Peterbilt Model 320 Operator's Manual after 8-07 - Peterbilt Motors ...

Peterbilt Model 320 Operator's Manual after 8-07 - Peterbilt Motors ... Peterbilt Model 320 Operator's Manual after 8-07 - Peterbilt Motors ...

Preventive Maintenance Schedule PART 8: MAINTENANCE AND SERVICE SYSTEM COMPONENT MAINTENANCE TASK Recommended PM Interval I A B C D E Tires & Wheels Tires Check inflationpressure(see"Checking Inflation Pressure"). Inspect for cuts, irregular wear, missing lugs, sidewall damage, etc. X Disc wheels Inspect the wheel disc for any cracks or surface irregularities. Inspect the rim edge and bead seat area for damage. Replace any damaged wheels - DO NOT ATTEMPT TO REPAIR. X Demountable rims Inspect the mounting ring, rim gutter, side ring, and lock ring for damage; replace as required. X Wheel nuts and studs Check the tightness of the fasteners and tighten the fasteners to the specified torque as required (see "Wheel Cap Nut Torque"). X Wheel nuts and studs Inspect for damaged hex corners, stripped or damaged threads, and excessive corrosion; clean or replace as required. X – 126 – Y53-6015 R(08/07)

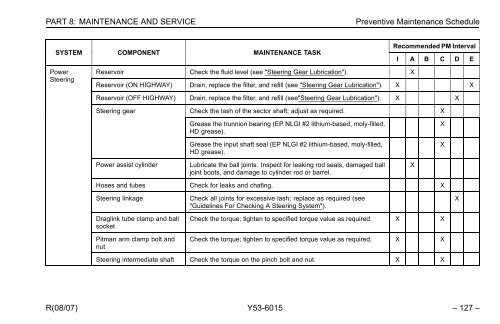

PART 8: MAINTENANCE AND SERVICE Preventive Maintenance Schedule SYSTEM COMPONENT MAINTENANCE TASK Recommended PM Interval I A B C D E Power Steering Reservoir Check the fluid level (see "Steering Gear Lubrication"). X Reservoir (ON HIGHWAY) Drain, replace the filter, and refill (see "Steering Gear Lubrication"). X X Reservoir (OFF HIGHWAY) Drain, replace the filter, and refill (see"Steering Gear Lubrication"). X X Steering gear Check the lash of the sector shaft; adjust as required. Grease the trunnion bearing (EP NLGI #2 lithium-based, moly-filled, HD grease). Grease the input shaft seal (EP NLGI #2 lithium-based, moly-filled, HD grease). X X X Power assist cylinder Lubricate the ball joints. Inspect for leaking rod seals, damaged ball joint boots, and damage to cylinder rod or barrel. X Hoses and tubes Check for leaks and chafing. X Steering linkage Draglink tube clamp and ball socket Pitman arm clamp bolt and nut Check all joints for excessive lash; replace as required (see "Guidelines For Checking A Steering System"). Check the torque; tighten to specified torque value as required. X X Check the torque; tighten to specified torque value as required. X X X Steering intermediate shaft Check the torque on the pinch bolt and nut. X X R(08/07) Y53-6015 – 127 –

- Page 80 and 81: Transmission Warmup CAUTION: The us

- Page 82 and 83: Shifting Gears in a New Vehicle CAU

- Page 84 and 85: Operating the Clutch service depart

- Page 86 and 87: Dual Range (Two Speed) Axles WARNIN

- Page 88 and 89: Automatic and Automated Transmissio

- Page 90 and 91: If Your Vehicle Must Be Towed PART

- Page 92 and 93: Anti-Lock Braking System Operating

- Page 94 and 95: ABS Warning Lamps PART 7: STARTING

- Page 96 and 97: Overheated Brakes PART 7: STARTING

- Page 98 and 99: Parking Brakes and Their Use PART 7

- Page 100 and 101: Manually Releasing Spring Brakes PA

- Page 102 and 103: Before Stopping The Engine PART 7:

- Page 104 and 105: Setting Ride Height PART 7: STARTIN

- Page 106 and 107: Setting Ride Height PART 7: STARTIN

- Page 108 and 109: Driving Tips And Techniques WARNING

- Page 110 and 111: Dual Steer Vehicle Operation NOTE:

- Page 112 and 113: Dual Steer Vehicle Operation PART 7

- Page 114 and 115: Preventive Maintenance Schedule PAR

- Page 116 and 117: Preventive Maintenance Schedule PAR

- Page 118 and 119: Preventive Maintenance Schedule PAR

- Page 120 and 121: Preventive Maintenance Schedule PAR

- Page 122 and 123: Preventive Maintenance Schedule PAR

- Page 124 and 125: Preventive Maintenance Schedule PAR

- Page 126 and 127: Preventive Maintenance Schedule PAR

- Page 128 and 129: Preventive Maintenance Schedule PAR

- Page 132 and 133: Preventive Maintenance Schedule PAR

- Page 134 and 135: Preventive Maintenance Schedule PAR

- Page 136 and 137: Preventive Maintenance Schedule PAR

- Page 138 and 139: Preventive Maintenance Schedule PAR

- Page 140 and 141: Master Lubrication Index WARNING! E

- Page 142 and 143: Fuller Transmission Lubrication PAR

- Page 144 and 145: Spicer Transmission Lubrication Rec

- Page 146 and 147: Meritor Axle Lubrication PART 8: MA

- Page 148 and 149: Wheel Bearing Lubrication PART 8: M

- Page 150 and 151: Brake Adjustment PART 8: MAINTENANC

- Page 152 and 153: Brake Adjustment PART 8: MAINTENANC

- Page 154 and 155: Tires Checking Inflation Pressure G

- Page 156 and 157: Tires PART 8: MAINTENANCE AND SERVI

- Page 158 and 159: Tires PART 8: MAINTENANCE AND SERVI

- Page 160 and 161: Tires PART 8: MAINTENANCE AND SERVI

- Page 162 and 163: Wheels And Rims Wheels And Rims PAR

- Page 164 and 165: Wheels And Rims PART 8: MAINTENANCE

- Page 166 and 167: Vehicle Loading PART 8: MAINTENANCE

- Page 168 and 169: Air Dryer then goes to the reservoi

- Page 170 and 171: Engine Cooling System Engine Coolin

- Page 172 and 173: Engine Cooling System ELC Extender

- Page 174 and 175: Battery Care Electrical CAUTION: Do

- Page 176 and 177: Battery Care • Keep the battery c

- Page 178 and 179: Battery Care damage to the vehicle,

PART 8: MAINTENANCE AND SERVICE<br />

Preventive Maintenance Schedule<br />

SYSTEM COMPONENT MAINTENANCE TASK<br />

Recommended PM Interval<br />

I A B C D E<br />

Power<br />

Steering<br />

Reservoir Check the fluid level (see "Steering Gear Lubrication"). X<br />

Reservoir (ON HIGHWAY) Drain, replace the filter, and refill (see "Steering Gear Lubrication"). X X<br />

Reservoir (OFF HIGHWAY) Drain, replace the filter, and refill (see"Steering Gear Lubrication"). X X<br />

Steering gear<br />

Check the lash of the sector shaft; adjust as required.<br />

Grease the trunnion bearing (EP NLGI #2 lithium-based, moly-filled,<br />

HD grease).<br />

Grease the input shaft seal (EP NLGI #2 lithium-based, moly-filled,<br />

HD grease).<br />

X<br />

X<br />

X<br />

Power assist cylinder<br />

Lubricate the ball joints. Inspect for leaking rod seals, damaged ball<br />

joint boots, and damage to cylinder rod or barrel.<br />

X<br />

Hoses and tubes Check for leaks and chafing. X<br />

Steering linkage<br />

Draglink tube clamp and ball<br />

socket<br />

Pitman arm clamp bolt and<br />

nut<br />

Check all joints for excessive lash; replace as required (see<br />

"Guidelines For Checking A Steering System").<br />

Check the torque; tighten to specified torque value as required. X X<br />

Check the torque; tighten to specified torque value as required. X X<br />

X<br />

Steering intermediate shaft Check the torque on the pinch bolt and nut. X X<br />

R(08/<strong>07</strong>) Y53-6015 – 127 –