AGFA d-lab.3 Digital Compact Lab

AGFA d-lab.3 Digital Compact Lab AGFA d-lab.3 Digital Compact Lab

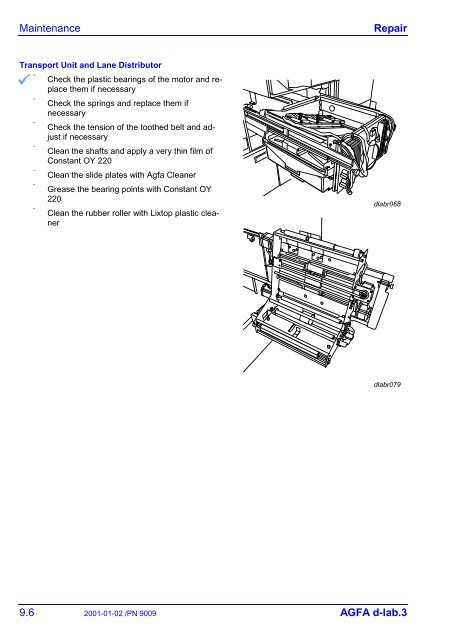

Maintenance Repair Transport Unit and Lane Distributor Check the plastic bearings of the motor and replace them if necessary Check the springs and replace them if necessary Check the tension of the toothed belt and adjust if necessary Clean the shafts and apply a very thin film of Constant OY 220 Clean the slide plates with Agfa Cleaner Grease the bearing points with Constant OY 220 Clean the rubber roller with Lixtop plastic cleaner dlabr068 dlabr079 9.6 2001-01-02 /PN 9009 AGFA d-lab.3

Repair Maintenance Paper Processor Whole Machine − Clean all chains, gears and bearings and grease them with Klübersynth Processing Racks Clean the racks and check them for smooth movement (25-60 Ncm) On all racks including the squeegee unit over the STB3 rack: Check the gears, roller shafts, slide bearings and springs for damage / wear and replace them if necessary Check the position of the slide bearings: The nipple points to the inside (see figure) − Two squeeze rollers are the most critical points in all racks (see arrows in figure above). The stress is the strongest in the CD racks because they are very close to the liquid level: − Check the backlash of the squeeze rollers with AGFA Prestige paper or similar − If necessary, replace the bottom rollers (P3-E5146) and the squeeze rollers (P3-86682) − Replace all sponge rubber rollers for STB in the squeegee area − Clean the bearing points and remove the crystals in this area − To protect the dry running bearing points (above the liquid level) from the penetration of chemistry (crystals) and keep the rack torque small at the same time, the chemical-resistant Klüberplex (sealing grease) is recommended: Apply an evenly thin film on the shaft bearing points (take out the bearings and grease the inside). roll_02 AGFA d-lab.3 2001-01-02 /PN 9009 9.7

- Page 389 and 390: Repair Paper Processor Block Circui

- Page 393 and 394: Repair Paper Processor Signal Lists

- Page 395 and 396: Repair Paper Processor Paper Exit P

- Page 397 and 398: Repair Paper Processor Connections

- Page 401 and 402: Repair Paper Processor Functional D

- Page 403 and 404: Repair Paper Processor Electrical S

- Page 405 and 406: Repair Paper Processor Paper Proces

- Page 407 and 408: Repair Paper Processor AC/DC Power

- Page 409 and 410: Repair Paper Processor AC Power Sup

- Page 411 and 412: Repair Paper Processor Densitometer

- Page 415 and 416: Repair Paper Processor Repair Repla

- Page 417 and 418: Repair Paper Processor Replacing Pr

- Page 419 and 420: Repair Paper Processor Temperature

- Page 421 and 422: Repair Software Contents Software S

- Page 425 and 426: Repair Software Software Structure

- Page 427 and 428: Repair Software Software Structure

- Page 429 and 430: Repair Maintenance Contents Mainten

- Page 433 and 434: Repair Maintenance Maintenance Sche

- Page 435 and 436: Repair Maintenance Maintenance Jobs

- Page 437: Repair Maintenance Negative Mask: L

- Page 441 and 442: Repair Maintenance Cleaning the Eva

- Page 443 and 444: Repair Maintenance Paper Magazine A

- Page 445 and 446: Repair Maintenance Consumables / Cl

- Page 447 and 448: Repair General Data and Information

- Page 451 and 452: Repair General Data and Information

- Page 453 and 454: Repair General Data and Information

- Page 455 and 456: Repair General Data and Information

- Page 457 and 458: Repair General Data and Information

- Page 459 and 460: Repair General Data and Information

- Page 461 and 462: Repair General Data and Information

- Page 463 and 464: Repair Index Index A Additional Air

- Page 465 and 466: Repair Index S (cont.) Service Func

Maintenance<br />

Repair<br />

Transport Unit and Lane Distributor<br />

Check the plastic bearings of the motor and replace<br />

them if necessary<br />

Check the springs and replace them if<br />

necessary<br />

Check the tension of the toothed belt and adjust<br />

if necessary<br />

Clean the shafts and apply a very thin film of<br />

Constant OY 220<br />

Clean the slide plates with Agfa Cleaner<br />

Grease the bearing points with Constant OY<br />

220<br />

Clean the rubber roller with Lixtop plastic cleaner<br />

dlabr068<br />

dlabr079<br />

9.6 2001-01-02 /PN 9009 <strong>AGFA</strong> d-<strong>lab.3</strong>