issue 1 - Roland Berger

issue 1 - Roland Berger

issue 1 - Roland Berger

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

p industry report oems will reduce in-house production from 35 percent today to 20 percent in 2015<br />

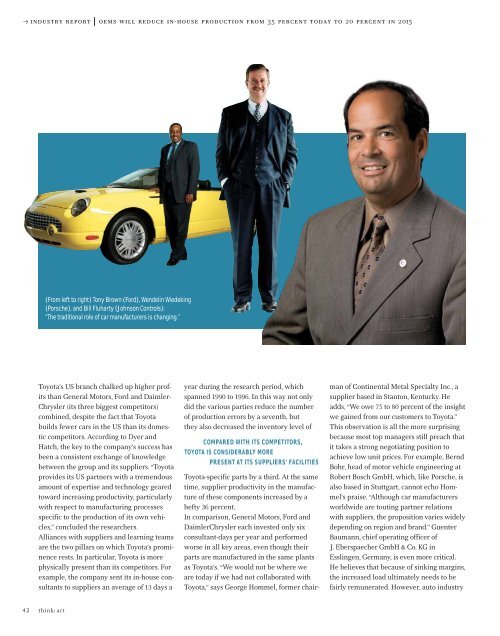

(From left to right) Tony Brown (Ford), Wendelin Wiedeking<br />

(Porsche), and Bill Fluharty (Johnson Controls):<br />

“The traditional role of car manufacturers is changing.”<br />

Toyota’s US branch chalked up higher profits<br />

than General Motors, Ford and Daimler-<br />

Chrysler (its three biggest competitors)<br />

combined, despite the fact that Toyota<br />

builds fewer cars in the US than its domestic<br />

competitors. According to Dyer and<br />

Hatch, the key to the company’s success has<br />

been a consistent exchange of knowledge<br />

between the group and its suppliers. “Toyota<br />

provides its US partners with a tremendous<br />

amount of expertise and technology geared<br />

toward increasing productivity, particularly<br />

with respect to manufacturing processes<br />

specific to the production of its own vehicles,”<br />

concluded the researchers.<br />

Alliances with suppliers and learning teams<br />

are the two pillars on which Toyota’s prominence<br />

rests. In particular, Toyota is more<br />

physically present than its competitors. For<br />

example, the company sent its in-house consultants<br />

to suppliers an average of 13 days a<br />

year during the research period, which<br />

spanned 1990 to 1996. In this way not only<br />

did the various parties reduce the number<br />

of production errors by a seventh, but<br />

they also decreased the inventory level of<br />

COMPARED WITH ITS COMPETITORS,<br />

TOYOTA IS CONSIDERABLY MORE<br />

PRESENT AT ITS SUPPLIERS’ FACILITIES<br />

Toyota-specific parts by a third. At the same<br />

time, supplier productivity in the manufacture<br />

of these components increased by a<br />

hefty 36 percent.<br />

In comparison, General Motors, Ford and<br />

DaimlerChrysler each invested only six<br />

consultant-days per year and performed<br />

worse in all key areas, even though their<br />

parts are manufactured in the same plants<br />

as Toyota’s. “We would not be where we<br />

are today if we had not collaborated with<br />

Toyota,” says George Hommel, former chairman<br />

of Continental Metal Specialty Inc., a<br />

supplier based in Stanton, Kentucky. He<br />

adds, “We owe 75 to 80 percent of the insight<br />

we gained from our customers to Toyota.”<br />

This observation is all the more surprising<br />

because most top managers still preach that<br />

it takes a strong negotiating position to<br />

achieve low unit prices. For example, Bernd<br />

Bohr, head of motor vehicle engineering at<br />

Robert Bosch GmbH, which, like Porsche, is<br />

also based in Stuttgart, cannot echo Hommel’s<br />

praise. “Although car manufacturers<br />

worldwide are touting partner relations<br />

with suppliers, the proposition varies widely<br />

depending on region and brand.” Guenter<br />

Baumann, chief operating officer of<br />

J. Eberspaecher GmbH & Co. KG in<br />

Esslingen, Germany, is even more critical.<br />

He believes that because of sinking margins,<br />

the increased load ultimately needs to be<br />

fairly remunerated. However, auto industry<br />

42<br />

think: act