Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

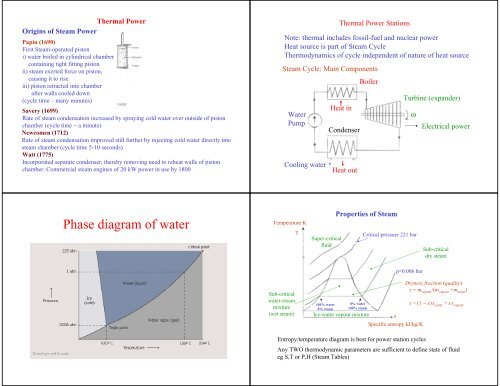

Thermal Power<br />

Origins <strong>of</strong> Steam Power<br />

Papin (1690)<br />

First Steam-operated piston<br />

i) <strong>water</strong> boiled in cylindrical chamber<br />

containing tight fitting piston<br />

ii) steam exerted force on piston,<br />

causing it to rise<br />

iii) piston retracted into chamber<br />

after walls cooled down<br />

(cycle time – many minutes)<br />

Savery (1699)<br />

Rate <strong>of</strong> steam condensation increased by spraying cold <strong>water</strong> over outside <strong>of</strong> piston<br />

chamber (cycle time ~ a minute)<br />

Newcomen (1712)<br />

Rate <strong>of</strong> steam condensation improved still further by injecting cold <strong>water</strong> directly into<br />

steam chamber (cycle time 5-10 seconds)<br />

Watt (1775)<br />

Incorporated separate condenser, thereby removing need to reheat walls <strong>of</strong> piston<br />

chamber. Commercial steam engines <strong>of</strong> 20 kW power in use by 1800<br />

Thermal Power Stations<br />

Note: thermal includes fossil-fuel and nuclear power<br />

Heat source is part <strong>of</strong> Steam Cycle<br />

Thermodynamics <strong>of</strong> cycle independent <strong>of</strong> nature <strong>of</strong> heat source<br />

Steam Cycle: Main Components<br />

Water<br />

Pump<br />

Cooling <strong>water</strong><br />

Heat in<br />

Condenser<br />

Heat out<br />

Boiler<br />

Turbine (expander)<br />

ω<br />

Electrical power<br />

<strong>Phase</strong> <strong>diagram</strong> <strong>of</strong> <strong>water</strong><br />

Temperature K<br />

T<br />

Super-critical<br />

fluid<br />

Properties <strong>of</strong> Steam<br />

Critical pressure 221 bar<br />

Sub-critical<br />

dry steam<br />

p=0.006 bar<br />

Sub-critical<br />

<strong>water</strong>-steam<br />

mixture<br />

(wet steam)<br />

100% <strong>water</strong><br />

0% steam<br />

0% <strong>water</strong><br />

100% steam<br />

Ice-<strong>water</strong> vapour mixture<br />

s<br />

Specific entropy kJ/kg/K<br />

Dryness fraction (quality)<br />

x = m vapour<br />

/(m vapour<br />

+m <strong>water</strong><br />

)<br />

s = (1 − x)s <strong>water</strong><br />

+ xs vapour<br />

Entropy/temperature <strong>diagram</strong> is best for power station cycles<br />

Any TWO thermodynamic parameters are sufficient to define state <strong>of</strong> fluid<br />

eg S,T or P,H (Steam Tables)

Carnot Cycle (Ideal Cycle)<br />

T<br />

Q 12<br />

T 1 2<br />

a<br />

W 41<br />

W 23<br />

Q 34<br />

T b<br />

4 3<br />

S<br />

1) Heat absorption at constant<br />

temperature, T a (boiler) 12<br />

2) Isentropic expansion work<br />

output (turbine) 23<br />

3) Heat rejection at constant<br />

temperature, T b (condenser) 34<br />

4) Isentropic compression<br />

(pump) 41<br />

Energy Conservation (1 st Law <strong>of</strong> Thermodynamics)<br />

Q 12 + W 23 + Q 34 + W 41 = 0<br />

(Note: Q 12<br />

> 0, W 23<br />

< 0, Q 34<br />

< 0, W 41<br />

> 0)<br />

Cycle efficiency, η c = (Useful work out)/(Heat input at T a )<br />

ie η c = (| W 23 | − W 41 )/ Q 12 | = (T a − T b )/ T a = 1 − T b / T a<br />

(Note: T measured in K (absolute temperature) – formal<br />

definition <strong>of</strong> absolute temperature scale)<br />

Practical difficulties in using a Carnot Cycle<br />

1) Boiler operates only in wet-steam regime otherwise temperature<br />

would rise when all the <strong>water</strong> has turned to steam, violating<br />

condition for Carnot Cycle<br />

turbine expands wet steam<br />

<strong>water</strong> droplets hit turbine blades (damage)<br />

2) Maximum temperature (T a ) is limited to ~650 K<br />

efficiency <strong>of</strong> cycle is severely constrained<br />

3) Compression <strong>of</strong> <strong>water</strong>/steam mixture is thermodynamically<br />

unstable (<strong>water</strong> droplets)<br />

very large volume compressor (expensive)<br />

Rankine Cycle overcomes all these problems<br />

T<br />

2b<br />

2a<br />

T b<br />

1b 1a<br />

2c<br />

S<br />

Rankine Cycle<br />

Step 1:<br />

a) Condense all the steam to <strong>water</strong><br />

in the condenser<br />

b) Pumping <strong>water</strong> to high pressure requires<br />

small volume machine and little energy<br />

T<br />

T b<br />

T a<br />

S<br />

Step 3:<br />

Expand dry steam through a turbine<br />

to generate shaft power<br />

In practice, <strong>water</strong> droplets still form in<br />

the low pressure end <strong>of</strong> the turbine, so<br />

the steam is reheated at various stages<br />

Step 2:<br />

Use 3-stage boiler (~ constant pressure)<br />

a) Economiser – <strong>water</strong> heated at constant pressure<br />

b) Evaporator – <strong>water</strong>/steam mixture heated at constant pressure<br />

c) Superheater – dry steam heated at constant pressure<br />

[Note that there is a small drop in pressure through the boiler tube<br />

in order to overcome frictional losses]<br />

T<br />

T a<br />

T b<br />

S<br />

HP<br />

from<br />

IP LP<br />

boiler<br />

reheaters<br />

HP: high pressure turbine<br />

IP: intermediate pressure turbine<br />

LP: low pressure turbine<br />

to condenser

Frictional losses across turbine blades vary like u 2 (F D =½C D ρAu 2 )<br />

ie very large for large u (near speed <strong>of</strong> sound)<br />

Losses reduced significantly by using many stages in series (~50 stages)<br />

Other practical effects limiting efficiency<br />

The loss <strong>of</strong> kinetic energy at each stage is<br />

small and turbulence is reduced<br />

a) Boiler tubes have finite thickness, so outer wall temperature is higher<br />

than <strong>water</strong>/steam temperature<br />

b) Metallurgical limit to temperature/pressure difference boiler tubes<br />

can withstand (creep/crack formation)<br />

c) Many pipes/tubes in flow circuit frictional losses<br />

d) Condenser is a vacuum chamber air leaks in but can not condense,<br />

so ‘air blanket’ forms, preventing <strong>water</strong> vapour from condensing on<br />

cold surface <strong>of</strong> condenser tubes<br />

T<br />

W 12<br />

2<br />

1<br />

3<br />

Q 23<br />

W 34<br />

Q 41<br />

4<br />

Efficiency <strong>of</strong> Rankine Cycle<br />

S<br />

Condenser at 30 C at a pressure <strong>of</strong> 0.04 bar<br />

Compressor increases pressure to 170 bar<br />

Three-stage boiler at 170 bar<br />

a) economiser raises temperature to 352 C<br />

b) evaporator at 352 C<br />

c) superheater raises temperature to 600 C<br />

Adiabatic turbine<br />

T p h f h g s f s g<br />

Water/Steam 30 0.04 126 2566 0.436 8.452<br />

Water/Steam 352 170 1690 2548 3.808 5.181<br />

Dry Steam 600 170 3564 6.603<br />

where h f and h g are the specific enthalpies and s f and s g are the<br />

specific entropies <strong>of</strong> the fluid and gas, respectively, in kJ/kg.<br />

Adiabatic compression or expansion<br />

W = W s + (p 1 v 1 − p 2 v 2 ) = ∆U = u 2 − u 1<br />

W s = (u 2 − u 1 ) − (p 1 v 1 − p 2 v 2 )<br />

= (u 2 + p 2 v 2 ) − (u 1 + p 1 v 1 )<br />

= h 2 − h 1<br />

Work done by the shaft W s<br />

on the fluid<br />

Adiabatic so Q = 0<br />

Total work W<br />

First Law: ∆U = Q + W<br />

Note sign convention<br />

In adiabatic process work done equals change in enthalpy<br />

Specific enthalpy h = u +pv; dh = TdS + Vdp<br />

isobaric, constant pressure, dh = du + pdv = dQ<br />

isentropic dh = dW = Vdp<br />

i) W 12 = V(p 2 − p 1 ) = 10 −3 (170 − 0.04) 10 5<br />

=17 kJ/kg 3<br />

ii) 12 isentropic so<br />

h 2 = h 1 + W 12 = 126 + 17 = 143 kJ/kg<br />

iii) 23 isobaric so<br />

Q 23 = h 3 – h 2 = 3564 − 143 = 3421 kJ/kg<br />

iv) 34 isentropic so<br />

W 34 = h 3 – h 4 and s 3 = s 4<br />

s 4 = (1−x)s f4 + xs g4<br />

s 3 = 6.603 = (1−x)0.436 + 8.452 x<br />

x = 0.769<br />

T<br />

W 12<br />

2<br />

1<br />

Q 23<br />

W 34<br />

Q 41<br />

4<br />

S

Combined Cycle Gas Turbine (CCGT) Stations<br />

v) h 4 = (1−x)h f4 + xh g4<br />

h 4 = (1−x)126 + 2566 x<br />

x = 0.769<br />

h 4 = 2002 kJ/kg<br />

In recent years gas turbines and steam turbines have been combined to<br />

increase the efficiency to around 50-60% (upper temperature ~1200 C)<br />

Gas Turbine<br />

air<br />

34 isentropic so<br />

W 34 = h 3 – h 4<br />

= 3564 – 2002 = 1562 kJ/kg<br />

vi) η = useful work/heat in<br />

= (W 34 – W 12 )/Q 23 = (1562 – 17)/3421<br />

= 0.452 = 45.2%<br />

vii) cf Carnot Cycle<br />

η c = (T 3 − T 4 )/T 3 = (873 − 303)/873<br />

= 0.653 = 65.3%<br />

T<br />

W 12<br />

Q<br />

3<br />

23<br />

2<br />

W 34<br />

1<br />

4<br />

Q 41 S<br />

T<br />

T max<br />

Compressor<br />

Combustion<br />

Compressor<br />

Gaseous<br />

fuel<br />

p<br />

compressed<br />

air<br />

Combustion<br />

Chamber<br />

p atmos<br />

Turbine<br />

Brayton Cycle<br />

S<br />

Turbine<br />

Exhaust gas<br />

a) Heat generated by internal combustion rather than<br />

via a high temperature heat exchanger (boiler)<br />

b) No cooler required since exhaust gases vented to<br />

atmosphere<br />

Plant much smaller. Work done by compressor is<br />

significant, though this is compensated by very high<br />

temperature ~ 1200 C (Turbine blades ceramic coated<br />

and <strong>water</strong> cooled)<br />

ω<br />

CCGT Station<br />

660 MW Power Plant<br />

air<br />

Compressor<br />

Gaseous<br />

fuel<br />

compressed<br />

air<br />

Combustion<br />

Chamber<br />

Turbine<br />

Exhaust gas<br />

Water<br />

Pump<br />

Heat in<br />

Boiler<br />

Turbine<br />

Exhaust gas<br />

Condenser<br />

ω<br />

combustion<br />

Cooling <strong>water</strong><br />

Heat out<br />

T<br />

Rankine<br />

Cycle<br />

compressor<br />

S<br />

turbine<br />

boiler<br />

Brayton<br />

Cycle<br />

Heat <strong>of</strong> exhaust gases used to<br />

raise steam for steam turbine<br />

Many CCGTs have been built in the<br />

UK in the 90s due to availability <strong>of</strong><br />

cheap gas and relaxation <strong>of</strong><br />

governmental controls<br />

Stator for a 660 MW<br />

generator being assembled<br />

Low pressure turbine, part <strong>of</strong> a<br />

660 MW assembly<br />

Power density ~ 1000 MW e per sq km

Types <strong>of</strong> Fossil Fuel Power Stations<br />

CCS<br />

Type<br />

T o C<br />

bar<br />

Efficiency<br />

Subcritical<br />

538<br />

167<br />

up to 39%<br />

Supercritical<br />

540-566<br />

250<br />

up to 46%<br />

Ultra-supercritical<br />

580-620<br />

270-285<br />

50-55%<br />

IGCC: Integrated gasification combined cycle<br />

Coal + O 2 + H 2 O → H 2 + CO (syngas)<br />

mainly Power Plant Today Future<br />

Syngas used in combined cycle gas turbine (CCGT) power station<br />

Efficiency ~ 45%<br />

Shift reaction : CO + H 2 O → H 2 + CO 2<br />

Pre-combustion Carbon Capture and Storage (CCS)<br />

Conventional Coal 24-40% 15-20%<br />

Natural Gas 11-24% 8-11%<br />

Advanced Coal 14-25% 9-12%<br />

Typical Energy Penalty(increase fuel use per KWh produced due to CO 2 capture)<br />

Potential by 2050<br />

~1000 GW e with CCS<br />

Power density<br />

~ 1000 MW e per sq km<br />

CCS<br />

CCS<br />

Technical Solutions to Disposing <strong>of</strong> CO 2<br />

• Underground storage<br />

In aquifiers, used gas/oil fields - huge storage potential, but<br />

possibility <strong>of</strong> spontaneous gas eruptions (1750 people killed by CO 2<br />

eruption from volcanic lake in 1986)<br />

•Deep ocean disposal<br />

Large hydrostatic pressure CO 2 liquifies<br />

- long-term viability uncertain<br />

- effect on ocean deep-sea creatures uncertain (affects food chain <strong>of</strong><br />

surface creatures<br />

Air Capture<br />

Electrocatalytic CO 2<br />

Conversion to Oxalate<br />

by a Copper Complex.<br />

SCIENCE VOL 327 15 JAN. 2010<br />

• Pump CO 2 into lakes/breed algae<br />

Algae dried biomass alternative to fossil fuel<br />

Or<br />

Algae biodiesel alternative to petrol or diesel from oil<br />

(CO 2 –neutral if re-used; sequestered if buried)

Historical Milestones<br />

Nuclear Power<br />

1896 Becquerel Fogging <strong>of</strong> photographic plates near U salts<br />

1905 Einstein Special theory <strong>of</strong> relativity- E = mc 2<br />

1911 Rutherford Discovery <strong>of</strong> nucleus - α-particle scattering<br />

1913 Bohr Quantum model <strong>of</strong> H atom<br />

1932 Chadwick Discovery <strong>of</strong> neutron<br />

1936 Bohr, Frenkel Liquid drop model <strong>of</strong> nucleus<br />

1938 Hahn, Strassmann Discovery <strong>of</strong> fission<br />

1939 Joliot, von Halban Discovery <strong>of</strong> neutrons produced in fission<br />

Kowarski reactions possibility <strong>of</strong> ‘chain reaction’<br />

1939 Szilard, Wigner Advised Roosevelt <strong>of</strong> feasibility <strong>of</strong> uranium<br />

bomb<br />

1939 Booth, Dunning, Start <strong>of</strong> projects to separate isotopes <strong>of</strong><br />

Urey<br />

235<br />

U and 238 U<br />

1940 Anderson, Fermi Showed that 12 C would be a good moderator<br />

1940 Joliot, Dautry Transferred D 2 O from Norway to UK<br />

1940 Seaborg Discovered Plutonium<br />

1942 Groves Manhattan Project started<br />

1942 Fermi First nuclear reactor- demonstrated that<br />

chain reaction controllable<br />

1943 Bethe, Weisskopf Defined specification <strong>of</strong> atomic bomb<br />

Teller, Feynman (sub-critical sphere surrounded by<br />

explosives compression criticality)<br />

May 1945<br />

July 1945<br />

Aug 1945<br />

Experimental uranium bomb exploded<br />

Experimental plutonium bomb exploded<br />

Hiroshima destroyed by U-bomb<br />

Nagasaki destroyed by Pu-bomb<br />

First self-sustaining chain reaction<br />

Fermi December 1942 Chicago University Stadium<br />

1945 UKAEA established in UK, CEA established in France<br />

1954 Fast reactor programme started<br />

1956 First prototype power station (Calder Hall) – gas cooled<br />

1956 Suez crisis oil shortage nuclear power stations<br />

first commercial reactors 1962 (Berkeley, Bradwell)<br />

1957 Pressurised Water Reactor (PWR) developed for<br />

nuclear submarines by the USA<br />

1957 Windscale fire (Wigner energy underestimated)<br />

1957 Campaign for Nuclear Disarmament (CND) established<br />

1959 Dounreay fast reactor critical<br />

1964 UK decide to build Advanced Gas cooled Reactors (AGR)<br />

1976 First AGRs commissioned (Hinckley B, Hunterston B)<br />

1979 Three Mile Island accident (operator errors)<br />

1986 Chernobyl accident (design faults, operator errors,<br />

no regulation<br />

1991/2 Collapse <strong>of</strong> communism in E.Europe nuclear<br />

cooperation (civil and military)<br />

1995 First PWR in UK (Sizewell B)

B/A<br />

Fusion<br />

Binding Energy <strong>of</strong> Nuclei<br />

Fission<br />

Mass Number A<br />

MeV<br />

Above mass ~20 approximately constant binding energy per nucleon<br />

However: more stable nuclei can be formed either by:<br />

i) Fusion (combining 2 nuclei with low mass number A)<br />

ii) Fission (breakup <strong>of</strong> large A nucleus into lower A fragments plus<br />

release <strong>of</strong> neutrons)<br />

8<br />

6<br />

4<br />

2<br />

0<br />

In fission<br />

A 1 → A 2 + A 3 + neutrons,<br />

where A 2 and A 3 are the final<br />

stable nuclei, the total energy<br />

release E R is approximately<br />

E R = A 2 {b(A 2 ) − b(A 1 )} +<br />

A 3 {b(A 3 ) − b(A 1 )}.<br />

Basic Ideas : Fission Reactors<br />

141<br />

Ba 56<br />

n<br />

n<br />

235 236<br />

U U n<br />

92 92<br />

n<br />

neutron<br />

92<br />

Kr<br />

absorption<br />

36<br />

fission<br />

n + 235 U 92 141 Ba 56 + 92 Kr 36 + 3n<br />

Change in mass, δm = 3.6 10 −28 kg<br />

Energy released, E = (δm)c 2<br />

= (3 10 8 ) 2 3.6 10 −28<br />

= 3.2 10 −11 J<br />

⇒ chain reaction<br />

cf chemical combustion<br />

C + O 2 CO 2 E = 7 10 −19 J<br />

Energy release from 1 uranium nucleus = 5 10 7 carbon atoms<br />

1 tonne <strong>of</strong> 235 U = 2.7 10 6 tonnes <strong>of</strong> coal<br />

U is 0.7% 235 U so 1 tonne U ≡ 20,000 tonnes <strong>of</strong> coal<br />

Naturally-occurring uranium consists <strong>of</strong><br />

• fissile isotope 235 U<br />

• stable isotope 238 U }ratio = 1/138 ~ 0.7%<br />

In a reactor, neutrons are lost by :<br />

1) absorption by 238 U 239 U 239 Pu<br />

2) absorption by 235 U 236 U (18% for thermal n)<br />

3) absorption by moderator<br />

4) absorption by reactor structure<br />

5) escape from reactor core<br />

Not enough n to continue chain reaction with H 2 O moderation<br />

enrichment necessary to increase ratio 235 U/ 238 U 3%<br />

Note: the naturally-occurring ratio was higher in the past<br />

%<br />

Oklo ‘reactor’ (Gabon)<br />

3<br />

0.7<br />

−2.10 9<br />

−10 9<br />

0<br />

years<br />

β<br />

nb t 1/2 <strong>of</strong><br />

235<br />

U = 7.1 10 8 years<br />

cf t 1/2 <strong>of</strong><br />

238<br />

U = 3 10 9 years<br />

Fuel Enrichment<br />

Enrichment is process <strong>of</strong> increasing proportion <strong>of</strong> fissionable nuclei<br />

in natural uranium (0.7% 235 U)<br />

Methods <strong>of</strong> enrichment<br />

1 Electromagnetic Separation<br />

accelerating<br />

electrodes<br />

B<br />

mv 2 /r = qBv r = mv/qB<br />

vacuum chamber<br />

heavy isotope<br />

light isotope<br />

Used for Manhattan project (1g/day) and by Iraq before Gulf War

2 Gaseous Diffusion<br />

Uranium ore converted to UF 6 gas passed through very thin porous<br />

membranes. Light 235 U molecule diffuses faster than the heavier<br />

238<br />

U molecule. ~1400 stages to achieve 3-5% 235 U/ 238 U<br />

Enrichment<br />

3 Ultracentrifuge<br />

Gaseous UF 6 is rotated at high angular velocity in a cascade <strong>of</strong><br />

centrifuges, causing partial separation<br />

4 Laser Separation<br />

Tuned lasers selectively ionise the lighter isotope in UF 6 vapour<br />

Positive ion attracted to charged collector plates – still being<br />

developed<br />

Energy Released by Fission Process<br />

Instantaneous Release (per fission) MeV<br />

Fission products<br />

168 heat<br />

Neutrons 5<br />

γ-rays<br />

7 heat<br />

Delayed Release (per fission) MeV<br />

β-particles<br />

8 heat<br />

γ-rays<br />

7 heat<br />

Antineutrinos<br />

12 lost from reactor<br />

Neutron Capture by 238 U<br />

β<br />

β<br />

n + 238 U 92 239 U 92 <br />

239<br />

Np 93 <br />

239<br />

Pu 94<br />

23.5 m 2.3 d<br />

In practice many neutrons do not contribute to fission because<br />

they are absorbed by 238 U<br />

f(E)<br />

0 2 4 6<br />

Neutron energy (MeV)<br />

Neutron cross-sections on Uranium<br />

Barns<br />

10 3<br />

10 2<br />

10 1<br />

10 0<br />

σ∼1/v<br />

Neutron Energy Distribution<br />

average energy<br />

Neutron energy density, f(E)<br />

f(E) ~ 0.77(E) 1/2 exp(−0.775E)<br />

On average, 2.44 neutrons are<br />

produced per fission<br />

Average neutron energy is ~ 2MeV<br />

fission by 235 U 92<br />

capture by 238 U 92<br />

fission by 238 U 92<br />

10 −1 10 1 10 3 10 5 10 7 eV

Macroscopic cross-sections for natural<br />

uranium (Σ t<br />

= Σn i<br />

σ ti<br />

)<br />

Factors affecting chain reaction<br />

1) For each thermal neutron absorbed, η effective fast neutrons emitted<br />

η < ν, mean number produced (ν =2.42 for 235 U), because not all<br />

neutrons absorbed by fuel cause fission. Nat U (0.72% 235 U) η =1.33<br />

2) Some fast neutrons cause fission before slowing down which<br />

increases the number <strong>of</strong> neutrons by the fast fission factor ε<br />

3) The probability that a neutron will avoid resonance capture by 238 U<br />

the resonance escape probability p - depends on the moderator<br />

4) The fraction <strong>of</strong> thermal neutrons that are absorbed by the fuel in the<br />

core (fuel, moderator, can) is called the thermal utilization factor f<br />

5) There are a fraction l f <strong>of</strong> fast neutrons and a fraction l t <strong>of</strong> thermal<br />

neutrons that leak out <strong>of</strong> the reactor<br />

The neutron multiplication factor k is therefore given by:<br />

k = ηεpf(1− l f ) (1− l t )<br />

For infinite core k ∞ = ηεpf<br />

Four factors formula<br />

Neutron Moderation<br />

Moderator is a medium for reducing the kinetic energy <strong>of</strong> neutrons from<br />

MeV to thermal level without losing many in the ‘resonant trap’ <strong>of</strong> 238 U<br />

m<br />

M<br />

For 180 deg scattering<br />

neutron<br />

E s = [(M − m)/(M + m)] 2 E i = [(A − 1)/(A + 1)] 2 E i<br />

For 0 deg scattering<br />

E s = E i<br />

Averaging, E s = ½{1 + [(A − 1)/(A + 1)] 2 }E s<br />

nucleus<br />

= [(A 2 + 1)/(A + 1) 2 ]E s<br />

(Averaging over all angles gives the same result)<br />

1<br />

H<br />

12<br />

C<br />

238<br />

U<br />

A 1 12 238<br />

E s /E i 0.5 0.86 0.99<br />

How many collisions required to reduce neutron energy from<br />

2 MeV to 1 eV ? (factor <strong>of</strong> 2 10 6 )<br />

Put (E s /E i ) n = 1/(2.10 6 ) = 5.10 −7<br />

eg 1 H gives n ~ 21, 12 C gives n ~ 96<br />

Moderating Ratio, MR<br />

Good moderators require<br />

• large σ elastic (σ el )<br />

• low σ capture (σ c )<br />

• significant loss in KE per collision<br />

• chemical stability (in hot, radioactive environment)<br />

Moderating ratio, MR = (1− E s /E i ) σ el /σ c<br />

Reactor Control<br />

H 2 O 62; D 2 O 4830; C 216<br />

If the neutron flux increases to a higher level than that needed for a<br />

stable chain reaction, how can the reactor be controlled, ie how can<br />

equilibrium be restored?

Lower ‘control rods’ into reactor to absorb excess neutrons<br />

Materials used: 113 Cd (σ c = 20,000 barns)<br />

10<br />

B (σ c = 4,000 barns)<br />

cross section is for thermal neutrons (~0.025 eV)<br />

[σ c (max) ~ π(λ/2π) 2 ∼ 2.6 10 7 barns]<br />

(withdraw control rods if reactivity gets too low)<br />

In practice control would be virtually impossible but for the existence<br />

<strong>of</strong> ‘delayed’ neutrons<br />

Delayed neutrons are released only after the β-decay <strong>of</strong> a fission product<br />

Typically, about 1% <strong>of</strong> neutrons produced by fission are delayed by<br />

10-20 seconds, which is enough time for small adjustments in the<br />

position <strong>of</strong> the control rods (automatically controlled)<br />

eg<br />

87<br />

Br β −<br />

t 1/2<br />

54.5 s<br />

n<br />

87<br />

Kr *<br />

86<br />

Kr<br />

137<br />

I β −<br />

t 1/2<br />

21.8 s<br />

n<br />

137<br />

Xe *<br />

136<br />

Xe<br />

Neutron Population Growth<br />

η is number <strong>of</strong> neutrons emitted per neutron absorbed<br />

Because <strong>of</strong> losses the mean number is k, where k < η<br />

k is the effective multiplication factor<br />

If all neutrons were prompt the neutron population would grow like<br />

dn/dt = n(k−1)/τ = nq/τ<br />

where q=(k−1) and τ is the average neutron lifetime in the reactor<br />

So<br />

n = n o exp{qt/τ}<br />

eg q = 0.001, τ = 0.001 second gives n = n o exp(t), so after 10 s<br />

n/n o increases by a factor <strong>of</strong> 22,000<br />

In 235 U the mean lifetime <strong>of</strong> the<br />

groups <strong>of</strong> delayed neutrons is<br />

about τ d = 9 s and they represent<br />

a fraction β = 0.65% <strong>of</strong> the total<br />

neutron emission<br />

235<br />

U delayed neutrons<br />

If q

Safety Features in a PWR<br />

• The control rods can be lowered fully in the case <strong>of</strong> an emergency<br />

• Should the pressure drop in the primary loop and the <strong>water</strong> start to<br />

boil, the creation <strong>of</strong> bubbles (voids) decreases the moderation and also<br />

the absorption. The effect on the moderation is the more significant<br />

and the chain reaction stops and the reactor is no longer critical<br />

• The moderation is also decreased if the core temperature rises, as<br />

this increases the Doppler broadening <strong>of</strong> the 238 U resonances, which<br />

decreases the resonance escape probability p<br />

• A loss-<strong>of</strong>-coolant accident (LOCA) in which the <strong>water</strong> in the<br />

primary loop is lost requires additional emergency cooling to be<br />

available. The outer containment vessel provides a final barrier and<br />

worked successfully in the Three Mile Island accident<br />

Power Output <strong>of</strong> Nuclear Reactor<br />

Reaction rate R = (Neutron Flux)×(Cross-section)×(Number <strong>of</strong> Nuclei)<br />

Flux φ = Neutrons m −2 s −1 Number <strong>of</strong> Nuclei = N<br />

Cross-section σ = effective area, unit is barn = 10 −28 m 2<br />

Example: Reactor core contains 10 4 kg <strong>of</strong> uranium enriched to 2%<br />

in 235 U. Cross-section for neutron induced fission <strong>of</strong> 235 U = 579 barns.<br />

Flux φ = 10 18 m −2 s −1 . Calculate the power output.<br />

Number <strong>of</strong> 235 U nuclei = 10 4 (1000/238)(6 ×10 23 )(0.02) = 5.0×10 26<br />

R = φσN = 10 18 ×579×10 −28 ×5.0×10 26 = 2.9×10 19 s −1<br />

Energy per fission = 200 MeV = 200×10 6 ×1.6×10 −19 = 3.2×10 −11 J<br />

So power output = 3.2×10 −11 ×2.9×10 19 = 0.93 GW th .<br />

10 4 kg U(2%) 5.0×10 26 × 3.2 ×10 −11 J = 1.6 × 10 16 J ≡ 0.5 GW th y<br />

Fast Breeder Reactors (FBR)<br />

Predicted fossil reserves<br />

~ 8.10 22 J<br />

Fission reactors (thermal neutron) ~ 4.10 21 J<br />

Fast breeder reactors (fast neutrons) ~ 2.10 23 J<br />

fast breeder reactors are possible long-term solution to world’s<br />

energy needs (~10 3 years) - ~50 times fission reactor energy reserve<br />

Fission reactors consume 235 U so < 1% uranium utilised<br />

Fast breeder reactors have small core <strong>of</strong> highly enriched fissile fuel<br />

with no moderator. Emitted fast neutrons convert surrounding 238 U<br />

to fissile 239 Pu quicker than fuel consumed by fast neutron induced<br />

fission in core.<br />

Basic reactions<br />

β − β − α<br />

n + 238 U 239 U 239 Np 239 Pu 235 U<br />

t 1/2<br />

=23.5m t 1/2<br />

=2.35d t 1/2<br />

=24,000y<br />

‘fertile’ ie<br />

spawns Pu<br />

‘fissile’ ie<br />

chain reaction

A Schematic <strong>of</strong> an ADSR<br />

Use three<br />

accelerators<br />

for reliability<br />

Energy Amplifier or Accelerator Driven Subcritical Reactor<br />

World NUCLEAR POWER REACTORS 2003-04<br />

Belgium<br />

Canada*<br />

China**<br />

France<br />

Germany<br />

India<br />

Japan<br />

Korea (South)<br />

Russia<br />

Sweden<br />

United Kingdom<br />

USA<br />

WORLD<br />

billion<br />

kWh<br />

44.6<br />

70.3<br />

79.0<br />

420.7<br />

157.4<br />

16.4<br />

230.8<br />

123.3<br />

138.4<br />

65.5<br />

85.3<br />

763.7<br />

2525<br />

% e<br />

55<br />

13<br />

**<br />

78<br />

28<br />

3<br />

25<br />

40<br />

17<br />

50<br />

24<br />

20<br />

16<br />

Operating<br />

7<br />

17<br />

15<br />

59<br />

18<br />

14<br />

54<br />

19<br />

30<br />

11<br />

23<br />

103<br />

438<br />

Building<br />

0<br />

1<br />

4<br />

0<br />

0<br />

9<br />

3<br />

1<br />

5<br />

0<br />

0<br />

1<br />

28<br />

Planned/<br />

Proposed<br />

0<br />

2<br />

26<br />

0<br />

0<br />

24<br />

12<br />

8<br />

9<br />

0<br />

0<br />

0<br />

106<br />

Relative costs <strong>of</strong> electricity in the US (2003)<br />

Costs <strong>of</strong> Electricity Generation (2003)<br />

(25-year capital recovery, 85% lifetime capacity factor)<br />

Source<br />

Cents/kWe-hr<br />

Nuclear 7.0<br />

Coal 4.4<br />

Gas 4.1<br />

Nuclear Costs with reduced<br />

Construction costs by 25% 5.8<br />

Construction time by 12 months 5.6<br />

Cost <strong>of</strong> capital ≡ coal and gas 4.7<br />

With Carbon Tax $50/tC $100/tC $200/tC<br />

Coal 5.6 6.8 9.2<br />

Gas 4.6 5.1 6.2

Environmental Impact <strong>of</strong> Nuclear Power<br />

Nuclear Fuel Cycle for typical reactor<br />

Uranium<br />

mining,<br />

milling and<br />

concentration<br />

Final<br />

disposaldeep<br />

geological<br />

depository)<br />

4200tU as<br />

enriched U 3 O 8<br />

24t HLW<br />

100m 3<br />

600tU<br />

in used<br />

fuel<br />

900m 3 in<br />

containers<br />

Conversion<br />

to UF 6<br />

(gas)<br />

Reprocessing<br />

and vitrification<br />

<strong>of</strong> HLW<br />

Interim storage<br />

option (20 yrs +)<br />

4200tU as<br />

enriched UF 6<br />

1<br />

600tU<br />

in used<br />

fuel<br />

2<br />

Enrichment<br />

to 3.5%<br />

235<br />

U<br />

Reactor<br />

Operation<br />

1000 MW<br />

30 years<br />

operation<br />

10,000 m 3 waste<br />

(operating and<br />

decommissioning)<br />

600tU as<br />

enriched<br />

UF 6<br />

Fuel<br />

fabrication<br />

as UO 2<br />

600tU as fresh UO 2 fuel<br />

200 10 9 kWh <strong>of</strong><br />

electricity<br />

equivalent to<br />

17.10 6 tonnes <strong>of</strong> oil<br />

Categories <strong>of</strong> Nuclear Waste<br />

1. LLW(Low Level Waste) ~89% <strong>of</strong> total volume<br />

Low radioactivity, negligible long-lived activity (rags, tools, filters,<br />

etc, from hospitals, research labs and nuclear power stations<br />

2. ILW (Intermediate Level Waste) ~11% <strong>of</strong> total volume<br />

Requires shielding, contains some long-lived activity (resins, sludges,<br />

Fuel cladding) can be set in concrete/bitumen<br />

3. HLW (High Level Waste) ~0.3% <strong>of</strong> total volume<br />

Highly active, heat generating, long-lived activity requires vitrification<br />

and long-term storage<br />

National Waste Disposal Programmes<br />

France: 400,000 m 3 <strong>of</strong> short-lived waste in shallow land burial at<br />

La Manche site<br />

Investigating sites for deep disposal <strong>of</strong> long-lived waste (including<br />

vitrified HLW) from 2015<br />

Germany :LLW and ILW in former salt mine<br />

Investigations <strong>of</strong> Gorleben salt dome for final disposal <strong>of</strong> vitrified HLW<br />

Japan: LLW put in shallow burial site (200,000m 3 capacity). HLW being<br />

vitrified and stored for 30-50 years until suitable deep repository found<br />

UK: Underground repository for LLW/ILW at Sellafield. HHW vitrified<br />

stored 50 years at Sellafield before eventual disposal in deep repository<br />

USA: Three LLW sites. National HLW site Yucca Mountain (?) (Nevada)<br />

Outstanding Issues<br />

• Deep repositories required to keep HLW intact for 10,000 years<br />

Geological stability and <strong>water</strong> ingress are uncertain<br />

• Long-term stability <strong>of</strong> vitrified waste unknown<br />

• Public unease- easy target for anti-nuclear lobby<br />

• Moral issue- should we burden future generations with our waste?<br />

Counter argument: they will also need to dispose <strong>of</strong> nuclear waste, so<br />

we are solving the technical problems for them. Also danger from<br />

not reducing CO 2<br />

Nuclear<br />

Power<br />

Chernobyl

Summary Nuclear<br />

• Advantages: Low Carbon; Constant output;<br />

Relatively cheap ~1.5x Fossil Fuels.<br />

• Disadvantages: Perceived risk is high and concern<br />

over radioactive waste disposal and proliferation<br />

• Resource: 16 Mt U ~200 yrs at current output<br />

(~300GW) [38 Mt U- including phosphates]<br />

• Potential by 2050: ~ 1 TW e<br />

• Increased resource using Th to breed 233 U<br />

232<br />

Th + n → 233 Th → 233 Pa (27d)→ 233 U<br />

fertile<br />

fissile<br />

Resource ~ 2.5 Mt Th cf ~0.1 Mt 235 U<br />

• Power density: ~ 1000 MW e per sq km