Download - R&M Materials Handling equipment

Download - R&M Materials Handling equipment

Download - R&M Materials Handling equipment

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

R&M <strong>Materials</strong> <strong>Handling</strong>, Inc.<br />

4501 Gateway Boulevard<br />

Springfield, Ohio 45502<br />

P.: (937) 328-5100<br />

FAX: (937) 325-5319<br />

7.1 Standard settings<br />

7.1.1 Settings for sensor bearing<br />

The table below indicate the SSU settings for standard cases. Motors with nominal frequency 100Hz or 120Hz<br />

are equipped with bearing sensor. After adjustment, check that parameters V 4.8.1 Overspd Lim 1 and V 4.8.2<br />

Overspd Lim 2 have value between 115% and 125%.<br />

Max Freq S2 is normally set to 120Hz, also when nominal frequency and Max freq S1 are 100Hz. Check that<br />

parameters P 2.2.2. Motor Nom Freq and P 2.2.3. Motor Nom Speed have correct values from motor type<br />

plate.<br />

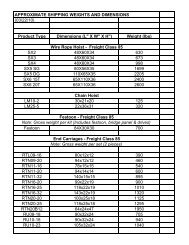

Settings for sensor bearings<br />

Power class 002 – 005 007 – 011 015 - 055<br />

P 2.2.11, Max Freq S2 120 120 120<br />

P 2.2.14 Pulse Number 32 64 80<br />

Rotary switch S1 1 A D<br />

Switch S2-1 ON ON ON<br />

Switch S2-2 OFF OFF OFF<br />

Switch S2-3 OFF OFF OFF<br />

Switch S2-4 ON ON ON<br />

Rotary switch S3 1 A D<br />

S1<br />

S2<br />

S3<br />

ON OFF<br />

1 2 3 4<br />

7.1.2 Settings for pulse wheel speed sensor or encoder (24 ppr)<br />

The table below indicate the SSU settings for standard cases. Motors with nominal frequency 50Hz or 60Hz<br />

are equipped with pulse wheel speed sensor or encoder. After adjustment, check that parameters V 4.8.1<br />

Overspd Lim 1 and V 4.8.2 Overspd Lim 2 have value between 115% and 125%.<br />

Check that parameters P 2.2.2. Motor Nom Freq and P 2.2.3. Motor Nom Speed have correct values from<br />

motor type plate.<br />

Settings for pulse wheel sensor or encoder (24 ppr)<br />

Power class 002 – 055 002 – 055<br />

P 2.2.11, Max Freq S2 50 / 100 60 / 120<br />

P 2.2.14 Pulse Number 24 24<br />

Rotary switch S1 4 7<br />

Switch S2-1 ON ON<br />

Switch S2-2 ON ON<br />

Switch S2-3 OFF OFF<br />

Switch S2-4 ON ON<br />

Rotary switch S3 4 7<br />

7.2 Functional test run for SSU<br />

# Test run must be made without load.<br />

• Disconnect the signal wire coming from the pulse sensor to terminal X1:51.<br />

• Drive with minimum speed. The motion must stop within 1 s.<br />

fault F63 (stall supervision) is activated<br />

S1<br />

S2<br />

S3<br />

ON OFF<br />

1 2 3 4<br />

44/79<br />

This document and the information contained herein, is the exclusive property of R&M <strong>Materials</strong> <strong>Handling</strong> Inc. and represents a non-public, confidential and proprietary<br />

trade secret that may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of R&M<br />

<strong>Materials</strong> <strong>Handling</strong> Inc. Copyright © (2005) R&M <strong>Materials</strong> <strong>Handling</strong> Inc. All rights reserved.