TO 00-25-172 - Robins Air Force Base

TO 00-25-172 - Robins Air Force Base

TO 00-25-172 - Robins Air Force Base

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>TO</strong> <strong>00</strong>-<strong>25</strong>-<strong>172</strong><br />

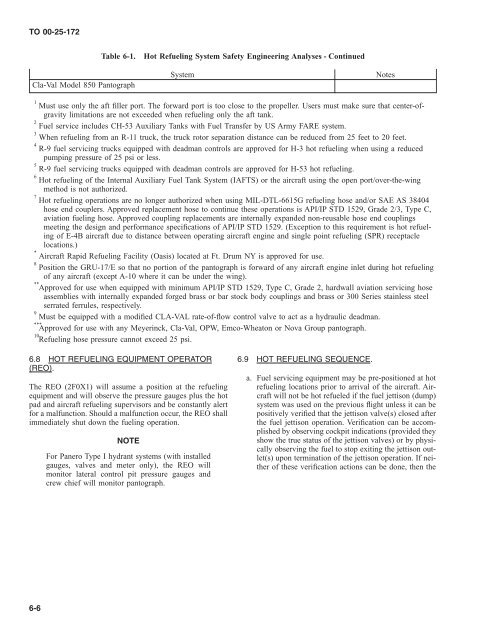

Table 6-1.<br />

Cla-Val Model 850 Pantograph<br />

Hot Refueling System Safety Engineering Analyses - Continued<br />

System<br />

Notes<br />

1<br />

Must use only the aft filler port. The forward port is too close to the propeller. Users must make sure that center-ofgravity<br />

limitations are not exceeded when refueling only the aft tank.<br />

2<br />

Fuel service includes CH-53 Auxiliary Tanks with Fuel Transfer by US Army FARE system.<br />

3<br />

When refueling from an R-11 truck, the truck rotor separation distance can be reduced from <strong>25</strong> feet to 20 feet.<br />

4<br />

R-9 fuel servicing trucks equipped with deadman controls are approved for H-3 hot refueling when using a reduced<br />

pumping pressure of <strong>25</strong> psi or less.<br />

5<br />

R-9 fuel servicing trucks equipped with deadman controls are approved for H-53 hot refueling.<br />

6<br />

Hot refueling of the Internal Auxiliary Fuel Tank System (IAFTS) or the aircraft using the open port/over-the-wing<br />

method is not authorized.<br />

7<br />

Hot refueling operations are no longer authorized when using MIL-DTL-6615G refueling hose and/or SAE AS 38404<br />

hose end couplers. Approved replacement hose to continue these operations is API/IP STD 1529, Grade 2/3, Type C,<br />

aviation fueling hose. Approved coupling replacements are internally expanded non-reusable hose end couplings<br />

meeting the design and performance specifications of API/IP STD 1529. (Exception to this requirement is hot refueling<br />

of E-4B aircraft due to distance between operating aircraft engine and single point refueling (SPR) receptacle<br />

locations.)<br />

*<br />

<strong>Air</strong>craft Rapid Refueling Facility (Oasis) located at Ft. Drum NY is approved for use.<br />

8<br />

Position the GRU-17/E so that no portion of the pantograph is forward of any aircraft engine inlet during hot refueling<br />

of any aircraft (except A-10 where it can be under the wing).<br />

**<br />

Approved for use when equipped with minimum API/IP STD 1529, Type C, Grade 2, hardwall aviation servicing hose<br />

assemblies with internally expanded forged brass or bar stock body couplings and brass or 3<strong>00</strong> Series stainless steel<br />

serrated ferrules, respectively.<br />

9<br />

Must be equipped with a modified CLA-VAL rate-of-flow control valve to act as a hydraulic deadman.<br />

***<br />

Approved for use with any Meyerinck, Cla-Val, OPW, Emco-Wheaton or Nova Group pantograph.<br />

10<br />

Refueling hose pressure cannot exceed <strong>25</strong> psi.<br />

6.8 HOT REFUELING EQUIPMENT OPERA<strong>TO</strong>R<br />

(REO).<br />

The REO (2F0X1) will assume a position at the refueling<br />

equipment and will observe the pressure gauges plus the hot<br />

pad and aircraft refueling supervisors and be constantly alert<br />

for a malfunction. Should a malfunction occur, the REO shall<br />

immediately shut down the fueling operation.<br />

NOTE<br />

For Panero Type I hydrant systems (with installed<br />

gauges, valves and meter only), the REO will<br />

monitor lateral control pit pressure gauges and<br />

crew chief will monitor pantograph.<br />

6.9 HOT REFUELING SEQUENCE.<br />

a. Fuel servicing equipment may be pre-positioned at hot<br />

refueling locations prior to arrival of the aircraft. <strong>Air</strong>craft<br />

will not be hot refueled if the fuel jettison (dump)<br />

system was used on the previous flight unless it can be<br />

positively verified that the jettison valve(s) closed after<br />

the fuel jettison operation. Verification can be accomplished<br />

by observing cockpit indications (provided they<br />

show the true status of the jettison valves) or by physically<br />

observing the fuel to stop exiting the jettison outlet(s)<br />

upon termination of the jettison operation. If neither<br />

of these verification actions can be done, then the<br />

6-6