“Alternative Energy for the Food Industry” - pcaarrd - Department of ...

“Alternative Energy for the Food Industry” - pcaarrd - Department of ...

“Alternative Energy for the Food Industry” - pcaarrd - Department of ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ISO 9001:2000<br />

PCARRD ISSN 0116-9491<br />

FARMNEWS<br />

Published quarterly by <strong>the</strong> PHILIPPINE COUNCIL FOR AGRICULTURE,<br />

FORESTRY AND NATURAL RESOURCES RESEARCH AND DEVELOPMENT<br />

(PCARRD), <strong>Department</strong> <strong>of</strong> Science and Technology (DOST)<br />

Volume XXXIV No. 1, January–March 2009<br />

<strong>“Alternative</strong> <strong>Energy</strong><br />

<strong>for</strong> <strong>the</strong> <strong>Food</strong> <strong>Industry”</strong><br />

“Serving <strong>the</strong> needs <strong>of</strong> <strong>the</strong> Filipino farmers is our concern”

This issue<br />

From <strong>the</strong> Editorial Team<br />

Alternative energy resources <strong>for</strong> <strong>the</strong> food<br />

Technologies<br />

industry 2<br />

6715 Bi<strong>of</strong>uel law should not sacrifice food<br />

nor energy security 3<br />

6716 Aklan researchers produce diesel additives<br />

from waste fats and oils 5<br />

6717 Plant oil cookstove: an environmentfriendly<br />

Yari Ko Ito!<br />

technology 7<br />

6718 A farmer’s passion sweetens smell <strong>of</strong><br />

Saka Iskwela<br />

biogas 10<br />

6719 MMSU sets trend in charcoal making 13<br />

Negosyo Bro<br />

6720 PCARRD TechnoMart highlights alternative<br />

energy <strong>for</strong> <strong>the</strong> food industry 17<br />

Sa labas na ito<br />

Mga Balitang Pambukid<br />

Teknolohiya<br />

6721 Enerhiya at pagkain magkasinghalaga<br />

ayon sa PCARRD 20<br />

6722 “Diesel additives” mula sa mga patapong<br />

mantika ng hayop at langis ng<br />

gulay 23<br />

6723 “Plant cook oil stove”: makakalikasang<br />

teknolohiya 25<br />

Yari Ko Ito!<br />

6724 Ang Magsasaka Siyentista ng Davao at<br />

ang kanyang “biogas digester” 28<br />

Saka Iskwela<br />

6725 Bagong pamamaraan at materyales sa<br />

paggawa ng uling mula sa kawayan<br />

ipinakita ng Mariano Marcos<br />

State University 31<br />

Negosyo Bro<br />

6726 Panghaliling enerhiya para sa industriya ng<br />

pagkain binigyang pansin ng<br />

TechnoMart 34

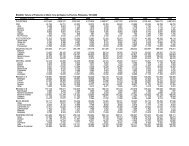

2<br />

From <strong>the</strong> Editorial Team<br />

Alternative energy resources <strong>for</strong> <strong>the</strong> food industry<br />

The food industry is heavily dependent on energy. The various<br />

energy-related aspects <strong>of</strong> food processing and packaging, such<br />

as food preparation, sterilization, and refrigeration consume much<br />

energy. The food industry, <strong>the</strong>re<strong>for</strong>e, is one sector most adversely<br />

affected by <strong>the</strong> turmoil in <strong>the</strong> energy market. With this problem, food<br />

manufacturers experienced a dramatic increase in energy cost to <strong>the</strong><br />

detriment <strong>of</strong> <strong>the</strong> consumers who in most cases have to shoulder<br />

this cost.<br />

To combat rising energy expenses, and as an act <strong>of</strong> good<br />

citizenship in <strong>the</strong> corporate world, food manufacturers have to operate<br />

using alternative energy and renewable sources. This will lessen<br />

<strong>the</strong>ir operational costs and will make <strong>the</strong>m more credible among<br />

environmental groups, a critical advantage in <strong>the</strong> highly competitive<br />

food business especially in <strong>the</strong> global market. Today, energy concern<br />

is no longer viewed as an optional task in business operations. The<br />

use <strong>of</strong> renewable and alternative sources <strong>of</strong> energy has become a<br />

primordial concern.<br />

With PCARRD’s main goal <strong>of</strong> becoming an effective science and<br />

technology leader in <strong>the</strong> agriculture, <strong>for</strong>estry and natural resources<br />

sectors, it seeks to assist industries akin to <strong>the</strong>se sectors, most<br />

especially <strong>the</strong> small and medium enterprises engaged in food<br />

production.<br />

The <strong>the</strong>me <strong>“Alternative</strong> <strong>Energy</strong> Resources <strong>for</strong> <strong>the</strong> <strong>Food</strong> <strong>Industry”</strong><br />

seeks to present important technologies on <strong>the</strong> use <strong>of</strong> alternative<br />

energy. PCARRD hopes that this issue <strong>of</strong> <strong>the</strong> Farmnews will empower<br />

small and medium enterprises in <strong>the</strong> production <strong>of</strong> af<strong>for</strong>dable quality<br />

food commodities to <strong>the</strong> greater benefit <strong>of</strong> Filipino consumers and<br />

contribute to <strong>the</strong> government’s goal <strong>of</strong> attaining food sufficiency.

3<br />

TECHNOLOGIES<br />

Bi<strong>of</strong>uel law should not sacrifice<br />

food nor energy security<br />

Policymakers are at loggerheads on food/energy security concerns<br />

relative to <strong>the</strong> implementation <strong>of</strong> <strong>the</strong> Bi<strong>of</strong>uels Act <strong>of</strong> 2006, <strong>the</strong> law<br />

calculated to lessen <strong>the</strong> country’s dependence on fossil fuel.<br />

With <strong>the</strong> mandate that oil companies will have to blend an<br />

increasing quantity <strong>of</strong> bi<strong>of</strong>uels into fuels sold in <strong>the</strong> market, after<br />

a two and four years successive period from <strong>the</strong> effectivity <strong>of</strong> <strong>the</strong><br />

Act, <strong>the</strong> government is faced with a major concern—<strong>the</strong> source <strong>of</strong><br />

feedstocks.<br />

Since coconut and jatropha are <strong>the</strong> potential sources <strong>of</strong> feedstocks<br />

<strong>for</strong> biodiesel, while sugarcane, cassava, and sweet sorghum are<br />

<strong>the</strong> prospective crops <strong>for</strong> bioethanol, feedstock production triggers<br />

issue on whe<strong>the</strong>r <strong>the</strong> country’s arable land could be compromised<br />

to prioritize energy security.<br />

Viewing <strong>the</strong> issues in even scale, <strong>the</strong> Los Baños-based Philippine<br />

Council <strong>for</strong> Agriculture, Forestry and Natural Resources Research<br />

and Development <strong>of</strong> <strong>the</strong> <strong>Department</strong> <strong>of</strong> Science and Technology<br />

(PCARRD-DOST) said that nei<strong>the</strong>r food nor energy should be<br />

compromised.<br />

As it spearheads <strong>the</strong> implementation <strong>of</strong> <strong>the</strong> National Bi<strong>of</strong>uels<br />

Program (NBP), where <strong>the</strong> production <strong>of</strong> feedstocks is primordial,

4<br />

PCARRD, toge<strong>the</strong>r with <strong>the</strong> science and technology (S&T) community,<br />

ensures that only areas not devoted to <strong>the</strong> cultivation <strong>of</strong> food crops<br />

are targeted <strong>for</strong> <strong>the</strong> purpose.<br />

With <strong>the</strong> required production area <strong>of</strong> around 2.123 million (M)<br />

hectares, <strong>the</strong> program implementors focus on marginal areas not<br />

devoted <strong>for</strong> food crops cultivation, such as degraded grasslands,<br />

denuded uplands, lahar-affected areas, and mined waste areas <strong>for</strong><br />

jatropha, while areas where rice, corn, and sugar cannot be productive<br />

because <strong>of</strong> limiting irrigation water, as well as rainfed rice areas, are<br />

being considered <strong>for</strong> sweet sorghum.<br />

To bolster its equal priority stance, PCARRD said that <strong>the</strong>re is<br />

a need to develop or concentrate bi<strong>of</strong>uel crops in agroecosystems<br />

where <strong>the</strong>y can best per<strong>for</strong>m without compromising <strong>the</strong> country’s<br />

food requirements. Towards this end, production systems that<br />

integrate jatropha in agro<strong>for</strong>estry and agricultural systems such as<br />

in coconut and hilly lands are also being explored under <strong>the</strong> NBP.<br />

(Ricardo R. Argana, S&T Service)<br />

# # #<br />

PFN No. 6715 January-–March 2009

5<br />

Aklan researchers produce diesel additives<br />

from waste fats and oils<br />

Waste products <strong>of</strong> meat processing plants and food servers<br />

such as used animal fats and vegetable oils can be converted into<br />

biodiesel based on a study conducted by researchers <strong>of</strong> <strong>the</strong> Aklan<br />

State University (ASU).<br />

The product is a clear liquid without unpleasant smell with <strong>the</strong><br />

same properties as mineral fossil diesel oil.<br />

Biodiesel may be used in a standard combustion engine without<br />

modifications and may also be blended with petroleum diesel to<br />

improve its quality.<br />

ASU researchers said that engine fueled by a mixture <strong>of</strong> 80<br />

percent petroleum diesel and 20 percent biodiesel had lesser smoke<br />

emissions and lower engine noise compared to that fueled by pure<br />

petroleum diesel.<br />

Previous studies by <strong>the</strong> <strong>Department</strong> <strong>of</strong> Science and Technology<br />

(DOST), National Power Corporation (NAPOCOR) and Philippine<br />

National Oil Company (PNOC)-<strong>Energy</strong> Development Corporation<br />

showed that biodiesel from vegetable oils and animal fats could<br />

match, if not surpass, petroleum diesel in terms <strong>of</strong> engine per<strong>for</strong>mance<br />

and lifespan.<br />

The problem <strong>of</strong> disposing <strong>the</strong> estimated 2,000 kilograms <strong>of</strong><br />

waste animal fats and oils produced by meat product manufacturers<br />

and food servers in Kalibo, Aklan and Boracay Island every month<br />

motivated <strong>the</strong> ASU researchers to conduct <strong>the</strong> study.<br />

Biodiesel does not only provide a source <strong>of</strong> sustainable energy<br />

but also ensures a sustainable environment because it is renewable<br />

or recyclable.

6<br />

This research was presented and evaluated by <strong>the</strong> Philippine<br />

Council <strong>for</strong> Agriculture, Forestry and Natural Resources Research<br />

and Development (PCARRD), among o<strong>the</strong>r evaluators, during <strong>the</strong><br />

Western Visayas Agriculture Resources Research and Development<br />

Consortium Research and Development Symposium. (Bianca Z. Ferrer,<br />

S&T Media Service)<br />

# # #<br />

PFN No. 6716 January-–March 2009<br />

Source:<br />

Ferrer, Bianca Z. “Aklan researchers produce diesel<br />

additives from waste fats and oils.” (S&T Media Service,<br />

Press Release No. 05, 2009).

7<br />

Plant oil cookstove: an environment-friendly technology<br />

The environment has gotten itself a new ally, this time in abating<br />

<strong>the</strong> intense heat and smoke from <strong>the</strong> millions <strong>of</strong> cook stoves. Thanks<br />

to Protos – <strong>the</strong> cook stove powered by plant oil and <strong>the</strong> most recent<br />

environment-friendly technology in cooking devices.<br />

Clean, safe and environment-friendly, “Protos” is a better<br />

alternative to existing cook stoves, which use fossil-based fuel. It<br />

is even far better than <strong>the</strong> traditional three-stone fireplace that uses<br />

firewood.<br />

The use <strong>of</strong> firewood-powered stoves depletes <strong>for</strong>est resources<br />

and consequently leads to ecological disasters like erosion and<br />

flooding. Smoke from burning firewood causes eye and lung diseases<br />

in humans and aggravates air pollution problems. On <strong>the</strong> o<strong>the</strong>r hand,<br />

fossil-based fueled-cook stoves emit high levels <strong>of</strong> carbon monoxide,<br />

a chemical that harms <strong>the</strong> environment. More so, to majority <strong>of</strong> <strong>the</strong><br />

Filipino poor, this type <strong>of</strong> cook stove is unaf<strong>for</strong>dable.<br />

Experts from Visayas State University (VSU) led by Dr. Roberto<br />

C. Guarte developed, optimized, and evaluated “protos,” through<br />

<strong>the</strong> funding support <strong>of</strong> <strong>the</strong> BSH Bosch and Siemens Home Appliances<br />

Group <strong>of</strong> Munich, Germany.<br />

The stove consists <strong>of</strong> a tank, pump, frame, valve, fuel line, and a<br />

vaporizer originally made at <strong>the</strong> University <strong>of</strong> Hohenheim and acquired<br />

by BSH Group in Germany.<br />

Reports provided to <strong>the</strong> Philippine Council <strong>for</strong> Agriculture, Forestry,<br />

and Natural Resources Research and Development (PCARRD) show<br />

that “protos” per<strong>for</strong>ms well using different types <strong>of</strong> fossil-based fuel<br />

and plant oil. Despite its versatility, Guarte suggested <strong>the</strong> use <strong>of</strong><br />

plant oil such as coconut oil because it emits lower carbon monoxide

8<br />

and is a natural source <strong>of</strong> renewable energy. Aside from coconut<br />

palm, o<strong>the</strong>r suitable plants are sunflower, castor, corn, soybean,<br />

and jatropha.<br />

Cooperators from 100 household in selected areas in Leyte attest<br />

to <strong>the</strong> stove’s satisfactory per<strong>for</strong>mance. The cooperators consumed<br />

an average <strong>of</strong> 11.64 liters per month at a daily cooking time <strong>of</strong><br />

1.53 hours. The six small restaurants at <strong>the</strong> VSU market, which also<br />

served as project operators, had average monthly oil consumption<br />

<strong>of</strong> about 28 liters per month at an average daily cooking time <strong>of</strong><br />

5.24 hours.<br />

Generally, its overall per<strong>for</strong>mance is almost <strong>the</strong> same as gas stove<br />

and much better than o<strong>the</strong>r local stoves in terms <strong>of</strong> cost <strong>of</strong> operation,<br />

safety, carbon monoxide emission, and sustainability.<br />

The VSU engineering workshop produces 1,500 units <strong>of</strong> plant<br />

oil cook stove per year in coordination with BSH Group in Germany.

9<br />

The university established a complete production line to ensure<br />

sustainable production <strong>of</strong> <strong>the</strong> plant oil cookstove <strong>for</strong> marketing and<br />

distribution in Region 8.<br />

By expanding its production to cooperatives, this project will<br />

help create jobs in <strong>the</strong> rural areas, provide income to <strong>the</strong> poor,<br />

and cooperatives with additional pr<strong>of</strong>its, hence bringing not only<br />

environmental, but also economic and social benefits. (Ofelia F.<br />

Domingo, S&T Media Service)<br />

# # #<br />

PFN No. 6717 January–March 2009<br />

Source:<br />

Domingo, Ofelia F. “Plant oil cook stove: an environmentfriendly<br />

technology.” (S&T Media Service, Press Release<br />

No. 20, 2009).

10<br />

YARI KO ITO !<br />

A farmer’s passion sweetens smell <strong>of</strong> biogas<br />

Controlling <strong>the</strong> odor<br />

from pigpens, if not<br />

totally eliminating it,<br />

has been <strong>the</strong> challenge<br />

<strong>for</strong> many swine raisers,<br />

especially in urban<br />

areas.<br />

P C A R R D ’ s<br />

Magsasaka-Siyentista<br />

(MS) Felimon ‘Boy’<br />

Santander from Mandug,<br />

Davao City, a swine<br />

raiser and a biogas<br />

advocate, has come up<br />

with an alternative and<br />

environment-friendly<br />

farming technology to<br />

combat this problem.<br />

Problem no more<br />

M S S a n t a n d e r<br />

constructed his own<br />

Above: MS<br />

Santander speaks<br />

about his modified<br />

biogas technology<br />

during <strong>the</strong> 1st<br />

Biogas Techno<br />

Caravan in Davao<br />

del Norte.<br />

Left: MS<br />

Santander’s biogas<br />

digester in his<br />

backyard.

11<br />

modified biogas digester in his backyard in 1995. It eliminated <strong>the</strong><br />

unpleasant odor coming from <strong>the</strong> pigpen, at <strong>the</strong> same time provided<br />

a free source <strong>of</strong> cooking gas. He also started to promote biogas<br />

and provide free fuel to his neighbors. Consequently, o<strong>the</strong>r pigpen<br />

owners requested Santander’s assistance in constructing <strong>the</strong>ir own<br />

biogas digester.<br />

MS Santander’s modified digester’s features are simple. It uses<br />

concrete materials and ranges from 2 cubic meters to 20 cubic<br />

meters. Through his modified biogas digester, Santander has proven<br />

that biogas technology can also be used in small-scale, backyard<br />

pigpens.<br />

From hobby to money<br />

MS Santander, a political science graduate, was a Sangguniang<br />

Bayan technical staff <strong>for</strong> eight years. During those years, swine<br />

raising was his hobby and source <strong>of</strong> additional income. With <strong>the</strong><br />

Cookstove fueled by biogas.

12<br />

need to have ends meet, he made <strong>the</strong> hobby a full time source <strong>of</strong><br />

income in 1997.<br />

Continuing advocacy<br />

Santander’s skills in constructing a modified biogas digester<br />

gained prominence not only in Davao City but also in Davao del<br />

Sur, Compostela Valley Province, Davao del Norte, Bukidnon,<br />

Capiz, and in o<strong>the</strong>r parts <strong>of</strong> <strong>the</strong> country. He did this by conducting<br />

technology clinics and <strong>for</strong>a through <strong>the</strong> help <strong>of</strong> Sou<strong>the</strong>rn Mindanao<br />

Agriculture and Resources Research and Development Consortium<br />

(SMARRDEC). Fur<strong>the</strong>r, he advocated <strong>for</strong> agri-waste management and<br />

sludge utilization from biogas as organic fertilizer with SMARRDEC<br />

and B-Meg Philippines. Santander also founded <strong>the</strong> Mandug Peoples’<br />

Cooperative with his neighbors who established <strong>the</strong>ir own pigpens<br />

and went into biogas technology as members.<br />

At <strong>the</strong> recently concluded 8 th Philippine <strong>Food</strong> Expo held at <strong>the</strong> SM<br />

Megamall Trade Hall in Pasig City, Santander’s biogas digester was<br />

also showcased through <strong>the</strong> auspices <strong>of</strong> SMARRDEC and PCARRD.<br />

(Vanessa G. Villegas and Lorelyn A. Poblete with reports from Noel<br />

Provido and Jocelyn A. Amarante, S&T Media Service)<br />

# # #<br />

PFN No. 6718 January–March 2009<br />

Source:<br />

Villegas, Vanessa G.; Poblete, Lorelyn A.; Provido, Noel T.;<br />

and Amarante, Jocelyn A. “From stench to sweet-smelling<br />

success: A farmer’s passion <strong>for</strong> biogas technology.”<br />

PCARRD Monitor 35(2):8-9,15 April-June 2007.

13<br />

SAKA ISKWELA<br />

MMSU sets trend in charcoal making<br />

Mariano Marco State University (MMSU) researchers set new<br />

trend in charcoal making fashioning to <strong>the</strong>ir utmost importance <strong>the</strong><br />

once worthless bamboo wastes and rice hull abandoned in <strong>the</strong> fields<br />

<strong>of</strong> <strong>the</strong> countryside.<br />

With this technology, tons <strong>of</strong> bamboo wastes and rice hull, instead<br />

<strong>of</strong> being an eyesore, will now be a source <strong>of</strong> income. And more! It<br />

will provide good use <strong>for</strong> wastewater from chichacorn (crispy fried<br />

corn kernels) production, a possible environmental hazard especially<br />

<strong>for</strong> water sources.<br />

Burning kawayan charcoal briquette.

14<br />

Chichacorn effluent which are abundant in some areas like <strong>the</strong><br />

Ilocos region, contains corn starch, a suitable binder and good<br />

substitute <strong>for</strong> cassava starch in <strong>the</strong> production <strong>of</strong> charcoal briquette .<br />

Thanks to <strong>the</strong> kawayan charcoal briquette technology developed<br />

by MMSU researchers Stanley C. Malab and Jose A. Zaparalla.<br />

Seeing <strong>the</strong>se environmental nuisance burn to waste in <strong>the</strong> fields <strong>of</strong><br />

<strong>the</strong> countryside will soon be a thing <strong>of</strong> <strong>the</strong> past because <strong>of</strong> <strong>the</strong>ir<br />

new found importance.<br />

Briquetting Process.<br />

Malab is <strong>the</strong> director <strong>of</strong> <strong>the</strong> Ilocos Agriculture Resources Research<br />

and Development Consortium (ILARRDEC), one <strong>of</strong> <strong>the</strong> consortia<br />

organized by <strong>the</strong> Philippine Council <strong>for</strong> Agriculture, Forestry and<br />

Natural Resources Research and Development (PCARRD).<br />

Originally designed <strong>for</strong> bamboo waste such as leaves, small<br />

branches, bamboo shavings or trimmings, <strong>the</strong> charcoal briquette<br />

technology has been improved to include rice hull as production<br />

material.

15<br />

Kawayan Charcoal Briquettes with chichacorn processing effluent<br />

as binder won <strong>the</strong> most outstanding award <strong>for</strong> <strong>the</strong> research category<br />

during <strong>the</strong> National Symposium on Agriculture and Resources and<br />

Development (NSARRD).<br />

The NSARRD where <strong>the</strong> KCB technology was first recognized,<br />

was initiated by <strong>the</strong> Philippine Council <strong>for</strong> Agriculture, Forestry<br />

and Natural Resources Research and Development (PCARRD) in<br />

appreciation <strong>of</strong> <strong>the</strong> government <strong>for</strong> <strong>the</strong> outstanding contributions <strong>of</strong><br />

individuals and institutions in <strong>the</strong> improvement <strong>of</strong> agriculture <strong>for</strong>estry<br />

and natural resources research and development (R&D).<br />

KCB’s modification which makes use <strong>of</strong> rice hull under ano<strong>the</strong>r<br />

project (Enhancing recovery <strong>of</strong> rice hull, chichacorn and bamboo<br />

processing wastes as bioenergy source and environmental mitigation)<br />

also by Malab and Zafaralla, toge<strong>the</strong>r with MMSU researchers Beatriz<br />

Rice Hull and Bamboo Carbonization Process.

16<br />

S. Malab, and Angelina Tagay, won second place in <strong>the</strong> Luzon Cluster<br />

7 th Regional S&T Fora and Competitions in Industry and <strong>Energy</strong><br />

Research and Development.<br />

The technology was presented during <strong>the</strong> 28 th International<br />

Convention <strong>of</strong> <strong>the</strong> Philippine-American Academy <strong>of</strong> Science and<br />

Engineering (PAASE) held at Georgetown University Washington<br />

DC, USA.<br />

With <strong>the</strong> need to find alternative and renewable energy brought<br />

by <strong>the</strong> energy turbulence, <strong>the</strong> KCB technology once more took center<br />

stage, during <strong>the</strong> Technology to People Media Conference sponsored<br />

by PCARRD recently.<br />

The conference also featured <strong>the</strong> jatropha enterprise <strong>for</strong> biodiesel<br />

production which was presented by Dr. Roberto Guarte, Vice<br />

President <strong>for</strong> Administration and Finance Project Director <strong>for</strong> Jatropha<br />

project in Eastern Visayas.<br />

A model <strong>of</strong> biogas digester was also presented by Felimon<br />

Santander, a Magsasaka Siyentista from <strong>the</strong> Sou<strong>the</strong>rn Mindanao<br />

Agriculture Resources Research and Development Consortium<br />

(SMARRDEC).<br />

PCARRD provided <strong>the</strong> venue <strong>for</strong> <strong>the</strong> dissemination <strong>of</strong> alternative<br />

energy sources under its Technology to People program to lessen<br />

<strong>the</strong> burden <strong>of</strong> <strong>the</strong> food industry in relation to high energy cost in food<br />

production. (Ricardo R. Argana, S&T Media Service)<br />

# # #<br />

PFN No.6719 January-–March 2009<br />

Source:<br />

Argana, Ricardo R. “MMSU sets trend in charcoal making.”<br />

(S&T Media Service, Press Release No. 24, 2009).

17<br />

NEGOSYO BRO<br />

PCARRD TechnoMart highlights<br />

alternative energy <strong>for</strong> <strong>the</strong> food industry<br />

The recent energy turmoil leaves <strong>the</strong> food industry with one<br />

important lesson in resource management—<strong>the</strong> need to find<br />

alternative sources <strong>of</strong> energy <strong>for</strong> various aspects <strong>of</strong> food processing<br />

and packaging.<br />

Seeking to assist <strong>the</strong> country’s food manufacturers and producers,<br />

particulalry those run by small and medium enterprises (SMEs), <strong>the</strong><br />

Philippine Council <strong>for</strong> Agriculture, Forestry and Natural Resources<br />

Research and Development (PCARRD), through its TechnoMart<br />

program, higlighted some <strong>of</strong> <strong>the</strong> most recent inventions on <strong>the</strong> use<br />

<strong>of</strong> alternative energy during <strong>the</strong> 8 th Philippine <strong>Food</strong> Expo.<br />

Bearing <strong>the</strong> <strong>the</strong>me Strategic Regional Cooperation Towards<br />

<strong>Food</strong> Self-Sufficiency, <strong>the</strong> food expo initiated by <strong>the</strong> Philippine <strong>Food</strong><br />

Exporters Inc., was held at <strong>the</strong> SM Megamall in Ortigas Avenue in<br />

Quezon City from March 5 to 7. The expo featured various food<br />

products <strong>of</strong> 175 companies in 249 booths representing Luzon,<br />

Visayas, Mindanao, and <strong>the</strong> National Capital Region.<br />

The inventions featured by PCARRD and its partner member<br />

agencies include protos, a stove which uses plant oil; biogas, fuel<br />

from waste; biogas digester model; and <strong>the</strong> kawayan charcoal<br />

briquettes.

18<br />

The inventions were generated by <strong>the</strong> National Agriculture<br />

Resources Research and Development Network (NARRDN)-member<br />

agencies Visayas State University, Baybay, Leyte; University <strong>of</strong><br />

Sou<strong>the</strong>astern Philippines, Davao City; Cavite State University,<br />

Indang, Cavite, and <strong>the</strong> Mariano Marcos State University, Batac,<br />

Ilocos Norte.<br />

As PCARRD’s most recent technology diffusion modality,<br />

TechnoMart bridges <strong>the</strong> gap between science and technology<br />

(S&T)-based enterprises and <strong>the</strong> thriving industires through business<br />

mentoring and product market matching.<br />

PHILFOODEX supports governmet programs on agricultural<br />

productivity such as <strong>the</strong> Ginintuang Masaganang Ani and FIELDS<br />

(fertilizer, irrigation, infrastructure, extension, education, loans, driers<br />

and post harvest, and seeds) to achieve food self-sufficiency and<br />

modernize Philippine agriculture.<br />

PCARRD hopes that this undertaking, among o<strong>the</strong>rs, will empower<br />

small and medium enterprises in <strong>the</strong> production <strong>of</strong> af<strong>for</strong>dable quality<br />

food commodities to <strong>the</strong> greater benefit <strong>of</strong> Filipino consumers and<br />

contribute in <strong>the</strong> government’s goal <strong>of</strong> attaining food sufficiency <strong>for</strong><br />

every Filipino family. (Ricardo R. Argana, S&T Media Service)<br />

# # #<br />

PFN No. 6720 January-–March 2009

19<br />

BALITANG<br />

PAMBUKID<br />

para sa Radyo<br />

IMPORMASYON!<br />

TEKNOLOHIYA!<br />

KAALAMAN!

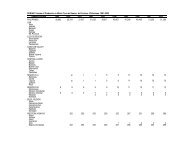

20<br />

TEKNOLOHIYA<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22<br />

23<br />

Enerhiya at pagkain magkasing halaga<br />

ayon sa PCARRD<br />

Maari bang isakripisyo ang mga lupang nakalaan<br />

para sa produksyon ng pagkain para sa pagtatanim ng<br />

“feedstocks” tulad ng jatropha o “tubang bakod” at sweet<br />

sorghum bilang hilaw na sangkap ng “bi<strong>of</strong>uels”?<br />

Ito ang isang mahalagang isyu na di maiwasang<br />

pagusapan kaugnay ng implementasyon ng Bi<strong>of</strong>uels Act<br />

<strong>of</strong> 2006, ang batas na inaasahang makakabawas sa<br />

pangangailangan ng bansa sa “fossil fuel”.<br />

Sa ilalim ng nasabing batas, ang mga kumpanya ng<br />

langis sa bansa ay kinakailangang maghalo ng bi<strong>of</strong>uel<br />

sa “commercial fuel” ayon sa itinakdang dami matapos<br />

ang dalawang taon at apat na taon mula sa araw ng<br />

pagiging epektibo ng batas. Dahilan dito ay kinakaharap<br />

ngayon ng bansa ang suliranin kung saan kukuhanin ang<br />

kinakailangang “supply” ng feedstocks.<br />

Ang niyog at jatropha ang pangunahing maaaring<br />

pagkunan ng feedstocks para sa biodiesel. Ang

21<br />

24<br />

25<br />

26<br />

27<br />

28<br />

29<br />

30<br />

31<br />

32<br />

33<br />

34<br />

35<br />

36<br />

37<br />

38<br />

39<br />

40<br />

41<br />

42<br />

43<br />

44<br />

45<br />

46<br />

47<br />

48<br />

49<br />

50<br />

51<br />

52<br />

53<br />

54<br />

55<br />

tubo, kamoteng kahoy, at sweet sorghum naman ang<br />

pangunahing tinitingnan bilang hilaw na sangkap para sa<br />

bioethanol.<br />

Kinikilala ng Philippine Council <strong>for</strong> Agriculture, Forestry<br />

and Natural Resources Research and Development o<br />

P-CARRD ang kahalagahan ng pagkain at enerhiya at<br />

walang dapat masakripisyo sa dalawang ito, ayon sa<br />

ahensiya.<br />

Sa pagpapatupad ng implementasyon ng National<br />

Bi<strong>of</strong>uels Program, kung saan ang produksyon ng feedstocks<br />

ang pangunahing konsiderasyon, sinisiguro ng P-CARRD,<br />

kasama ang iba pang mga katuwang na ahensiya, na<br />

tanging ang mga lugar na di ginagamit sa pagtatanim ng<br />

mga agrikulturang produkto para sa pagkain ang gagamitin<br />

sa pagtatanim ng feedstocks.<br />

Sa pagtatanim ng jatropha, halimbawa, “target” ng<br />

programa ang mga damuhan, mga di natatanimang lupa<br />

sa mga matataas na lugar, mga lugar na apektado ng<br />

lahar, at mga lugar na pinagtatambakan ng mga “waste<br />

materials” na galing sa mga minahan.<br />

Tinitingnan din ng programa ang pagsasanib ng<br />

pagtatanim ng feedstocks, partikular ang jatropha sa<br />

“agroecosystems” tulad ng mga taniman ng niyog at<br />

bulubunduking lugar, kung saan inaasahang sila ay<br />

lalago at bubuti sa paraang di masasakripisyo ang mga<br />

lugar na dapat pangbungkalan ng mga halamang para sa<br />

pagkain.<br />

Tinitinganan naman ng programa, para sa pagtatanim<br />

ng sweet sorghum, ang mga lugar kung saan ang palay,

22<br />

56<br />

57<br />

58<br />

59<br />

60<br />

61<br />

62<br />

63<br />

64<br />

65<br />

mais, at tubo ay di maaring maitanim ng produktibo dahilan<br />

sa kakulangang ng irigasyon, ganon din ang mga lugar<br />

na umaasa lamang sa patak ng ulan. (Ricardo R. Argana,<br />

S&T Service)<br />

# # #<br />

PBP Blg. 6721 Enero-–Marso 2009<br />

Pinagkunan: Argana, Ricardo R. “Enerhiya at pagkain<br />

magkasing halaga ayon sa PCARRD.” (S&T<br />

Media Service, Press Release No. 19,<br />

2009).

23<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22<br />

23<br />

24<br />

25<br />

26<br />

27<br />

28<br />

29<br />

30<br />

31<br />

32<br />

33<br />

“Diesel additives” mula sa mga patapong mantika<br />

ng hayop at langis ng gulay<br />

Ang mantika mula sa taba ng hayop at langis mula sa<br />

mga gulay na itinatapon ng mga plantang nagpoproseso<br />

nito, ganon din ng mga naghahanda ng pagkain gaya<br />

ng mga kantina at “restaurant,” ay maaring gawing<br />

“biodiesel.” Ito ay ayon sa isang pag-aaral na isinagawa<br />

ng mga mananaliksik ng Aklan State University o<br />

A-SU.<br />

Ang biodiesel na makukuha mula rito ay isang<br />

malinaw na likido, walang masamang amoy, at may<br />

parehong katangian ng “mineral fossil diesel oil.”<br />

Ang biodiesel na ito ay maaring gamitin sa isang<br />

“standard” na “combustion engine” na di kinakailangan<br />

ang ano mang pagbabago sa katangian nito. Maaari rin<br />

itong haluan ng “petroleum diesel” para pabutihin ang<br />

kailidad nito.<br />

Sinabi ng mga mananaliksik ng A-SU na ang makina<br />

na ginamitan ng 80 posiyento na petroleum diesel at 20<br />

porsiyento ng biodiesel na nalinang mula sa pag-aaral<br />

ay may mas kakaunting usok at mas mababang antas<br />

ng ingay kumpara sa makina na ginamitan ng purong<br />

petroleum diesel.<br />

Nakita sa mga huling pag-aaral na isinagawa ng<br />

<strong>Department</strong> <strong>of</strong> Science and Technology o D-O-S-T,<br />

ng National Power Corporation o NA-PO-COR at ng<br />

Philippine National Oil Company o P-N-O-C-<strong>Energy</strong><br />

Development Corporation na ang biodiesel mula sa mga<br />

patapon ng taba ng hayop at langis ng gulay ay maaring<br />

makatumbas, kung hindi man makahigit sa petroleum

24<br />

34<br />

35<br />

36<br />

37<br />

38<br />

39<br />

40<br />

41<br />

42<br />

43<br />

44<br />

45<br />

46<br />

47<br />

48<br />

49<br />

50<br />

51<br />

52<br />

53<br />

54<br />

55<br />

56<br />

57<br />

58<br />

59<br />

60<br />

diesel, pagdating sa maayos na pagpapatakbo ng makina<br />

at sa itatagal ng kapakinabangan nito.<br />

Ang suliranin sa pagtatapon ng tinatayang 2,000 kilo<br />

ng mantika mula sa mga taba ng hayop na nagmumula<br />

sa mga planta ng nagpoproseso ng mga produkto mula<br />

sa karne ng hayop at mga nagsisilbi ng pagkain sa Kalibo,<br />

Aklan at isla ng Boracay bawat buwan ang siyang naging<br />

dahilan ng mga mananaliksik ng A-SU upang isagawa ang<br />

pag-aaral.<br />

Bukod sa ang nalinang na teknolohiya ay makapagbibigay<br />

ng tuloy-tuloy na mapagkukunan ng biodiesel, ito<br />

ay makakatulong din upang mapangalagaan ang<br />

kapaligiran.<br />

Ang teknolohiya ng biodiesel mula sa mga patapon ng<br />

taba ng hayop at langis mula sa mga gulay ay inihayag at<br />

sinuri ng Philippine Council <strong>for</strong> Agriculture, Forestry and<br />

Natural Resources Research and Development o P-CARRD,<br />

kasama ang iba pang ahensiya sa ginanap na Western<br />

Visayas Agriculture Resources Research and Development<br />

Consortium Research and Development Symposium.<br />

(Ricardo R. Argana, S&T Media Service)<br />

# # #<br />

PBP Blg. 6722 Enero–Marso 2009

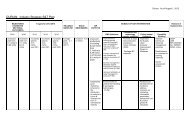

25<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

18<br />

18<br />

20<br />

21<br />

22<br />

23<br />

24<br />

25<br />

26<br />

27<br />

28<br />

29<br />

30<br />

31<br />

32<br />

33<br />

“Plant oil cookstove”: makakalikasang teknolohiya<br />

May bagong kakampi ang kapaligiran sa isa sa<br />

pinakahuling inbensiyon na may kinalaman sa paggamit<br />

ng alternatibong enerhiya. Ito ay ang “protos cookstove,”<br />

isang lutuan na ginagamitan ng “plant oil.” Inaasahang<br />

ang inbensiyon ay makakatulong upang mabawasan ang<br />

matinding init at usok na nagmumula sa mga lutuang<br />

kalan.<br />

Ang protos ay makakapaligiran, malinis, ligtas, at<br />

mas mainam na panghalili sa mga nakaugaliang lutuan na<br />

gumagamit ng “fossil-based fuel.” Mas mainam din ito sa<br />

mga tungko na gumagamit ng kahoy bilang pangatong.<br />

Ang paggamit ng kahoy bilang panggatong ay isa sa<br />

nagiging dahilan ng pagkaubos ng mga kahoy sa kagubatan.<br />

Nagdudulot din ito ng mga likas na kapahamakan tulad ng<br />

pagbaha at mga pagguho. Ang usok na nagmumula sa mga<br />

kahoy na panggatong ay nakakapagpalala sa suliranin sa<br />

polyusyon na nagiging dahilan din ng mga sakit sa mata<br />

at baga ng tao. Ang mga lutuan naman na ginagamitan ng<br />

fossil-based fuel ay nagbubuga sa kapaligiran ng mataas<br />

na antas ng “carbon monoxide,” na pumipinsala rin sa<br />

kapaligiran. Bukod pa rito, karamihan sa mga mahihirap na<br />

mga Filipino ay walang kakayanan na makabili ng ganitong<br />

klase ng lutuan.<br />

Ang protos ay nilinang, pinahusay, at sinuri ang<br />

kakayanan ng mga dalubhasa mula sa Visayas State<br />

University o V-S-U sa pangunguna ni Dr. Roberto C.<br />

Guarte. Ito ay sa suportang pinansiyal ng Bosch and<br />

Siemens Home o B-S-H Appliances Group ng Munich,<br />

Germany.

26<br />

34<br />

35<br />

36<br />

37<br />

38<br />

39<br />

40<br />

41<br />

42<br />

43<br />

44<br />

45<br />

46<br />

47<br />

48<br />

49<br />

50<br />

51<br />

52<br />

53<br />

54<br />

55<br />

56<br />

57<br />

58<br />

59<br />

60<br />

61<br />

62<br />

63<br />

64<br />

65<br />

Ang protos ay binubuo ng tangke, pangbomba,<br />

balangkas o “frame” barbula, daluyan ng gatong, at<br />

isang “vaporizer.” Ang vaporizer na ito na binili ng B-S-H<br />

Group sa Alemanya ay orihinal na ginawa sa University<br />

<strong>of</strong> Hohenheim.<br />

Ayon sa ulat na tinanggap ng Philippine Council <strong>for</strong><br />

Agriculture, Forestry, and Natural Resources Research<br />

and Development o P-CARRD, mahusay na nagagamit ang<br />

protos sa parehong uri ng panggatong, ang fossil-based<br />

fuel at ang plant oil. Sa kabila nito, ipinayo ni Guarte<br />

ang paggamit ng plant oil gaya ng langis na nagmumula<br />

sa niyog dahil sa ito ay nagbubuga ng mas mababang<br />

carbon monoxide at likas na mapagkukunan ng tinatawag<br />

na “renewable energy.” Bukod sa niyog, ang iba pang<br />

halaman na maaring gamitin ay ang “sunflower,” “castor,”<br />

“soybean,” at jatropha.<br />

Ang isang daang sambahayan na nakiisa sa proyekto<br />

sa mga piling lugar sa Leyte ay nagpatunay sa kahusayan<br />

ng protos. Sinabi nila na sila ay karaniwang gumagamit<br />

ng nasa 11.64 litro ng plant oil bawat buwan. Ito ay sa<br />

loob ng nasa isa at kalahating oras ng pagluluto araw araw.<br />

Ang may ari ng anim na maliliit na kainan sa pamilihan<br />

ng V-S-U na nakiisa rin sa proyekto ay nagsabi na sila<br />

ay karaniwang gumagamit ng 28 litro ng plant oil sa<br />

bawat buwan sa loob ng nasa isang oras at dalawampung<br />

minutong pagluluto araw araw.<br />

Sa kabuuan, ang kagalingan ng protos ay halos katulad<br />

ng gas stove at mas mahusay kaysa mga lokal na lutuan<br />

sa aspeto ng halaga ng gamit, pagiging ligtas, dami ng<br />

carbon monoxide, at ang kakayanan nitong magamit ng<br />

matagalan.

27<br />

66<br />

67<br />

68<br />

69<br />

70<br />

71<br />

72<br />

73<br />

74<br />

75<br />

76<br />

77<br />

78<br />

79<br />

80<br />

Ang V-S-U ay nakakagawa ng 1,500 protos bawat<br />

taon sa pakikipagtulungan ng B-S-H Group sa Germany.<br />

Naitatag na ng V-S-U ang buong hanay ng produksyon<br />

upang siguruhin ang tuloy tuloy na paggawa nito para sa<br />

mga pamilihan ng Region 8.<br />

Sa pamamagitan ng pagpapalaki sa produksyon<br />

ng protos sa tulong ng mga kooperatiba, inasahang<br />

makakatulong ang proyekto sa paglikha ng mga hanap<br />

buhay sa kanayunan, pagbibigay ng karagdagang kita sa<br />

mga kooperatiba, bukod pa sa magandang ibubunga nito<br />

sa kapaligiran. (Ricardo R. Argana, S&T Media Service)<br />

# # #<br />

PBP Blg. 6723 Enero–Marso 2009<br />

Pinagkunan:<br />

Domingo, Ofelia F. “Plant oil cookstove:<br />

an environment-friendly technology.” (S&T<br />

Media Service, Press Release No. 20, 2009).<br />

Isinalin sa Tagalog ni Ricardo R. Argana.

28<br />

YARI KO ITO !<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22<br />

23<br />

24<br />

25<br />

26<br />

Ang Magsasaka Siyentista ng Davao<br />

at ang kanyang “biogas digester”<br />

Ang pag-aalis ng masamang amoy, o ang pagbabawas<br />

man lamang dito, ay isang hamon para sa mga maraming<br />

nagaalaga ng baboy lalo na sa mga kanayunan.<br />

Ito ang naging inspirasyon ni Ginoong Felimon “Boy”<br />

Santander ng Mandug, Davao City, isang taga suporta<br />

ng teknolohiya ng biogas, upang humanap ng isang<br />

alternatibong enerhiya na makakalikasan at makakapaligiran<br />

upang tugunan ang nasabing problema.<br />

Si Mang Boy ay isa ring Magsasaka Siyentista na<br />

nahirang ng Philippine Council <strong>for</strong> Agriculture, Forestry<br />

and Natural Resources Research and Development o<br />

P-CARRD.<br />

Gumawa si Ginoong Santander ng kanyang sariling<br />

disenyo ng “biogas digester” sa kanyang bakuran noong<br />

1995. Sa pamamagitan nito ay nawala ang masamang<br />

amoy na nagmumula sa kanyang mga kural. Ito ay<br />

nagbigay din sa kanya ng mapagkukunan ng “gas” para<br />

sa pagluluto.<br />

Dahilan sa pakinabang ng kanyang dinisenyong biogas<br />

digester, sinimulan niyang ibahagi ang teknolohiya sa

29<br />

27<br />

28<br />

29<br />

30<br />

31<br />

32<br />

33<br />

34<br />

35<br />

36<br />

37<br />

38<br />

39<br />

40<br />

41<br />

42<br />

43<br />

44<br />

45<br />

46<br />

47<br />

48<br />

49<br />

50<br />

51<br />

52<br />

53<br />

54<br />

55<br />

56<br />

57<br />

58<br />

59<br />

kanyang mga kapitbahay. Ibinahagi rin niya ang libreng<br />

mapagkukunan ng gas sa kanila. Matapos ito ay mismong<br />

ang mga nagaalaga na ng baboy sa paligid ang humingi ng<br />

kanyang tulong upang maisagawa rin nila ang teknolohiya<br />

sa kanilang babuyan.<br />

Simple lamang ang disenyo ng biogas digester ni Mang<br />

Boy. Gumagamit ito ng konkretong materyales at may<br />

sukat na dalawang metro kubiko sa dalawampung metro<br />

kubiko (2m 3 X 20m 3 ). Sa pamamagitan ng teknolohiyang<br />

ito, ay naipakita niya na ang ang teknolohiya ng biogas ay<br />

maari ring gamitin sa maliliit na alagaan ng baboy.<br />

Si Mang Boy ay nagtapos ng kursong “political<br />

science” at naging isang “technical staff” ng Sanguniang<br />

Bayan. Sa mga panahong iyon, ang pagaalaga ng baboy,<br />

para sa kanya, ay isa lamang libangan at pinagkukunan<br />

ng karagdagang kita. Ngunit dahil sa kakapusan ng kita,<br />

ay nagpasya siya na gawing isang pangmatagalang<br />

hanapbuhay ito noong 1997.<br />

Nakilala si Mang Boy sa kanyang kakayahan ng<br />

paggawa ng kanyang sariling disenyo ng biogas digester<br />

hindi lamang sa Davao City kung hindi maging sa Davao<br />

del Sur, Compostela Valley Province, Davao del Norte,<br />

Bukidnon, Capiz, at iba pang bahagi ng bansa. Isinagawa<br />

niya ang pagbabahagi ng teknolohiya sa pamamagitan ng<br />

pagsasagawa ng mga “technology clinic” at mga “<strong>for</strong>a” sa<br />

tulong ng Sou<strong>the</strong>rn Mindanao Agriculture and Resources<br />

Research and Development Consortium o SMARR-DEC.<br />

Si Mang Boy ay naging taga sulong rin ng teknolohiya<br />

ng pangangasiwa ng mga dumi na mula sa agrikultura<br />

o “agri-waste” at maging ng mga dumi o latak mula sa<br />

proseso ng biogas technology bilang “organic fertilizer.” Ito

30<br />

60<br />

61<br />

62<br />

63<br />

64<br />

65<br />

66<br />

67<br />

68<br />

69<br />

70<br />

71<br />

72<br />

73<br />

ay sa suporta rin ng SMARR-DEC at ng B-Meg Philippines.<br />

Itinatag rin ni Mang Boy ang Mandug Peoples’ Cooperative.<br />

Ito ay kinabibilangan ng kanyang mga kapitbahay na<br />

may mga babuyan at tumatangkilik din ng teknolohiya<br />

ng biogas.<br />

Ipinamalas ang disenyo ng biogas digester na nalinang<br />

ni Mang Boy noong nagdaang 8 th Philippine <strong>Food</strong> Expo na<br />

isinagawa sa SM Megamall Trade Hall sa Pasig City. Ito<br />

ay sa pakikipagtulungan ng SMARRDEC at ng PCARRD.<br />

(Ricardo R. Argana, S&T Media Service)<br />

# # #<br />

PBP Blg 6724 Enero–Marso 2009<br />

Pinagkunan:<br />

Villegas, Vanessa G.; Poblete, Lorelyn A.;<br />

Provido, Noel T.; and Amarante, Jocelyn A.<br />

“From stench to sweet-smelling success:<br />

A farmer’s passion <strong>for</strong> biogas technology.”<br />

PCARRD Monitor 35(2):8-9,15 April-June<br />

2007. Isinalin sa Tagalog ni Ricardo R.<br />

Argana.

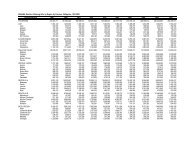

31<br />

SAKA ISKWELA<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22<br />

23<br />

24<br />

25<br />

26<br />

Bagong pamamaraan at materyales<br />

sa paggawa ng uling ipinakilala ng Mariano Marcos<br />

State University<br />

Ipinakilala ng mga mananaliksik ng Mariano Marcos<br />

State University o M-M-S-U ang pinakabagong pamamaraan<br />

at materyales sa paggawa ng uling. Sa pamamaraang ito,<br />

ginagamit ang dati ay walang halagang mga retaso ng<br />

kawayan at pinagkiskisan ng palay na itinapon o sinisilaban<br />

sa mga bukid.<br />

Sa pamamagitan ng teknolohiyang ito, ang tonetoneladang<br />

retaso ng mga kawayan at pinagkiskisan ng<br />

palay ay maari nang mapagkakitaan sa halip na maging<br />

dumi ng kapaligiran.<br />

Bukod pa rito, binigyang pakinabang din ng teknolohiya<br />

ang tubig na pinaglutuan ng “chichacorn” (malutong na<br />

butil ng mais na ipinirito), na kung basta itatapon lamang<br />

ay maaring maging banta sa kapaligiran lalo na sa mga<br />

pinagkukunan ng tubig na inumin.<br />

Ang pinaglutuan ng chichacorn, na may malawak<br />

na mapagkukunan sa Ilocos “region”, ay nagtataglay ng<br />

mantika na maaring gawing panghulma ng mga pinulbos<br />

na uling. Ito ay isang mabisang panghalili sa mantika na<br />

galing sa kamoteng kahoy.

32<br />

26<br />

27<br />

28<br />

29<br />

30<br />

31<br />

32<br />

33<br />

34<br />

35<br />

36<br />

37<br />

38<br />

39<br />

40<br />

41<br />

42<br />

43<br />

44<br />

45<br />

46<br />

47<br />

48<br />

49<br />

50<br />

51<br />

52<br />

53<br />

54<br />

55<br />

56<br />

57<br />

58<br />

59<br />

Ang teknolohiya ng hinulmang mga uling mula sa<br />

kawayan at pinagkiskisan ng palay ay nilinang ng mga<br />

mananaliksik ng MMSU na sina Dr. Stanley C. Malab at<br />

Dr. Jose A. Zaparalla.<br />

Si Malab ay direktor ng Ilocos Agriculture Resources<br />

Research and Development Consortium o I-LARR-DEC,<br />

isa sa mga konsorsya na itinatag ng Philippine Council <strong>for</strong><br />

Agriculture, Forestry and Natural Resources Research and<br />

Development o P-CARRD.<br />

Ang teknolohiya ay orihinal na nilinang at dinisenyo<br />

para sa mga retaso at dumi ng kawayan kagaya ng dahon,<br />

maliliit na sanga, pinagkataman o pinagkayasan, at mas<br />

pinabuti upang magamit din ang pinagkiskisan ng palay.<br />

Napanalunan ng teknolohiya ng kawayan “charcoal<br />

briquettes” o K-C-B na ginamitan ng pinaglutuan ng<br />

chichacorn bilang pandikit sa paghuhulma ang pagkilala<br />

bilang pinakamahusay na pagsasaliksik sa “National<br />

Symposium on Agriculture and Resources and Development<br />

o N-SARRD.“<br />

Ang N-SARRD ay inilunsad ng P-CARRD bilang<br />

pagpapahalaga sa mga katangi-tanging naiambag ng mga<br />

indibiduwal at institusyon sa pagpapabuti ng “research<br />

and development” o R&D sa larangan ng pagsasaka,<br />

paggugubat, at likas na yaman.<br />

Napanalunan naman ng pinabuting teknolohiya ng<br />

KCB, gamit ang pinagkiskisan ng palay, ang ikalawang<br />

gantimpla sa inilunsad na “Luzon Cluster 7 th Regional S&T<br />

Fora and Competitions in Industry and <strong>Energy</strong> Research<br />

and Development.” Ito ay dinisenyo rin nina Malab at<br />

Zafaralla, kasama ang iba pang mananaliksik ng M-M-S-U<br />

na sina Dr. Beatriz S. Malab at Dr. Angelina Tagay,

33<br />

60<br />

61<br />

62<br />

63<br />

64<br />

65<br />

66<br />

67<br />

68<br />

69<br />

70<br />

71<br />

72<br />

73<br />

74<br />

75<br />

76<br />

77<br />

78<br />

Ipinakilala rin ang teknolohiyang ito sa ika-28<br />

pandaigdigang pagpupulong ng Philippine-American<br />

Academy <strong>of</strong> Science and Engineering o PA-A-SE na ginanap<br />

sa Georgetown University Washington DC, USA.<br />

Muling ipinakilala ang teknolohiya sa nagdaang<br />

“Technology to People (T2P)/Media Conference” na<br />

pinangunahan ng P-CARRD. Ito ay dahilan sa pagtukoy<br />

sa mga alternatibong pagkukunan ng enerhiya dulot ng<br />

pagtaas ng halaga nito sa pandaigdigang pamilihan.<br />

Pinangunahan ng P-CARRD ang pagpapalaganap sa<br />

alternatibong pagkukunan ng enerhiya sa pamamagitan<br />

ng programang T2P na isinagawa upang makabawas sa<br />

alalahanin ng industriya ng pagkain kaugnay sa mataas<br />

na halaga ng produksyon nito. (Ricardo R. Argana, S&T<br />

Media Service)<br />

# # #<br />

PBP Blg 6725 Enero–Marso 2009<br />

Pinagkunan:<br />

Argana, Ricardo R. “MMSU sets trend in<br />

charcoal making.” (S&T Media Service, Press<br />

Release No. 24, 2009). Isinalin sa Tagalog<br />

ni Ricardo R. Argana.

34<br />

NEGOSYO BRO<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22<br />

23<br />

24<br />

Panghaliling enerhiya para sa industriya ng pagkain<br />

binigyang pansin ng TechnoMart<br />

Ang naging suliranin sa mataas na halaga ng enerhiya<br />

kamakailan ay nagiwan ng isang mahalagang aral sa<br />

industriya ng pagkain. Ito ay ang pangangailangang matukoy<br />

ang mga posibleng mapagkukunan ng alternatibong<br />

enerhiya upang mapababa ang gugugulin sa pagpoproseso<br />

ganon din ng pagiimpake ng pagkain.<br />

Binigyang pansin ng Philippine Council <strong>for</strong> Agriculture,<br />

Forestry and Natural Resources Research and Development<br />

o P-CARRD sa pamamagitan ng kanyang “TechnoMart<br />

program,” sa nagdaang 8 th Philippine <strong>Food</strong> Expo, ang<br />

mga pinakabagong bunga ng pagsasalikisik kaugnay<br />

ng alternatibong enerhiya na inaasahang makakatulong<br />

sa industriya ng pagkain partikular ang mga maliliit at<br />

katamtamang mga mamumuhunan.<br />

Ang 8 th Philippine <strong>Food</strong> Expo ay ginanap sa S-M<br />

Megamall sa Ortigas Avenue, Quezon City mula ikalima<br />

hanggang ika-pito ng Marso. Ito ay inilunsad ng<br />

Philippine Exporters, Inc. o PHIL-FOO-DEX at may temang<br />

“Pangrehiyong Kooperasyon bilang Istratehiya tungo sa<br />

Sapat na Pagkain.”

35<br />

25<br />

26<br />

27<br />

28<br />

29<br />

30<br />

31<br />

32<br />

33<br />

34<br />

35<br />

36<br />

37<br />

38<br />

39<br />

40<br />

41<br />

42<br />

43<br />

44<br />

45<br />

46<br />

47<br />

48<br />

49<br />

50<br />

51<br />

52<br />

53<br />

54<br />

55<br />

56<br />

57<br />

Itinampok sa nasabing expo ang iba’t-ibang produktong<br />

pagkain ng 175 kompanya mula sa Luzon, Visayas,<br />

Mindanao, at National Capital Region.<br />

Ibinahagi ng P-CARRD at ng mga katulong nitong<br />

ahensiya ang ilang inbensiyon kaugnay ng alternatibong<br />

enerhiya. Ito ay kinabibilangan ng “Protos,” isang uri ng<br />

lutuan na gumagamit ng langis mula sa halaman; “biogas,”<br />

na gumagamit ng paggatong mula sa iba’t-ibang dumi;<br />

isang modelo ng “biogas digester model”; at ang mga<br />

hinulmang uling mula sa kawayan.<br />

Ang mga nasabing inbensiyon ay nalinang sa<br />

pamamagitan ng mga kasaping ahensiya ng National<br />

Agriculture Resources Research and Development<br />

Network na kinabibilangan ng Visayas State University<br />

sa Baybay, Leyte; University <strong>of</strong> Sou<strong>the</strong>astern Philippines<br />

sa Davao City; Cavite State University sa Indang, Cavite;<br />

at ng Mariano Marcos State University sa Batac, Ilocos<br />

Norte.<br />

Bilang pinakabagong pamamaraan ng P-CARRD sa<br />

pagbabahagi ng teknolohiya, pinaguugnay ng TechnoMart<br />

ang puwang sa pagitan ng siyensiya at teknolohiya at ng<br />

industriya sa pamagitan ng pamamatnubay sa mga maliliit<br />

at katamtamang mamumuhunan ng may mga kasanayan<br />

sa isang uri ng produkto.<br />

Sinusuportahan ng PHIL-FOO-DEX ang mga programa<br />

ng pamahalaan tungo sa ibayong produksyon sa pagsasaka<br />

tulad ng Ginintuang Masaganang Ani at FIELDS (fertilizer,<br />

irrigation, infrastructure, extension, education, loans,<br />

driers and postharvest, and seeds) upang magkaroon ng<br />

sapat na pagkain at upang maging moderno ang pagsasaka<br />

sa bansa.

36<br />

58<br />

59<br />

60<br />

62<br />

62<br />

63<br />

64<br />

65<br />

66<br />

Inaasahan ng P-CARRD na sa pamamagitan ng<br />

TechnoMart at ng iba pang istratehiya ay mapapalakas<br />

nito ang mga maliliit at katamtamang mga mamumuhunan<br />

tungo sa produksyon ng mura at may kalidad na mga<br />

pagkain para sa kapakanan ng mga mamimiling Pilipino.<br />

(Ricardo R. Argana, S&T Media Service)<br />

# # #<br />

PBP Blg. 6726 Enero–Marso 2009

37<br />

Ang mga isyu ng PCARRD<br />

Farmnews<br />

ay matatagpuan din sa<br />

http://www.pcarrd.dost.gov.ph<br />

Para sa karagdagang kaalaman,<br />

mag-email sa:<br />

pcarrd@pcarrd.dost.gov.ph<br />

Para sa mga makabagong<br />

teknolohiya sa pagsasaka,<br />

Ugaliing makinig ng<br />

Ba g o Ya n Ah!<br />

sa inyong lokal na istasyon ng radyo sa<br />

DZMM 630 kHz<br />

at Home Cable Channel 26<br />

tuwing Linggo alas 4:30<br />

hanggang 6:00 ng hapon<br />

PAGTATUWA<br />

Ang mga produktong pang-agrikultura, kasangkapan, o kemikal at ang mga<br />

tagapamahagi nito na nabanggit ay hindi pagpapahiwatig ng pagtangkilik o pagpula<br />

ng Philippine Council <strong>for</strong> Agriculture, Forestry and Natural Resources Research and<br />

Development sa mga nasabing produkto, bagkos ay nabanggit lamang ang mga<br />

ito upang maipaabot ang mga kaukulang impormasyon sa mga mambabasa ng<br />

lathalaing ito.

The<br />

PCARRD FARMNEWS<br />

is winner <strong>of</strong> <strong>the</strong><br />

1993 Binhi Award<br />

as Agiricultural Newsletter<br />

<strong>of</strong> <strong>the</strong> Year<br />

BALITANG<br />

PAMBUKID<br />

Maikatluhang buwang inilalathala ng PHILIPPINE COUNCIL<br />

FOR AGRICULTURE, FORESTRY AND NATURAL RESOURCES<br />

RESEARCH AND DEVELOPMENT (PCARRD), <strong>Department</strong><br />

<strong>of</strong> Science and Technology (DOST)<br />

3rd Gawad<br />

Oscar M. Florendo<br />

as Outstanding In<strong>for</strong>mation<br />

tool, Print Category<br />

<strong>for</strong> 1994<br />

1994 Binhi Award<br />

as Agiricultural Newsletter<br />

<strong>of</strong> <strong>the</strong> Year<br />

PCARRD<br />

FARMNEWS<br />

Editor-in-Chief:<br />

Ricardo R. Argana<br />

Managing Editor:<br />

Layout Artist<br />

Flordeliza R. Gutierrez/<br />

Simeon R. Manahan, Jr.<br />

Circulation:<br />

Pacifico V. Africa<br />

Advisers:<br />

Patricio S. Faylon<br />

Lily Ann D. Lando<br />

Ruel S Pagcaliwagan<br />

1995 Binhi Award<br />

as Agiricultural Newsletter<br />

<strong>of</strong> <strong>the</strong> Year<br />

Mailing Address:<br />

PCARRD FARMNEWS<br />

PCARRD, Los Baños, Laguna,<br />

Philippines<br />

Re-Entered as “Second Class Mail” at <strong>the</strong> Los Baños Post<br />

Office, Laguna on 10 February 2009, Permit No. 2009-07