Conclusion Get more connected.

Conclusion Get more connected.

Conclusion Get more connected.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

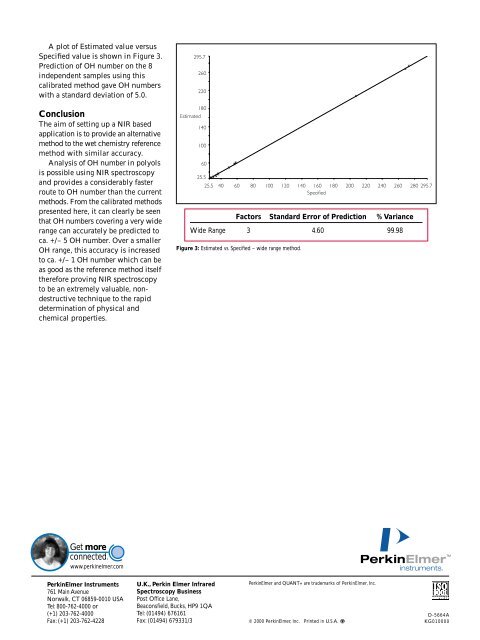

A plot of Estimated value versus<br />

Specified value is shown in Figure 3.<br />

Prediction of OH number on the 8<br />

independent samples using this<br />

calibrated method gave OH numbers<br />

with a standard deviation of 5.0.<br />

<strong>Conclusion</strong><br />

The aim of setting up a NIR based<br />

application is to provide an alternative<br />

method to the wet chemistry reference<br />

method with similar accuracy.<br />

Analysis of OH number in polyols<br />

is possible using NIR spectroscopy<br />

and provides a considerably faster<br />

route to OH number than the current<br />

methods. From the calibrated methods<br />

presented here, it can clearly be seen<br />

that OH numbers covering a very wide<br />

range can accurately be predicted to<br />

ca. +/– 5 OH number. Over a smaller<br />

OH range, this accuracy is increased<br />

to ca. +/– 1 OH number which can be<br />

as good as the reference method itself<br />

therefore proving NIR spectroscopy<br />

to be an extremely valuable, nondestructive<br />

technique to the rapid<br />

determination of physical and<br />

chemical properties.<br />

Factors Standard Error of Prediction % Variance<br />

Wide Range 3 4.60 99.98<br />

Figure 3: Estimated vs. Specified – wide range method.<br />

<strong>Get</strong> <strong>more</strong><br />

<strong>connected</strong>.<br />

www.perkinelmer.com<br />

PerkinElmer Instruments<br />

761 Main Avenue<br />

Norwalk, CT 06859-0010 USA<br />

Tel: 800-762-4000 or<br />

(+1) 203-762-4000<br />

Fax: (+1) 203-762-4228<br />

U.K., Perkin Elmer Infrared<br />

PerkinElmer and QUANT+ are trademarks of PerkinElmer, Inc.<br />

Spectroscopy Business<br />

Post Office Lane,<br />

Beaconsfield, Bucks, HP9 1QA<br />

Tel: (01494) 676161<br />

Fax: (01494) 679331/3 © 2000 PerkinElmer, Inc. Printed in U.S.A.<br />

D-5664A<br />

KG010000

FT-NIR SPECTROSCOPY<br />

application note<br />

The Determination of OH Number in<br />

Polyols Using FT-NIR Spectroscopy<br />

Summary<br />

NIR spectroscopy is an invaluable tool<br />

for the quantitative analysis of a wide<br />

range of chemical compounds. In<br />

combination with a number of<br />

chemometric methods, the technique<br />

provides a fast, non-destructive route<br />

to the determination of physical and<br />

chemical properties.<br />

This note describes the use of<br />

FT-NIR spectroscopy in a typical<br />

polyol analysis with an outline of<br />

the development of the quantitative<br />

method used for the application.<br />

Introduction<br />

Polyols are long-chain polymers<br />

which contain alcohol functional<br />

groups and are produced via<br />

reactions involving organic oxides,<br />

acids and multi-functional alcohols.<br />

A wide range of products<br />

including, surfactants, foams, paint<br />

additives, and adhesives are<br />

manufactured using polyols. The<br />

production of polyurethanes, for<br />

instance, involves polyol<br />

intermediates.<br />

Polyol products are typically<br />

produced via batch reactor processes<br />

held at high temperatures (>250˚C).<br />

Current analysis of the polyols<br />

produced normally take the form of<br />

back titrations. The resultant OH<br />

number is an average value over a<br />

number of titrations.<br />

This analysis generally takes<br />

place in an off-site laboratory, often<br />

far removed from the conditions<br />

present at the production site. The<br />

sample is extracted from the bulk,<br />

and the production process halted<br />

while the analysis is completed; a<br />

process that can take several hours.<br />

Care must be taken in handling the<br />

chemicals involved, especially when<br />

analyzing samples at elevated<br />

temperatures. The possibility of<br />

moisture being absorbed from the air<br />

is highly detrimental to the analysis<br />

of the OH value. A system whereby<br />

the sample must be heated is applied<br />

if the sample is a solid or highly<br />

viscous liquid. Even when all these<br />

factors have been minimized or<br />

taken into account, the process still<br />

depends on the analyst. The current<br />

method for determining OH number<br />

is expensive, time consuming, and<br />

prone to human error.<br />

A typical NIR based application<br />

is faster, <strong>more</strong> precise and reliable<br />

than other methods. It also reduces<br />

the need to handle potentially<br />

hazardous substances. The bands in<br />

the NIR region (ca. 15000 – 3000<br />

cm-1, 667 – 3333 nm) are primarily<br />

overtones and combination bands<br />

normally associated with C-H, N-H<br />

and O-H bonds. Since organic<br />

polymers are composed of carbon,<br />

hydrogen, nitrogen and oxygen<br />

atoms, the NIR spectra of polymers<br />

feature sharp, strong absorbance<br />

bands.<br />

Polymer manufacturers can use<br />

NIR spectroscopy to perform<br />

analyses on the production site.<br />

This has obvious advantages in the<br />

area of quality assurance. NIR<br />

analysis is also capable of process<br />

control as the analysis of<br />

intermediates occurs in real-time.<br />

Since many polyol reactions are<br />

irreversible, the analysis of such<br />

intermediates by NIR spectroscopy<br />

provides a commercially valuable<br />

tool.<br />

A typical NIR method<br />

development for OH determination<br />

consists of first assembling a set of<br />

preanalyzed samples which must<br />

span the OH range for which the<br />

calibration is intended. The number<br />

of samples used depends on the OH<br />

range and accuracy required, but for<br />

most applications in the range ca.<br />

20 – 200 OH approximately 20<br />

samples are adequate for calibration.

Once a set of reference samples is<br />

obtained, it is advisable to divide these<br />

into two sets; a set for calibration, and<br />

a set to test the calibration often<br />

referred to as the validation set. The<br />

suitability of the samples used in the<br />

calibration set is particularly important<br />

since it must closely match the<br />

product being manufactured at the<br />

production site. A calibration set must<br />

contain enough samples to enable the<br />

estimation of the calibration constants,<br />

and the range of the samples should<br />

be representative of the range of<br />

future samples.<br />

A calibration, based on ‘ideal’<br />

samples prepared in a completely<br />

stable environment, may give very<br />

small errors when used for similar<br />

samples. However, when the<br />

calibration is used to produce a value<br />

for a real product, the accuracy is<br />

often degraded. Further<strong>more</strong>, a tradeoff<br />

exists between calibration sets<br />

covering a very wide range of OH<br />

number and the accuracy with which<br />

OH number can be predicted.<br />

Therefore, it has been found that the<br />

accuracy increases when using a<br />

method calibrated over a <strong>more</strong><br />

restricted (ca. 50) OH range.<br />

The PLS (Partial Least Squares)<br />

method available in the Perkin-Elmer<br />

QUANT+ TM software uses the NIR<br />

spectra recorded to derive a<br />

calibration. This equation is then<br />

used to predict the value of the<br />

constituent of interest of future<br />

samples using their NIR spectra. An<br />

application that is analyzed by using<br />

spectroscopy is <strong>more</strong> precise than<br />

when measured by other methods.<br />

However, the accuracy of the method<br />

in predicting the true value of the<br />

future samples is dependant upon<br />

the accuracy of the reference method.<br />

It is therefore important to stress<br />

that the steps involved in setting up<br />

the calibration are crucial to the<br />

success of the NIR application. This<br />

is particularly true for the collection<br />

of suitable calibration standards,<br />

and the analysis of the calibration<br />

set by titration. This step should be<br />

carried out with an objective of<br />

producing the greatest possible<br />

accuracy.<br />

A suggestion for achieving this<br />

accuracy is to perform the titration<br />

in duplicate or triplicate. However,<br />

it is <strong>more</strong> important to have as many<br />

samples in the calibration set as<br />

possible. In comparison, it is better<br />

to collect twice as many calibration<br />

samples than it is to perform the<br />

reference analysis of the original<br />

calibration standards in duplicate.<br />

The most ideal, though costly and<br />

time consuming, situation would<br />

allow for the inclusion of a large set<br />

of calibration standards, with each<br />

sample analyzed in duplicate or<br />

triplicate.<br />

QUANT+ software was used to<br />

derive a calibration matrix between<br />

the calibration spectra and their<br />

Figure 1: Extremes of calibration set.<br />

reference OH values. The technique<br />

of PLS extracts those spectral<br />

contributions which are correlated<br />

with OH value, and eliminates the<br />

need to select specific wavelengths<br />

for the calibration.<br />

As previously stated, the near<br />

infrared region consists of many<br />

overlapping bands that contain<br />

overtone and combination bands<br />

involving the absorptions of mainly<br />

OH, NH and CH bonds. The bands<br />

of interest in the determination of<br />

OH value are due to the OH first<br />

overtone at 7150 – 6670 cm-1<br />

(1399 – 1499 nm), the OH<br />

combination bands of 5260 – 4760<br />

cm-1 (1900 – 2100 nm), and<br />

moisture content changes: ~5155<br />

cm-1 (1940 nm).<br />

Experimental<br />

Fourteen standards of known OH<br />

value were supplied to serve as a<br />

calibration set. A further eight<br />

samples were also supplied to act as<br />

an independent validation set. These<br />

were used to compare the reference<br />

values with those values predicted by<br />

the calibration equation. All samples<br />

had been analyzed previously in<br />

triplicate by the reference ‘wet’<br />

chemistry method (titration).<br />

The infrared spectra of all samples<br />

were recorded on a PerkinElmer<br />

FT-NIR Spectrometer. The samples<br />

were scanned in an NIR quartz<br />

transmission cell through a range<br />

of 10000 – 4000 cm -1 at a resolution<br />

of 8 cm -1 and strong apodization.<br />

All spectra were recorded in ratio<br />

mode using the shuttle accessory.<br />

The shuttle automatically collects<br />

alternate background and sample<br />

scans to eliminate the effects of<br />

water vapor in the air. A pathlength<br />

of 5 mm was considered to provide<br />

useful absorbance values. The<br />

cuvettes were cleaned with acetone<br />

and dried before refilling with the<br />

next sample.<br />

Two calibrated methods were<br />

built using the reference data and<br />

the spectra collected from the<br />

FT-NIR Spectrometer. These were<br />

setup using the QUANT+ software.<br />

Both methods used the range 9000 –<br />

4528 cm -1 with an upper threshold of<br />

1.5 A. The offset option was<br />

employed to minimize baseline drift

effects. The number of factors was<br />

set between 2 and 6. The validation<br />

option was set to Full Cross<br />

Validation (see later), and the Expert<br />

Assist (see later) was selected for the<br />

calibration. The first method was built<br />

using the full range (20 – 270 OH<br />

number) of samples. However, the<br />

second method was built covering a<br />

much smaller range of OH number<br />

(25 – 60). The second method was<br />

able to predict <strong>more</strong> accurately<br />

values within its low OH range. The<br />

first method however, was able to<br />

predict values better for the samples<br />

lying higher in the range, but was not<br />

as accurate for the mid-range values.<br />

Results and discussion<br />

The absorbance spectra for the<br />

polyol standards and the unknowns<br />

were collected and two examples,<br />

representing extremes of OH number,<br />

are shown in Figure 1. The spectral<br />

variations at approximately 7200 –<br />

6670 and 5300 – 4760 cm -1 (1389 –<br />

1499 and 1887 – 2100 nm) clearly<br />

show differing OH number, and<br />

correspond to polymeric O-H first<br />

overtone and O-H combination bands<br />

respectively. Temperature variation is<br />

important to consider in the analysis<br />

of polyols and other NIR applications.<br />

This application did not require<br />

temperature control, and heating<br />

was not necessary as all the samples<br />

were liquid at room temperature.<br />

However, care was taken to ensure<br />

that the sample temperatures were<br />

allowed to equilibrate and the<br />

samples were left in the beam for the<br />

same length of time before each<br />

measurement was made.<br />

The QUANT+ software is capable<br />

of modeling the concentrations in<br />

terms of the spectral contributions<br />

relevant to OH determination. This<br />

algorithm can extract the factors in<br />

the calibration that are not responsible<br />

for the specific OH value (the<br />

chemical constituent of interest)<br />

by eliminating the corresponding<br />

dimensions (spectral absorptions)<br />

from the model.<br />

The error present in an OH<br />

evaluation due to hydroxyl band of<br />

moisture absorbed in the sample can<br />

then therefore be minimized by<br />

Factors Standard Error of Prediction % Variance<br />

Limited Range 2 0.91 99.86<br />

Figure 2: Estimated vs. Specified – limited range method.<br />

digitally separating the different OH<br />

bands using this feature of the<br />

software. The calibration equation is<br />

modeled to exclude irrelevant bands<br />

from the analysis, and minimize the<br />

error in the prediction results.<br />

The Full Cross Validation feature<br />

used in this application further<br />

improves the reliability of results.<br />

The software drops one sample from<br />

the calibration set and performs an<br />

entire calibration with the remaining<br />

samples, then makes a prediction for<br />

the sample left. In normal<br />

applications the sample being<br />

predicted is not present in the<br />

calibration set, this gives a <strong>more</strong><br />

realistic if less accurate result. The<br />

Expert Assist option in the software<br />

makes intelligent decisions<br />

regarding the spectra in the<br />

calibration set. The Expert will<br />

decide whether to reject any spectra<br />

or specific regions of spectra in the<br />

calibration set, or disregard any<br />

property values on the basis of a set<br />

of rules developed for IR quantitative<br />

analysis. It will also identify any<br />

outliers in the set. Once these<br />

decisions have been made to exclude<br />

some data in the set, the software<br />

will decide whether or not the<br />

calibration needs to be repeated.<br />

The procedure continues iteratively<br />

until all the rules are satisfied.<br />

The method built over the narrow<br />

range of OH number was used to<br />

predict the samples of OH value<br />

ranging from 20 to 50. The error<br />

estimates are considerably better<br />

than the results obtained using the<br />

full calibration set. By looking at the<br />

results tabulated in the table in Figure<br />

2, 99.86 % of the data can be<br />

explained using 2 factors with a<br />

standard estimate of prediction (SEP)<br />

of 0.91 OH number. Figure 2 illustrates<br />

the accuracy of the method in the<br />

form of an Estimated value versus<br />

Specified value plot. Prediction of<br />

OH number on the 8 independent<br />

samples using this calibrated method<br />

gave OH numbers that were found to<br />

lie within ca. +/– 1 OH number of<br />

the value obtained from the<br />

reference method (titration).<br />

The full range method uses a larger<br />

calibration set to predict OH number<br />

over a much wider range (20 – 275).<br />

The values recorded in the table in<br />

Figure 3 show that in this method,<br />

99.98% of the data can be explained<br />

using three factors in this analysis.<br />

The SEP is much larger in this<br />

method (4.60 OH number) and was<br />

found to be better at predicting<br />

OH number of the higher valued<br />

unknowns.