Application Pasteurizer Calculation - Rexnord FlatTop Europe

Application Pasteurizer Calculation - Rexnord FlatTop Europe

Application Pasteurizer Calculation - Rexnord FlatTop Europe

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

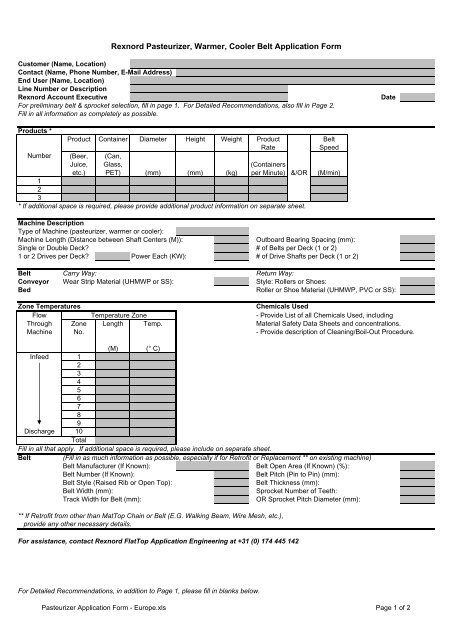

<strong>Rexnord</strong> <strong>Pasteurizer</strong>, Warmer, Cooler Belt <strong>Application</strong> Form<br />

Customer (Name, Location)<br />

Contact (Name, Phone Number, E-Mail Address)<br />

End User (Name, Location)<br />

Line Number or Description<br />

<strong>Rexnord</strong> Account Executive<br />

For preliminary belt & sprocket selection, fill in page 1. For Detailed Recommendations, also fill in Page 2.<br />

Fill in all information as completely as possible.<br />

Date<br />

Products *<br />

Product Container Diameter Height Weight Product<br />

Rate<br />

Belt<br />

Speed<br />

Number (Beer, (Can,<br />

Juice,<br />

etc.)<br />

Glass,<br />

PET) (mm) (mm) (kg)<br />

(Containers<br />

per Minute) &/OR (M/min)<br />

1<br />

2<br />

3<br />

* If additional space is required, please provide additional product information on separate sheet.<br />

Machine Description<br />

Type of Machine (pasteurizer, warmer or cooler):<br />

Machine Length (Distance between Shaft Centers (M)):<br />

Outboard Bearing Spacing (mm):<br />

Single or Double Deck? # of Belts per Deck (1 or 2)<br />

1 or 2 Drives per Deck? Power Each (KW): # of Drive Shafts per Deck (1 or 2)<br />

Belt Carry Way: Return Way:<br />

Conveyor Wear Strip Material (UHMWP or SS): Style: Rollers or Shoes:<br />

Bed<br />

Roller or Shoe Material (UHMWP, PVC or SS):<br />

Zone Temperatures<br />

Chemicals Used<br />

Flow<br />

Temperature Zone<br />

- Provide List of all Chemicals Used, including<br />

Through Zone Length Temp. Material Safety Data Sheets and concentrations.<br />

Machine No. - Provide description of Cleaning/Boil-Out Procedure.<br />

(M) (° C)<br />

Infeed 1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

Discharge 10<br />

Total<br />

Fill in all that apply. If additional space is required, please include on separate sheet.<br />

Belt (Fill in as much information as possible, especially if for Retrofit or Replacement ** on existing machine)<br />

Belt Manufacturer (If Known): Belt Open Area (If Known) (%):<br />

Belt Number (If Known):<br />

Belt Pitch (Pin to Pin) (mm):<br />

Belt Style (Raised Rib or Open Top):<br />

Belt Thickness (mm):<br />

Belt Width (mm):<br />

Sprocket Number of Teeth:<br />

Track Width for Belt (mm):<br />

OR Sprocket Pitch Diameter (mm):<br />

** If Retrofit from other than MatTop Chain or Belt (E.G. Walking Beam, Wire Mesh, etc.),<br />

provide any other necessary details.<br />

For assistance, contact <strong>Rexnord</strong> <strong>FlatTop</strong> <strong>Application</strong> Engineering at +31 (0) 174 445 142<br />

For Detailed Recommendations, in addition to Page 1, please fill in blanks below.<br />

<strong>Pasteurizer</strong> <strong>Application</strong> Form - <strong>Europe</strong>.xls Page 1 of 2

<strong>Rexnord</strong> <strong>Pasteurizer</strong>, Warmer, Cooler Belt <strong>Application</strong> Form<br />

Customer (Name, Location)<br />

Contact (Name, Phone Number, E-Mail Address)<br />

End User (Name, Location)<br />

Line Number or Description<br />

<strong>Rexnord</strong> Account Executive<br />

Fill in all information as completely as possible.<br />

Date<br />

Machine Description (Additional Details. Provide Drawings or Sketches, if available)<br />

For Single Deck or Lower Deck, distance from<br />

If Double Deck, distance from Top of Bottom<br />

Bottom of Return Rollers/Shoes to Top of<br />

Belt to Bottom of Upper Return Rollers or<br />

Highest Water Level in Tank(s) (mm):<br />

Shoes (mm):<br />

Belt Carry Way: Return Way:<br />

Conveyor Style of Track (In-line or Chevron / Roller or Shoe): Is Return inside or below Machine?<br />

Bed Spacing between Carryway Wear Strips (mm):<br />

If Roller or Shoe, Radius & Spacing (mm):<br />

Return Roller or Shoe Details (If Known)<br />

Flow Posi- Type: Roller<br />

NOTES: Through tion Roller or<br />

In-Line = Parallel to Belt Travel Machine or Shoe<br />

Shoe Radius<br />

Rollers or Shoes are not normally recommended for *** (mm)<br />

Carry Ways due to possible container instability. Infeed NA NA NA<br />

Review with <strong>Rexnord</strong>. 1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

Discharge NA NA NA<br />

NA<br />

Fill in all that apply. If additional space is required,<br />

please include on separate sheet.<br />

*** Some Returns use a combination of Rollers and Shoes.<br />

Shafting Infeed End: Discharge End:<br />

Type (Square or Round):<br />

Type (Square or Round):<br />

If Round, 1 or 2 Keyways for Center Sprockets:<br />

If Round, 1 or 2 Keyways:<br />

Tail Shaft Size (Square or Diameter) (mm):<br />

Total # of Bearings on Tail End:<br />

Drive Shaft Size (Square or Diameter) (mm):<br />

Total # of Bearings on Drive End:<br />

If Dual Drive Shafts, are they coupled<br />

together in the middle? (Y or N)<br />

Return<br />

Roller or Shoe<br />

Spacing<br />

(M)<br />

NA<br />

Transfers<br />

Is Machine Layout "C" Shaped or "Z" Shaped?<br />

Infeed End:<br />

Discharge End:<br />

Conveyor Chain (SS or Plastic TT, or MT)<br />

Conveyor Chain (SS or Plastic TT, or MT)<br />

Conveyor Chain Number<br />

Conveyor Chain Number<br />

Number of Lanes of Chain<br />

Number of Lanes of Chain<br />

Transfers (Finger Plates, DTS or DTS-C)<br />

Transfers (Finger Plates, DTS or DTS-C)<br />

Overhead Self-Clearing Mechanism (Y or N)<br />

If possible, provide detailed sketches or drawings of infeed and discharge areas.<br />

<strong>Pasteurizer</strong> <strong>Application</strong> Form - <strong>Europe</strong>.xls Page 2 of 2