Download - R&M Materials Handling equipment

Download - R&M Materials Handling equipment Download - R&M Materials Handling equipment

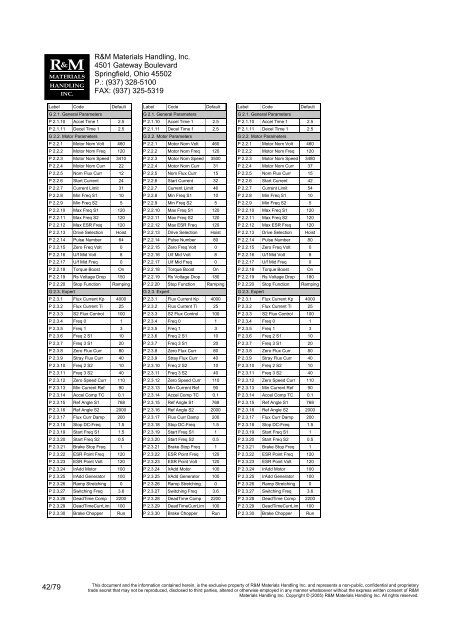

R&M Materials Handling, Inc. 4501 Gateway Boulevard Springfield, Ohio 45502 P.: (937) 328-5100 FAX: (937) 325-5319 Label Code Default Label Code Default Label Code Default G 2.1. General Parameters G 2.1. General Parameters G 2.1. General Parameters P 2.1.10 Accel Time 1 2.5 P 2.1.10 Accel Time 1 2.5 P 2.1.10 Accel Time 1 2.5 P 2.1.11 Decel Time 1 2.5 P 2.1.11 Decel Time 1 2.5 P 2.1.11 Decel Time 1 2.5 G 2.2. Motor Parameters G 2.2. Motor Parameters G 2.2. Motor Parameters P 2.2.1 Motor Nom Volt 460 P 2.2.1 Motor Nom Volt 460 P 2.2.1 Motor Nom Volt 460 P 2.2.2 Motor Nom Freq 120 P 2.2.2 Motor Nom Freq 120 P 2.2.2 Motor Nom Freq 120 P 2.2.3 Motor Nom Speed 3410 P 2.2.3 Motor Nom Speed 3500 P 2.2.3 Motor Nom Speed 3480 P 2.2.4 Motor Nom Curr 22 P 2.2.4 Motor Nom Curr 31 P 2.2.4 Motor Nom Curr 37 P 2.2.5 Nom Flux Curr 12 P 2.2.5 Nom Flux Curr 15 P 2.2.5 Nom Flux Curr 15 P 2.2.6 Start Current 24 P 2.2.6 Start Current 32 P 2.2.6 Start Current 42 P 2.2.7 Current Limit 31 P 2.2.7 Current Limit 46 P 2.2.7 Current Limit 54 P 2.2.8 Min Freq S1 10 P 2.2.8 Min Freq S1 10 P 2.2.8 Min Freq S1 10 P 2.2.9 Min Freq S2 5 P 2.2.9 Min Freq S2 5 P 2.2.9 Min Freq S2 5 P 2.2.10 Max Freq S1 120 P 2.2.10 Max Freq S1 120 P 2.2.10 Max Freq S1 120 P 2.2.11 Max Freq S2 120 P 2.2.11 Max Freq S2 120 P 2.2.11 Max Freq S2 120 P 2.2.12 Max ESR Freq 120 P 2.2.12 Max ESR Freq 120 P 2.2.12 Max ESR Freq 120 P 2.2.13 Drive Selection Hoist P 2.2.13 Drive Selection Hoist P 2.2.13 Drive Selection Hoist P 2.2.14 Pulse Number 64 P 2.2.14 Pulse Number 80 P 2.2.14 Pulse Number 80 P 2.2.15 Zero Freq Volt 0 P 2.2.15 Zero Freq Volt 0 P 2.2.15 Zero Freq Volt 0 P 2.2.16 U/f Mid Volt 8 P 2.2.16 U/f Mid Volt 8 P 2.2.16 U/f Mid Volt 8 P 2.2.17 U/f Mid Freq 0 P 2.2.17 U/f Mid Freq 0 P 2.2.17 U/f Mid Freq 0 P 2.2.18 Torque Boost On P 2.2.18 Torque Boost On P 2.2.18 Torque Boost On P 2.2.19 Rs Voltage Drop 150 P 2.2.19 Rs Voltage Drop 180 P 2.2.19 Rs Voltage Drop 180 P 2.2.20 Stop Function Ramping P 2.2.20 Stop Function Ramping P 2.2.20 Stop Function Ramping G 2.3. Expert G 2.3. Expert G 2.3. Expert P 2.3.1 Flux Current Kp 4000 P 2.3.1 Flux Current Kp 4000 P 2.3.1 Flux Current Kp 4000 P 2.3.2 Flux Current Ti 25 P 2.3.2 Flux Current Ti 25 P 2.3.2 Flux Current Ti 25 P 2.3.3 S2 Flux Control 100 P 2.3.3 S2 Flux Control 100 P 2.3.3 S2 Flux Control 100 P 2.3.4 Freq 0 1 P 2.3.4 Freq 0 1 P 2.3.4 Freq 0 1 P 2.3.5 Freq 1 3 P 2.3.5 Freq 1 3 P 2.3.5 Freq 1 3 P 2.3.6 Freq 2 S1 10 P 2.3.6 Freq 2 S1 10 P 2.3.6 Freq 2 S1 10 P 2.3.7 Freq 3 S1 20 P 2.3.7 Freq 3 S1 20 P 2.3.7 Freq 3 S1 20 P 2.3.8 Zero Flux Curr 80 P 2.3.8 Zero Flux Curr 80 P 2.3.8 Zero Flux Curr 80 P 2.3.9 Stray Flux Curr 40 P 2.3.9 Stray Flux Curr 40 P 2.3.9 Stray Flux Curr 40 P 2.3.10 Freq 2 S2 10 P 2.3.10 Freq 2 S2 10 P 2.3.10 Freq 2 S2 10 P 2.3.11 Freq 3 S2 40 P 2.3.11 Freq 3 S2 40 P 2.3.11 Freq 3 S2 40 P 2.3.12 Zero Speed Curr 110 P 2.3.12 Zero Speed Curr 110 P 2.3.12 Zero Speed Curr 110 P 2.3.13 Min Current Ref 90 P 2.3.13 Min Current Ref 90 P 2.3.13 Min Current Ref 90 P 2.3.14 Accel Comp TC 0.1 P 2.3.14 Accel Comp TC 0.1 P 2.3.14 Accel Comp TC 0.1 P 2.3.15 Ref Angle S1 768 P 2.3.15 Ref Angle S1 768 P 2.3.15 Ref Angle S1 768 P 2.3.16 Ref Angle S2 2000 P 2.3.16 Ref Angle S2 2000 P 2.3.16 Ref Angle S2 2000 P 2.3.17 Flux Curr Damp 200 P 2.3.17 Flux Curr Damp 200 P 2.3.17 Flux Curr Damp 200 P 2.3.18 Stop DC-Freq 1.5 P 2.3.18 Stop DC-Freq 1.5 P 2.3.18 Stop DC-Freq 1.5 P 2.3.19 Start Freq S1 1.5 P 2.3.19 Start Freq S1 1 P 2.3.19 Start Freq S1 1 P 2.3.20 Start Freq S2 0.5 P 2.3.20 Start Freq S2 0.5 P 2.3.20 Start Freq S2 0.5 P 2.3.21 Brake Stop Freq 1 P 2.3.21 Brake Stop Freq 1 P 2.3.21 Brake Stop Freq 1 P 2.3.22 ESR Point Freq 120 P 2.3.22 ESR Point Freq 120 P 2.3.22 ESR Point Freq 120 P 2.3.23 ESR Point Volt 120 P 2.3.23 ESR Point Volt 120 P 2.3.23 ESR Point Volt 120 P 2.3.24 IrAdd Motor 100 P 2.3.24 IrAdd Motor 100 P 2.3.24 IrAdd Motor 100 P 2.3.25 IrAdd Generator 100 P 2.3.25 IrAdd Generator 100 P 2.3.25 IrAdd Generator 100 P 2.3.26 Ramp Stretching 0 P 2.3.26 Ramp Stretching 0 P 2.3.26 Ramp Stretching 0 P 2.3.27 Switching Freq 3.6 P 2.3.27 Switching Freq 3.6 P 2.3.27 Switching Freq 3.6 P 2.3.28 DeadTime Comp 2200 P 2.3.28 DeadTime Comp 2200 P 2.3.28 DeadTime Comp 2200 P 2.3.29 DeadTimeCurrLim 100 P 2.3.29 DeadTimeCurrLim 100 P 2.3.29 DeadTimeCurrLim 100 P 2.3.30 Brake Chopper Run P 2.3.30 Brake Chopper Run P 2.3.30 Brake Chopper Run 42/79 This document and the information contained herein, is the exclusive property of R&M Materials Handling Inc. and represents a non-public, confidential and proprietary trade secret that may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of R&M Materials Handling Inc. Copyright © (2005) R&M Materials Handling Inc. All rights reserved.

R&M Materials Handling, Inc. 4501 Gateway Boulevard Springfield, Ohio 45502 P.: (937) 328-5100 FAX: (937) 325-5319 7 SPEED SUPERVISION SETTINGS SSU is a hoist motion speed supervision unit, which reads the pulse frequency from the hoist motor sensor bearing, encoder or pulse sensor. This pulse frequency is compared with a fixed oscillator frequency and inverter frequency reference. As a result of frequency comparison, there are three different speed supervision functions available: - overspeed supervision (rush control) - stall supervision - speed difference supervision Overspeed supervision (F61) is totally implemented by hardware. Switches S2-2 and S2-3 divide the full frequency range to four frequency areas. Selected frequency area is the same for normal and ESR speeds. The four frequency areas are each divided to lower and upper frequency ranges Switch S2-1 selects the frequency range at normal speed. Switch S2-4 selects the frequency range at ESR speed (Extended Speed Range). The exact tripping frequency level is selected with rotary switches. Switch S1 sets the tripping level at normal speed (value shown in V4.8.1). Switch S3 sets the tripping level at ESR speed (value shown in V4.8.2). Overspeed tripping levels are shown at display as % of the nominal speed. The overspeed setting should be 15-25% above the full speed. Switches S2-2 and S2-3 select range for overspeed detection level. Range of detection level is the same for both, normal and ESR (Extended Speed range) use. Fine adjustment for normal use is done by rotary switch S1 and switch S2-1. Fine adjustment for ESR use is done by rotary switch S3 and switch S2-4. Overspeed detection levels are shown at display panel as % of nominal speed. Overspeed setting should be 15-25% above the full speed. Adjusted overspeed detection level for normal use is shown in parameter V4.8.1. Adjusted overspeed detection level for ESR use is shown in parameter V4.8.2. Speed difference supervision (F62) compares the motor actual speed (= pulse frequency) with Drive frequency reference. In practice this means that the motor slip is measured and if that exceeds a limit, supervision stops the motion. Stall supervision (F63) stops the motion if there are no pulses coming from the sensor when the brake is open (K7 energised). SSU relay test (F64): SSU Relay is tested in every power up. Driving is prevented if fault has been detected. SSU Watchdog fault (F65): Communication between SSU board and control board is tested once in 50ms. Fault will be detected if there is communication error. When a fault is detected the drive is stopped. SSU Overspeed Limit (F66): maximum setting of overspeed limit is 1.4×maximum speed of direction S2. Fault will be detected if overspeed limit is set over that value. When a fault is detected the drive is prevented. 43/79 This document and the information contained herein, is the exclusive property of R&M Materials Handling Inc. and represents a non-public, confidential and proprietary trade secret that may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of R&M Materials Handling Inc. Copyright © (2005) R&M Materials Handling Inc. All rights reserved.

- Page 1 and 2: English 2.11.2006 SERVICE MANUAL FO

- Page 3 and 4: R&M Materials Handling, Inc. 4501 G

- Page 5 and 6: R&M Materials Handling, Inc. 4501 G

- Page 7 and 8: Example layout R&M Materials Handli

- Page 9 and 10: R&M Materials Handling, Inc. 4501 G

- Page 11 and 12: R&M Materials Handling, Inc. 4501 G

- Page 13 and 14: R&M Materials Handling, Inc. 4501 G

- Page 15 and 16: R&M Materials Handling, Inc. 4501 G

- Page 17 and 18: R&M Materials Handling, Inc. 4501 G

- Page 19 and 20: R&M Materials Handling, Inc. 4501 G

- Page 21 and 22: R&M Materials Handling, Inc. 4501 G

- Page 23 and 24: R&M Materials Handling, Inc. 4501 G

- Page 25 and 26: R&M Materials Handling, Inc. 4501 G

- Page 27 and 28: R&M Materials Handling, Inc. 4501 G

- Page 29 and 30: R&M Materials Handling, Inc. 4501 G

- Page 31 and 32: R&M Materials Handling, Inc. 4501 G

- Page 33 and 34: R&M Materials Handling, Inc. 4501 G

- Page 35 and 36: R&M Materials Handling, Inc. 4501 G

- Page 37 and 38: R&M Materials Handling, Inc. 4501 G

- Page 39 and 40: R&M Materials Handling, Inc. 4501 G

- Page 41: R&M Materials Handling, Inc. 4501 G

- Page 45 and 46: R&M Materials Handling, Inc. 4501 G

- Page 47 and 48: R&M Materials Handling, Inc. 4501 G

- Page 49 and 50: R&M Materials Handling, Inc. 4501 G

- Page 51 and 52: R&M Materials Handling, Inc. 4501 G

- Page 53 and 54: R&M Materials Handling, Inc. 4501 G

- Page 55 and 56: 10.3.2 Fault Counter R&M Materials

- Page 57 and 58: R&M Materials Handling, Inc. 4501 G

- Page 59 and 60: R&M Materials Handling, Inc. 4501 G

- Page 61 and 62: R&M Materials Handling, Inc. 4501 G

- Page 63 and 64: R&M Materials Handling, Inc. 4501 G

- Page 65 and 66: R&M Materials Handling, Inc. 4501 G

- Page 67 and 68: R&M Materials Handling, Inc. 4501 G

- Page 69 and 70: R&M Materials Handling, Inc. 4501 G

- Page 71 and 72: R&M Materials Handling, Inc. 4501 G

- Page 73 and 74: R&M Materials Handling, Inc. 4501 G

- Page 75 and 76: R&M Materials Handling, Inc. 4501 G

- Page 77 and 78: R&M Materials Handling, Inc. 4501 G

- Page 79: R&M Materials Handling, Inc. 4501 G

R&M <strong>Materials</strong> <strong>Handling</strong>, Inc.<br />

4501 Gateway Boulevard<br />

Springfield, Ohio 45502<br />

P.: (937) 328-5100<br />

FAX: (937) 325-5319<br />

Label Code Default Label Code Default Label Code Default<br />

G 2.1. General Parameters G 2.1. General Parameters G 2.1. General Parameters<br />

P 2.1.10 Accel Time 1 2.5 P 2.1.10 Accel Time 1 2.5 P 2.1.10 Accel Time 1 2.5<br />

P 2.1.11 Decel Time 1 2.5 P 2.1.11 Decel Time 1 2.5 P 2.1.11 Decel Time 1 2.5<br />

G 2.2. Motor Parameters G 2.2. Motor Parameters G 2.2. Motor Parameters<br />

P 2.2.1 Motor Nom Volt 460 P 2.2.1 Motor Nom Volt 460 P 2.2.1 Motor Nom Volt 460<br />

P 2.2.2 Motor Nom Freq 120 P 2.2.2 Motor Nom Freq 120 P 2.2.2 Motor Nom Freq 120<br />

P 2.2.3 Motor Nom Speed 3410 P 2.2.3 Motor Nom Speed 3500 P 2.2.3 Motor Nom Speed 3480<br />

P 2.2.4 Motor Nom Curr 22 P 2.2.4 Motor Nom Curr 31 P 2.2.4 Motor Nom Curr 37<br />

P 2.2.5 Nom Flux Curr 12 P 2.2.5 Nom Flux Curr 15 P 2.2.5 Nom Flux Curr 15<br />

P 2.2.6 Start Current 24 P 2.2.6 Start Current 32 P 2.2.6 Start Current 42<br />

P 2.2.7 Current Limit 31 P 2.2.7 Current Limit 46 P 2.2.7 Current Limit 54<br />

P 2.2.8 Min Freq S1 10 P 2.2.8 Min Freq S1 10 P 2.2.8 Min Freq S1 10<br />

P 2.2.9 Min Freq S2 5 P 2.2.9 Min Freq S2 5 P 2.2.9 Min Freq S2 5<br />

P 2.2.10 Max Freq S1 120 P 2.2.10 Max Freq S1 120 P 2.2.10 Max Freq S1 120<br />

P 2.2.11 Max Freq S2 120 P 2.2.11 Max Freq S2 120 P 2.2.11 Max Freq S2 120<br />

P 2.2.12 Max ESR Freq 120 P 2.2.12 Max ESR Freq 120 P 2.2.12 Max ESR Freq 120<br />

P 2.2.13 Drive Selection Hoist P 2.2.13 Drive Selection Hoist P 2.2.13 Drive Selection Hoist<br />

P 2.2.14 Pulse Number 64 P 2.2.14 Pulse Number 80 P 2.2.14 Pulse Number 80<br />

P 2.2.15 Zero Freq Volt 0 P 2.2.15 Zero Freq Volt 0 P 2.2.15 Zero Freq Volt 0<br />

P 2.2.16 U/f Mid Volt 8 P 2.2.16 U/f Mid Volt 8 P 2.2.16 U/f Mid Volt 8<br />

P 2.2.17 U/f Mid Freq 0 P 2.2.17 U/f Mid Freq 0 P 2.2.17 U/f Mid Freq 0<br />

P 2.2.18 Torque Boost On P 2.2.18 Torque Boost On P 2.2.18 Torque Boost On<br />

P 2.2.19 Rs Voltage Drop 150 P 2.2.19 Rs Voltage Drop 180 P 2.2.19 Rs Voltage Drop 180<br />

P 2.2.20 Stop Function Ramping P 2.2.20 Stop Function Ramping P 2.2.20 Stop Function Ramping<br />

G 2.3. Expert G 2.3. Expert G 2.3. Expert<br />

P 2.3.1 Flux Current Kp 4000 P 2.3.1 Flux Current Kp 4000 P 2.3.1 Flux Current Kp 4000<br />

P 2.3.2 Flux Current Ti 25 P 2.3.2 Flux Current Ti 25 P 2.3.2 Flux Current Ti 25<br />

P 2.3.3 S2 Flux Control 100 P 2.3.3 S2 Flux Control 100 P 2.3.3 S2 Flux Control 100<br />

P 2.3.4 Freq 0 1 P 2.3.4 Freq 0 1 P 2.3.4 Freq 0 1<br />

P 2.3.5 Freq 1 3 P 2.3.5 Freq 1 3 P 2.3.5 Freq 1 3<br />

P 2.3.6 Freq 2 S1 10 P 2.3.6 Freq 2 S1 10 P 2.3.6 Freq 2 S1 10<br />

P 2.3.7 Freq 3 S1 20 P 2.3.7 Freq 3 S1 20 P 2.3.7 Freq 3 S1 20<br />

P 2.3.8 Zero Flux Curr 80 P 2.3.8 Zero Flux Curr 80 P 2.3.8 Zero Flux Curr 80<br />

P 2.3.9 Stray Flux Curr 40 P 2.3.9 Stray Flux Curr 40 P 2.3.9 Stray Flux Curr 40<br />

P 2.3.10 Freq 2 S2 10 P 2.3.10 Freq 2 S2 10 P 2.3.10 Freq 2 S2 10<br />

P 2.3.11 Freq 3 S2 40 P 2.3.11 Freq 3 S2 40 P 2.3.11 Freq 3 S2 40<br />

P 2.3.12 Zero Speed Curr 110 P 2.3.12 Zero Speed Curr 110 P 2.3.12 Zero Speed Curr 110<br />

P 2.3.13 Min Current Ref 90 P 2.3.13 Min Current Ref 90 P 2.3.13 Min Current Ref 90<br />

P 2.3.14 Accel Comp TC 0.1 P 2.3.14 Accel Comp TC 0.1 P 2.3.14 Accel Comp TC 0.1<br />

P 2.3.15 Ref Angle S1 768 P 2.3.15 Ref Angle S1 768 P 2.3.15 Ref Angle S1 768<br />

P 2.3.16 Ref Angle S2 2000 P 2.3.16 Ref Angle S2 2000 P 2.3.16 Ref Angle S2 2000<br />

P 2.3.17 Flux Curr Damp 200 P 2.3.17 Flux Curr Damp 200 P 2.3.17 Flux Curr Damp 200<br />

P 2.3.18 Stop DC-Freq 1.5 P 2.3.18 Stop DC-Freq 1.5 P 2.3.18 Stop DC-Freq 1.5<br />

P 2.3.19 Start Freq S1 1.5 P 2.3.19 Start Freq S1 1 P 2.3.19 Start Freq S1 1<br />

P 2.3.20 Start Freq S2 0.5 P 2.3.20 Start Freq S2 0.5 P 2.3.20 Start Freq S2 0.5<br />

P 2.3.21 Brake Stop Freq 1 P 2.3.21 Brake Stop Freq 1 P 2.3.21 Brake Stop Freq 1<br />

P 2.3.22 ESR Point Freq 120 P 2.3.22 ESR Point Freq 120 P 2.3.22 ESR Point Freq 120<br />

P 2.3.23 ESR Point Volt 120 P 2.3.23 ESR Point Volt 120 P 2.3.23 ESR Point Volt 120<br />

P 2.3.24 IrAdd Motor 100 P 2.3.24 IrAdd Motor 100 P 2.3.24 IrAdd Motor 100<br />

P 2.3.25 IrAdd Generator 100 P 2.3.25 IrAdd Generator 100 P 2.3.25 IrAdd Generator 100<br />

P 2.3.26 Ramp Stretching 0 P 2.3.26 Ramp Stretching 0 P 2.3.26 Ramp Stretching 0<br />

P 2.3.27 Switching Freq 3.6 P 2.3.27 Switching Freq 3.6 P 2.3.27 Switching Freq 3.6<br />

P 2.3.28 DeadTime Comp 2200 P 2.3.28 DeadTime Comp 2200 P 2.3.28 DeadTime Comp 2200<br />

P 2.3.29 DeadTimeCurrLim 100 P 2.3.29 DeadTimeCurrLim 100 P 2.3.29 DeadTimeCurrLim 100<br />

P 2.3.30 Brake Chopper Run P 2.3.30 Brake Chopper Run P 2.3.30 Brake Chopper Run<br />

42/79<br />

This document and the information contained herein, is the exclusive property of R&M <strong>Materials</strong> <strong>Handling</strong> Inc. and represents a non-public, confidential and proprietary<br />

trade secret that may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of R&M<br />

<strong>Materials</strong> <strong>Handling</strong> Inc. Copyright © (2005) R&M <strong>Materials</strong> <strong>Handling</strong> Inc. All rights reserved.