TO 35-1-3 - Robins Air Force Base

TO 35-1-3 - Robins Air Force Base

TO 35-1-3 - Robins Air Force Base

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>TO</strong> <strong>35</strong>-1-3<br />

5.3.1.1 Follow the manufacturer's application instructions for<br />

corrosion removal. Repeat the process until all corrosion is<br />

removed. Allow to air dry prior to the application of a protective<br />

coating.<br />

5.3.1.2 Rust remover Permatex 81287 is available from:<br />

5.4 PRIMERS.<br />

Permatex<br />

Rocky Hill CT, 06067<br />

(860) 571-5100<br />

5.4.1 Organic Zinc-Rich Primers. The primer will be one<br />

of the previously described zinc-rich primers as identified in<br />

Chapter 3.<br />

5.4.1.2 This primer requires top coating when used on exterior<br />

surfaces (refer to Table 5-1).<br />

5.4.2 Inorganic Zinc-Rich Primers. MIL-PRF-23236, Type<br />

I, Class 3 is an inorganic zinc/rich primer that is usually furnished<br />

as two or three components.<br />

5.4.2.1 Follow the manufacturer's instructions for mixing,<br />

thinning, and application.<br />

5.4.2.2 Only those products listed on QPD-23236 are authorized.<br />

5.4.2.3 During application of the MIL-PRF-23236 primer,<br />

the product should be constantly agitated to prevent the zinc<br />

dust from settling.<br />

5.4.1.1 Dry film thickness should be 3.0 mils and approximately<br />

5.0 mils wet.<br />

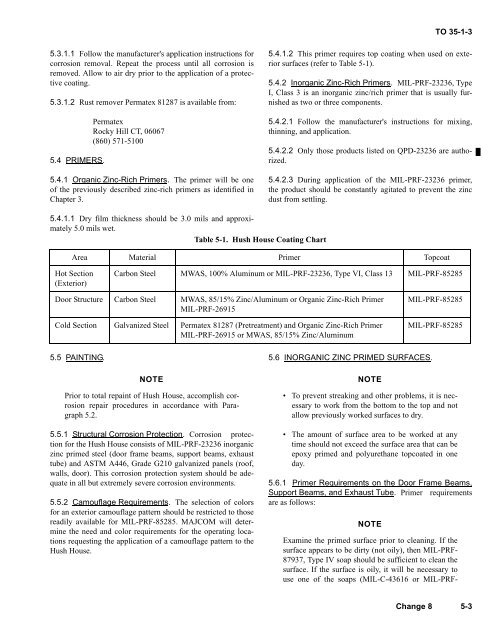

Table 5-1. Hush House Coating Chart<br />

Area Material Primer Topcoat<br />

Hot Section<br />

(Exterior)<br />

Carbon Steel MWAS, 100% Aluminum or MIL-PRF-23236, Type VI, Class 13 MIL-PRF-85285<br />

Door Structure Carbon Steel MWAS, 85/15% Zinc/Aluminum or Organic Zinc-Rich Primer<br />

MIL-PRF-26915<br />

Cold Section Galvanized Steel Permatex 81287 (Pretreatment) and Organic Zinc-Rich Primer<br />

MIL-PRF-26915 or MWAS, 85/15% Zinc/Aluminum<br />

MIL-PRF-85285<br />

MIL-PRF-85285<br />

5.5 PAINTING.<br />

5.6 INORGANIC ZINC PRIMED SURFACES.<br />

NOTE<br />

Prior to total repaint of Hush House, accomplish corrosion<br />

repair procedures in accordance with Paragraph<br />

5.2.<br />

5.5.1 Structural Corrosion Protection. Corrosion protection<br />

for the Hush House consists of MIL-PRF-23236 inorganic<br />

zinc primed steel (door frame beams, support beams, exhaust<br />

tube) and ASTM A446, Grade G210 galvanized panels (roof,<br />

walls, door). This corrosion protection system should be adequate<br />

in all but extremely severe corrosion environments.<br />

5.5.2 Camouflage Requirements. The selection of colors<br />

for an exterior camouflage pattern should be restricted to those<br />

readily available for MIL-PRF-85285. MAJCOM will determine<br />

the need and color requirements for the operating locations<br />

requesting the application of a camouflage pattern to the<br />

Hush House.<br />

NOTE<br />

• To prevent streaking and other problems, it is necessary<br />

to work from the bottom to the top and not<br />

allow previously worked surfaces to dry.<br />

• The amount of surface area to be worked at any<br />

time should not exceed the surface area that can be<br />

epoxy primed and polyurethane topcoated in one<br />

day.<br />

5.6.1 Primer Requirements on the Door Frame Beams,<br />

Support Beams, and Exhaust Tube. Primer requirements<br />

are as follows:<br />

NOTE<br />

Examine the primed surface prior to cleaning. If the<br />

surface appears to be dirty (not oily), then MIL-PRF-<br />

87937, Type IV soap should be sufficient to clean the<br />

surface. If the surface is oily, it will be necessary to<br />

use one of the soaps (MIL-C-43616 or MIL-PRF-<br />

Change 8 5-3