Scania Annual Report 2011

Scania Annual Report 2011

Scania Annual Report 2011

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

50 SCANIA’S SUSTAINABILITY WORK<br />

<strong>Scania</strong>’s environmental work<br />

<strong>Scania</strong> works actively to minimise both the resource consumption and the environmental impact<br />

of its products through out their life cycle. The environmental aspects are taken into account right<br />

from the development and investment stage to ensure that <strong>Scania</strong> can meet future requirements<br />

with the best applicable technology, do the right things from the start and eliminate waste.<br />

miljö – energi ENG<br />

Energy<br />

<strong>Scania</strong>’s environmental work is integrated into all its<br />

operations. In the production and service networks,<br />

environmental work is integrated into day-to-day efforts<br />

to achieve continuous improvements through a strong<br />

connection to the <strong>Scania</strong> Production System (SPS) and<br />

the <strong>Scania</strong> Retail System (SRS).<br />

Production units and service workshops are continuously<br />

evaluated in order to find examples of best<br />

practice that can be passed on to other parts of the<br />

organisation and to identify areas for improvement.<br />

Continuous improvements<br />

Improvement efforts are based on doing the right thing<br />

from the start and eliminating waste. Existing processes<br />

miljö – vatten ENG<br />

Water<br />

are examined to identify unnecessary, resourceintensive<br />

steps and to stimulate improved performance.<br />

Energy efficiency improvements are a high priority.<br />

There is continuous, systematic work with local energy<br />

surveys and action plans. Fossil fuels account for a<br />

steadily shrinking share of <strong>Scania</strong>’s energy use.<br />

There have been major efforts to reduce volatile<br />

organic compound (VOC) emissions, mainly focusing<br />

on a transition to painting systems with little or no VOC<br />

content. In São Paulo (Brazil), water-borne painting<br />

is being introduced. In Meppel (the Netherlands) and<br />

Słupsk (Poland), where solvent-borne paint is still used,<br />

purification equipment has been installed.<br />

miljö – kemikalier ChemicalsENG<br />

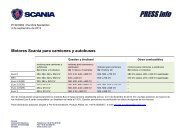

MWh per vehicle<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

07<br />

08<br />

09<br />

10<br />

Total, GWh<br />

11<br />

800<br />

600<br />

400<br />

200<br />

Energy use was slightly lower than<br />

2010 despite an increased production<br />

volume and was reduced to 7.7 MWh<br />

per vehicle produced.<br />

flyktiga organiska ämnen ENG<br />

VOC emissions<br />

0<br />

m 3 per vehicle Total, m 3<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

07<br />

08<br />

09<br />

10<br />

11<br />

koldioxid produktion ENG<br />

1,000,000<br />

800,000<br />

600,000<br />

400,000<br />

200,000<br />

The trend towards reduced water<br />

use per vehicle produced continued<br />

and stood at 6.5 m 3 per vehicle.<br />

Carbon dioxide from production<br />

0<br />

Oil/Greases<br />

Cutting fluids<br />

Cleaning agents<br />

Paint, water-borne<br />

Paint, solvent-borne<br />

Paint, powder<br />

Anti-corrosive agents<br />

Solvents<br />

Foundry chemicals<br />

Other chemicals<br />

0 200 400 600 800 1,000 1,200 m 3<br />

Chemical use totalled about 7,400 m 3 . Consumption per vehicle amounted to 88 litres,<br />

which represents approximately the same use of chemicals per produced vehicle as last<br />

Deponering av avfall ENG<br />

year (89 litres).<br />

koldioxid godstransporter ENG<br />

Carbon dioxide from goods transport<br />

Waste sent to landfills<br />

Kg per vehicle<br />

Total, tonnes<br />

18<br />

600<br />

16<br />

500<br />

14<br />

12<br />

400<br />

10<br />

300<br />

8<br />

6<br />

200<br />

4<br />

100<br />

2<br />

0 0<br />

07 08 09 10 11<br />

Ton per vehicle<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

07 08<br />

09<br />

Total, ktonnes<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

10 11<br />

Distribution of<br />

parts in the EU<br />

and Brazil, 12%<br />

Vehicles<br />

deliveries,<br />

23%<br />

Transport to and from<br />

<strong>Scania</strong>’s production<br />

units, 40%<br />

Airfreight global, 25%<br />

Kg per vehicle<br />

300<br />

240<br />

180<br />

120<br />

60<br />

0<br />

07 08<br />

09<br />

10<br />

Total, tonnes<br />

8,000<br />

6,000<br />

4,000<br />

2,000<br />

0<br />

11<br />

Volatile organic compound (VOC)<br />

emissions amounted to 4.0 kg per<br />

vehicle produced, which represents<br />

approximately the same emissions<br />

per vehicle as last year (3.9 kg).<br />

Carbon dioxide emissions decreased<br />

despite higher production volume.<br />

Total emissions fell to 0.94 tonnes per<br />

vehicle produced, a reduction of more<br />

than 20 percent compared to 2010.<br />

In <strong>2011</strong>, <strong>Scania</strong>’s goods transport-related<br />

emissions totalled 233,000 tonnes.<br />

Recycling continued to increase. In<br />

<strong>2011</strong>, <strong>Scania</strong> disposed of 83,200<br />

tonnes of waste (excluding foundry<br />

sand), of which nearly 85 percent was<br />

used in order to recycle materials and<br />

recover energy. Waste sent for off-site<br />

disposal, mainly classified as hazardous,<br />

totalled 8,100 tonnes.<br />

<strong>Report</strong> of the directors <strong>Scania</strong> <strong>2011</strong>