d-lab.1 family Repair - Saal Digital Fotoservice GmbH

d-lab.1 family Repair - Saal Digital Fotoservice GmbH

d-lab.1 family Repair - Saal Digital Fotoservice GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

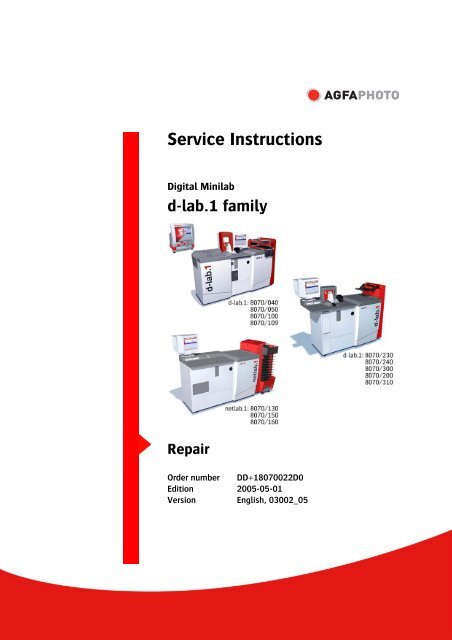

Service Instructions<br />

<strong>Digital</strong> Minilab<br />

d-<strong>lab.1</strong> <strong>family</strong><br />

<strong>Repair</strong><br />

Order number DD+18070022D0<br />

Edition 2005-05-01<br />

Version English, 03002_05

List of Chapters<br />

Edition<br />

Chapter<br />

Contents..................................................................2005-05-01 ...................0<br />

General ....................................................................2005-05-01 ...................1<br />

Basic Machine.......................................................2005-05-01 ...................2<br />

Software ..................................................................2005-05-01 ...................3<br />

Service / Diagnosis.............................................2005-05-01 ...................4<br />

Power Supply.........................................................2005-05-01 ...................5<br />

Computer System ................................................2005-05-01 ...................6<br />

Film Processor.......................................................2005-05-01 ...................7<br />

Scanner....................................................................2005-05-01 ...................8<br />

Printer ......................................................................2005-05-01 ...................9<br />

Paper Processor....................................................2005-05-01 ................10<br />

Maintenance..........................................................2005-05-01 ................11<br />

Index.........................................................................2005-05-01 ................12<br />

Preinstallation / Installation...........................2005-05-01 ................13

Modification History<br />

Version Edition Modifications<br />

03002_00 2004-01-02 Start Version<br />

03002_01 2004-04-01 Update<br />

03002_02 2004-06-01 Four Machine Variants<br />

New Software Version<br />

03002_03 2004-07-30 Modified Maintenance Kit (yearly)<br />

New Maintenance Kit (every second year)<br />

Updated chapters do to new software versions 8.00x<br />

03002_04 2004-12-15 Updated chapters due to new software versions 9.00x<br />

03002_05 2005-05-01 Twelve Machine Variants<br />

Published in compliance with EN 55022 (valid in EU):<br />

Warning!<br />

The equipment complies with the limits for a Class A device. Operation of the equipment<br />

in residential areas may cause radio interference in which case the user at his own<br />

expense will be requested to take whatever measures may be required to correct the<br />

interference.<br />

© 2005 AgfaPhoto <strong>GmbH</strong>. All rights reserved.<br />

No part of these instructions may be reproduced, copied, or transmitted in any form or by<br />

any means without prior written permission by AgfaPhoto <strong>GmbH</strong>.<br />

AgfaPhoto is used under license of Agfa-Gevaert AG.

d-<strong>lab.1</strong> <strong>family</strong>: <strong>Repair</strong><br />

Contents<br />

Contents<br />

1 General .............................................................................................................................1-1<br />

1.1 Available Documentation...........................................................................................................................................1-1<br />

1.2 <strong>Repair</strong>.................................................................................................................................................................................1-1<br />

1.2.1 Guideline for the Technician.................................................................................................................1-2<br />

1.2.2 Means of Representation........................................................................................................................1-3<br />

1.2.2.1 Text Styles and Symbols...............................................................................................1-3<br />

1.2.2.2 Safety Notes......................................................................................................................1-3<br />

1.3 Machine ............................................................................................................................................................................1-4<br />

1.3.1 Standards and Rules.................................................................................................................................1-4<br />

1.3.2 CE Symbol ....................................................................................................................................................1-4<br />

1.3.3 Use ..................................................................................................................................................................1-5<br />

1.3.3.1 Purpose................................................................................................................................1-5<br />

1.3.3.2 Appropriate Use................................................................................................................1-5<br />

1.3.3.3 Inappropriate Use............................................................................................................1-5<br />

1.4 Manufacturer...................................................................................................................................................................1-6<br />

1.4.1 Warranty........................................................................................................................................................1-6<br />

1.4.2 Exclusion of Liability.................................................................................................................................1-6<br />

1.4.3 Manufacturer Information ......................................................................................................................1-6<br />

1.5 Legal Situation ...............................................................................................................................................................1-7<br />

1.5.1 Safety Notes ................................................................................................................................................1-7<br />

1.5.1.1 Terms for Users.................................................................................................................1-7<br />

1.5.1.2 General................................................................................................................................1-8<br />

1.5.1.3 Installation.........................................................................................................................1-8<br />

1.5.1.4 Transport.............................................................................................................................1-8<br />

1.5.1.5 Operation............................................................................................................................1-9<br />

1.5.1.6 Service / <strong>Repair</strong>s ..........................................................................................................1-10<br />

1.5.1.7 Warnings and Information Labels on the Machine .........................................1-11<br />

1.6 Handling of Processing Chemicals......................................................................................................................1-14<br />

1.6.1 Safety Instructions .................................................................................................................................1-14<br />

2 Basic Machines..................................................................................................................2-1<br />

2.1 Versions.............................................................................................................................................................................2-1<br />

2.2 Versions (Illustrations).................................................................................................................................................2-1<br />

2.2.1 d-<strong>lab.1</strong> with Film Processor ...................................................................................................................2-1<br />

2.2.2 d-<strong>lab.1</strong>s..........................................................................................................................................................2-2<br />

2.2.3 net<strong>lab.1</strong> .........................................................................................................................................................2-3<br />

2.2.4 Overview (Table).........................................................................................................................................2-4<br />

2.3 Complete Machine .......................................................................................................................................................2-5<br />

2.3.1 Main Components.....................................................................................................................................2-5<br />

2.3.2 Components ................................................................................................................................................2-7<br />

2.4 List of Machine Parts ...................................................................................................................................................2-8<br />

3 Software............................................................................................................................3-1<br />

3.1 Software installation....................................................................................................................................................3-1<br />

3.1.1 Save customer settings and data base..............................................................................................3-1<br />

3.1.2 Installation of the Operating System MPU......................................................................................3-2<br />

3.1.3 First Installation of the d-<strong>lab.1</strong> Main Software...............................................................................3-4<br />

3.1.4 Update of the Operating System MPU ..............................................................................................3-9<br />

3.2 Error Messages ............................................................................................................................................................3-12<br />

3.2.1 Film Processor (FP), only d-<strong>lab.1</strong>with Film Processor ...............................................................3-13<br />

3.2.2 Scanner (SC) .............................................................................................................................................3-24<br />

3.2.3 Print Engine (PE) / Exposure Controller (EC)................................................................................3-37<br />

3.2.4 Paper Advance (PA)................................................................................................................................3-42<br />

3.2.5 Paper Processor (PP)..............................................................................................................................3-45<br />

3.2.6 Timer (TI) ....................................................................................................................................................3-55<br />

AgfaPhoto 2005-05-01 / PN 03002_05 0-i

Contents<br />

d-<strong>lab.1</strong> <strong>family</strong>: <strong>Repair</strong><br />

3.2.7 Messages (Custom Errors) ................................................................................................................... 3-56<br />

3.2.7.1 Film Prozessor (FP), only d-<strong>lab.1</strong> allrounder....................................................... 3-56<br />

3.2.7.2 Scanner (SC)...................................................................................................................3-56<br />

3.2.7.3 Exposure Controller (EC)............................................................................................ 3-56<br />

3.2.7.4 Paper Advance (PA) ..................................................................................................... 3-57<br />

3.2.7.5 Paper Processor (PP) ................................................................................................... 3-57<br />

3.2.7.6 IP / IPP............................................................................................................................. 3-58<br />

3.2.7.7 Software........................................................................................................................... 3-60<br />

3.2.7.8 Timer................................................................................................................................. 3-61<br />

3.2.8 Messages (Custom Info)....................................................................................................................... 3-62<br />

3.3 Production Statistics (Clickrate)........................................................................................................................... 3-65<br />

3.3.1 Recorded Data ......................................................................................................................................... 3-65<br />

3.3.2 Type of Saving ......................................................................................................................................... 3-65<br />

3.3.3 Export of Data .......................................................................................................................................... 3-65<br />

3.3.4 Fetching Data........................................................................................................................................... 3-66<br />

3.3.5 Installation and Deinstallation of the Software Clickrate ...................................................... 3-66<br />

3.3.6 Additional Tools supplied by AgfaPhoto........................................................................................ 3-66<br />

3.3.6.1 ClickrateReport.mdb ................................................................................................... 3-66<br />

3.3.6.2 ClickrateChecker.exe .................................................................................................. 3-66<br />

4 Service / Diagnosis............................................................................................................ 4-1<br />

4.1 Scripts................................................................................................................................................................................4-1<br />

4.1.1 Overview of the Script Folder ...............................................................................................................4-1<br />

4.2 Scripts for Service (Folder).........................................................................................................................................4-2<br />

4.2.1 Exposure Controller ..................................................................................................................................4-2<br />

4.2.2 Film Processor ............................................................................................................................................4-4<br />

4.2.3 General..........................................................................................................................................................4-6<br />

4.2.4 Initialization ................................................................................................................................................4-7<br />

4.2.5 Paper Advance (Paper Drive).................................................................................................................4-8<br />

4.2.6 Paper Processor....................................................................................................................................... 4-12<br />

4.2.7 Scanner ...................................................................................................................................................... 4-15<br />

4.2.8 Setup........................................................................................................................................................... 4-20<br />

4.3 Passwords...................................................................................................................................................................... 4-22<br />

4.4 Remote Diagnosis via Modem.............................................................................................................................. 4-23<br />

4.4.1 Netsupport Manager for the d-lab ................................................................................................... 4-24<br />

4.4.1.1 Prerequisites ..................................................................................................................4-24<br />

4.4.1.2 Setup in the d-lab ........................................................................................................ 4-24<br />

4.4.1.3 Deactivate Timer Card Watchdog ON for Remote Access via Modem.... 4-29<br />

4.5 Log Views and Log Levels....................................................................................................................................... 4-30<br />

4.6 Watchdog...................................................................................................................................................................... 4-32<br />

4.6.1 Introduction.............................................................................................................................................. 4-32<br />

4.6.2 Operation and User Interface............................................................................................................. 4-32<br />

4.6.2.1 Overview.......................................................................................................................... 4-32<br />

4.6.2.2 Startup screen ............................................................................................................... 4-33<br />

4.6.2.3 Standard operator interface...................................................................................... 4-36<br />

4.6.3 Extended operator interface............................................................................................................... 4-37<br />

4.6.4 Keyboard Hooks ...................................................................................................................................... 4-39<br />

4.6.5 System Logbook...................................................................................................................................... 4-40<br />

4.6.5.1 Change of Log settings during operation............................................................ 4-41<br />

4.6.5.2 Browsing through the Logbook............................................................................... 4-41<br />

4.6.5.3 Overview of the existing filter functions............................................................. 4-42<br />

4.6.5.4 Display of the software versions ............................................................................ 4-43<br />

4.6.5.5 Registration codes....................................................................................................... 4-44<br />

4.6.6 Structure of the Software .................................................................................................................... 4-47<br />

4.6.6.1 Interface interprocess communication................................................................ 4-48<br />

4.6.6.2 Interface to the Timer card....................................................................................... 4-49<br />

0-ii 2005-05-01 / PN 03002_05 AgfaPhoto

d-<strong>lab.1</strong> <strong>family</strong>: <strong>Repair</strong><br />

Contents<br />

4.6.7 Sequence diagram..................................................................................................................................4-50<br />

4.6.7.1 d-<strong>lab.1</strong> startup ...............................................................................................................4-50<br />

4.6.7.2 Watch function..............................................................................................................4-50<br />

4.6.7.3 d-<strong>lab.1</strong> Shutdown .........................................................................................................4-51<br />

4.7 MC Data.........................................................................................................................................................................4-53<br />

4.7.1 Modify and save MC Data ...................................................................................................................4-53<br />

4.7.2 FP MC Data Lists (only d-<strong>lab.1</strong> allrounder)..................................................................................4-54<br />

4.7.3 PA MC Data List ......................................................................................................................................4-57<br />

4.7.4 PP MC Data List ......................................................................................................................................4-59<br />

5 Power Supply Units and PCBs .............................................................................................5-1<br />

5.1 Power Supply Units – Overview ..............................................................................................................................5-1<br />

5.2 Power Supply System..................................................................................................................................................5-2<br />

5.2.1 Power ON Sequence.................................................................................................................................5-2<br />

5.3 Main Power Supply.......................................................................................................................................................5-4<br />

5.3.1 Components of the Main Power Supply ...........................................................................................5-6<br />

5.3.2 Connections – Overview.........................................................................................................................5-7<br />

5.3.3 Fuses...............................................................................................................................................................5-8<br />

5.3.3.1 Fuses on AC Main Power Supply...............................................................................5-8<br />

5.3.3.2 Fuses on 90A-FUS............................................................................................................5-8<br />

5.3.3.3 Fuses on 90A-LPS............................................................................................................5-8<br />

5.3.4 Command of the Power Supply Units................................................................................................5-9<br />

5.3.4.1 Connection diagram: Activation of Power Supply PS1..................................5-10<br />

5.3.4.2 Connection diagram: Activation of Power Supply PS2..................................5-10<br />

5.3.4.3 Connection diagram: Activation of Power Supply PS3..................................5-11<br />

5.3.5 PCB 90A-LPS ............................................................................................................................................5-12<br />

5.3.6 Adjustment of the Power Supply Units ..........................................................................................5-13<br />

5.3.7 Connection diagrams: Pilot voltages..............................................................................................5-14<br />

5.3.7.1 Connection diagram +8V (PL) pilot voltage.......................................................5-14<br />

5.3.7.2 Connection diagram +24V (PL) pilot voltage ....................................................5-14<br />

5.3.8 Connection diagrams: Power Supply Units Paper Advance (PA) and<br />

Paper Processor (PP)..............................................................................................................................5-15<br />

5.3.8.1 Connection diagram +5V (CD) voltage ................................................................5-15<br />

5.3.8.2 Connection diagram +36V (PB) voltage..............................................................5-15<br />

5.3.8.3 Connection diagram +24V (PC) voltage..............................................................5-16<br />

5.3.8.4 Connection diagram +24V (PA) voltage..............................................................5-16<br />

5.3.9 Connection diagrams: Power Supply Units Scanner (SC), Print Engine (PE)<br />

and Densitometer...................................................................................................................................5-17<br />

5.3.9.1 Connection diagram +6.5V (AD) voltage.............................................................5-17<br />

5.3.9.2 Connection diagram –15V (AA) voltage..............................................................5-18<br />

5.3.9.3 Connection diagram +18V (AA) voltage..............................................................5-18<br />

5.3.9.4 Connection diagram +24V (FD) voltage ..............................................................5-19<br />

5.4 Film Processor Power Supply (only d-<strong>lab.1</strong> with Film Processor) ............................................................5-20<br />

5.4.1 Components of the Film Processor Power Supply.....................................................................5-21<br />

5.4.2 Connections – Overview......................................................................................................................5-21<br />

5.4.3 Fuses............................................................................................................................................................5-22<br />

5.4.3.1 Fuses on 90P-SSR.........................................................................................................5-22<br />

5.4.4 Command of the Film Processor Power Supply Unit ................................................................5-22<br />

5.5 PCBs ................................................................................................................................................................................5-23<br />

5.5.1 Functions of the most important PCBs ..........................................................................................5-23<br />

5.5.2 Diagram: PCBs of the Paper Processor (PP), Paper Advance (PA) and Film<br />

Processor (FP)...........................................................................................................................................5-24<br />

5.5.3 Functions: LEDs and DIP Switches of the CPU PCBs ................................................................5-25<br />

5.5.3.1 LEDs...................................................................................................................................5-25<br />

5.5.3.2 DIP Switches..................................................................................................................5-25<br />

5.5.3.3 Replacing CPU PCBs ...................................................................................................5-26<br />

AgfaPhoto 2005-05-01 / PN 03002_05 0-iii

Contents<br />

d-<strong>lab.1</strong> <strong>family</strong>: <strong>Repair</strong><br />

6 Computer System .............................................................................................................. 6-1<br />

6.1 Version dependent Computer Systems ................................................................................................................6-1<br />

6.2 General Data...................................................................................................................................................................6-2<br />

6.2.1 Room conditions........................................................................................................................................6-2<br />

6.2.2 Power distribution and power supply of the components.........................................................6-2<br />

6.2.3 Power distribution and power supply of the components.........................................................6-2<br />

6.2.4 Network settings .......................................................................................................................................6-3<br />

6.2.5 Settings and Registry entries................................................................................................................6-3<br />

6.2.6 Product Security and Certificates........................................................................................................6-4<br />

6.3 Functional Description of the Main Processor Unit (MPU)............................................................................6-5<br />

6.3.1 Signal Diagram MPU................................................................................................................................6-6<br />

6.3.2 ON / OFF and Reset of the Computer System ...............................................................................6-8<br />

6.3.3 Interfaces / Connections........................................................................................................................6-9<br />

6.3.3.1 Serial Interfaces / 4-fach SIO (RS232)................................................................. 6-11<br />

6.3.4 Drives.......................................................................................................................................................... 6-12<br />

6.3.4.1 Dismounting the MPU drive..................................................................................... 6-12<br />

6.3.4.2 Jumper settings of the drive .................................................................................... 6-12<br />

6.3.5 Graphic card ............................................................................................................................................. 6-12<br />

6.3.6 Ethernet cards.......................................................................................................................................... 6-12<br />

6.3.7 Drive Module............................................................................................................................................ 6-13<br />

6.3.7.1 Power Supply for Drive Module.............................................................................. 6-13<br />

6.3.7.2 Card Reader (optional)................................................................................................ 6-14<br />

6.3.8 MPU Mainboard ...................................................................................................................................... 6-14<br />

6.3.8.1 MPU Mainboard connections .................................................................................. 6-15<br />

6.3.9 Operating System................................................................................................................................... 6-16<br />

6.3.10 Bios Settings ............................................................................................................................................ 6-16<br />

6.3.11 Touch Screen calibration..................................................................................................................... 6-22<br />

6.4 Functional Description of the Image Processor System (IPU)................................................................... 6-23<br />

6.4.1 Signal Diagram IPU ............................................................................................................................... 6-23<br />

6.4.2 Interfaces / Connections..................................................................................................................... 6-24<br />

6.4.2.1 Serial interface Timer board..................................................................................... 6-25<br />

6.4.3 Drives.......................................................................................................................................................... 6-28<br />

6.4.3.1 Dismounting the IPU drives..................................................................................... 6-28<br />

6.4.3.2 Jumper settings on the drives................................................................................. 6-28<br />

6.4.4 Graphic Card............................................................................................................................................. 6-29<br />

6.4.5 LVDS Card.................................................................................................................................................. 6-29<br />

6.4.6 Ethernet Card ........................................................................................................................................... 6-29<br />

6.4.7 IPU Mainboard......................................................................................................................................... 6-30<br />

6.4.7.1 IP Mainboard connections........................................................................................ 6-30<br />

6.4.8 Operating System................................................................................................................................... 6-31<br />

6.4.9 Bios Settings ............................................................................................................................................ 6-31<br />

6.5 Troubleshooting.......................................................................................................................................................... 6-36<br />

6.5.1 IPU does not start................................................................................................................................... 6-36<br />

6.5.1.1 Startup sequence of Computer system................................................................ 6-36<br />

6.5.1.2 Particularities during IPU software installation................................................ 6-38<br />

6.5.1.3 IP function test ............................................................................................................. 6-38<br />

6.5.1.4 Possible failures during IPU startup or operation ............................................ 6-41<br />

6.5.1.5 Possible failures during IPU startup...................................................................... 6-42<br />

6.5.1.6 Forced software installation of IPU ....................................................................... 6-44<br />

6.5.1.7 Manual start of IPU or MPU ..................................................................................... 6-45<br />

6.5.1.8 Connection diagram: Computer System ............................................................. 6-46<br />

6.5.1.9 Computer System Startup timing chart............................................................... 6-47<br />

6.6 Tools for Computer System Check ...................................................................................................................... 6-48<br />

6.6.1 COMTool .................................................................................................................................................... 6-48<br />

6.6.2 Drives.......................................................................................................................................................... 6-50<br />

6.6.3 LAN Test..................................................................................................................................................... 6-51<br />

0-iv 2005-05-01 / PN 03002_05 AgfaPhoto

d-<strong>lab.1</strong> <strong>family</strong>: <strong>Repair</strong><br />

Contents<br />

6.6.4 PuTTY...........................................................................................................................................................6-52<br />

6.6.5 Flash MPU with current BIOS and current settings...................................................................6-53<br />

6.6.6 Flash IPU with current BIOS and current settings......................................................................6-54<br />

6.6.7 HGST DFT Drive Fitness Test...............................................................................................................6-55<br />

6.6.8 Description of DFT Codes ....................................................................................................................6-67<br />

6.6.9 HGST Drive Feature Tool ......................................................................................................................6-68<br />

6.7 Maxtor Power Max Drivetest..................................................................................................................................6-71<br />

6.7.1 Memorytest...............................................................................................................................................6-71<br />

6.7.2 Boot OS for advanced tests.................................................................................................................6-72<br />

6.7.2.1 IntelPro DiagnosticTool .............................................................................................6-73<br />

6.8 Dismount the Computer System..........................................................................................................................6-78<br />

6.9 Installation of the Card Reader.............................................................................................................................6-79<br />

6.9.1 Hardware Installation............................................................................................................................6-80<br />

7 Film Processor ...................................................................................................................7-1<br />

7.1 Functional description.................................................................................................................................................7-1<br />

7.2 Assembly Groups in the Film Processor ...............................................................................................................7-1<br />

7.2.1 Location.........................................................................................................................................................7-1<br />

7.2.2 Designation and shortcuts .....................................................................................................................7-1<br />

7.3 Actuators and Sensors in the Film Processor .....................................................................................................7-2<br />

7.3.1 Designation and Shortcuts.....................................................................................................................7-3<br />

7.3.2 Funktion of the parts................................................................................................................................7-3<br />

7.3.3 Actuators and Sensors List.....................................................................................................................7-4<br />

7.4 Components of the Film Processor.........................................................................................................................7-9<br />

7.4.1 Main Drive....................................................................................................................................................7-9<br />

7.4.1.1 Checking the main drive ..............................................................................................7-9<br />

7.4.1.2 Replacing the main drive motor................................................................................7-9<br />

7.4.1.3 Lubricating the chains and sprocket gears.........................................................7-10<br />

7.4.2 Gear for Frequency Adjustment.........................................................................................................7-10<br />

7.4.2.1 Replacing the Gear 50 / 60 Hz...............................................................................7-10<br />

7.4.3 Loading Unit .............................................................................................................................................7-11<br />

7.4.3.1 Sensors.............................................................................................................................7-11<br />

7.4.3.2 Actuators..........................................................................................................................7-12<br />

7.4.4 Leader Cutter............................................................................................................................................7-13<br />

7.4.4.1 Function...........................................................................................................................7-13<br />

7.4.4.2 Actuators and Sensors................................................................................................7-13<br />

7.4.4.3 Motor positions (half steps)......................................................................................7-14<br />

7.4.5 Processing Racks ....................................................................................................................................7-15<br />

7.4.5.1 Replacing parts .............................................................................................................7-15<br />

7.4.6 Docking ......................................................................................................................................................7-17<br />

7.4.6.1 Actuators and Sensors................................................................................................7-18<br />

7.4.6.2 Replacing parts .............................................................................................................7-20<br />

7.4.7 Replenisher tanks...................................................................................................................................7-25<br />

7.4.7.1 Replacing parts .............................................................................................................7-25<br />

7.4.8 Effluent tanks...........................................................................................................................................7-26<br />

7.4.8.1 Checking parts...............................................................................................................7-26<br />

8 Scanner .............................................................................................................................8-1<br />

8.1 Designation of Assembly Groups and Shortcuts ...............................................................................................8-1<br />

8.2 Actuators and Sensors.................................................................................................................................................8-2<br />

8.2.1 General overview.......................................................................................................................................8-2<br />

8.2.2 Camera Module CM..................................................................................................................................8-3<br />

8.2.3 Lighting Module LM .................................................................................................................................8-3<br />

8.2.4 Scanner Frame SF......................................................................................................................................8-4<br />

8.2.5 Cartridge Feeder CF ..................................................................................................................................8-4<br />

8.2.6 Film Feeder FF.............................................................................................................................................8-5<br />

8.2.7 Film Supply FS............................................................................................................................................8-5<br />

8.2.8 Main Board MB...........................................................................................................................................8-6<br />

AgfaPhoto 2005-05-01 / PN 03002_05 0-v

Contents<br />

d-<strong>lab.1</strong> <strong>family</strong>: <strong>Repair</strong><br />

8.3 Functional Description................................................................................................................................................8-7<br />

8.3.1 Scanner data and signal paths.............................................................................................................8-7<br />

8.3.2 Integration into the global system.....................................................................................................8-8<br />

8.3.3 Driver Sensor Board (DS, SF_GS01)....................................................................................................8-9<br />

8.3.4 Scanner Motherboard ........................................................................................................................... 8-10<br />

9 Printer............................................................................................................................... 9-1<br />

9.1 Assembly Groups in the Printer...............................................................................................................................9-1<br />

9.1.1 Location ........................................................................................................................................................9-1<br />

9.1.2 Designation and shortcuts.....................................................................................................................9-1<br />

9.1.3 Designation and Shortcuts ....................................................................................................................9-2<br />

9.1.4 Funktion of the parts................................................................................................................................9-2<br />

9.2 Actuators and Sensors in the Exposure Unit.......................................................................................................9-3<br />

9.3 Exchange of the Print Engine ...................................................................................................................................9-4<br />

9.3.1 Demounting.................................................................................................................................................9-4<br />

9.3.2 Mounting......................................................................................................................................................9-5<br />

9.3.3 Copying correction files..........................................................................................................................9-6<br />

9.3.4 Calibrating the machine.........................................................................................................................9-6<br />

9.4 Actuators and Sensors in the Paper Advance (PA) ...........................................................................................9-7<br />

9.4.1 Actuators and Sensors Diagram...........................................................................................................9-7<br />

9.4.2 Actuators and Sensors List.....................................................................................................................9-8<br />

9.5 Paper Advance Sequence........................................................................................................................................ 9-12<br />

9.6 Components of the Paper Advance..................................................................................................................... 9-15<br />

9.6.1 Paper magazine drives ......................................................................................................................... 9-15<br />

9.6.1.1 Actuators ......................................................................................................................... 9-15<br />

9.6.1.2 Sensors............................................................................................................................. 9-16<br />

9.6.2 Transport Unit TU.................................................................................................................................... 9-17<br />

9.6.2.1 Actuators / Sensors..................................................................................................... 9-17<br />

9.6.2.2 Troubleshooting TU ..................................................................................................... 9-18<br />

9.6.2.3 Adjustment of paper transport and cut length ................................................. 9-20<br />

9.6.3 Auxiliary Paper Drive............................................................................................................................. 9-21<br />

9.6.3.1 Actuators / Sensors..................................................................................................... 9-21<br />

9.6.4 Exposure Unit........................................................................................................................................... 9-22<br />

9.6.4.1 Exposure table 55A-0102.......................................................................................... 9-22<br />

9.6.4.2 LED Exposure Unit........................................................................................................ 9-22<br />

9.6.4.3 Troubleshooting............................................................................................................ 9-23<br />

9.6.5 Lane Distributor LD................................................................................................................................ 9-24<br />

9.6.5.1 Actuators and Sensors................................................................................................ 9-24<br />

9.6.5.2 Troubleshooting LD ..................................................................................................... 9-26<br />

9.6.6 Back Printer.............................................................................................................................................. 9-27<br />

9.6.6.1 Actuators and Sensors................................................................................................ 9-27<br />

9.6.6.2 Back Printer Adjustment ........................................................................................... 9-28<br />

9.6.7 Shutter........................................................................................................................................................ 9-30<br />

9.6.7.1 Actuator ........................................................................................................................... 9-30<br />

10 Paper Processor............................................................................................................... 10-1<br />

10.1 Functional description.............................................................................................................................................. 10-1<br />

10.2 Assembly Groups in the Paper Processor.......................................................................................................... 10-1<br />

10.2.1 Location ..................................................................................................................................................... 10-1<br />

10.2.2 Designations and shortcuts................................................................................................................ 10-1<br />

10.3 Actuators and Sensors in the Paper Processor................................................................................................ 10-2<br />

10.3.1 Designation and Shortcuts ................................................................................................................. 10-3<br />

10.3.2 Funktion of the parts............................................................................................................................. 10-3<br />

10.3.3 Actuators and Sensors List.................................................................................................................. 10-4<br />

10.4 Components of the Paper Processor................................................................................................................... 10-9<br />

10.4.1 Switches..................................................................................................................................................... 10-9<br />

10.4.2 Main Drive................................................................................................................................................. 10-9<br />

10.4.2.1 Checking the main drive........................................................................................... 10-9<br />

10.4.2.2 Replacing the main Drive Motor..........................................................................10-10<br />

0-vi 2005-05-01 / PN 03002_05 AgfaPhoto

d-<strong>lab.1</strong> <strong>family</strong>: <strong>Repair</strong><br />

Contents<br />

10.4.3 Gear for Frequency Adjustment...................................................................................................... 10-10<br />

10.4.3.1 Replacing the Gear 50 / 60 Hz............................................................................ 10-10<br />

10.4.4 Processing Racks ................................................................................................................................. 10-11<br />

10.4.4.1 Replace worn parts................................................................................................... 10-11<br />

10.4.5 Rack drive and torque limiter ......................................................................................................... 10-12<br />

10.4.5.1 Replacing parts .......................................................................................................... 10-12<br />

10.4.6 Replenisher tanks................................................................................................................................ 10-13<br />

10.4.6.1 Replacing parts .......................................................................................................... 10-13<br />

10.4.7 Effluent tanks........................................................................................................................................ 10-14<br />

10.4.7.1 Checking parts............................................................................................................ 10-14<br />

10.4.8 Water Replenishment Tank ............................................................................................................. 10-15<br />

10.4.8.1 Functional description............................................................................................. 10-15<br />

10.4.9 Docking Station.................................................................................................................................... 10-16<br />

10.4.9.1 Functional description............................................................................................. 10-16<br />

10.4.9.2 Actuators and Sensors............................................................................................. 10-17<br />

10.4.9.3 Flow charts................................................................................................................... 10-20<br />

10.4.9.4 Timing............................................................................................................................ 10-25<br />

10.4.9.5 Troubleshooting ......................................................................................................... 10-26<br />

10.4.10 Dryer......................................................................................................................................................... 10-30<br />

10.4.10.1 Functional description............................................................................................. 10-30<br />

10.4.10.2 Temperature sensors dryer..................................................................................... 10-30<br />

10.4.11 Paper Exit................................................................................................................................................ 10-31<br />

10.4.11.1 Functional description............................................................................................. 10-31<br />

10.4.12 Densitometer......................................................................................................................................... 10-34<br />

10.4.12.1 Functional description............................................................................................. 10-34<br />

10.4.12.2 Technical Data............................................................................................................ 10-34<br />

10.4.12.3 Climatic conditions................................................................................................... 10-35<br />

10.4.12.4 Measuring characteristics...................................................................................... 10-35<br />

10.4.12.5 Zeroing .......................................................................................................................... 10-35<br />

10.4.12.6 Data rate (RS 232 Connection) ............................................................................ 10-35<br />

10.4.12.7 Interfaces......................................................................................................................10-35<br />

10.4.12.8 Jumper positions........................................................................................................ 10-36<br />

10.4.12.9 Measurement.............................................................................................................. 10-36<br />

10.4.12.10 MBL, PBL Test print .................................................................................................. 10-36<br />

10.4.12.11 Block circuit diagram of the 5.5 V power supply.......................................... 10-37<br />

10.4.12.12 7-Segment display.................................................................................................... 10-37<br />

10.4.12.13 Data output for MBL and PBL test print ........................................................... 10-38<br />

10.4.12.14 Densitometer Error Messages............................................................................... 10-38<br />

10.4.12.15 Generally valid Error Codes (independent of the machine or<br />

process) ......................................................................................................................... 10-41<br />

10.4.12.16 Error Codes specified for Process Control ........................................................ 10-41<br />

10.4.12.17 Error Codes specific for Grey Wedge Measurement..................................... 10-42<br />

10.4.12.18 Error Codes specific for FLASH Programming ................................................. 10-42<br />

10.4.12.19 Densitometer Types.................................................................................................. 10-43<br />

10.4.12.20 Sudden Density Change in the Print caused by the Densitometer........ 10-44<br />

10.4.12.21 Densi Error Messages when measuring the Test Print................................ 10-47<br />

10.4.12.22 Error: Densitometer communication time out ............................................... 10-48<br />

10.4.13 Lane Shifter LS...................................................................................................................................... 10-49<br />

10.4.13.1 Functional description............................................................................................. 10-49<br />

10.4.14 Sorter SO................................................................................................................................................. 10-50<br />

10.4.14.1 Functional description............................................................................................. 10-50<br />

10.4.14.2 Troubleshooting ......................................................................................................... 10-51<br />

11 Maintenance....................................................................................................................11-1<br />

11.1 Purpose ..........................................................................................................................................................................11-1<br />

11.2 Safety Prescriptions...................................................................................................................................................11-1<br />

11.3 To all Service Engineers...........................................................................................................................................11-2<br />

AgfaPhoto 2005-05-01 / PN 03002_05 0-vii

Contents<br />

d-<strong>lab.1</strong> <strong>family</strong>: <strong>Repair</strong><br />

11.4 Maintenance Kits (wearing Parts)........................................................................................................................ 11-3<br />

11.4.1 Kit for Maintenance – Yearly............................................................................................................. 11-3<br />

11.4.2 Kit for Maintenance – Every Second Year .................................................................................... 11-4<br />

11.5 Lubricants and Cleaning Agents........................................................................................................................... 11-5<br />

11.6 Special Tool.................................................................................................................................................................. 11-5<br />

11.7 Overview: Maintenance Jobs to be performed by the Service Engineer............................................... 11-6<br />

11.7.1 General machine .................................................................................................................................... 11-6<br />

11.7.2 All Paper magazines.............................................................................................................................. 11-6<br />

11.7.3 Paper magazine compartment left and right .............................................................................. 11-6<br />

11.7.4 Film Processor (FP)................................................................................................................................. 11-6<br />

11.7.5 Computer System (CS).......................................................................................................................... 11-7<br />

11.7.6 Scanner (SC) ............................................................................................................................................. 11-7<br />

11.7.7 Paper Advance (PA)................................................................................................................................ 11-7<br />

11.7.8 Paper Processor (PP).............................................................................................................................. 11-8<br />

11.7.9 End of the Maintenance Work (Machine ON).............................................................................. 11-9<br />

11.8 Overview: Maintenance Jobs to be performed by the Customer...........................................................11-10<br />

11.9 General machine......................................................................................................................................................11-11<br />

11.9.1 Cleaning the inside compartments...............................................................................................11-11<br />

11.10 Cleaning the Paper Magazines inside..............................................................................................................11-11<br />

11.11 Checking the Paper Magazine Compartments.............................................................................................11-11<br />

11.12 Film Processor (FP) (d-<strong>lab.1</strong> allrounder)...........................................................................................................11-12<br />

11.12.1 FP: Cleaning and checking the film loading units and the film magazines..................11-12<br />

11.12.2 FP: Lubricating the main drive chain and the motor gear, cleaning and<br />

lubricating the dryer............................................................................................................................11-12<br />

11.12.3 FP: Squeegee unit, replace worn parts if required...................................................................11-13<br />

11.12.4 FP: Cleaning the racks and replacing worn parts if required...............................................11-14<br />

11.12.5 FP: Cleaning the processing tanks.................................................................................................11-15<br />

11.12.6 FP: Servicing hoses, valves, circulation pumps.........................................................................11-16<br />

11.12.7 FP: Servicing the replenisher pumps ............................................................................................11-16<br />

11.12.8 FP: Servicing the Docking System.................................................................................................11-17<br />

11.12.8.1 Nozzle sets and Opener...........................................................................................11-17<br />

11.12.8.2 Locking mechanism of the docking door..........................................................11-21<br />

11.12.9 FP: Cleaning and lubricating the Leader cutter........................................................................11-22<br />

11.13 Computer System ....................................................................................................................................................11-23<br />

11.14 Scanner (SC)...............................................................................................................................................................11-24<br />

11.14.1 SC: Negative mask support, replacing worn parts if required .............................................11-24<br />

11.14.2 SC: Cleaning the Cartridge Feeder.................................................................................................11-24<br />

11.14.3 SC: Lubricating all negative masks (if required).......................................................................11-25<br />

11.15 Paper Transport (PA)................................................................................................................................................11-26<br />

11.15.1 PA: Cleaning the Print Engine.........................................................................................................11-26<br />

11.15.2 PA: Cleaning the cutter units ..........................................................................................................11-26<br />

11.15.3 PA: Servicing the Lane Distributor.................................................................................................11-27<br />

11.15.4 PA: Cleaning the back printer head...............................................................................................11-27<br />

11.16 Paper Processor (PP) ...............................................................................................................................................11-28<br />

11.16.1 Paper Processor – Important note.................................................................................................11-28<br />

11.16.2 PP: Cleaning the gears and bearings............................................................................................11-28<br />

11.16.3 PP: Checking / replacing the gear for frequency adjustment (every second year).....11-29<br />

11.16.4 PP: Crossovers, replace worn parts if required ..........................................................................11-29<br />

11.16.5 Cleaning / servicing the squeegee unit......................................................................................11-30<br />

11.16.6 PP: Racks, replace worn parts if required....................................................................................11-31<br />

11.16.7 PP: Cleaning the processing tanks................................................................................................11-32<br />

11.16.8 PP: Servicing hoses, valves, pumps...............................................................................................11-32<br />

11.16.9 PP: Cleaning the water tank ............................................................................................................11-33<br />

11.16.10 PP: Servicing the replenisher pumps............................................................................................11-33<br />

11.16.10.1 PP: Replacing the poppet valves of the replenisher and water<br />

pumps if required .......................................................................................................11-34<br />

0-viii 2005-05-01 / PN 03002_05 AgfaPhoto

d-<strong>lab.1</strong> <strong>family</strong>: <strong>Repair</strong><br />

Contents<br />

11.16.11 PP: Cleaning the Docking System ................................................................................................ 11-35<br />

11.16.11.1 Locking mechanism of the docking door......................................................... 11-39<br />

11.16.12 PP: Cleaning the dryer rack ............................................................................................................. 11-40<br />

11.16.13 PP: Dryer rack, replace worn parts if required, lubricate the chain.................................. 11-40<br />

11.16.14 PP: Cleaning and checking the densitometer.......................................................................... 11-41<br />

11.16.15 PP: Cleaning the Sorter..................................................................................................................... 11-41<br />

11.17 Switching on the machine................................................................................................................................... 11-42<br />

11.17.1 FP/PP: Checking the circulation pumps (running noise) ..................................................... 11-42<br />

11.17.2 FP/PP: Calibrating the water pumps............................................................................................ 11-42<br />

11.17.3 Functional check of the machine.................................................................................................. 11-42<br />

11.17.4 Eliminate ghost effects (if required) ............................................................................................. 11-42<br />

12 Index...............................................................................................................................12-1<br />

AgfaPhoto 2005-05-01 / PN 03002_05 0-ix

Contents<br />

d-<strong>lab.1</strong> <strong>family</strong>: <strong>Repair</strong><br />

■<br />

0-x 2005-05-01 / PN 03002_05 AgfaPhoto

d-<strong>lab.1</strong> <strong>family</strong>: <strong>Repair</strong><br />

General<br />

1 General<br />

1.1 Available Documentation<br />

Available documentation, see Table.<br />

The customer receives the Preinstallation Instructions when he orders the machine.<br />

The Operation folder includes a CD with the available documentation (with the exception<br />

of the circuit diagrams. The Operation Manual – Installation and Operation – are included<br />

with the machine shipment. All other parts can be ordered from AgfaPhoto.<br />

The Operating Instructions must be kept around the machine to ensure that all users have<br />

access to them.<br />

Instructions Folder / Booklet Owner Operator Technician<br />

Preinstallation Preinstallation (booklet) x<br />

Operating Instructions Operation<br />

x<br />

Installation (booklet)<br />

x<br />

Service Instructions <strong>Repair</strong><br />

x<br />

Spare Parts List x x<br />

Circuit Diagrams<br />

x<br />

1.2 <strong>Repair</strong><br />

The Operation Manual is useful for safe and appropriate working on the machine and with<br />

the machine. Perfect and safe operation of the product requires careful observation of the<br />

Operation Manual and the contained safety instructions. Therefore it must always be<br />

complete and in good condition for easy reading.<br />

All persons working on the machine and with the machine must<br />

– have read and understood the Operation Manual before they switch on the machine<br />

for the first time.<br />

– have the Operation Manual at hand when they work on the machine.<br />

– observe all information and instructions of the Operation Manual.<br />

AgfaPhoto 2005-05-01 / PN 03002_05 1-1

General<br />

d-<strong>lab.1</strong> <strong>family</strong>: <strong>Repair</strong><br />

1.2.1 Guideline for the Technician<br />

Instructions<br />

Preinstallation<br />

Installation<br />

<strong>Repair</strong><br />

Information<br />

The owner takes care of the listed preinstallation measures and returns the checklist to<br />

AgfaPhoto no later than two weeks prior to the installation date.<br />

This document describes the transport to the installation site, as well as the installation<br />

and implementation of the machine.<br />

Appendix: Declaration of Conformity<br />

The declaration of conformity is the first sheet in the Operation folder.<br />

This document includes all important information to ensure correct operation by a<br />

technician:<br />

Chapter 1:<br />

Notes on the <strong>Repair</strong> Manual, legal notes, safety notes, transport and storage.<br />

Chapter 2:<br />