Download fact sheet for oceanographic & research ... - Rolls-Royce

Download fact sheet for oceanographic & research ... - Rolls-Royce Download fact sheet for oceanographic & research ... - Rolls-Royce

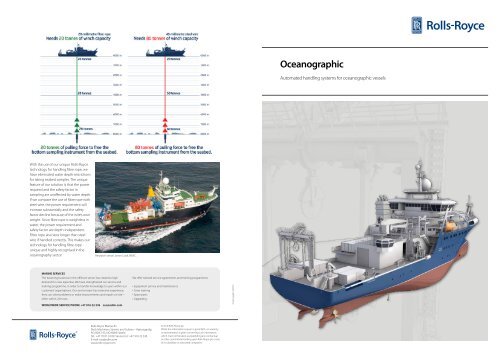

Oceanographic Automated handling systems for oceanographic vessels With the use of our unique Rolls-Royce technology for handling fibre rope, we have eliminated water depth restrictions for taking seabed samples. The unique feature of our solution is that the power required and the safety factor in sampling are unaffected by water depth. If we compare the use of fibre rope with steel wire, the power requirement will increase substantially and the safety factor decline because of the wire’s own weight. Since fibre rope is weightless in water, the power requirement and safety factor are depth- independent. Fibre rope also lasts longer than steel wire if handled correctly. This makes our technology for handling fibre rope unique and highly recognised in the oceanography sector. Research vessel James Cook, NERC. MARINE SERVICES The booming business in the offshore sector has created a high demand for crew expertise. We have strengthened our service and training programme, in order to transfer knowledge to users within our customers’ organisations. Our service team has extensive experience, they can solve problems or make improvements and repairs on-site – often within 24 hours. WORLDWIDE SERVICE PHONE +47 916 22 336 osc@odim.com We offer tailored service agreements and training programmes: • Equipment service and maintenance • Crew training • Spare parts • Upgrading Oceanographic-092010 Rolls-Royce Marine AS Deck Machinery Seismic and Subsea – Hjørungavåg P.O. BOX 193, NO-6069 Hareid Tel.: +47 70 01 33 00. Service tel.: +47 916 22 336 E-mail: osc@odim.com www.rolls-royce.com © 2010 Rolls-Royce plc Whilst this information is given in good faith, no warranty or representation is given concerning such information, which must not be taken as establishing any contractual or other commitment binding upon Rolls-Royce plc or any of its subsidiary or associated companies.

Oceanographic<br />

Automated handling systems <strong>for</strong> <strong>oceanographic</strong> vessels<br />

With the use of our unique <strong>Rolls</strong>-<strong>Royce</strong><br />

technology <strong>for</strong> handling fibre rope, we<br />

have eliminated water depth restrictions<br />

<strong>for</strong> taking seabed samples. The unique<br />

feature of our solution is that the power<br />

required and the safety <strong>fact</strong>or in<br />

sampling are unaffected by water depth.<br />

If we compare the use of fibre rope with<br />

steel wire, the power requirement will<br />

increase substantially and the safety<br />

<strong>fact</strong>or decline because of the wire’s own<br />

weight. Since fibre rope is weightless in<br />

water, the power requirement and<br />

safety <strong>fact</strong>or are depth- independent.<br />

Fibre rope also lasts longer than steel<br />

wire if handled correctly. This makes our<br />

technology <strong>for</strong> handling fibre rope<br />

unique and highly recognised in the<br />

oceanography sector.<br />

Research vessel James Cook, NERC.<br />

MARINE SERVICES<br />

The booming business in the offshore sector has created a high<br />

demand <strong>for</strong> crew expertise. We have strengthened our service and<br />

training programme, in order to transfer knowledge to users within our<br />

customers’ organisations. Our service team has extensive experience,<br />

they can solve problems or make improvements and repairs on-site –<br />

often within 24 hours.<br />

WORLDWIDE SERVICE PHONE +47 916 22 336 osc@odim.com<br />

We offer tailored service agreements and training programmes:<br />

• Equipment service and maintenance<br />

• Crew training<br />

• Spare parts<br />

• Upgrading<br />

Oceanographic-092010<br />

<strong>Rolls</strong>-<strong>Royce</strong> Marine AS<br />

Deck Machinery Seismic and Subsea – Hjørungavåg<br />

P.O. BOX 193, NO-6069 Hareid<br />

Tel.: +47 70 01 33 00. Service tel.: +47 916 22 336<br />

E-mail: osc@odim.com<br />

www.rolls-royce.com<br />

© 2010 <strong>Rolls</strong>-<strong>Royce</strong> plc<br />

Whilst this in<strong>for</strong>mation is given in good faith, no warranty<br />

or representation is given concerning such in<strong>for</strong>mation,<br />

which must not be taken as establishing any contractual<br />

or other commitment binding upon <strong>Rolls</strong>-<strong>Royce</strong> plc or any<br />

of its subsidiary or associated companies.

Automated handling systems <strong>for</strong> <strong>oceanographic</strong> vessels<br />

Following the acquisition of ODIM, we now have the<br />

capability to deliver complete automated handling systems<br />

<strong>for</strong> well intervention in addition to our current range of ship<br />

design and integrated systems solutions. Systems<br />

comprising engines, propellers, thrusters, steering gear,<br />

rudders, stabilisers, deck machinery and automation &<br />

control systems.<br />

ODIM has, during several years, produced<br />

unique cable traction solutions that enable the<br />

use of fiber rope as a substitute <strong>for</strong> steel wire<br />

when working at great sea depths. Thus, the<br />

fiber rope’s light weight is effectively utilised to<br />

handle larger payloads.<br />

Control systems, winches and over-board<br />

systems are designed <strong>for</strong> the specific needs on<br />

vessels used in oceanography and deep-sea<br />

operations. Among the benefits are integrated<br />

solutions that free the floor space and increase<br />

safety <strong>for</strong> those working on deck as well as the<br />

expensive underwater equipment.<br />

Tailor-made solutions<br />

We deliver complete and tailor-made solutions,<br />

including our patented and field proven cable<br />

traction control unit technology to the<br />

Oceanographic market.<br />

Benefits:<br />

Our complete system<br />

deliveries include fully<br />

integrated control systems,<br />

providing manoeuvring<br />

monitoring and safety features.<br />

One provider secures easy<br />

interfacing <strong>for</strong> installation and<br />

service.<br />

Cabel traction control unit<br />

Electric drive:<br />

• Liquid/Air cooled design<br />

• Frequency controlled<br />

• Slip control<br />

• Anti-spin<br />

• Pre-conditioning of rope<br />

• Load distribution<br />

• Automatic landing and lift-off<br />

• Pull limit<br />

• Active heave compensation<br />

• Constant tension<br />

• Rope management system<br />

• Splice handling<br />

• Max pull capacity 30 Te<br />

Deep tow and deep water coring<br />

systems<br />

Electric drive:<br />

• Liquid/Air cooled design<br />

• Frequency controlled<br />

Drum deep tow<br />

• Lebus fitted<br />

• Focal slip ring<br />

Drum deep water coring<br />

• Max line speed 2m/s<br />

Frames<br />

• Up to 30 Te<br />

• Outreach 4,5 m<br />

• Clear lifting height 8 m<br />

• Width between legs 9,5 m<br />

• Aux. towing eyes 5 T<br />

• Aux. winches 5T/100 m<br />

Hydro booms<br />

• Up to 7 Te<br />

• SWL 5 T<br />

• Outreach over side 5 m<br />

• Deployment speed 0.5 m/s<br />

(maximum)<br />

Piston corer handling system<br />

• SWL up to 30 Te<br />

• Outreach 3 meters<br />

• Flexible corer head holder<br />

• Hydraulically driven<br />

Parallellogram frames<br />

• SWL 20 T<br />

• Outreach over side 2,5 m<br />

• Secondary load 4,5 m/12 T<br />

• Lifting height deck 5 m<br />

• Eye plates 2 x 5 T<br />

• Aux. winches 5 T/100 m<br />

Outhaulers<br />

CTD winch systems<br />

Active heave compensation (AHC)<br />

Electric drive:<br />

• Liquid/Air cooled design<br />

• Frequency controlled<br />

Drum<br />

• Lebus fitted<br />

• Focal slip ring<br />

Max line speed 2 m/s<br />

Max line pull:<br />

• Storage drum, 1 Te @ 2 m/s<br />

• Traction winch, 5 Te @ 1 m/s