High Performance Highway Structures - RIBAProductSelector.com

High Performance Highway Structures - RIBAProductSelector.com High Performance Highway Structures - RIBAProductSelector.com

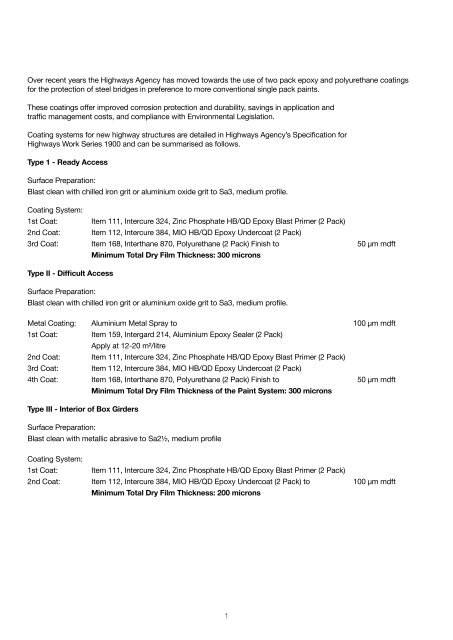

Over recent years the Highways Agency has moved towards the use of two pack epoxy and polyurethane coatings for the protection of steel bridges in preference to more conventional single pack paints. These coatings offer improved corrosion protection and durability, savings in application and traffic management costs, and compliance with Environmental Legislation. Coating systems for new highway structures are detailed in Highways Agency’s Specification for Highways Work Series 1900 and can be summarised as follows. Type 1 - Ready Access Surface Preparation: Blast clean with chilled iron grit or aluminium oxide grit to Sa3, medium profile. Coating System: 1st Coat: Item 111, Intercure 324, Zinc Phosphate HB/QD Epoxy Blast Primer (2 Pack) 2nd Coat: Item 112, Intercure 384, MIO HB/QD Epoxy Undercoat (2 Pack) 3rd Coat: Item 168, Interthane 870, Polyurethane (2 Pack) Finish to 50 μm mdft Minimum Total Dry Film Thickness: 300 microns Type II - Difficult Access Surface Preparation: Blast clean with chilled iron grit or aluminium oxide grit to Sa3, medium profile. Metal Coating: Aluminium Metal Spray to 100 μm mdft 1st Coat: Item 159, Intergard 214, Aluminium Epoxy Sealer (2 Pack) Apply at 12-20 m²/litre 2nd Coat: Item 111, Intercure 324, Zinc Phosphate HB/QD Epoxy Blast Primer (2 Pack) 3rd Coat: Item 112, Intercure 384, MIO HB/QD Epoxy Undercoat (2 Pack) 4th Coat: Item 168, Interthane 870, Polyurethane (2 Pack) Finish to 50 μm mdft Minimum Total Dry Film Thickness of the Paint System: 300 microns Type III - Interior of Box Girders Surface Preparation: Blast clean with metallic abrasive to Sa2½, medium profile Coating System: 1st Coat: Item 111, Intercure 324, Zinc Phosphate HB/QD Epoxy Blast Primer (2 Pack) 2nd Coat: Item 112, Intercure 384, MIO HB/QD Epoxy Undercoat (2 Pack) to 100 μm mdft Minimum Total Dry Film Thickness: 200 microns 1

Type IV - Galvanised Parapets Metal Coating: Hot Dip Galvanising Coating System: 1st Coat: Item 155, Interprime 160, ‘T’ Wash 2nd Coat: Item 110, Intergard 307, Zinc Phosphate Epoxy Blast Primer (2 Pack) 3rd Coat: Item 111, Intercure 324, Zinc Phosphate HB/QD Epoxy Blast Primer (2 Pack) 4th Coat: Item 168, Interthane 870, Polyurethane (2 Pack) Finish to 50 μm mdft Minimum Total Dry Film Thickness of the Paint System: 175 microns For the maintenance of steel highway bridges the Type I system would be applied to structures where all of the existing coatings are to be removed by combined wet/dry abrasive blast cleaning to Sa2½ standard. Under circumstances where total removal of the existing paint system is not seen as necessary or where blast cleaning is not practical the use of surface tolerant epoxy primers and barrier coats is recommended and a typical system utilising these coatings would be:- Surface Preparation: Prepare all areas of corrosion by abrasive blast cleaning or power tool cleaning to clean steel, removing all loose coatings to a firm edge. Clean down overall and present a clean, dry surface for painting. Coating System: Patch Prime: Item 115, Interplus 256, HB Epoxy Aluminium Primer (2 Pack) to 100 μm mdft 1st Overall Coat: Item 116, Interseal 670 HS*, HB Epoxy Undercoat (2 Pack) to 75 μm mdft 2nd Overall Coat: Item 116, Interseal 670 HS*, HB Epoxy Undercoat (2 Pack) to 75 μm mdft 3rd Overall Coat: Item 168, Interthane 870, Polyurethane (2 Pack) Finish to 50 μm mdft Minimum Total Dry Film Thickness: 300 microns *For overcoating existing chlorinated rubber or acrylated rubber paints the use of Item 116, Interplus 770, is preferred. 2

- Page 1: High Performance Highway Structures

- Page 5 and 6: Track Record Interzone glass flake

Over recent years the <strong>High</strong>ways Agency has moved towards the use of two pack epoxy and polyurethane coatings<br />

for the protection of steel bridges in preference to more conventional single pack paints.<br />

These coatings offer improved corrosion protection and durability, savings in application and<br />

traffic management costs, and <strong>com</strong>pliance with Environmental Legislation.<br />

Coating systems for new highway structures are detailed in <strong>High</strong>ways Agency’s Specification for<br />

<strong>High</strong>ways Work Series 1900 and can be summarised as follows.<br />

Type 1 - Ready Access<br />

Surface Preparation:<br />

Blast clean with chilled iron grit or aluminium oxide grit to Sa3, medium profile.<br />

Coating System:<br />

1st Coat: Item 111, Intercure 324, Zinc Phosphate HB/QD Epoxy Blast Primer (2 Pack)<br />

2nd Coat: Item 112, Intercure 384, MIO HB/QD Epoxy Undercoat (2 Pack)<br />

3rd Coat: Item 168, Interthane 870, Polyurethane (2 Pack) Finish to 50 μm mdft<br />

Minimum Total Dry Film Thickness: 300 microns<br />

Type II - Difficult Access<br />

Surface Preparation:<br />

Blast clean with chilled iron grit or aluminium oxide grit to Sa3, medium profile.<br />

Metal Coating: Aluminium Metal Spray to 100 μm mdft<br />

1st Coat: Item 159, Intergard 214, Aluminium Epoxy Sealer (2 Pack)<br />

Apply at 12-20 m²/litre<br />

2nd Coat: Item 111, Intercure 324, Zinc Phosphate HB/QD Epoxy Blast Primer (2 Pack)<br />

3rd Coat: Item 112, Intercure 384, MIO HB/QD Epoxy Undercoat (2 Pack)<br />

4th Coat: Item 168, Interthane 870, Polyurethane (2 Pack) Finish to 50 μm mdft<br />

Minimum Total Dry Film Thickness of the Paint System: 300 microns<br />

Type III - Interior of Box Girders<br />

Surface Preparation:<br />

Blast clean with metallic abrasive to Sa2½, medium profile<br />

Coating System:<br />

1st Coat: Item 111, Intercure 324, Zinc Phosphate HB/QD Epoxy Blast Primer (2 Pack)<br />

2nd Coat: Item 112, Intercure 384, MIO HB/QD Epoxy Undercoat (2 Pack) to 100 μm mdft<br />

Minimum Total Dry Film Thickness: 200 microns<br />

1