Peterbilt Model 320 Operator's Manual after 8-07 - Peterbilt Motors ...

Peterbilt Model 320 Operator's Manual after 8-07 - Peterbilt Motors ...

Peterbilt Model 320 Operator's Manual after 8-07 - Peterbilt Motors ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Wheel Bearing Lubrication<br />

PART 8: MAINTENANCE AND SERVICE<br />

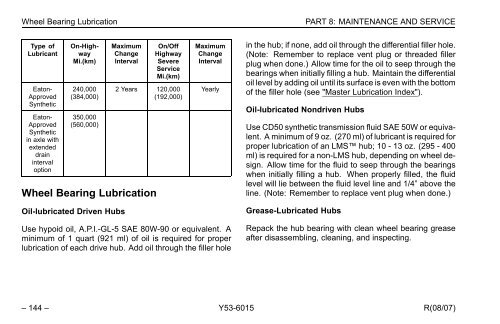

Type of<br />

Lubricant<br />

Eaton-<br />

Approved<br />

Synthetic<br />

Eaton-<br />

Approved<br />

Synthetic<br />

in axle with<br />

extended<br />

drain<br />

interval<br />

option<br />

On-Highway<br />

Mi.(km)<br />

240,000<br />

(384,000)<br />

350,000<br />

(560,000)<br />

Maximum<br />

Change<br />

Interval<br />

On/Off<br />

Highway<br />

Severe<br />

Service<br />

Mi.(km)<br />

2 Years 120,000<br />

(192,000)<br />

Wheel Bearing Lubrication<br />

Oil-lubricated Driven Hubs<br />

Maximum<br />

Change<br />

Interval<br />

Yearly<br />

in the hub; if none, add oil through the differential filler hole.<br />

(Note: Remember to replace vent plug or threaded filler<br />

plug when done.) Allow time for the oil to seep through the<br />

bearings when initially filling a hub. Maintain the differential<br />

oil level by adding oil until its surface is even with the bottom<br />

of the filler hole (see "Master Lubrication Index").<br />

Oil-lubricated Nondriven Hubs<br />

Use CD50 synthetic transmission fluid SAE 50W or equivalent.<br />

A minimum of 9 oz. (270 ml) of lubricant is required for<br />

proper lubrication of an LMS hub; 10 - 13 oz. (295 - 400<br />

ml) is required for a non-LMS hub, depending on wheel design.<br />

Allow time for the fluid to seep through the bearings<br />

when initially filling a hub. When properly filled, the fluid<br />

level will lie between the fluid level line and 1/4” above the<br />

line. (Note: Remember to replace vent plug when done.)<br />

Grease-Lubricated Hubs<br />

Use hypoid oil, A.P.I.-GL-5 SAE 80W-90 or equivalent. A<br />

minimum of 1 quart (921 ml) of oil is required for proper<br />

lubrication of each drive hub. Add oil through the filler hole<br />

Repack the hub bearing with clean wheel bearing grease<br />

<strong>after</strong> disassembling, cleaning, and inspecting.<br />

– 144 – Y53-6015 R(08/<strong>07</strong>)