full screen - Umicore Precious Metals Refining

full screen - Umicore Precious Metals Refining

full screen - Umicore Precious Metals Refining

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

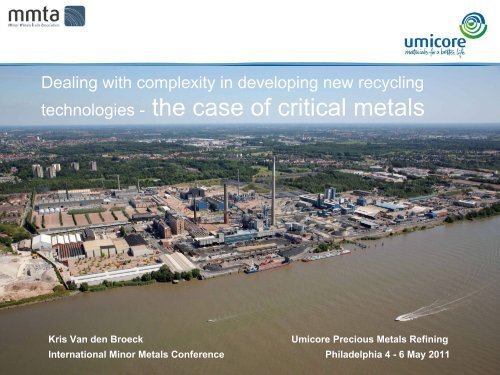

Dealing with complexity in developing new recycling<br />

technologies - the case of critical metals<br />

Kris Van den Broeck<br />

<strong>Umicore</strong> <strong>Precious</strong> <strong>Metals</strong> <strong>Refining</strong><br />

International Minor <strong>Metals</strong> Conference<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Philadelphia 4 - 6 May 2011

Introduction to <strong>Umicore</strong><br />

• Global materials technology company<br />

• Mission: “materials for a better life”<br />

• Majority of growth comes from clean technologies:<br />

technologies that are specifically designed to optimize the use of<br />

natural resources and to reduce environmental impact<br />

• 2010: turnover €9.7 billion , 14,386 employees<br />

• Listed Euronext Brussels, market capitalization €4.5 billion<br />

• Visit us at www.umicore.com<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

2<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Key megatrends for <strong>Umicore</strong><br />

Resource scarcity<br />

More stringent emission control<br />

Renewable energy<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

3<br />

Electrification of the automobile<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Leading manufacturer of Special <strong>Metals</strong><br />

Tellurium<br />

Capacity: 150 t/y<br />

Quality: 2N5<br />

Form: powder<br />

Indium<br />

Capacity: 50 t/y<br />

Quality: 4N, 4N8<br />

Forms: ingots, shots, shells<br />

Selenium<br />

Capacity: 600 t/y<br />

Quality: 2N5, 3N, 4N5, 5N,<br />

5N+<br />

Forms: powder, shots<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

4<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Roadmap<br />

● What are critical metals? Why recycling?<br />

● Complexitiy in recycling<br />

• Economic<br />

• Technological<br />

• Commercial<br />

● Case studies<br />

• ITO recycling<br />

• CIGS recycling<br />

• Battery recycling<br />

● Closing remarks<br />

International Minor <strong>Metals</strong> Conference 2011

Dealing with complexity in developing<br />

new recycling technologies<br />

6<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Critical raw materials (EU Commission)<br />

materials for which a threat to supply could involve harm to the national economy,<br />

and for which the risk is higher than for most other raw materials in the coming 10 years<br />

minor<br />

metal<br />

Source: Critical Raw Materials for the EU – European Commission Enterprise & Industry, July 2010<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

7<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Critical raw materials (USA-DOE)<br />

importance to the clean energy economy and risk of supply disruption<br />

on short (0-5 years) and medium term (5-15 years)<br />

Source: U.S. Department of Energy – Critical materials strategy, December 2010<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

8<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

“Within the next five years (short-term perspective), Öko-Institut (DE)<br />

estimates metals tellurium, indium and gallium to be regarded as most<br />

critical due to rapid demand growth as well as serious supply risks<br />

combined with moderate recycling restrictions.”<br />

Source: UNEP report, July 2009<br />

Critical metals for future sustainable technologies and their recycling potential<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

9<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Policies for secure access & materials efficiency<br />

EU Commission:<br />

US – Department Of Energy:<br />

• improve access to and extraction of<br />

primary resources<br />

• diversify global supply chains<br />

• level playing field in trade & investment<br />

• recycling<br />

• substitution<br />

• materials efficiency<br />

• reuse<br />

• recycling<br />

• substitution<br />

• materials efficiency<br />

Criticality factors & need for recycling do not come out of the blue<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

10<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Clean tech applications: impact on demand<br />

Compound Annual Growth Rate by 2015 [%]<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

Selenium Indium Tellurium Gallium<br />

Glass & pigments Metallurgy (incl alloys) Optics & electronics (incl LCD)<br />

Photovoltaics<br />

Others (incl chem & pharma)<br />

Source: <strong>Umicore</strong> scenario for PV: 80 GW/y in 2020, 35% share Thin Film PV<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

11<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

jan/11<br />

jul/10<br />

apr/11<br />

jan/11<br />

In,Se,Te,Ga - price evolution [$/kg] update 26-Apr-11<br />

150<br />

140<br />

130<br />

120<br />

110<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

jul/00<br />

jan/01<br />

jul/01<br />

jan/02<br />

jul/02<br />

jan/03<br />

jul/03<br />

jan/04<br />

jul/04<br />

jan/05<br />

jul/05<br />

jan/06<br />

jul/06<br />

jan/07<br />

jul/07<br />

jan/08<br />

jul/08<br />

jan/09<br />

jul/09<br />

jan/10<br />

jul/10<br />

jan/11<br />

jan/00<br />

jul/00<br />

jan/01<br />

jul/01<br />

jan/02<br />

jul/02<br />

jan/03<br />

jul/03<br />

jan/04<br />

jul/04<br />

jan/05<br />

jul/05<br />

jan/06<br />

jul/06<br />

jan/07<br />

jul/07<br />

jan/08<br />

jul/08<br />

jan/09<br />

jul/09<br />

jan/10<br />

1100<br />

1000<br />

900<br />

800<br />

700<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

0<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

12<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck<br />

jan/00<br />

450<br />

425<br />

400<br />

375<br />

350<br />

325<br />

300<br />

275<br />

250<br />

225<br />

200<br />

175<br />

150<br />

125<br />

100<br />

75<br />

50<br />

25<br />

0<br />

Indium, AvgMetalBulletin 2000-2011 Selenium, AvgMetalBulletin 2000-2011<br />

Tellurium, AvgMetalPrices 2004-2011 Gallium, LowMetalPages 2005-2011<br />

jan/04 jul/04 jan/05 jul/05 jan/06 jul/06 jan/07 jul/07 jan/08 jul/08 jan/09 jul/09 jan/10 jul/10 jan/11<br />

1000<br />

900<br />

800<br />

700<br />

600<br />

500<br />

400<br />

300<br />

200<br />

100<br />

0<br />

oct/10<br />

jan/05<br />

apr/05<br />

jul/05<br />

okt/05<br />

jan/06<br />

apr/06<br />

jul/06<br />

okt/06<br />

jan/07<br />

apr/07<br />

jul/07<br />

okt/07<br />

jan/08<br />

apr/08<br />

jul/08<br />

oct/08<br />

jan/09<br />

apr/09<br />

jul/09<br />

okt/09<br />

jan/10<br />

apr/10<br />

jul/10

continuously increasing demand for a.o.<br />

clean tech applications<br />

&<br />

government policies<br />

&<br />

consumer + producer policies<br />

<br />

need for recycling<br />

International Minor <strong>Metals</strong> Conference 2011

Recycling: clear benefits<br />

<br />

De-coupling from primary production<br />

production scrap is a significant, readily available resource<br />

<br />

Economically justifiable<br />

production scrap has an economic value<br />

<br />

<br />

<br />

<br />

Lower environmental impact<br />

recycling needs less energy & has lower CO 2<br />

emissions<br />

Mitigate metal scarcity by resource conservation<br />

special metals are reused in products, instead of landfilled<br />

Remove impact of metal price fluctuations<br />

the producer may remain owner of the metal in the scrap<br />

Secure access to raw materials<br />

you know the location, the recycler and the owner<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

14<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Roadmap<br />

What are critical metals? Why recycling?<br />

● Complexitiy in recycling<br />

• Economic<br />

• Technological<br />

• Commercial<br />

● Case studies<br />

• ITO recycling<br />

• CIGS recycling<br />

• Battery recycling<br />

● Closing remarks<br />

International Minor <strong>Metals</strong> Conference 2011

Recycling: as easy as in the movies?<br />

Wall-E (Pixar movies)<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

16<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Economic complexity<br />

Positive vs negative value materials<br />

Production scraps vs End-Of-Life materials<br />

Value<br />

Contained<br />

metals<br />

Positive value recycling<br />

Lost metals<br />

Recovered<br />

metals<br />

Supplier’s<br />

return<br />

Recycler’s<br />

return<br />

• e-scrap / printed circuit boards<br />

• spent automotive catalysts<br />

• spent industrial catalysts<br />

• spent ITO targets<br />

• CIGS production scraps<br />

Recycling cost<br />

The value of the material is sufficient to cover<br />

suppliers return + recyclers return + recycling cost<br />

no direct need for regulation or incentives<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

17<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Recycling potential<br />

From production wastes -TODAY<br />

Very high<br />

High<br />

Medium<br />

Low<br />

Very low<br />

Selenium Indium Tellurium Gallium<br />

Glass & pigments Metallurgy (incl alloys) Optics & electronics (incl LCD)<br />

Photovoltaics<br />

Source: <strong>Umicore</strong><br />

Others (incl chem & pharma)<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

18<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Economic complexity (2)<br />

Positive vs negative value materials<br />

Production scraps vs End-Of-Life materials<br />

Negative value recycling<br />

Value<br />

Lost metals<br />

Recycler’s<br />

return<br />

• rechargeable batteries<br />

• LCD displays<br />

• PhotoVoltaic (end-of-life) modules<br />

Contained<br />

metals<br />

Recovered<br />

metals<br />

Recycling cost<br />

Supplier’s recycling fee<br />

The value of the material is not sufficient to cover<br />

suppliers return + recyclers return + recycling cost<br />

financing models, government incentives or legislation is needed<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

19<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Recycling potential<br />

From End-of-LIfe wastes –FUTURE<br />

Very high<br />

High<br />

Medium<br />

Low<br />

Very low<br />

Selenium Indium Tellurium Gallium<br />

Glass & pigments Metallurgy (incl alloys) Optics & electronics (incl LCD)<br />

Photovoltaics<br />

Source: <strong>Umicore</strong><br />

Others (incl chem & pharma)<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

20<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Technological complexity<br />

Multi-metal (complex) materials require:<br />

• State-of-the-art technology;<br />

• combination pyro-& hydrometallurgy<br />

• Knowledge management (knowhow, IP)<br />

• R&D support;<br />

• continuous improvement<br />

• break-through ideas<br />

In<br />

Pb<br />

Au<br />

Pd<br />

Cu<br />

As<br />

Sb<br />

Bi<br />

Sn<br />

Se<br />

Ir<br />

Ru<br />

Ag Rh<br />

Te Pt<br />

Ni<br />

• Sampling & assaying essential to determine return distribution<br />

• Environmental management excellence;<br />

• resource efficiency (materials and energy)<br />

• eco-efficiency<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

21<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Commercial complexity<br />

• Market intelligence;<br />

• supply market<br />

• metals market<br />

• worldwide sales network in order to secure access to scraps<br />

• ethical supply<br />

• Credit worthiness important in business where high (metal) values are in the<br />

loop<br />

• Control the costs<br />

• Offer a no-worries service (pick-up, customs formalities, metal account)<br />

• EHS support: MSDS, CLP, REACh-compliant<br />

• Auditing<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

22<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Roadmap<br />

What are critical metals? Why recycling?<br />

Complexitiy in recycling<br />

• Economic<br />

• Technological<br />

• Commercial<br />

● Case studies<br />

• ITO recycling<br />

• CIGS recycling<br />

• Battery recycling<br />

● Closing remarks<br />

International Minor <strong>Metals</strong> Conference 2011

ITO target recycling<br />

Closed loop recycling of indium in Providence (US)<br />

• Spent ITO targets have a high value, which drives recycling<br />

• <strong>Umicore</strong> combines production of indium and ITO targets with recycling<br />

of spent targets, all in-house<br />

• Old target can easily be swapped for new target via regional centers in<br />

US, Taiwan and Liechtenstein<br />

• Indium (as ITO target) quickly enters the life cycle again<br />

Efficient material usage and a closed material loop<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

24<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

CIGS production scrap recycling<br />

New process in Hoboken (BE) [capacity 50 t/y]<br />

• <strong>Umicore</strong> has closed the cycle for production wastes<br />

from sputtering and evaporation chambers<br />

• Convert hazardous waste into valuable materials<br />

• Cu, In, Ga and Se are recovered for use in the PV or<br />

other industries<br />

• Business model:<br />

• Customer pays a treatment charge for the recycling service<br />

• <strong>Metals</strong> return is based on sampling and assaying of the<br />

production scrap<br />

• The customer may remain owner of the metals, so no<br />

impact of price fluctuations<br />

• Assistance with waste shipments etc. can be provided<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

25<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Battery Recycling<br />

New process in Hoboken (BE) [capacity 7,000 t/y]<br />

First ever developed process with a specific focus<br />

on the need for rechargeable battery recycling<br />

Li-ion & NiMh<br />

• Unique recycling process with a maximum<br />

valorisation of valuable metals Co & Ni<br />

• Clean process with minimum energy use, CO 2 and<br />

waste generation<br />

• Safe and <strong>full</strong> service from battery transport to<br />

recycling, all complying with the strictest regulations<br />

First industrial pilot plant under construction, to be<br />

commissioned mid 2011<br />

• Future volume of this business is driven by the<br />

merging electrification of transport<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

26<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Roadmap<br />

What are critical metals? Why recycling?<br />

Complexitiy in recycling<br />

• Economic<br />

• Technological<br />

• Commercial<br />

Case studies<br />

• ITO recycling<br />

• CIGS recycling<br />

• Battery recycling<br />

● Closing remarks<br />

International Minor <strong>Metals</strong> Conference 2011

Closing remarks<br />

• Present and expected future growth of the clean tech & high tech<br />

industry will place strong demand on specific “critical” materials<br />

that leads to a debate on their respective future availability<br />

• Recycling of production scraps (today) and End-of-Life modules<br />

(future) can make significant contributions to ensuring a secure<br />

metals supply<br />

• This recycling potential is found in currently minor applications,<br />

with high CAGR creating future material resources<br />

• <strong>Umicore</strong> operates appropriate technologies for efficient and<br />

environmentally sound recycling of production scraps<br />

• Effective recycling goes beyond technology aspects.<br />

Dealing with complexity in developing<br />

new recycling technologies<br />

28<br />

International Minor <strong>Metals</strong> Conference 2011<br />

Kris Van den Broeck

Thank you<br />

Contact<br />

Kris Van den Broeck<br />

Christina Meskers<br />

Address Adolf Greinerstraat 14<br />

2660 Hoboken<br />

Belgium<br />

e-mail<br />

kris.vandenbroeck@umicore.com<br />

christina.meskers@eu.umicore.com<br />

Website<br />

www.preciousmetals.umicore.com<br />

www.pvmaterials.umicore.com<br />

International Minor <strong>Metals</strong> Conference 2011