spray Pattern<br />

3 Spray Fan Fluttering<br />

4 Gun Drips or Will Not<br />

Shut Off<br />

5 Loses Prime<br />

6 Needle Packings<br />

Leak<br />

7 Pressure pot requires<br />

over 20 psi material<br />

pressure to get wet<br />

coat<br />

8 Getting runs on<br />

workpiece<br />

9 Spray fan heavy in<br />

center (pressure<br />

feed only)<br />

10 Gun is too slow,<br />

producing<br />

“dry” <strong>spray</strong><br />

11 Excessive over<strong>spray</strong><br />

Cause<br />

1) Volume control knob adjustment<br />

2) <strong>Air</strong> pressure too low<br />

3) Paint too thick or orifice too small<br />

4) Dirty <strong>spray</strong> head<br />

5) Unmatched air cap or misaligned cap<br />

6) Loose seat<br />

7) Cup is not pressurizing (A711/A928 only)<br />

8) Pressure pot is not pressurizing<br />

1) Plugged air cap jets<br />

2) Damaged air cap<br />

3) <strong>Air</strong> pressure too low<br />

4) Paint too thick<br />

5) <strong>Air</strong> passages blocked in air cap, fluid<br />

nozzle partially plugged.<br />

6) Cup is not pressurizing (A711/A928 only)<br />

1) Suction pot swivel loose or dirty<br />

2) Plugged air vent or air feed on HVLP<br />

3) Loose needle packings<br />

4) Loose seat<br />

1) Dirty or worn needle and seat<br />

2) Paint pressure too high<br />

3) Packings too tight<br />

1) Dirty or worn needle and seat (A-900)<br />

2) Loose or worn packings (A-900)<br />

3) Dirty check valve (A-711)<br />

1) Loose or worn packing<br />

2) Paint pressure too high<br />

1) Nozzle too small<br />

2) Paint too thick<br />

1) Paint pressure too high<br />

2) Nozzle too large<br />

3) Paint too thin<br />

1) Paint pressure too high<br />

2) Nozzle too small<br />

1) Paint pressure too low<br />

2) Nozzle too small<br />

3) Paint too thick<br />

1) <strong>Air</strong> pressure too high<br />

Remedy<br />

1) Turn counter clockwise<br />

2) Increase air pressure<br />

3) Thin paint or change <strong>spray</strong> head<br />

4) Disassemble and clean<br />

5) Use correct air cap or tighten properly<br />

6) Tighten<br />

7) Check cup seal & check valve<br />

8) Clean regulated air inlet on underside of lid<br />

1) Clean<br />

2) Replace<br />

3) Increase air pressure<br />

4) Thin paint<br />

5) Remove and soak in solvent. Do not use metal<br />

probes to clean orifices as this will permanently<br />

damage them.<br />

6) Replace leaking cup gasket<br />

1) Tighten or clean<br />

2) Clean<br />

3) Tighten or replace<br />

4) Tighten<br />

1) Clean or replace<br />

2) Reduce pressure (pressure pot only)<br />

3) Readjust packing nut<br />

1) Clean or replace<br />

2) Tighten or replace<br />

3) Clean check valve (A-711 HVLP)<br />

1) Tighten or replace<br />

2) Reduce pressure (pressure pot only)<br />

1) Use larger size nozzle<br />

2) Thin paint more<br />

1) Reduce pressure (pressure pot only)<br />

2) Use smaller nozzle<br />

3) Thin paint less<br />

1) Reduce pressure (pressure pot only)<br />

2) Use larger size nozzle<br />

1) Increase pressure (pressure pot only)<br />

2) Use larger size nozzle<br />

3) Thin paint more<br />

1) Decrease air pressure.<br />

16

TROUBLESHOOTING GUIDE<br />

Problem<br />

12 Rough or “orange<br />

peel” finish<br />

13 Rough or “orange<br />

peel” finish<br />

(The atomized paint<br />

droplets are not<br />

flowing together to<br />

form a smooth, level,<br />

uniform surface).<br />

14 Blushing - clear<br />

coatings appearing<br />

milky<br />

15 Fish eyes - small<br />

pools on painted<br />

surface that will not<br />

fill<br />

16 Runs and sags<br />

17 Solvent pops or<br />

bubbles<br />

18 Boxer pump does<br />

not cycle.<br />

Cause<br />

1) <strong>Air</strong> pressure too low<br />

2) Paint pressure too high<br />

3) Paint too thick<br />

1) Droplets too large<br />

2) Droplets drying too fast to flow out<br />

3) Cold weather <strong>spray</strong>ing.<br />

Condensation of moisture trapped in the<br />

applied coating when <strong>spray</strong>ing in hot, humid<br />

conditions.<br />

Silicone contamination from lubricants,<br />

grease, polish of waxes on the surface being<br />

<strong>spray</strong>ed.<br />

Applying too much paint per pass for the<br />

drying conditions.<br />

Sprayed film surface drying before solvent gas<br />

can be released.<br />

1) <strong>Air</strong> supply is not connected.<br />

2) Dump valve is not open.<br />

3) Jammed air shifter.<br />

4) Damaged air shifter.<br />

Remedy<br />

1) Increase air pressure<br />

2) Reduce pressure (pressure pot only)<br />

3) Thin paint more<br />

1) Be sure to maintain proper gun distance, 4" to 8".<br />

Reduce material or use a smaller air cap. An air<br />

hose that is too long will reduce atomizing air.<br />

2) Keep object being <strong>spray</strong>ed out of direct sunlight.<br />

When <strong>spray</strong>ing in warmer temperatures use a<br />

slower evaporating solvent or a retarder.<br />

3) Try to keep material and object being <strong>spray</strong>ed as<br />

close to room temperature as possible. When<br />

<strong>spray</strong>ed on a cold surface most paints will<br />

become too thick to flow out properly.<br />

1) Store material off concrete floors at room temperature.<br />

2) Apply lighter coats and allow for proper dry time.<br />

3) Use a slower evaporating solvent or retarder.<br />

4) Do not <strong>spray</strong> in windy conditions.<br />

Clean all parts with a cleaning solvent. Use one<br />

solvent rag and a clean wiping rag. Change rags as<br />

required. If problem persists use a fish eye eliminator.<br />

1) Move gun faster or decrease material flow.<br />

2) Maintain proper gun distance.<br />

3) Reduce amount of thinner or use a faster drying<br />

thinner.<br />

1) Apply material in lighter coats to allow proper<br />

evaporation.<br />

2) Be sure to use recommended thinners.<br />

3) Follow steps above in "droplets too large” to<br />

increase atomization.<br />

1) Turn on.<br />

2) Open (handle inline with valve body).<br />

3) Shift air motor shifter manually to help identifiy<br />

problem. Push "side button".<br />

4) Replace shifter.<br />

19 Boxer pump cycles<br />

but does not draw up<br />

fluid.<br />

1) No fluid or suction tube not totally<br />

immersed in fluid.<br />

2) Suction filter clogged.<br />

3) Suction tube loose at inlet.<br />

4) Valve(s) stuck or dirty.<br />

1) Add more fluid or immerse suction tube in fluid.<br />

2) Clean or replace filter.<br />

3) Clean connection and tighten.<br />

4) Unstick valve balls and clean.<br />

20 Boxer pump pressurizes<br />

fluid but<br />

pressure is<br />

inconsistant.<br />

1) Inlet valve cap(s) loose and sucking air.<br />

2) One of the valve(s) stuck or dirty.<br />

3) Suction tube loose at inlet.<br />

4) Pump pressure too low.<br />

1) Clean & retighten or replace.<br />

2) Unstick valve balls and clean.<br />

3) Clean connection and tighten.<br />

4) Increase air regulator pressure setting.<br />

17

OTHER LEMMER PRODUCTS<br />

LEMMER'S Full line of <strong>equipment</strong> comes with FIRST CLASS SERVICE in numerous<br />

locations across CANADA, and a FULL ONE YEAR WARRANTY. For information on choosing the<br />

right <strong>spray</strong>er for your job, please contact your nearest LEMMER outlet.<br />

May 2002<br />

ELECTRIC CUP GUNS<br />

Hand held airless <strong>spray</strong>ers to <strong>spray</strong> all<br />

standard paints. They are suitable for<br />

large jobs where time is not a factor, and<br />

also for the professional to touch up after<br />

the large <strong>equipment</strong> is finished.<br />

AIR GUNS & PRESSURE POTS<br />

Conventional air <strong>spray</strong> guns for fine<br />

finishing. Suitable for countless industrial<br />

and automotive applications. Available in<br />

suction, gravity, and pressure feed<br />

versions. Each is available in many<br />

different needle sizes.<br />

HVLP TURBINE & VENTURI UNITS<br />

High Volume Low Pressure <strong>spray</strong>ers are<br />

used for fine finishing where over<strong>spray</strong><br />

must be kept to a minimum. The finish<br />

results are equal to or better than<br />

conventional air <strong>spray</strong>. The turbine<br />

systems are self contained and do not<br />

require an outside air source. The<br />

VENTURI <strong>spray</strong> gun only uses about 8<br />

CFM of shop air. Applications vary from<br />

automotive finishing to commercial multicolor<br />

architectural coating.<br />

AIRLESS ACCESSORIES<br />

A very large assortment of hoses, guns,<br />

tips, and filters, etc. These items are<br />

universal to most airless <strong>spray</strong> <strong>equipment</strong><br />

on the market.<br />

AUTOMATIC GUNS<br />

Suitable for all heavy duty airless applications.<br />

<strong>Air</strong> actuated, universal rod mounting,<br />

and standard 1/4" NPS hose connection.<br />

PAINTING SUNDRIES<br />

Overalls, strainer bags, stir rods, etc. A<br />

large variety of painting accessories to<br />

help make a cleaner and more efficient<br />

working environment.<br />

ELECTROSTATIC UNITS<br />

The electrostatic WRAP-A-ROUND<br />

charge makes this the best method of<br />

<strong>spray</strong>ing metal with next to no over<strong>spray</strong>.<br />

It is best suited for industrial paints with<br />