Instructions for use I - Hofmann Megaplan

Instructions for use I - Hofmann Megaplan

Instructions for use I - Hofmann Megaplan

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

3.3 - PNEUMATIC CONNECTION (P version)<br />

For the operation of the spindle with pneumatic locking, (constant thrust gas springs) connect the machine<br />

to the compressed air mains. The connection Þ tting is on the rear of the machine. At least 7 kg/cm²<br />

(~0.7Mpa; ~ 7 BAR; ~ 100 PSI) are required <strong>for</strong> the correct operation of the locking device.<br />

3.4 - FURTHER SAFETY DEVICES (P version)<br />

- The wheel is always locked also in the event of insufÞ cient pressure during the balancing cycle.<br />

- A wheel check device with rotating block which prevents the wheel <strong>for</strong> slipping off the adapter in<br />

the event of accidental pressure on the wheel locking footswitch during the cycle. Always actuate the<br />

unlocking footswitch when the machine is stationary in order to avoid stress and abnormal wear on<br />

the adapter.<br />

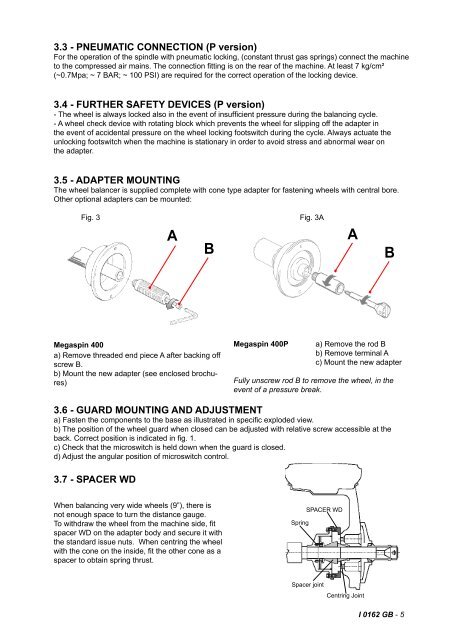

3.5 - ADAPTER MOUNTING<br />

The wheel balancer is supplied complete with cone type adapter <strong>for</strong> fastening wheels with central bore.<br />

Other optional adapters can be mounted:<br />

Fig. 3<br />

A<br />

B<br />

Fig. 3A<br />

A<br />

B<br />

Megaspin 400<br />

a) Remove threaded end piece A after backing off<br />

screw B.<br />

b) Mount the new adapter (see enclosed brochures)<br />

Megaspin 400P<br />

a) Remove the rod B<br />

b) Remove terminal A<br />

c) Mount the new adapter<br />

Fully unscrew rod B to remove the wheel, in the<br />

event of a pressure break.<br />

3.6 - GUARD MOUNTING AND ADJUSTMENT<br />

a) Fasten the components to the base as illustrated in speciÞ c exploded view.<br />

b) The position of the wheel guard when closed can be adjusted with relative screw accessible at the<br />

back. Correct position is indicated in Þ g. 1.<br />

c) Check that the microswitch is held down when the guard is closed.<br />

d) Adjust the angular position of microswitch control.<br />

3.7 - SPACER WD<br />

When balancing very wide wheels (9”), there is<br />

not enough space to turn the distance gauge.<br />

To withdraw the wheel from the machine side, Þ t<br />

spacer WD on the adapter body and secure it with<br />

the standard issue nuts. When centring the wheel<br />

with the cone on the inside, Þ t the other cone as a<br />

spacer to obtain spring thrust.<br />

Spring<br />

SPACER WD<br />

Spacer joint<br />

Centring Joint<br />

I 0162 GB - 5