In-depth Issue 17 - Rolls-Royce

In-depth Issue 17 - Rolls-Royce

In-depth Issue 17 - Rolls-Royce

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

issue<br />

<strong>17</strong><br />

2012<br />

WORLD’S FIRST<br />

GAS TUGS<br />

Gas propulsion for maximum efficiency with<br />

lowest emissions<br />

REGIONAL FOCUS CENTRAL EUROPE<br />

Service centres expand to serve this hub of<br />

marine activity<br />

FLEXIBLE DP UPGRADES<br />

<strong>In</strong>stalling an integrated dynamic positioning<br />

system enhances performance

issue<br />

Contents<br />

36<br />

26<br />

06<br />

PHOTO Aluminium Boats<br />

COVER IMAGE PHOTOLIBRARY<br />

<strong>17</strong><br />

WORLD’S FIRST<br />

GAS TUG<br />

Gas propulsion for maximum efficiency with<br />

lowest emissions<br />

REGIONAL FOCUS CENTRAL EUROPE<br />

Service centres expand to serve this hub of<br />

marine activity<br />

FLEXIBLE DP UPGRADES<br />

<strong>In</strong>stalling an integrated dynamic positioning<br />

system enhances performance<br />

Front cover:<br />

The world’s first LNG-fuelled<br />

tugs are now in build for<br />

operator Buksér og Berging.<br />

Read about them on pages 2<br />

and 6.<br />

<strong>17</strong><br />

2012<br />

News<br />

02-05 News and future events<br />

Technology<br />

06-09 LNG is an option for harbour<br />

and escort tugs<br />

10-12 <strong>Rolls</strong>-<strong>Royce</strong> and Bestway<br />

unveil new energy-efficient<br />

ship designs<br />

13-15 <strong>In</strong>tegrated ship and systems<br />

design = Efficiency<br />

16-19 Stronger together<br />

20-21 Anti-heeling with<br />

simultaneous roll-reduction<br />

22-23 Venice Syncrolift®<br />

demonstrates step change<br />

in shiplift lift capacity<br />

24-25 Safe and efficient deck<br />

operations with new crane<br />

technology<br />

Regional Focus<br />

26-30 Maritime excellence: from<br />

the Bosporus to the Baltic<br />

31 New European Service<br />

Centres up and running<br />

Updates<br />

32-35 EMAS invests in flexibility<br />

with performance<br />

36-37 Working together to reduce weight and<br />

enhance efficiency<br />

38-39 Propelling and positioning drillships<br />

40-43 QE carrier programme advances<br />

44 Accurately placing rocks 1,200 metres deep<br />

45 Pulling power for today’s advanced designs<br />

46-47 Offshore deliveries and orders<br />

48-51 Azimuth thrusters deliver for Swedish<br />

Coast Guard<br />

52 Helping harness the power of the wind<br />

53-55 Power and speed for effective windfarm support<br />

56-57 <strong>In</strong>novation in fishing vessel design<br />

58-59 DDG 1000 programme gathers momentum<br />

Support and Service<br />

60-63 Focusing on training<br />

64-65 Playing a key role in vessel conversion<br />

66 Rapid response for emergency maintenance<br />

67 DFDS ferry trio upgraded with Promas Lite<br />

Contacts<br />

68-69 Contacts<br />

issue <strong>17</strong> 2012<br />

Opinions expressed may not necessarily represent the views of <strong>Rolls</strong>-<strong>Royce</strong> or the editorial team.<br />

The publishers cannot accept liability for errors or omissions.<br />

All photographs © <strong>Rolls</strong>-<strong>Royce</strong> plc unless otherwise stated. <strong>In</strong> which case copyright owned by<br />

photographer/organisation.<br />

EDITOR: Andrew Rice<br />

DESIGNED BY: Paperclip Communications<br />

CONTRIBUTORS: RW – Richard White | CT – Craig Taylor | DC – David Cheong | AM – Amy MacKay |<br />

MG – Mirko Gutemann | MH – Marianne Hovden | AR – Andrew Rice<br />

Printed in the UK.<br />

If your details have changed or if you wish to receive a regular complimentary copy of <strong>In</strong>-<strong>depth</strong> please<br />

email us at: in.<strong>depth</strong>@rolls-royce.com<br />

© <strong>Rolls</strong>-<strong>Royce</strong> plc 2012<br />

The information in this document is the property of <strong>Rolls</strong>-<strong>Royce</strong> plc and may not be<br />

copied, communicated to a third party, or used for any purpose other than that for which<br />

it is supplied, without the express written consent of <strong>Rolls</strong>-<strong>Royce</strong> plc.<br />

While the information is given in good faith, based upon the latest information available<br />

to <strong>Rolls</strong>-<strong>Royce</strong> plc, no warranty or representation is given concerning such information,<br />

which must not be taken as establishing any contractual or other commitment binding<br />

upon <strong>Rolls</strong>-<strong>Royce</strong> plc or any of its subsidiary or associated companies.

Viewpoint<br />

The quest for operating<br />

efficiency drives innovation and<br />

technology.<br />

The message from governments,<br />

bankers and ship operators<br />

seems to be very similar this<br />

year to last, 2012 will be another<br />

tough year. Banks have been cutting<br />

their shipping exposure and financing<br />

has become more difficult as lending<br />

has tightened. The European Union<br />

continues to pursue tighter financial<br />

integration, and in the U.S. real growth<br />

is proving elusive. With China slowing,<br />

global growth forecasts for 2012 have<br />

now reduced to around 3.5 per cent.<br />

How things will eventually unfold<br />

– and the knock-on effect this will have<br />

– is not clear. Continuing volatility, at<br />

least in the near term, is likely to be the<br />

norm and the eventual outcome is likely<br />

to have longer term implications for<br />

shipping in general.<br />

While challenges abound across<br />

the industry, the higher value sectors<br />

are proving resilient. <strong>In</strong> the highly<br />

specialised offshore oil and gas sector,<br />

further investment in deep water<br />

exploration and production looks<br />

particularly robust. We have recently<br />

secured orders to provide thrusters<br />

and engines for drillships in addition to<br />

UT-Design Platform Supply Vessels and<br />

Anchor Handlers.<br />

The shift to low sulphur fuels and<br />

the focus on sustainable shipping<br />

has seen the steady uptake in LNG as<br />

the fuel of choice for a growing number of newbuilds<br />

scheduled for delivery by the 2015 ECA regulation<br />

deadline. Our gas engines have been selected to power<br />

a number of these vessels, including the world’s first<br />

all-gas tugs.<br />

We recently secured orders for the NVC 405 general<br />

cargo carrier variant of our award winning Environship<br />

concept. This innovative design delivers greenhouse gas<br />

emission reductions of more than 40 per cent compared<br />

to similar vessels.<br />

The quest to reduce operating costs and the<br />

environmental impact of vessels has been at the centre<br />

of our thinking for some time, and this drives our<br />

innovation and technology investment programmes to<br />

meet the challenges our customers face.<br />

<strong>In</strong> the naval sector, we have received orders for<br />

power and propulsion systems for two more Littoral<br />

Combat Ships for the US Navy. Twin MT30s power these<br />

vessels, and benefit from over 45 million hours of airline<br />

operating experience.<br />

<strong>Rolls</strong>-<strong>Royce</strong> and Daimler have also joined forces<br />

to create a new marine and industrial engine joint<br />

venture through the acquisition of Tognum, maker of<br />

MTU high speed diesel engines for use at sea and on<br />

land. The engines and technology portfolios are highly<br />

complementary to our Bergen medium speed engines.<br />

As marine systems and equipment suppliers, the<br />

goal of <strong>Rolls</strong>-<strong>Royce</strong> is to provide ship builders and ship<br />

operators in the merchant, offshore and naval sectors with<br />

cost effective, efficient and environmentally compliant<br />

systems. A gas engine is a good start in reducing<br />

emissions, but it is the effective integration of other energy<br />

saving designs and technologies – for which we have a<br />

strong track record and remains our continuing goal – that<br />

makes the real difference.<br />

I hope you enjoy reading more about how this is<br />

being delivered through the articles in this latest edition<br />

of <strong>In</strong>-<strong>depth</strong>.<br />

TONY WOOD<br />

President - Marine

02 NEWS<br />

EVENTS<br />

Visit us at the<br />

following:<br />

2012<br />

JUNE<br />

4-7<br />

EAGE 74th<br />

Copenhagen, Denmark<br />

4-8<br />

Posidonia<br />

Athens, Greece<br />

AUGUST<br />

14-<strong>17</strong><br />

Norfishing<br />

Trondheim, Norway<br />

28-31<br />

ONS<br />

Stavanger, Norway<br />

SEPTEMBER<br />

4-7<br />

SMM<br />

Hamburg, Germany<br />

<strong>17</strong>-20<br />

Rio Oil & Gas<br />

Rio de Janeiro, Brazil<br />

19-22<br />

Monaco Yacht Show<br />

Monaco, France<br />

OCTOBER<br />

22-26<br />

Euronaval<br />

Paris, France<br />

NOVEMBER<br />

4-9<br />

SEG<br />

Las Vegas, Nevada, USA<br />

28-30<br />

<strong>In</strong>ternational<br />

Workboat Show<br />

New Orleans, Louisiana, USA<br />

DECEMBER<br />

4-7<br />

Exponaval<br />

Valparaíso, Chile<br />

For further information,<br />

contact:<br />

Naval and submarines:<br />

Donna Wightman<br />

donna.wightman@rolls-royce.com<br />

Merchant and offshore:<br />

Gunilla Wall<br />

gunilla.wall@rolls-royce.com<br />

NEWS<br />

World’s first<br />

LNG-powered<br />

tugs<br />

ordered<br />

for Norwegian<br />

terminal<br />

60<br />

waterjets for new<br />

<strong>In</strong>dian Coast Guard<br />

fast patrol boats<br />

<strong>Rolls</strong>-<strong>Royce</strong> has secured a contract from <strong>In</strong>dia’s Cochin<br />

Shipyard to supply waterjets for 20 new fast patrol<br />

vessels for the <strong>In</strong>dian Coast Guard.<br />

A total of 60 Kamewa 71S3np waterjets (three per<br />

vessel), and associated equipment including a joystick<br />

control system, which will enhance the manoeuvring<br />

capabilities of the vessels, are to be supplied. The new<br />

Kamewa S3 design offers higher speeds, improved<br />

acceleration and increased efficiency.<br />

Power for each of the 48m long vessels will be<br />

provided by three MTU 16V 4000 M90 engines, each<br />

rated at 3,648kW. The new vessels will be capable of<br />

speeds up to 33 knots.<br />

<strong>Rolls</strong>-<strong>Royce</strong> has been a supplier to the <strong>In</strong>dian<br />

Coast Guard for over 20 years with a large number of<br />

waterjets already in service, as well as CP propellers<br />

and stabilisers on other vessels in the fleet. The first<br />

of three UT 5<strong>17</strong> pollution control<br />

vessels, Samudra Prahari, entered<br />

service in 2010.<br />

Construction of the new ships<br />

is part of an expansion of the<br />

<strong>In</strong>dian Coast Guard.<br />

When they enter service they<br />

will operate in <strong>In</strong>dian coastal<br />

waters and around island<br />

territories. Their roles will include<br />

coastal patrolling, anti-smuggling<br />

missions, fisheries protection, as<br />

well as search and rescue duties.

www.rolls-royce.com<br />

03<br />

A milestone in green tug<br />

development has been reached<br />

with Buksér og Berging ordering<br />

<strong>Rolls</strong>-<strong>Royce</strong> gas propulsion systems<br />

for two powerful LNG-fuelled escort<br />

tugs to operate at the Kårstø gas<br />

terminal near Haugesund in Norway.<br />

The tugs will work for the<br />

state-owned oil company Statoil<br />

and the process plant operator<br />

Gassco on delivery in the third<br />

quarter of 2013. They are 35m long<br />

stern drive azimuth thruster tugs<br />

with a broad 15.4m beam and a<br />

bollard pull of about 65 tonnes. The<br />

design was developed by Buksér og<br />

Berging together with Marin Design.<br />

“This is a breakthrough for our<br />

Bergen gas engines in the tug<br />

market, and for our new US35<br />

thrusters in escort tugs,” says Robert<br />

Løseth, Senior VP - Merchant,<br />

Propulsion Systems and Engines.<br />

“It confirms that our unique engine<br />

performance characteristics in terms<br />

of response time, fuel consumption<br />

and low methane slip are important<br />

to our customers.”<br />

Two 1,705kW Bergen C26:33<br />

6 cyl in-line gas engines will<br />

provide the power. They will drive<br />

two US35 azimuth thrusters of the<br />

latest design through a mechanical<br />

transmission. <strong>Rolls</strong>-<strong>Royce</strong> will also<br />

provide its ACON control system<br />

and monitoring for the gas system,<br />

together with propulsion system<br />

engineering, and the AGA Cryo<br />

single LNG tank plus gas supply<br />

based on two coldboxes. The system<br />

is designed for weekly bunkering<br />

intervals and bunkering time is<br />

estimated to be 45 minutes.<br />

Vetle Sverdrup, Commercial<br />

Director at Buksér og Berging<br />

AS, said, “We wanted to base<br />

the design of the new tugs on<br />

the spark ignition lean burn<br />

engine concept, and the ability<br />

to accommodate direct drive in<br />

addition to a low emission profile.<br />

The propulsion system on high<br />

performance escort tugs needs<br />

to accommodate rapid load<br />

pickup over the entire load range.<br />

Due to these factors, we chose to<br />

work closely with <strong>Rolls</strong>-<strong>Royce</strong> on<br />

this project.”<br />

The tugs are being built in<br />

Turkey by Sanmar Marine. For<br />

more details, go to page 6.<br />

PHOTO Skipsteknisk AS<br />

PHOTO Buksér og Berging<br />

Seismic streamer systems for advanced<br />

COSL vessel<br />

The seismic survey vessel, named HYSY 720, has entered<br />

service with China Oilfield Services Limited (COSL) and is<br />

now operating in the South China Sea.<br />

The vessel is equipped with a <strong>Rolls</strong>-<strong>Royce</strong> streamer<br />

handling system capable of towing 12 streamers, each<br />

8,000m long, to perform high-density seismic data<br />

collection. It is the first and most advanced deepwater<br />

seismic survey vessel built in China so far and is 108.3m<br />

long with a 24m beam, a draught of 9.6m and has an<br />

endurance of 75 days.<br />

To increase operating efficiency,<br />

the vessel is designed for a speed<br />

of 16 knots and a towing speed<br />

of five knots and has a dieselelectric<br />

propulsion system. This will<br />

significantly reduce mobilisation<br />

and demobilisation times, and<br />

also contributes to improving the<br />

comfort of the working and living<br />

environment for the crew.<br />

The model ST-327L CD vessel is<br />

equipped with a new generation of<br />

seismic collection system, integrated<br />

navigation system and lateral control<br />

system. Up to 75 people can be<br />

accommodated onboard.

04 NEWS<br />

PHOTO U. S. Navy<br />

Power for two<br />

more Littoral<br />

Combat Ships<br />

The contract to supply power and propulsion systems for<br />

the two latest vessels in the U.S. Navy’s Littoral Combat Ship<br />

(LCS) programme was recently secured by <strong>Rolls</strong>-<strong>Royce</strong>.<br />

Designed to operate in combat zones close to the shore,<br />

each LCS will be equipped with two <strong>Rolls</strong>-<strong>Royce</strong> MT30 gas<br />

turbines driving four large Kamewa waterjets, enabling the<br />

vessels to reach speeds well in excess of 40 knots.<br />

This latest order is for ships named Little Rock and Sioux<br />

City, and follows previous orders for the Milwaukee and the<br />

Detroit, which are both under construction. <strong>Rolls</strong>-<strong>Royce</strong><br />

already powers two Lockheed Martin Littoral Combat<br />

Ships, the USS Freedom, first deployed two years ago, and<br />

the Fort Worth, which has now completed its U.S. Navy<br />

acceptance trials.<br />

Andrew Marsh, President - Naval said, “We have worked<br />

closely with Lockheed Martin, the U.S. Navy and other<br />

partners during the LCS programme, using our extensive<br />

experience to further develop these highly advanced ships.<br />

The combination of the MT30 gas turbine and our latest<br />

waterjet technology will ensure these ships are at the<br />

cutting edge of global naval capability.”<br />

The MT30 is derived from <strong>Rolls</strong>-<strong>Royce</strong> aero engine<br />

technology and builds on over 45 million hours of<br />

operating experience. At 36 megawatts, it is the world’s<br />

most powerful marine gas turbine and has the highest<br />

power density in its class. The waterjets are among the<br />

largest produced by <strong>Rolls</strong>-<strong>Royce</strong>.<br />

A range of other <strong>Rolls</strong>-<strong>Royce</strong> equipment is specified in<br />

the Lockheed Martin design, including shaftlines, bearings<br />

and propulsion system software.<br />

New service centre in Hong Kong<br />

The <strong>Rolls</strong>-<strong>Royce</strong> service presence<br />

in Hong Kong has been expanded<br />

recently with the opening of a new<br />

and enlarged service centre on Tsing<br />

Yi Island.<br />

It provides specialist support<br />

and engineering services to the<br />

Greater China region and forms<br />

an important component of the<br />

<strong>Rolls</strong>-<strong>Royce</strong> service network that<br />

covers the entire east coast of China,<br />

with existing facilities in Dalian,<br />

Guangzhou and Shanghai.<br />

“With a growing customer base<br />

in Greater China, coupled with an<br />

increasing number of customer<br />

operations within the region, we<br />

have relocated and expanded our<br />

facilities to ensure we can deliver<br />

our services close to where our<br />

customers operate,” says P. T. Tong,<br />

Branch Manager. “Service engineers<br />

based here are on hand to provide<br />

technical support wherever and<br />

whenever required.”<br />

The new facility will provide<br />

support for a variety of vessels,<br />

including a large number of fast<br />

ferries that are in service between<br />

Hong Kong, Macau and the<br />

Pearl Delta. A large number have<br />

<strong>Rolls</strong>-<strong>Royce</strong> propulsion systems<br />

installed. It provides direct waterfront<br />

access to major transport channels<br />

and is capable of undertaking major repair, overhauls<br />

and upgrades for popular <strong>Rolls</strong>-<strong>Royce</strong> products that<br />

include waterjets, tunnel thrusters, azimuth thrusters<br />

and deck machinery.<br />

Sales support in Hong Kong has also moved to the<br />

new facility.

www.rolls-royce.com<br />

05<br />

Four deepwater anchor handling vessels to get<br />

advanced deck machinery<br />

<strong>Rolls</strong>-<strong>Royce</strong> has secured a contract<br />

from Swire Pacific Offshore to supply<br />

advanced anchor handling systems<br />

for four offshore vessels, currently<br />

under construction in Singapore.<br />

The systems are developed for the<br />

safer handling of large anchors on<br />

deck, such as the torpedo anchors<br />

used in the deepwater oil and gas<br />

fields off the coast of Brazil.<br />

Arne Tande, Senior VP - Offshore Deck Machinery, said,<br />

“<strong>Rolls</strong>-<strong>Royce</strong> supplies world-leading marine technology<br />

that enables our customers to operate safely in challenging<br />

conditions, such as the deepwater oil and gas fields. We<br />

are delighted that Swire Pacific Offshore has again selected<br />

our safety-critical technology, which demonstrates that our<br />

focus on research and development and advancements<br />

in the technical capabilities of our products continues to<br />

position <strong>Rolls</strong>-<strong>Royce</strong> as the market leader for specialist<br />

handling equipment in the offshore industry.”<br />

<strong>Rolls</strong>-<strong>Royce</strong> will supply a complete<br />

deck machinery system to each of the<br />

four vessels, which are being built at<br />

the ST Marine Singapore shipyard.<br />

At the heart of each system is a<br />

low-pressure hydraulic winch for<br />

anchor handling and towing duties,<br />

with a pulling capacity of 500t.<br />

Asian orders for popular deepwater UT designs<br />

The rapid expansion of Asia into<br />

the offshore industry looks set<br />

to continue, with shipyards and<br />

operators selecting <strong>Rolls</strong>-<strong>Royce</strong><br />

designs for deeper waters.<br />

Singapore-based PaxOcean<br />

Engineering is building two PSVs to<br />

the <strong>Rolls</strong>-<strong>Royce</strong> UT 755 CD design,<br />

at its shipyard in Zhuhai, China. The<br />

vessels combine a proven ship design<br />

with a range of <strong>Rolls</strong>-<strong>Royce</strong> onboard technologies that<br />

include diesel-electric propulsion and deck machinery.<br />

They are also equipped for firefighting and oil recovery.<br />

The UT 755 CD has a deck cargo area of 670m 2 and an<br />

overall length of 78.7m with a 16m beam. Planned delivery<br />

is the first half of next year.<br />

<strong>In</strong> China four UT 771 CDL vessels will be built by the<br />

COSCO (Guangdong) Shipyard Co. Ltd. These complex<br />

vessels are flexible and highly efficient, featuring a fully<br />

integrated systems package comprising diesel electric<br />

propulsion system, deck machinery,<br />

bulk handling equipment and<br />

automation and control systems. The<br />

vessels will also be able to undertake<br />

firefighting duties. They will be<br />

equipped for transporting pipes,<br />

equipment and cargo to and from<br />

pipelaying barges, oil drilling and<br />

production platforms.<br />

Delivery is scheduled for 2014<br />

and the contract includes options<br />

to build an additional six vessels of<br />

the same design.<br />

Korean shipbuilder Hyundai Mipo<br />

Dockyard Co. Ltd is to build four<br />

UT 776 CD vessels.<br />

Hyundai’s President and CEO<br />

W G Choe said, “We are extremely<br />

pleased to enter into this deepwater<br />

segment by building vessels of<br />

a world-leading design from<br />

<strong>Rolls</strong>-<strong>Royce</strong>.”<br />

The 4,400t, 90m long UT 776 CD<br />

design incorporates a range<br />

of <strong>Rolls</strong>-<strong>Royce</strong> systems like<br />

diesel-electric propulsion. They will<br />

be built at Hyundai’s Ulsan shipyard<br />

for delivery in 2013 and 2014. The<br />

contract includes options for a further<br />

two vessels.

06<br />

PHOTO Øyvind Hagen/Statoil<br />

Technology<br />

The Kårstø gas<br />

terminal near<br />

Haugesund in<br />

Norway where<br />

gas-powered tugs<br />

will begin operating<br />

next year.

07<br />

LNG is an option for<br />

harbour and escort tugs<br />

<strong>Rolls</strong>-<strong>Royce</strong> has a long history of providing conventional<br />

tug propulsion systems and is now the first to provide full<br />

gas systems for this vital application.

08 TECHNOLOGY<br />

1<br />

2<br />

PHOTO Per Magne Einag<br />

3<br />

Providing propulsion systems for tugs comprising Bergen diesel<br />

engines driving azimuth thrusters of various specifications, is<br />

something <strong>Rolls</strong>-<strong>Royce</strong> has been successfully doing for over 25 years.<br />

The rapid response to load and excellent low load fuel<br />

consumption of the Bergen range of gas engines makes them ideally<br />

suited to tug applications. This, coupled with the extensive experience of<br />

<strong>Rolls</strong>-<strong>Royce</strong> in providing gas engines for marine propulsion, has seen designs<br />

for LNG-fuelled tug propulsion being developed for several years. The high<br />

power density of the recently introduced Bergen C-series gas engines is also<br />

an important factor.<br />

The particular attraction of <strong>Rolls</strong>-<strong>Royce</strong> Bergen C-series gas engines to<br />

power tugs is low levels of emissions. These include the greenhouse gas<br />

CO 2<br />

which has a global impact, and because methane slip is very low in this<br />

engine type, the total GHG emission reduction is not seriously compromised<br />

by unburnt methane in the exhaust. NOx emissions are reduced by around<br />

90 per cent and SOx is negligible. Also important in tugs working in ports<br />

and approaches, which are often close to residential areas of high population<br />

density, is the absence of soot and smoke particulates. Of growing concern<br />

are emissions to water, and the likelihood of oil spills is much reduced when<br />

LNG is the fuel.<br />

Bergen gas engines have a high thermal efficiency. SFC, NOx and CO 2<br />

emissions are actually lower at low engine loads, the reverse of most<br />

diesel engines. The C-series gas engines are also approved for both direct

www.rolls-royce.com<br />

09<br />

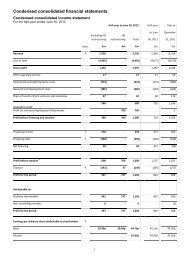

TABLE 1:<br />

All are based on a tug powered by two <strong>17</strong>05 kW engines driving azimuth thrusters, with a<br />

typical annual operating profile of 300 days per year with 4,200 operating hours.<br />

Operating Mode<br />

TIME%<br />

Standby (coupled & uncoupled) 38%<br />

Transit (sailing from & towards a job) 33%<br />

Assist (connected to ship) 29%<br />

1. The <strong>Rolls</strong>-<strong>Royce</strong><br />

LNG propulsion<br />

system for a<br />

harbour tug.<br />

2. The number of<br />

LNG bunkering<br />

facilities is<br />

growing and<br />

refuelling is a<br />

simple operation<br />

that can take<br />

under an hour.<br />

3. Gas propulsion is<br />

also an option for<br />

pusher tugs.<br />

TABLE 2:<br />

Illustrates the potential saving in fuel and lube oil consumption.<br />

Fuel use comparison MGO* LNG**<br />

Average fuel consumption g/kWh 194 157<br />

Annual fuel use tonnes per year 868 702<br />

Lube oil consumption g/kWh 0.8 0.4<br />

Annual lube oil use tonnes per year 3.3 1.6<br />

Test<br />

Cycle Type<br />

E3 (Variable speed propulsion)<br />

* MGO Specific Heat 43.0 MJ/kg. Density 858 kg/m³<br />

** LNG Specific Heat 49.4 MJ/kg. Density 430 kg/m³<br />

TABLE 3:<br />

Shows the projected reduction in emissions. The Bergen gas engine has a low methane slip of<br />

3.10g/kWh at full load, which has been taken into account when calculating the equivalent CO 2<br />

reduction of 23 per cent.<br />

Emissions comparison MGO LNG<br />

NOx emissions g/kWh 9.6 1,1<br />

NOx tonnes per year 41 5<br />

SOx emissions g/kWh 0.2 0<br />

SOx tonnes per year 0.9 0<br />

CO 2<br />

tonnes per year 2,716 2,202*<br />

Environmental Ship <strong>In</strong>dex ESI 7.27 90.66<br />

*<strong>In</strong>cludes an averaged 3.7 g/kWh methane slip equivalent CO 2<br />

mechanical drive or as gensets and can accept rapid changes in load. They<br />

can therefore be used in a variety of propulsion solutions, depending on the<br />

operating profile of the tug.<br />

A study of ship assist tug operations shows that a tug has a varied working<br />

profile. Long-term operational studies demonstrate that harbour tugs will<br />

typically only spend 29 per cent connected to a ship, actually carrying out its<br />

assistance duties, 33 per cent of total operation time in transit, sailing from<br />

and towards a job, while the remaining 38 per cent is spent on standby and<br />

loitering.<br />

Throughout a day or week, a tug’s power requirements can vary<br />

tremendously. Diesel engines normally have a much higher level of specific<br />

emissions and fuel consumption at low loads, compared with the most<br />

efficient operation at high loads in terms of emissions and fuel burnt per<br />

unit of power output. A characteristic that has resulted in the recent move<br />

to hybrid tugs by some operators. It is here that <strong>Rolls</strong>-<strong>Royce</strong> lean burn gas<br />

engines score.<br />

<strong>Rolls</strong>-<strong>Royce</strong> has evaluated a number of LNG-fuelled propulsion systems for<br />

harbour tugs and the first are now under contract (see page 2). The system<br />

selected produces over 65 tonnes bollard pull and uses a stern drive azimuth<br />

thruster layout based on two US 35 CP thrusters with controllable pitch<br />

propellers. They are directly driven by two Bergen C26:33L6PG gas engines,<br />

each delivering 1,705kW and running at 1,000rpm. Aquapilot controls and<br />

ACON automation are part of the package.<br />

A vertical C-type gas tank of<br />

78m3 capacity and two separate<br />

cold boxes are installed under the<br />

foredeck and provide sufficient<br />

capacity for 150 hours running at<br />

50 per cent load. Refuelling is a<br />

simple operation and is required<br />

once a week from either a<br />

shore-based tank, road tanker or<br />

transport storage unit. Fuel transfer<br />

time is just 45 minutes, provided a<br />

100m3/hr 3<br />

system is used.<br />

Although the initial capital costs<br />

are higher for gas propulsion due to<br />

the cost of the fuel system, this can<br />

be offset within a relatively short<br />

time by significantly lower annual<br />

operating costs. You also have a very<br />

environmentally friendly vessel that<br />

satisfies forthcoming legislation,<br />

with the emissions reduction<br />

advantage there from day one.<br />

Ship construction data is used to<br />

calculate the vessel environmental<br />

ship index (ESI). This is a score<br />

based on the vessels environmental<br />

credentials. It is expected that in<br />

the future, this, or a similar scoring<br />

system will be used to tax vessels<br />

entering port. The score does give a<br />

good indication of how much more<br />

environmentally friendly LNG as a<br />

fuel is, compared to MGO.<br />

These analyses are based on<br />

long-term experience with tug<br />

propulsion. <strong>Rolls</strong>-<strong>Royce</strong> supplies<br />

engines, thrusters and winches<br />

for tugs all over the world and the<br />

US series azimuth thrusters are<br />

particularly popular due to their<br />

good performance and robustness.<br />

US 205 FP thrusters already propel<br />

environmentally friendly tugs and<br />

have been selected for the second<br />

of the Foss hybrid tugs, following<br />

the successful operation of the first<br />

of the type, Carolyn Dorothy, at Long<br />

Beach and Los Angeles over the past<br />

two years. [AR]

10 TECHNOLOGY<br />

1<br />

2<br />

3<br />

4<br />

<strong>Rolls</strong>-<strong>Royce</strong> and Bestway unveil<br />

new energy-efficient ship designs<br />

Combining proven European ship design and systems experience with<br />

Chinese capabilities in ship building, <strong>Rolls</strong>-<strong>Royce</strong> is delivering a range of<br />

new commercial ship designs.<br />

T<br />

The global shipping industry is now firmly committed to using vessel<br />

Tdesigns and systems that will cut greenhouse gas emissions. China<br />

Tis also entering a green era, with national policy supporting energy<br />

Te Tfficiency and environmental protection, with the target of cutting<br />

CO 2 emissions per unit GDP by 40-45 per cent by 2020.<br />

To meet the evolving low emissions requirements of the global,<br />

intra-regional and inland shipping trade, particularly in Asia, <strong>Rolls</strong>-<strong>Royce</strong> and<br />

Bestway formed a Joint Project Team (JPT) in Shanghai at the start of 2011.<br />

The first of the new designs have now emerged.<br />

They range from 2,500 to 100,000 deadweight tonnes (dwt), including<br />

the 4100 Series roro carriers (from below 9,000 – 11,000dwt and above), the<br />

4400 Series container carriers (up to 2,000teu), the 4600<br />

Series general cargo carriers (up to 40,000dwt), the 6400<br />

Series LNG carriers (up to 40,000m 3 ) and the 4800 Series<br />

bulk carriers (up to 100,000dwt). All are designed to comply<br />

with and exceed future emissions targets.<br />

”As more international emissions controls are<br />

progressively introduced, the marine industry is<br />

collaborating to ensure that designers, equipment<br />

manufacturers, yards and owners work together to create<br />

highly efficient vessels that improve operating costs<br />

while reducing harmful environmental impacts,” says

www.rolls-royce.com<br />

11<br />

1. JD 4801 bulk carrier<br />

- 37,000dwt.<br />

2. JD 4601 cargo<br />

carrier - 37,000dwt.<br />

3. JD 4104 GF roro<br />

cargo carrier -<br />

9,000dwt/2,100lm.<br />

4. JD 4103 GF roro<br />

cargo carrier -<br />

9,000dwt/1,750lm.<br />

5. JD 4401 container<br />

carrier - 2,000teu.<br />

5<br />

Arne Magne Vik, JPT Technical Director. ”Through our collaboration with<br />

Bestway, we are well placed to lead this charge.”<br />

The designs benefit from the combined design and systems expertise of both<br />

companies in producing highly efficient vessels tailored specifically for the future<br />

merchant shipping market, in which low emissions and reduced operating<br />

costs are key drivers. This includes the application of Liquified Natural Gas (LNG)-<br />

fuelled propulsion, which is gaining acceptance globally as a marine fuel, and<br />

where <strong>Rolls</strong>-<strong>Royce</strong> has accumulated significant experience with 23 gas-powered<br />

vessels now in service or on order.<br />

With the exception of the general cargo/bulk designs, which have<br />

diesel-only systems at the moment, all designs have the propulsion options<br />

of either conventional diesel/hybrid or gas. Those designs featuring <strong>Rolls</strong>-<strong>Royce</strong><br />

Bergen gas engines already meet IMO Tier III requirements for nitrogen oxide<br />

(NOx), sulphur oxide (SOx) and carbon dioxide (CO 2<br />

) emissions, which come into<br />

force in 2016.<br />

With the Energy Efficiency Design <strong>In</strong>dex (EEDI) being mandated from 2013,<br />

each design has been given an EEDI rating calculated using MEPC 1/Circ 681.<br />

However, they are subject to change, as the formulae have not been fully<br />

clarified for some vessel types.<br />

Roro vessels in the JD4100 model range feature a low drag hull form and<br />

sea-friendly bow with twin Promas integrated propellers and rudders. Three are<br />

based on the same 150m hull design, have a deadweight of 9,000dwt and carry<br />

200teu on the upper deck with 1,800 lane-metres, but<br />

have different stern ramp arrangements. Diesel or gas<br />

propulsion can be specified.<br />

Lane-metre capacity of the gas-powered JD4103GF<br />

is reduced by 50m, as some cargo space is lost to<br />

the gas tank. The 166.6m long JD4104GF, with a<br />

deadweight of 11,000dwt, 21,000 lane-metres and<br />

capacity for more than 250teu, is currently the largest<br />

in the family. It has the same propulsion system as<br />

its smaller sister, which comprises of twin Bergen<br />

B32:40L8PG main engines, rated at 3,220kW, and<br />

a Bergen C26:33L6AG 2,000kW auxiliary generator,<br />

hence the slightly slower service-speed of 15.6 knots.<br />

Range for the gas-powered ships is 6,000nm, with<br />

6,500nm for conventional diesel power. EEDI ratings<br />

range from 19.4 to 15.9, although they do not yet<br />

apply to roro vessels.<br />

The JD4400 series container vessel family so far<br />

comprises two designs able to carry 2,250teu and<br />

2,194teu respectively. Both are 198.5m long with a<br />

deadweight of 30,000dwt. There is an extra cost for<br />

the LNG system and a reduction in cargo handling of

12 TECHNOLOGY<br />

1<br />

3<br />

2<br />

1. Much of the ship<br />

design work is<br />

undertaken in<br />

Shanghai.<br />

2. 6401 LNG carrier –<br />

5,000m³.<br />

3. 6405 LNG carrier –<br />

10,000m³.<br />

56teu to make room for the gas tank. However, the extra capital cost and<br />

the theoretical loss of earnings are more than offset by the fuel economies<br />

and lower emissions of the LNG-fuelled variant, which has an EEDI of 12.2.<br />

It is powered by a single Bergen B35:40V16PG, driving a single Promas<br />

system with CPP, supplemented by three Bergen C26:33L9AG generator<br />

sets, powering through a power-take-in (PTI). The diesel-powered JD4401<br />

drives a FP Promas system and has a 1 knot faster service speed of 18.5<br />

knots with an EEDI of 13.<br />

Adopting a similar hull design and propulsion arrangements are the<br />

JD4601, a 37,000dwt handysize bulker, and the JD4801, a 37,000dwt<br />

general cargo carrier. Both vessels are 180m long, with a beam of 29.8m<br />

and an EEDI of 4.4. Propulsion power is provided by a 6,250kW diesel,<br />

driving a FP Promas system for a service speed of 14 knots.<br />

The final designs are small LNG carriers with capacities from 5,000 to<br />

40,000m 3 , ideal for the anticipated demand in smaller vessels to supply LNG<br />

bunkering points as the world’s LNG infrastructure develops. All have an<br />

EEDI of 23.1, a range of 1,500nm and a service speed of 13 knots. Smallest is<br />

the 5,000m 3 JD6401, with a length of 99.9m and 18.4m beam. Main engine<br />

is a Bergen C26:33L8PG, rated at 2,160kW, which drive a<br />

single Promas system, and a Bergen C26:33L6AG genset.<br />

Both engines are able to run on boil-off gas (BOG) or LNG<br />

from twin 80m 3 storage tanks. A hybrid shaft generator<br />

provides the electrical power, which can be used to<br />

increase propulsion power or for redundant propulsion.<br />

The larger JD6405 with 10,000m 3 capacity can be<br />

specified with either gas or dual fuel propulsion. It is<br />

a shallow draft design well-suited for rivers and coastal<br />

waters and has a length of 124.9m and a 22.4m beam<br />

with 4.5m draught. Propulsion power is provided by twin<br />

1,620kW Bergen C26:33L6PG engines driving Promas<br />

systems and running on LNG stored in two 120m 3 tanks.<br />

The dual-fuel version incorporates two 425kW diesel<br />

gensets that can also provide extra power and emergency<br />

propulsion through a hybrid shaft generator system. [AR]

www.rolls-royce.com 13<br />

<strong>In</strong>tegrated ship and<br />

systems design = Efficiency<br />

Ship design is a complex<br />

subject with many factors<br />

influencing the shape of a<br />

vessel. A distinctive hull form<br />

is important for marketing,<br />

but it is the detail design of<br />

the hull hydrodynamics and<br />

the effective integration of<br />

the propulsion system that<br />

improves profitability and<br />

reduces operating costs<br />

and emissions.

14 TECHNOLOGY<br />

Ship and systems design is<br />

an area where <strong>Rolls</strong>-<strong>Royce</strong><br />

continues to invest heavily in<br />

research and development,<br />

to ensure that the company’s designs<br />

are the optimum for the customer’s<br />

needs and can cope with real<br />

operating conditions.<br />

A combination of CFD<br />

(computational fluid dynamics) and<br />

tank testing is used. Promising designs<br />

can then be verified by tank testing<br />

and compared with operational<br />

feedback from over 800 <strong>Rolls</strong>-<strong>Royce</strong><br />

designed offshore and merchant<br />

vessels operating globally.<br />

Because of its extensive product<br />

range, <strong>Rolls</strong>-<strong>Royce</strong> has the ability to<br />

integrate complex ship systems that<br />

are engineered to work efficiently<br />

together. As an integrator and a<br />

designer, it aims to get the best<br />

products together as an efficient<br />

system and design the optimum ship<br />

around them.<br />

The design process normally starts<br />

by sitting down with ship owners<br />

to gather as much data as possible<br />

on what they want their vessels to<br />

do. Details such as operating routes,<br />

anticipated weather conditions,<br />

turnaround times in port and the<br />

type of cargo all have a significant<br />

impact on the design. A detailed<br />

picture of the operating profile is<br />

built up long before a ship gets to<br />

the drawing board.<br />

With the introduction of new IMO<br />

emissions regulations in 2016, it is also<br />

very important to plan ahead and consider the legislative<br />

landscape and any other requirements that may be in place<br />

when the vessels enter service.<br />

The result for the customer is that the performance of a<br />

new design can be predicted early in contract negotiations,<br />

giving confidence that the actual ship will behave as<br />

calculated and the full benefits of innovation realised.<br />

<strong>In</strong>tegrated processes<br />

Development of a hull form with the required performance<br />

for the customer’s operation goes hand in hand with<br />

structural strength and steel work calculations. Once a ship<br />

design has been agreed on with the owner, <strong>Rolls</strong>-<strong>Royce</strong><br />

works closely with the shipyard and the owner to develop<br />

detailed specifications and working drawings.<br />

As shipyards across the world build <strong>Rolls</strong>-<strong>Royce</strong> designed<br />

vessels, there is a three-way relationship between the<br />

yard, the ship owner and the designer. For merchant<br />

vessels, a team in Croatia specialises in producing the<br />

detailed production drawings of the ship and the installed<br />

equipment. Using powerful software, the exact order<br />

of build can be specified, as can input for the computer<br />

programmes that will cut and weld the steel.<br />

Over the last year, there have been a number of<br />

examples.<br />

NVC 405 – the first of a new generation<br />

Last year, <strong>Rolls</strong>-<strong>Royce</strong> unveiled its new Environship concept<br />

general cargo vessel and secured its first orders from<br />

Norwegian transport group Norlines. The 112m long and<br />

5,000dwt design combines the best available gas power<br />

and propulsion technology into an innovative hull design<br />

to provide numerous environmental benefits, including the<br />

virtual elimination of SOx and a reduction of CO 2<br />

emissions<br />

by more than 40 per cent compared to similar vessels.<br />

The hull incorporates improvements in hydrodynamics<br />

and wave piecing technology (patent pending) that<br />

enables the ship to cut through rather than ride over<br />

waves for improved performance in a seaway, enabling<br />

operators to remain on schedule<br />

without needing to burn additional<br />

fuel to make up lost time.<br />

Powered by a single Bergen B35:40<br />

V12 gas engine developing 3,930kW,<br />

two of the vessels are now being built<br />

at the Tsuji Heavy <strong>In</strong>dustries shipyard<br />

in Jiangsu, China. The vessels will<br />

enter into service progressively from<br />

October 2013, operating along the<br />

West Coast of Norway.<br />

NVC 604 – Bunker tankers<br />

Three NVC 604 bunker tankers have<br />

been designed for Brazilian operator<br />

Navegação São Miguel Ltda (NSM)<br />

to build at their own yard in Niteroi,<br />

Brazil. The vessels have <strong>Rolls</strong>-<strong>Royce</strong><br />

systems and equipment and are to be<br />

delivered by the end of 2014.<br />

<strong>Rolls</strong>-<strong>Royce</strong> has had a fruitful<br />

cooperation with NSM for almost<br />

two years developing these vessels,<br />

which are optimised to meet very<br />

specific requirements, with a high<br />

focus on large cargo tank volume,<br />

high deadweight and good course<br />

keeping in shallow areas. The vessels<br />

will have DNV class, fly the Brazilian<br />

flag and are designed for coastal trade<br />

in Brazil. The cargo will be heavy fuel<br />

oil (HFO) and marine gas oil (MGO) to<br />

a total deadweight of about 4,350t at<br />

the design draught of 4.5m. Service<br />

speed will be approximately 10 knots.<br />

Overall length is 90.2m with a beam<br />

of 18.2m.<br />

NSM began to provide bunkering<br />

operations in 1964 in Guanabara Bay<br />

1

www.rolls-royce.com<br />

15<br />

2<br />

3<br />

4<br />

(Rio de Janeiro) to supply the then incipient Petrobras oil<br />

giant. The company is now responsible for more than 9,000<br />

fuel loading and supply operations to ships along the<br />

entire Brazilian coastline and the three new tankers will join<br />

the owner’s fleet of about 40 specialised vessels.<br />

NVC 401 – Forage carrier<br />

The gas-powered NVC 401 Forage Carrier is the latest ship<br />

design from the award-winning <strong>Rolls</strong>-<strong>Royce</strong> Environship<br />

range and incorporates a variety of features to reduce<br />

environmental impact while increasing efficiency.<br />

Ordered by Norwegian company Eidsvaag AS, it will<br />

undertake feed supply duties to fish farms along the<br />

Norwegian coast when delivered in 2013. The 75m long<br />

vessel can carry up to 1,450t of feed pellets that are stored<br />

in 62 specially designed tanks. A demanding schedule will<br />

ensure fish are fed at the same time every week, regardless<br />

of weather conditions.<br />

<strong>Rolls</strong>-<strong>Royce</strong> will supply all the main systems and<br />

equipment, as well as the ship design. These include a<br />

Bergen C26:33L9PG gas engine, a wave-piercing bow and a<br />

Promas propulsion system. <strong>Rolls</strong>-<strong>Royce</strong> will also supply the<br />

dynamic positioning (DP) system, which will hold the ship<br />

accurately in position during the offloading of fish feed via<br />

the unloading system at the bow.<br />

NVC 386 – First for live fish transport<br />

A new generation of wellboats has been designed and<br />

developed by <strong>Rolls</strong>-<strong>Royce</strong> in close cooperation with<br />

Sølvtrans, the world’s largest operator transporting live fish.<br />

The first vessel is scheduled for delivery in 2013.<br />

It will be 76m long with a beam of 16m and incorporates<br />

the latest developments in hull and systems design. An<br />

advanced diesel-electric propulsion system with hybrid<br />

shaft generator, powered by two Bergen C25:336P<br />

diesels rated at 1,440kW, will deliver low fuel consumption<br />

and emissions.<br />

The design incorporates the latest improvements in<br />

fish welfare and fish handling. Tank capacity of 3,000m3<br />

provides a capability to safely transport up to 450t of<br />

live fish and is divided into three equal cargo holds, with<br />

sliding bulkheads and a pressure system for loading and<br />

unloading. It is fully equipped for transport in a closed<br />

system with no discharge to the sea. Control of the water<br />

flow and circulation in the cargo compartments has been a<br />

key design priority to ensure optimal conditions for the fish.<br />

Considerable emphasis has also been placed on the<br />

living and working environment for the crew. Single cabins<br />

accommodate up to 11 people and there is a fitness centre<br />

and sauna.<br />

The vessel is being built by the Spanish shipyard<br />

Astilleros Zamakona S.A. [RW]<br />

1. NVC 405 general<br />

cargo vessel.<br />

2. NVC 604 bunker<br />

tanker.<br />

3. NVC 401 forage<br />

carrier.<br />

4. NVC 386 live fish<br />

transporter.

16 TECHNOLOGY<br />

Stronger together<br />

<strong>Rolls</strong>-<strong>Royce</strong> and Daimler have joined forces to create a new marine and<br />

industrial engine joint venture through the acquisition of Tognum.<br />

Tognum makes high speed<br />

diesel engines for use at sea<br />

and on land. The engines<br />

are highly complimentary<br />

to the Bergen medium speed diesel<br />

and gas engine portfolio supplied<br />

by <strong>Rolls</strong>-<strong>Royce</strong>. Daimler has global<br />

distribution capability, volume<br />

manufacturing expertise and<br />

technologies for lower emissions<br />

diesel engines. Combining the<br />

strengths of Tognum, <strong>Rolls</strong>-<strong>Royce</strong><br />

and Daimler will create significant<br />

new opportunities and accelerate<br />

growth in a fast-moving global<br />

market worth more than €30 billion a<br />

year. The three companies have wellaligned<br />

portfolios and together, they<br />

can offer a wide range of medium<br />

and high speed diesel and gas<br />

engines for propulsion and power<br />

generation applications. Over time,<br />

there are also clear opportunities in shared technologies,<br />

sales networks and after sales service expertise.<br />

While the Tognum name may not be familiar to all, its<br />

brands are certainly well-known: MTU, MTU Onsite Energy<br />

and L’Orange.<br />

Advanced marine propulsion technology<br />

What do many of the biggest mega yachts and the fastest<br />

high speed ferries of the world have in common? They are<br />

powered by MTU. The same applies worldwide for many<br />

other ships, frigates, tugs and platform supply vessels.<br />

With its two business units, Engines and Onsite Energy<br />

& Components, the Tognum Group is one of the world’s<br />

leading suppliers of engines and propulsion systems<br />

for off-highway applications and of distributed energy<br />

systems. The product portfolio of the Engines business unit<br />

comprises MTU engines and propulsion systems for ships,<br />

for heavy land, rail and defense vehicles and for the oil and<br />

gas industry. Products of the Onsite Energy & Components<br />

business unit include distributed energy systems of the<br />

brand MTU Onsite Energy and fuel-injection systems<br />

from L’Orange.<br />

Under the MTU brand name,<br />

propulsion system solutions are<br />

provided for a range of marine<br />

applications, from naval and<br />

governmental vessels, tugs, offshore<br />

vessels to fast ferries and yachts. The<br />

high speed marine diesel engines<br />

Series 60, Series 396, Series 4000,<br />

Series 1163 and Series 8000 cover<br />

a broad power range from 260 to<br />

9,100 kW. As a systems partner,<br />

complete propulsion packages are<br />

also supplied that include other<br />

equipment such as gearboxes,<br />

propellers, onboard power supplies<br />

and integrated ship automation<br />

systems. The range of products<br />

is complemented by extensive<br />

services provided under the<br />

MTU_ValueCare programme.<br />

<strong>In</strong> 2011, Tognum generated<br />

revenue of nearly €3 billion and<br />

1

www.rolls-royce.com<br />

<strong>17</strong><br />

2<br />

employed more than 9,000 people. With strategic<br />

hubs in Friedrichshafen in Germany, Detroit, Michigan<br />

in the US and Singapore, a point of contact is always<br />

within reach for customers or business partners. Its<br />

global manufacturing, distribution and service structure<br />

comprises 23 fully consolidated companies, more than<br />

140 sales partners and over 500 authorised dealerships at<br />

approximately 1,200 locations.<br />

Propulsion solutions for naval and<br />

coastguard vessels<br />

For more than 50 years, MTU has developed specific<br />

propulsion concepts for the naval sector. As a single<br />

source integrator, MTU configures the propulsion systems<br />

that include automation systems like ‘Callosum’ that best<br />

fit the requirements of navies and coast guards worldwide<br />

– from the Turkish MILGEM frigates – to the US Coast<br />

Guard’s National Security Cutters. Combined propulsion<br />

systems link several fuel-efficient diesel engines, or<br />

diesel engines with gas turbines to provide the needed<br />

flexibility, agility and redundancy. Highly advanced<br />

modern naval vessels like the US Navy’s<br />

<strong>In</strong>dependence-variant Littoral Combat Ships – designed<br />

by a General Dynamics and Austal team – are the first<br />

naval vessels in the world to feature a trimaran hull.<br />

They rely on a combined MTU diesel and gas turbine<br />

propulsion system for efficient operations.<br />

MTU has also been playing an important role in the<br />

development and design of diesel-electric submarine<br />

propulsion systems. The Series 396 is the most successful<br />

MTU submarine engine. It is currently installed in most of<br />

the world’s conventional submarines such as the German<br />

U212, where it generates power for both main propulsion<br />

and on-board utilities.<br />

Proven engines are also the key when it comes to cost,<br />

effectively extending a vessel’s operating lifetime. The<br />

Colombian Navy recently modernised its four Almirante<br />

1. MTU Model<br />

4000 M93 diesel<br />

engines have<br />

an outstanding<br />

power-to-weight<br />

ratio, which puts<br />

them at the top<br />

of their class for<br />

acceleration. With<br />

up to 4,300 kW<br />

of power, they<br />

are ideal for fast<br />

yachts. Pictured:<br />

20V 4000 M93L.<br />

Engine weight<br />

is 13t, with gear<br />

15,6t.<br />

2. The headquarters<br />

and main<br />

manufacturing<br />

is based at<br />

Friedrichshafen in<br />

Germany.<br />

MEDIUM AND HIGH SPEED ENGINES IN AN EXTENDED RANGE<br />

The new entity will bring together the well-known<br />

MTU and Bergen engine names, extending the product<br />

portfolio to include both medium speed and high<br />

speed diesel and gas engines.<br />

Once integrated with the extensive range of<br />

<strong>Rolls</strong>-<strong>Royce</strong> ship designs, systems and equipment, a<br />

much broader range of advanced marine solutions<br />

will be available for customers across the commercial<br />

and naval sectors. The goal is to provide the optimum<br />

system where economical and reliable performance,<br />

environmental compliance and power density are<br />

important factors.<br />

The new joint venture will provide:<br />

An integrated high and medium speed<br />

engine portfolio.<br />

A broader product range for marine and<br />

energy markets.<br />

A greater range of marine propulsion and power<br />

systems solutions.<br />

An enlarged distribution and service network.<br />

A customer and service focused organisation.<br />

At present, all three companies are engaged in<br />

discussions to prepare their future collaboration.<br />

Established individual sales relationships remain<br />

unchanged.<br />

Brands: MTU, MTU Onsite Energy, L’Orange

18 TECHNOLOGY<br />

1<br />

2 3<br />

Padilla class frigates by replacing the vessels’ 30-year-old MTU Series 1163<br />

engines with the current version of the same engine model. This included the<br />

‘Callosum’ ship monitoring, automation and control system, which will extend<br />

propulsion system overhaul period to 20 years. The on-board power generation<br />

systems were also replaced with MTU gensets based on Series 2000 engines.<br />

Opting to modernise this frigate class with MTU engines, the Colombian Navy<br />

was able to make the most of existing assets and facilities.<br />

MTU engines for tugs - reliable and durable<br />

MTU’s Series 4000 ‘Ironmen’ engines, which have a power range of 746 –<br />

1,840kW for unrestricted continuous operation and up to 2,240kW for vessels<br />

such as crewboats, were developed to meet the particular requirements of the<br />

workboat market. Specifically, this means maximising engine performance,<br />

extending the time between overhauls and reducing fuel consumption. As a<br />

result, the ‘Ironmen’ engines deliver a fuel consumption of 195g/kWhr and can<br />

operate for up to 33,000hrs before the engines are due a major overhaul – key<br />

advantages for tugs and other commercial vessels that depend on reliable<br />

and cost-efficient propulsion solutions with the highest<br />

possible availability. <strong>In</strong> a large number of tug systems, MTU<br />

diesels are driving <strong>Rolls</strong>-<strong>Royce</strong> azimuth thrusters.<br />

Power offshore<br />

The ‘Ironmen’ engines are also the base for MTU’s<br />

diesel-electric propulsion systems in the offshore sector.<br />

An example is the PSV Eldborg, which is powered by<br />

four 12 cylinder 4000 M40B engines rated at 1,560kW<br />

and delivered in 2009. Vessels in the offshore wind<br />

industry also benefit from MTU’s diesel and<br />

diesel-electric solutions. Two of the most recent<br />

windfarm support vessel designs feature MTU diesel<br />

and <strong>Rolls</strong>-<strong>Royce</strong> waterjet propulsion (see page 53).<br />

<strong>In</strong>stalling bulky wind turbine towers in rough seas is<br />

a real challenge for a workboat’s propulsion system.<br />

RWE <strong>In</strong>nogy’s latest installation vessels are equipped

www.rolls-royce.com<br />

19<br />

4<br />

with an MTU diesel-electric system for dynamic vessel<br />

positioning and reliable operation of all ship systems<br />

in powerful tidal currents and at high wind speeds. It is<br />

due to these advanced engine technologies that MTU’s<br />

diesel-electric propulsion solutions have since drawn the<br />

attention of a number of international naval architects.<br />

High-performance engines for<br />

fast ferries<br />

<strong>In</strong> order to quickly and reliably transport commuters<br />

and tourists to their destinations, fast ferries depend on<br />

powerful propulsion systems. MTU has been providing<br />

shipyards such as Austal with the solutions to meet<br />

increasing demands on new vessels, which have to carry<br />

more people while completing their routes to the same<br />

schedule. Large modern high-speed catamarans like<br />

the Jean de la Valette and the trimaran ferry Benchijigua<br />

Express are powered by the largest engines MTU<br />

produces, the power-dense 8000 series. Both vessels<br />

are also propelled by <strong>Rolls</strong>-<strong>Royce</strong> waterjets. <strong>In</strong> combination<br />

with comprehensive maintenance contracts, the fast<br />

ferries are well-equipped to meet any current and<br />

future requirements.<br />

State-of-the-art yacht propulsion<br />

The experience and expertise gained from naval and<br />

commercial applications have been incorporated into the<br />

design of MTU’s yacht propulsion systems. This results in<br />

MTU yacht engines not only being extremely powerful,<br />

quiet and compact, but also fuel-efficient, cost-effective<br />

and reliable. As a systems supplier, MTU integrates<br />

all components based on the clients’ most exclusive<br />

demands – from the engine as the heart of the system<br />

to the transmission and generators to the standardised<br />

electronic monitoring and control systems like ‘Blue Vision’.<br />

Drive solutions are individually designed for each yacht.<br />

Italian manufacturer Ferretti, for example, relies on MTU<br />

Series 2000 engines for best in class power-to-weight<br />

ratio. Semi-displacement yachts like those of Dutch<br />

builder Heesen are equipped with Series 4000 engines for<br />

especially high standards with regards to noise, vibration<br />

and reliability.<br />

Implementing key technologies<br />

The manufacture of diesel engines for marine applications<br />

at MTU has a long tradition. Fast-running and compact<br />

four-stroke diesel engines have been developed and<br />

manufactured since the 1930s.<br />

The most significant challenge in the development<br />

of next generation diesel engines is compliance with<br />

future exhaust gas emission limits, while also ensuring<br />

low fuel consumption.<br />

Tognum develops key technologies for clean and<br />

efficient diesel engines in-house. By combining<br />

turbocharging, fuel injection, electronic monitoring and<br />

control systems, in addition to advanced combustion<br />

technology, Tognum engineers have optimised the<br />

in-engine technologies to the point where no additional<br />

external after treatment is necessary to comply with<br />

today’s emission standards.<br />

If in-engine optimisation is no longer sufficient to meet<br />

the more stringent emission requirements, then exhaust<br />

gas after-treatment such as selective catalytic reduction<br />

(SCR) or a diesel particulate filter (DPF) is added. As a result,<br />

system solutions deliver minimised fuel consumption with<br />

low exhaust emissions and long engine life. [MG]<br />

1. The future F125<br />

frigates of the<br />

German Navy will<br />

each be powered<br />

by four MTU<br />

Series 4000 diesel<br />

gensets producing<br />

12,060kW, to power<br />

onboard systems<br />

and provide diesel<br />

electric propulsion<br />

for cruising speeds<br />

up to 20 knots.<br />

2. Four MTU series<br />

8000 engines<br />

rated at 9,100kW<br />

drive three<br />

<strong>Rolls</strong>-<strong>Royce</strong><br />

Kamewa waterjets<br />

to give the<br />

101m trimaran<br />

Benchijigua Express,<br />

operated by Fred<br />

Olsen in the<br />

Canary Islands a<br />

top speed in excess<br />

of 40 knots.<br />

3. Starnav’s line<br />

handling tug Sirius<br />

relies on MTU<br />

16V 4000 M63<br />

‘Ironmen’ engines<br />

to deliver 70t<br />

of bollard pull.<br />

Starnav provides<br />

oil & gas offshore<br />

services to<br />

Petrobras and<br />

Repsol activities<br />

in Brazil.<br />

4. The 73m super<br />

yacht Silver built by<br />

Hanseatic Marine<br />

in West Australia<br />

is powered by two<br />

MTU 16V 4000 M93<br />

diesel engines,<br />

which give a<br />

maximum speed<br />

of 27 knots.

20 TECHNOLOGY<br />

Anti-heeling<br />

with simultaneous roll-reduction<br />

<strong>Rolls</strong>-<strong>Royce</strong> can now provide anti-heeling<br />

and roll-reduction in a single system. Crane<br />

operations at sea can therefore be carried out<br />

on more days than previously possible.<br />

1<br />

<strong>Rolls</strong>-<strong>Royce</strong> has been<br />

designing U-tanks for roll-<br />

reduction and anti-heeling<br />

(formerly <strong>In</strong>tering) for over<br />

40 years. These systems have proved<br />

so reliable that in some places they<br />

have become the accepted standard<br />

for shipyards and shipping lines.<br />

A particular speciality is the<br />

combined U-tank. Roll-reduction<br />

during operations at sea and<br />

anti-heeling in harbour can be<br />

carried out with the one tank, saving<br />

significantly on space. The principle<br />

has been proven with installations<br />

on several hundred ships, but<br />

until recently, it was only possible<br />

to select one of the functions,<br />

depending on requirement.<br />

The next logical step –<br />

anti-heeling with simultaneous<br />

roll-reduction – has now been<br />

successfully realised, with<br />

installations on the ROV/dive<br />

support vessels Deep Cygnus and Normand Pacific, and<br />

feedback is good. They are no longer forced to wait<br />

for sea conditions almost as calm as in harbour before<br />

commencing lifting operations.<br />

The key to simultaneous operation is a multi-tank<br />

system of adequate tank capacity and momentum for<br />

both applications. Since in most cases the tank capacity<br />

is designed according to the maximum crane moment,<br />

simultaneous operation can only take place with the<br />

crane under part load, so that sufficient tank moment<br />

still remains for roll-reduction.<br />

These vessels each have three U-tanks. <strong>In</strong> normal<br />

mode, when crane operations are not being undertaken,<br />

all three tanks operate in roll damping mode. When<br />

crane operations are being carried out, one or two of the<br />

tanks are switched to the anti-heeling mode, depending<br />

on the sea state and the load being lifted. Both systems<br />

are designed for operation with maximum reliability and<br />

minimal energy consumption. There are no moving parts<br />

in the water.<br />

For ice breakers, the system gives another benefit, ice<br />

heeling or duck walk, where the system is set to give<br />

the vessel a gentle roll of 3-4 degrees in a three-minute<br />

cycle. This ensures a regular change in waterline <strong>depth</strong><br />

to keep the sides of the vessel wet,<br />

thereby reducing external ice<br />

build-up and increasing speed. A<br />

wider channel is also created.<br />

Roll-reduction<br />

The directly controlled U-tanks<br />

(wing tanks measuring<br />

approximately two to three decks<br />

in height, connected to each other<br />

by water and air cross-ducts) are<br />

designed to meet the shortest roll<br />

that can be expected from the ship<br />

during its normal operations.<br />

The movement of the tank water<br />

is passive, induced solely by the<br />

rolling movement of the ship, and<br />

the system maintains its full effect<br />

even at zero speed. The shifting of<br />

the centre of gravity, which is the<br />

difference in level between the<br />

two wing tanks, generates the tank<br />

momentum that counteracts the<br />

roll motion.

www.rolls-royce.com<br />

21<br />

2<br />

1. Deep Cygnus uses<br />

three tanks in<br />

combination for<br />

simultaneous<br />

anti-heeling and<br />

roll reduction.<br />

2. For improved<br />

roll reduction,<br />

multiple valves<br />

enable tank delay<br />

to be extended<br />

maintaining a 90°<br />

phase delay as the<br />

roll period varies.<br />

3. The 121m ROV/<br />

dive support<br />

vessel Deep<br />

Cygnus.<br />

4. The multi-tank<br />

system is used<br />

in combination<br />

to reduce roll<br />

and provide antiheeling<br />

during<br />

lifting operations.<br />

3<br />

4<br />

PHOTO Richard Paton<br />

With periodic interruption of the<br />

tank’s ventilation using a series of<br />

durable disc valves that open and<br />

close within 0.4 seconds, the tank<br />

moment can be held constant.<br />

The system can therefore react<br />

automatically to every individual roll<br />

movement of the ship. This control<br />

mode preserves the necessary<br />

delay of ¼ roll period, i.e. 90° of tank<br />

period versus the ship roll motion,<br />

in each single roll movement for the<br />

best possible reduction of roll.<br />

The tanks are usually positioned<br />

in the parallel mid-ship area, where<br />

the leverage is greatest for the tank<br />

moment and therefore the required<br />

mass is smallest. If this is not<br />

possible, the tank can be moved<br />

aft. Moving forward is undesirable<br />

as acceleration forces from pitching<br />

should be avoided inside the tank.<br />

Anti-heeling<br />

The anti-heeling action is achieved using the same tank<br />

but by means of an air blower, which acts on the water<br />

surface with a maximum over-pressure of 1Bar.<br />

The airflow is controlled by a special valve group, which<br />

can switch to any operating condition (water to starboard,<br />

to port, or stop) in less than one second. The system<br />

therefore reacts almost instantaneously to the current<br />

heeling moment. This is particularly useful if the moment<br />

of the crane does not change linearly, but resembles<br />

a sine-function. As air pressure is the weight transfer<br />

medium, the cross-duct no longer has to be tubular<br />

and a roll-reduction tank with its large and rectangular<br />

cross-duct can be used for anti-heeling duties.<br />

A further control option, already proven on<br />

paper-carrier vessels, reduces system reaction time<br />

even further. By programming the anti-heeling system<br />

to receive change of momentum (tm/min) signals<br />

directly from the crane reaction is immediate, no waiting<br />

for the delayed reaction to the ship’s list. <strong>In</strong> the ideal<br />

case, no further list occurs at all, since every crane<br />

movement is compensated for instantaneously by the<br />

anti-heeling system.<br />

Depending on the vessel<br />

application customers can select<br />

from a number of anti-heeling<br />

arrangements.<br />

Now that <strong>Rolls</strong>-<strong>Royce</strong> has become<br />

a major producer of shipboard<br />

cranes for demanding tasks<br />

offshore, as well as a ship designer<br />

and provider of anti-roll and<br />

anti-heel systems, fully integrated<br />

solutions can be designed and<br />

supplied. A combined system<br />

allows crane operations to continue<br />

safely, even in worsening weather<br />

conditions, for more operational<br />

revenue-earning days. [RW]

22 TECHNOLOGY<br />

Venice Syncrolift<br />

demonstrates step change<br />

in shiplift lift capacity<br />

The highest capacity Syncrolift® ever designed by <strong>Rolls</strong>-<strong>Royce</strong> was recently<br />

commissioned in Venice. It sets a new standard in tonne/metre lift capacity<br />

and means shiplifts can now be designed to lift Aframax size vessels.<br />

1<br />

2

www.rolls-royce.com<br />

23<br />

PHOTO GLF<br />

PHOTO GLF<br />

1. Caissons weighing<br />

up to 22,300t<br />

will be launched<br />

by the 52m wide<br />

Syncrolift.<br />

2. Once launched,<br />

the caissons will<br />

be towed out and<br />

placed in position<br />

at the lagoon<br />

inlets.<br />

3. The gates rest<br />

in the caissons<br />

anchored on the<br />

seabed.<br />

4. Aerial view of the<br />

Venice launch site.<br />

With a platform width of 52m and a length of<br />

just 60m, the Venice Syncrolift is the widest<br />

shiplift designed and constructed to date.<br />

Two rows of 1,200 tonne hoists give the<br />

shiplift a net lifting capacity of over 24,000 tonnes –<br />

the greatest tonne/metre capacity of any Syncrolift in<br />

the world.<br />

This latest advance in the application of <strong>Rolls</strong>-<strong>Royce</strong><br />

shiplift technology is now operational in Venice, Italy<br />

and is a revolutionary departure from standard Syncrolift<br />

designs. It will launch concrete caissons, not ships.<br />

The Syncrolift was custom designed to meet the<br />

requirements of the Venice flood barrier project, known<br />

as MOSE. It will be used to launch 18 giant concrete<br />