FDM magazine - AyA Kitchens and Baths

FDM magazine - AyA Kitchens and Baths

FDM magazine - AyA Kitchens and Baths

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

10 steps to lean manufacturing, p. 58<br />

a chartwell publication<br />

®<br />

For Builders of . Cabinets . Fixtures . Furniture . Millwork<br />

september 2003<br />

Cabinet<br />

producer off to<br />

fast start, p. 34<br />

Nesting — the<br />

inside story, p. 46<br />

15 wood waste<br />

ideas, p. 62<br />

Anatomy of<br />

a startup, p. 70<br />

visit us at www.fdmonline.com

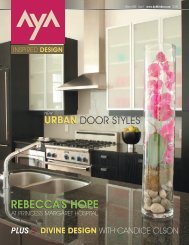

cabinets<br />

Charleston Glazed Mushroom is one of<br />

the styles <strong>AyA</strong> is offering. Company is<br />

producing mid- to upper-end cabinets.<br />

Cabinet<br />

producer<br />

off to fast start<br />

Toronto cabinet<br />

company uses<br />

advanced<br />

manufacturing<br />

methods to take<br />

advantage of a<br />

booming market.<br />

by Karl D. Forth<br />

kforth@chartcomm.com<br />

<strong>AyA</strong> <strong>Kitchens</strong> <strong>and</strong> <strong>Baths</strong> Ltd. identified<br />

a need in the market <strong>and</strong> set<br />

about filling that need. The company<br />

found an empty building, <strong>and</strong> assembled<br />

a state-of-the-art cabinet plant in<br />

Mississauga, Ont., with the current capacity<br />

to manufacture 70 kitchens per shift.<br />

Although the company is new (the plant<br />

went into operation in July 2001), the primary<br />

executives have plenty of experience.<br />

CEO Dave Martin worked for Canac<br />

<strong>Kitchens</strong> from 1986 to early 2000. Martin<br />

hired Peter Lorke to build the new plant.<br />

Lorke’s experience was in manufacturing<br />

office furniture, not kitchen cabinets, at<br />

Knoll.<br />

“What we applied from office furniture<br />

is mostly quality related: procedures, quality<br />

checks, documentation, working with<br />

numbers, colors <strong>and</strong> pictures to make it<br />

easy to train people,” Lorke says.<br />

Manufacturing methods used in the office<br />

furniture industry are typically more<br />

advanced <strong>and</strong> more flexible than in the<br />

kitchen cabinet industry. <strong>AyA</strong> documentation<br />

<strong>and</strong> manufacturing st<strong>and</strong>ards are similar<br />

to those used by ISO-certified<br />

manufacturers.<br />

<strong>AyA</strong> makes kitchen <strong>and</strong> bath cabinets,<br />

but also does some entertainment centers,<br />

closets, desks <strong>and</strong> bedroom furniture. Cabinet<br />

companies are doing more of these latter<br />

categories.<br />

Martin says <strong>AyA</strong> is producing mid- to<br />

upper-end cabinets. “We don’t go after a<br />

lot of the lower-end apartment work,” he<br />

says. “We’re in business to sell direct to<br />

builders <strong>and</strong> retail.”<br />

<strong>AyA</strong> got a big boost from the hot housing<br />

market in its hometown.<br />

p l a n t f a c t s<br />

<strong>AyA</strong> <strong>Kitchens</strong> <strong>and</strong> <strong>Baths</strong><br />

Mississauga, Ontario<br />

☛ Product: Kitchen <strong>and</strong> bath<br />

cabinets<br />

☛ Emplyees: 165 employees,<br />

106 in production<br />

☛ Plant size: 180,000 square feet;<br />

100,000 production<br />

☛ Annual sales: $18 million (U.S.) in<br />

2003<br />

www.<strong>AyA</strong>kitchens.com<br />

In the tenoning/edgeb<strong>and</strong>ing line pieces move from double-end tenoner at<br />

top, to one of two single-sided edgeb<strong>and</strong>ers in foreground. Boards are<br />

flipped 180 degrees <strong>and</strong> go through a second edgeb<strong>and</strong>er.<br />

2

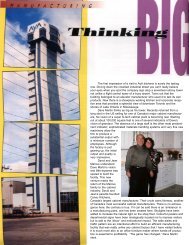

<strong>AyA</strong> was able<br />

to find an<br />

ideal location<br />

for its cabinet<br />

plant just<br />

outside<br />

Toronto,<br />

along with a<br />

bonus — an<br />

18-story<br />

tower.<br />

Sawing at <strong>AyA</strong> starts at lower left,<br />

with edgeb<strong>and</strong>ing <strong>and</strong> drilling<br />

beyond. The door department is to<br />

the right of the aisle.<br />

“The market here in Toronto is very<br />

strong, approaching 50,000 housing starts<br />

a year,” Martin says. “We realized that<br />

most of the other manufacturers were<br />

reaching their capacity levels, <strong>and</strong> most of<br />

them were l<strong>and</strong>locked <strong>and</strong> didn’t have the<br />

ability to exp<strong>and</strong>. The capacities were<br />

below what the dem<strong>and</strong> was.”<br />

There’s a showroom on site, <strong>and</strong> <strong>AyA</strong><br />

sells in Toronto through company-owned<br />

locations, <strong>and</strong> in several locations in the<br />

United States, including Chicago, Charlotte,<br />

Atlanta, Florida, New York <strong>and</strong> Virginia,<br />

where Martin spent eight years<br />

developing markets. He is expecting sales<br />

for 2003 to be $18 million (U.S.), which<br />

he expects to double next year.<br />

About 70 percent of <strong>AyA</strong>’s business is<br />

in Ontario, <strong>and</strong> 30 percent in the U.S. “By<br />

this time next year it will be the opposite,”<br />

Martin says.<br />

To take advantage of the hot local market,<br />

the Mississauga building, just a few<br />

blocks west of Toronto, proved to be almost<br />

ideal. The building was large enough<br />

to h<strong>and</strong>le the production <strong>AyA</strong> planned,<br />

with additional space for expansion. As a<br />

bonus, the building has an 18-story tower<br />

previously used to test elevators.<br />

“It’s the greatest signpost around,” Martin<br />

says. “Our challenge now is to get people<br />

to associate the tower with our<br />

business.”<br />

<strong>AyA</strong> was also fortunate to find good employees<br />

seeking greater opportunity <strong>and</strong> a<br />

shorter commute. The company employs<br />

165, with 106 in manufacturing.<br />

“We benefited from the fact that the<br />

office furniture industry slowed down the<br />

past two years, <strong>and</strong> we offered an excellent<br />

opportunity to people who had reduced<br />

hours <strong>and</strong> didn’t see any advancement in<br />

their own companies,” Martin says.<br />

Production planning<br />

The manufacturing process begins each<br />

Wednesday, when raw materials are purchased<br />

<strong>and</strong> production planned for the following<br />

week. Similar kitchens are grouped<br />

together <strong>and</strong> that batch is given a color, one<br />

of nine that is constantly rotated. Sheets of<br />

paper with that color are taped to each machine<br />

working on that job. Starting dates of<br />

different functions in the plant are staggered<br />

depending on shipment date.<br />

Lorke organized the 100,000-squarefoot<br />

manufacturing floor into cells: cutting,<br />

edgeb<strong>and</strong>ing, drilling, custom work,<br />

door department, finishing, assembly <strong>and</strong><br />

shipping. There is a manager for each five<br />

In <strong>AyA</strong>’s drilling section a Weeke Optimat BP 145 machining center is used<br />

along with a smaller Optimat <strong>and</strong> a Weeke BET 500, which does a large share<br />

of the drilling. Gluing <strong>and</strong> dowel insertion are h<strong>and</strong>led by two Koch machines.<br />

<strong>AyA</strong> combined manufacturing talents<br />

<strong>and</strong> office furniture background of<br />

Peter Lorke, left, <strong>and</strong> kitchen cabinet<br />

experience of Dave Martin, right.<br />

3

cabinet<br />

producer<br />

to 30 employees.<br />

The plant can produce 70 kitchens a<br />

shift at full capacity, but it is now producing<br />

an average of 30 kitchens a day.<br />

Lorke, a native of Germany, is a big proponent<br />

of Homag equipment. In the cutting<br />

cell are three Holzma saws, two HPL<br />

33 models <strong>and</strong> one HPL 11, <strong>and</strong> two Altendorf<br />

F45 sliding table saws.<br />

Most edgeb<strong>and</strong>ing is done on a single<br />

line with several machines. Two Homag<br />

Door department assembles doors<br />

from purchased components <strong>and</strong><br />

pieces cut here. A door is s<strong>and</strong>ed<br />

on a Viet widebelt s<strong>and</strong>er before<br />

going to the finishing department.<br />

double-end tenoners are used to produce<br />

the final edge cut (one machine does two<br />

sides, the board is flipped 180 degrees <strong>and</strong><br />

the second does the other two sides). Next<br />

are two single-sided Homag Profimat<br />

edgeb<strong>and</strong>ers in a row, <strong>and</strong> then another<br />

double-end tenoner, a Homag Profi-Line,<br />

that removes 2-1/2 mm from each edge,<br />

<strong>and</strong> cuts a groove in the back, if needed.<br />

Every part of the carcase can be done on<br />

this line. Employees on opposite ends of<br />

the line communicate with headsets. A<br />

separate edgeb<strong>and</strong>er, that is longer <strong>and</strong><br />

has a 24-edgeb<strong>and</strong> <strong>magazine</strong>, is used for<br />

shelves <strong>and</strong> rails.<br />

In <strong>AyA</strong>’s drilling section a Weeke BET<br />

500 is seen by Lorke as being the workhorse.<br />

It does a large share of the drilling,<br />

working with a Weeke BST 500 dowel inserter.<br />

Drilling is also done by a<br />

Weeke Optimat BP 145 machining<br />

center, <strong>and</strong> a smaller Optimat. Gluing<br />

<strong>and</strong> dowel insertion is also h<strong>and</strong>led<br />

by a Koch 310, <strong>and</strong> a new larger<br />

Koch BDB feedthrough machine.<br />

A small custom department uses<br />

a Weeke Optimat BP 85 for smaller<br />

volume, special work.<br />

Doors <strong>and</strong> finishing<br />

The door department is separated from<br />

the other functions by an aisle that runs<br />

the length of the plant. Outside suppliers<br />

deliver most of the door stiles, rails <strong>and</strong><br />

raised veneer center panels. <strong>AyA</strong> keeps an<br />

inventory of r<strong>and</strong>om-length solid wood<br />

panels for the other 20 percent of doors,<br />

which are cut there. The door department<br />

has a Voorwood A112<br />

shaper/s<strong>and</strong>er, Friulmac double-end<br />

tenoner, Hoffmann double-miter<br />

saw, <strong>and</strong> two clamp carriers. Two<br />

Homag double-end tenoners determine<br />

that the door is square. Three<br />

Viet widebelt s<strong>and</strong>ers complete the<br />

door department.<br />

There is a staging area for finishing,<br />

the next cell. Two finishing lines are<br />

in operation, with a third on order,<br />

Lorke says. The staining line starts<br />

with a Heesemann KSM2 s<strong>and</strong>er.<br />

Stain is applied by a Cattanair Rotoclean<br />

rotary spray booth, a process that Lorke<br />

says works especially well for raised panel<br />

doors. Both front <strong>and</strong> back are stained. A<br />

second finishing line applies sealer <strong>and</strong><br />

topcoat with a Cattinair EP2M UV curing<br />

unit.<br />

Pieces are fed into four assembly lines<br />

(two are currently used), each with a Ligmatech<br />

case clamp. Custom units come into assembly<br />

separately. Blum hardware <strong>and</strong><br />

insertion machines are used.<br />

Will the cabinet market continue to<br />

grow? “I believe it will,” Martin says. “One<br />

of the things we know in North America is<br />

that during this economic downswing,<br />

housing has stayed extremely strong.<br />

“<strong>AyA</strong> has a lot of capacity, <strong>and</strong> we’re diversifying<br />

our markets as quickly as possible.<br />

We are such a small player in those<br />

markets that our ability to gain market<br />

share is huge. In the next six months we<br />

expect to at least double production. I<br />

don’t see that as a challenge.” ▲<br />

Action in the finishing department.<br />

Doors are h<strong>and</strong> s<strong>and</strong>ed between a<br />

stain spray line in background,<br />

<strong>and</strong> a UV cure line.<br />

Custom software<br />

provides flexibility<br />

<strong>AyA</strong>’s Brad Budge, director of engineering<br />

<strong>and</strong> information technology,<br />

developed a completely custom software<br />

package called Manufacturing Manager<br />

that is primarily based on SQL technology,<br />

with more flexibility <strong>and</strong> the ability to<br />

track rework.<br />

“We created a well thought-out database<br />

design <strong>and</strong> built our business rules<br />

around it,” Budge says. “It gave us reliability<br />

on information <strong>and</strong> unprecedented<br />

speed. We went from a whole week to<br />

compile <strong>and</strong> print manufacturing information<br />

to only three hours.”<br />

The only major project was the order<br />

entry system, <strong>and</strong> creating simple GUI<br />

applications for different departments to<br />

access the data. Budge says there was<br />

very little application development.<br />

“I would only consider purchasing<br />

software if it is highly specialized,”<br />

Budge says. “You cannot beat the overall<br />

advantages creating it in house. The<br />

programming tools <strong>and</strong> database functionality<br />

today make things so easy.”<br />

Reprinted from <strong>FDM</strong> <strong>magazine</strong>,<br />

September, 2003 issue.<br />

©2003 Watt Publishing, Co.<br />

4