TO 35-1-3 - Robins Air Force Base

TO 35-1-3 - Robins Air Force Base

TO 35-1-3 - Robins Air Force Base

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>TO</strong> <strong>35</strong>-1-3<br />

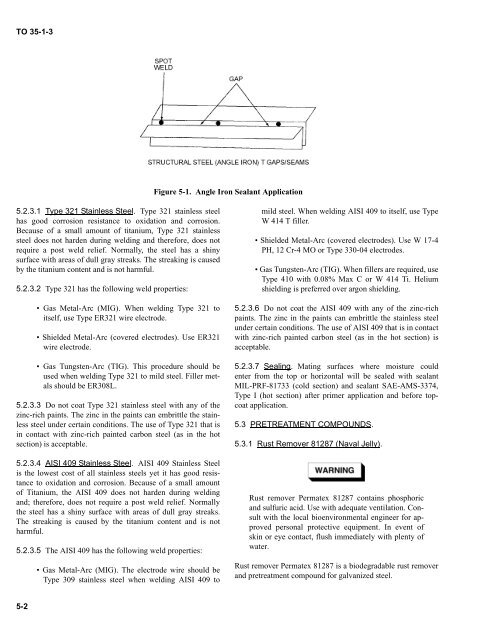

Figure 5-1. Angle Iron Sealant Application<br />

5.2.3.1 Type 321 Stainless Steel. Type 321 stainless steel<br />

has good corrosion resistance to oxidation and corrosion.<br />

Because of a small amount of titanium, Type 321 stainless<br />

steel does not harden during welding and therefore, does not<br />

require a post weld relief. Normally, the steel has a shiny<br />

surface with areas of dull gray streaks. The streaking is caused<br />

by the titanium content and is not harmful.<br />

5.2.3.2 Type 321 has the following weld properties:<br />

• Gas Metal-Arc (MIG). When welding Type 321 to<br />

itself, use Type ER321 wire electrode.<br />

• Shielded Metal-Arc (covered electrodes). Use ER321<br />

wire electrode.<br />

• Gas Tungsten-Arc (TIG). This procedure should be<br />

used when welding Type 321 to mild steel. Filler metals<br />

should be ER308L.<br />

5.2.3.3 Do not coat Type 321 stainless steel with any of the<br />

zinc-rich paints. The zinc in the paints can embrittle the stainless<br />

steel under certain conditions. The use of Type 321 that is<br />

in contact with zinc-rich painted carbon steel (as in the hot<br />

section) is acceptable.<br />

5.2.3.4 AISI 409 Stainless Steel. AISI 409 Stainless Steel<br />

is the lowest cost of all stainless steels yet it has good resistance<br />

to oxidation and corrosion. Because of a small amount<br />

of Titanium, the AISI 409 does not harden during welding<br />

and; therefore, does not require a post weld relief. Normally<br />

the steel has a shiny surface with areas of dull gray streaks.<br />

The streaking is caused by the titanium content and is not<br />

harmful.<br />

5.2.3.5 The AISI 409 has the following weld properties:<br />

• Gas Metal-Arc (MIG). The electrode wire should be<br />

Type 309 stainless steel when welding AISI 409 to<br />

mild steel. When welding AISI 409 to itself, use Type<br />

W 414 T filler.<br />

• Shielded Metal-Arc (covered electrodes). Use W 17-4<br />

PH, 12 Cr-4 MO or Type 330-04 electrodes.<br />

• Gas Tungsten-Arc (TIG). When fillers are required, use<br />

Type 410 with 0.08% Max C or W 414 Ti. Helium<br />

shielding is preferred over argon shielding.<br />

5.2.3.6 Do not coat the AISI 409 with any of the zinc-rich<br />

paints. The zinc in the paints can embrittle the stainless steel<br />

under certain conditions. The use of AISI 409 that is in contact<br />

with zinc-rich painted carbon steel (as in the hot section) is<br />

acceptable.<br />

5.2.3.7 Sealing. Mating surfaces where moisture could<br />

enter from the top or horizontal will be sealed with sealant<br />

MIL-PRF-81733 (cold section) and sealant SAE-AMS-3374,<br />

Type I (hot section) after primer application and before topcoat<br />

application.<br />

5.3 PRETREATMENT COMPOUNDS.<br />

5.3.1 Rust Remover 81287 (Naval Jelly).<br />

Rust remover Permatex 81287 contains phosphoric<br />

and sulfuric acid. Use with adequate ventilation. Consult<br />

with the local bioenvironmental engineer for approved<br />

personal protective equipment. In event of<br />

skin or eye contact, flush immediately with plenty of<br />

water.<br />

Rust remover Permatex 81287 is a biodegradable rust remover<br />

and pretreatment compound for galvanized steel.<br />

5-2