Scania Annual Report 2011

Scania Annual Report 2011

Scania Annual Report 2011

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

38 production<br />

Greater flexibility with new agreement<br />

During the summer, <strong>Scania</strong> reached a new agreement<br />

with the Swedish Metal Workers’ Union as part of the<br />

company’s efforts to boost flexibility at its production<br />

units in Sweden. The agreement regulates flexible<br />

working hours and flexible staffing and is an important<br />

element of <strong>Scania</strong>’s ability to respond to rapid changes<br />

in demand. It also increases <strong>Scania</strong>’s chances of retaining<br />

core competency at its Swedish production units in<br />

the long term.<br />

Under the new agreement, most flexible staffing will<br />

consist of personnel from staffing companies. The share<br />

of total production employees consisting of flexible staffing<br />

will not exceed 30 percent.<br />

Close collaboration with sub-contractors<br />

Of <strong>Scania</strong>’s total production costs, about 70 percent<br />

consist of purchased materials and components. Most<br />

of <strong>Scania</strong>’s sub-contractors have had a long-term<br />

relationship with the company. This allows for close<br />

cooperation, where a supplier’s production is increasingly<br />

integrated into <strong>Scania</strong>’s production network. This<br />

has clear benefits for <strong>Scania</strong>’s customers by means of<br />

higher product quality and reliability.<br />

For example, such cooperation includes training in<br />

the <strong>Scania</strong> Production System (SPS), help with improving<br />

the efficiency of production equipment and logistics<br />

as well as environmental work.<br />

<strong>Scania</strong> is also expanding its cooperation with bodybuilding<br />

companies that supply and assemble special<br />

equipment on vehicles. Integrating bodybuilding companies<br />

more closely into the chain leads to substantial<br />

time savings for the customer from the order date until a<br />

vehicle goes into operation and also broadens <strong>Scania</strong>’s<br />

business.<br />

Increase in capacity<br />

While ensuring the flexibility to meet short-term fluctuations,<br />

<strong>Scania</strong> has decided to raise its annual technical<br />

production capacity, with the aim of reaching 120,000<br />

vehicles from about 100,000 at present. Investments<br />

to achieve a 120,000 vehicle capacity will total about<br />

SEK 1.5 billion during a three-year period.<br />

This increase is a step on the way towards reaching a<br />

technical production capacity of 150,000 vehicles by the<br />

next peak in the economic cycle. This can be achieved<br />

with limited investments at the existing production units<br />

due to the gains in efficiency that are continually being<br />

achieved by working according to the <strong>Scania</strong> Production<br />

System (SPS).<br />

The largest investments in new capacity will occur<br />

at engine and cab production units in both Europe and<br />

Latin America.<br />

New regional product centre<br />

<strong>Scania</strong>’s strategy is to strengthen its position in key<br />

emerging markets by establishing regional product<br />

centres for assembling, bodyworking and fitting out<br />

locally-adapted vehicles. <strong>Scania</strong> is thus moving the<br />

factory gate closer to the customer, resulting in shorter<br />

delivery times and a major improvement in customer<br />

support. The task of opening a new facility in India has<br />

begun.<br />

Global healthy attendance<br />

%<br />

100<br />

75<br />

50<br />

25<br />

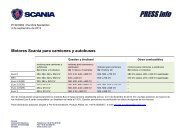

Antal producerade fordon per anställd<br />

Number of vehicles produced per employee<br />

Medarbetare – frisknärvaro globalt ENG<br />

Vehicles<br />

Employees<br />

Vehicles produced<br />

per employee<br />

78,300 80,400 84,000<br />

Production Sales and services<br />

units<br />

operations<br />

6.8<br />

67,700<br />

7.2<br />

96.3 96.3 97.2 97.5<br />

55,600 6.6<br />

6.6<br />

31,800<br />

3.0<br />

46,400<br />

3.5<br />

4.8<br />

3.8<br />

35,800<br />

12,000 13,100 11,600 11,800 11,800 9,500 10,300 11,700<br />

Number of employees*, <strong>2011</strong><br />

Södertälje 10,640<br />

São Paulo 3,527<br />

Oskarshamn 1,690<br />

Zwolle 1,460<br />

Słupsk 706<br />

Angers 590<br />

Luleå 585<br />

Tucumán 568<br />

0<br />

10<br />

11<br />

10<br />

11<br />

90 95 00 07 08 09 10 11<br />

Global healthy attendance<br />

among employees at <strong>Scania</strong>’s<br />

production units remained at<br />

the same level as in 2010.<br />

In <strong>2011</strong>, productivity reached its highest-ever level. This was a result<br />

of <strong>Scania</strong>’s day-to-day efforts to achieve continuous improvements,<br />

thereby also eliminating waste of time and materials as well as environ -<br />

mental waste. Vehicle production reached its highest-ever level, with<br />

84,000 units produced during the year.<br />

* Refers to the total number<br />

of employees at <strong>Scania</strong>’s<br />

production sites.<br />

<strong>Report</strong> of the directors <strong>Scania</strong> <strong>2011</strong>