Handout 7 Unrestrained beams lateral torsional buckling

Handout 7 Unrestrained beams lateral torsional buckling

Handout 7 Unrestrained beams lateral torsional buckling

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

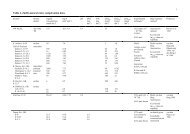

To get α LT , determine the <strong>buckling</strong> curve that you<br />

need to use from table 6.4 and then refer to table<br />

6.3 to get the corresponding value of α LT<br />

Crosssection<br />

Limits Buckling<br />

Curve<br />

Rolled I h/b ≤ 2 a<br />

sections h/b >2 s<br />

Welded I h/b ≤ 2 c<br />

sections h/b >2 d<br />

Other - d<br />

EN 1993-1-1 Table 6.4<br />

f= 1- 0.5(1 - k c )[1-2.0( - 0.8) 2 ]<br />

but f ≤1.0<br />

k c can be obtained from Table 6.6 in the<br />

Eurocodes:<br />

(6.58)<br />

Buckling a b c d<br />

curve<br />

α LT 0.21 0.34 0.49 0.76<br />

EN 1993-1-1 Table 6.3<br />

Special Case (for rolled sections):<br />

(6.57)<br />

where<br />

EN 1993-1-1 Table 6.6<br />

UK NA sets β = 0.75 and = 0.4<br />

To get α LT , determine the <strong>buckling</strong> curve that you<br />

need to use from the table from the National<br />

Annex NA.2.17 Clause 6.3.2.3(1) and then refer<br />

to table 6.3 to get the corresponding value of α LT<br />

You will need the value of<br />

special cases.<br />

for both the general and<br />

(6.56)<br />

Cross-section Limits Buckling<br />

Curve<br />

Rolled bi-symmetric I<br />

and H sections and hotfinished<br />

hollow sections<br />

Angles (for moments in<br />

the major principal<br />

plane) and other hotrolled<br />

sections<br />

Welded bi-symmetric<br />

sections and coldformed<br />

hollow sections<br />

h/b ≤ 2<br />

2.0 < h/b ≤ 3.1<br />

h/b ≤ 2<br />

h/b > 2<br />

Table from NA.2.17 Clause 6.3.2.3(1)<br />

Buckling a b c d<br />

curve<br />

α LT 0.21 0.34 0.49 0.76<br />

EN 1993-1-1 Table 6.3<br />

You can use a modified value of χ LT in the special<br />

case to give some extra resistance:<br />

b<br />

c<br />

d<br />

c<br />

d<br />

M cr<br />

Refer to SN003 document (NCCI) for detailed<br />

description of how to get Mcr<br />

where<br />

L is the distance between points of <strong>lateral</strong> restraint (L cr )<br />

E is the Young’s Modulus = 210000 N/mm 2<br />

G is the shear modulus = 80770 N/mm 2<br />

I z is the second moment of area about the weak axis<br />

I t is the torsion constant<br />

I w is the warping constant