The magazine for crane Technology aS a paSSion 80 ... - Palfinger

The magazine for crane Technology aS a paSSion 80 ... - Palfinger

The magazine for crane Technology aS a paSSion 80 ... - Palfinger

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

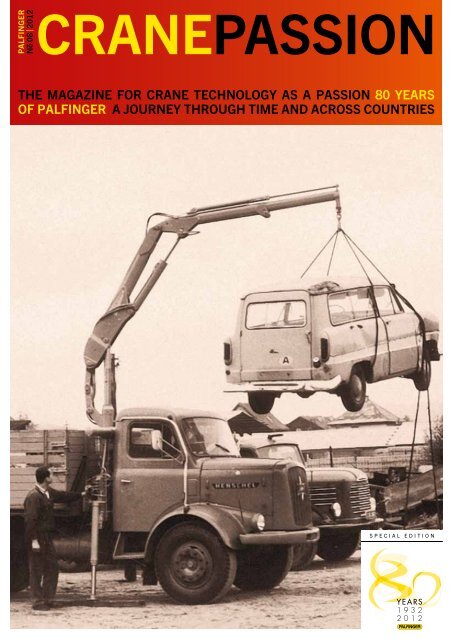

<strong>Palfinger</strong><br />

no 08 | 2012<br />

Cranepassion<br />

<strong>The</strong> <strong>magazine</strong> <strong>for</strong> <strong>crane</strong> technology AS A passion <strong>80</strong> YEARS<br />

OF PALFINGER A Journey THROUGH TIME AND ACROSS COUNTRIES<br />

special edition

1932 Founding of the company<br />

by Richard <strong>Palfinger</strong><br />

1942 Birth of<br />

Hubert <strong>Palfinger</strong><br />

1945 Move to Salzburg<br />

PaLfiNGer<br />

P<strong>aS</strong>SioN<br />

Per<strong>for</strong>mance<br />

Power<br />

Perfection<br />

<strong>The</strong> first <strong>crane</strong> my father built was a so-called “stiff-boom <strong>crane</strong>” and<br />

had a rigid arm system equipped with a cable winch. This <strong>crane</strong> was<br />

introduced in 1959 and the first small batch production of a knuckleboom<br />

<strong>crane</strong> with a hydraulic extension boom followed in 1968. Cranes<br />

were sold in Austria starting that year under the guidance of Mr. Söllner,<br />

who later became our general representative <strong>for</strong> Austria and Germany.<br />

Annual production in 1968/69 was 20 and 70 <strong>crane</strong>s respectively.<br />

<strong>The</strong> first exported <strong>crane</strong>s went to Switzerland in 1971 to the company<br />

Häusermann, Kran & Hydraulik AG. <strong>The</strong>re were tariff barriers across<br />

Europe to protect local manufacturers. Duties up to an amount of 40%,<br />

the dominating competitors Hiab and Atlas, the complete lack of a<br />

marketing structure as well as the fact that we were mostly unknown<br />

at the time were obstacles in dimensions that are unimaginable today.<br />

Nevertheless, there was dynamic expansion in Europe up to 1974 in<br />

which sales growth rates of 50% and more were perfectly normal.<br />

<strong>The</strong> oil crisis in 1974 crippled the European economy. At the same<br />

time, Kasern was built. It was 2 - 3 shoe sizes too big <strong>for</strong> that time.<br />

Within two weeks, our retailers cancelled a complete year of production<br />

and simultaneously our principal bank at that time cancelled all<br />

overdraft provisions, which had been used excessively until then due to<br />

the extremely high rate of expansion.<br />

2 <strong>crane</strong>passion

1959 <strong>The</strong> first <strong>crane</strong> WAS built<br />

1964 Takeover by Hubert <strong>Palfinger</strong>;<br />

Specialization in truck-mounted<br />

<strong>crane</strong>s.<br />

1968 <strong>The</strong> <strong>crane</strong>s WENT into seriAL<br />

production <strong>for</strong> the first time<br />

To be better than the others.<br />

our Vision<br />

right from the start.<br />

Suppliers flooded us with goods until this problem solved itself due to<br />

“reasons of risk management”. <strong>The</strong> existence of our company literally<br />

hung by a very thin thread, and it was ultimately a large order from Syria<br />

that saved us.<br />

We had to develop, build and deliver a product that was completely new<br />

to us in just 3 months. It was a “self-propelled stockyard <strong>crane</strong>.” It goes<br />

without saying that we planned, drafted and worked seven days a week,<br />

almost day and night and were completely motivated. After recovering<br />

from this tough situation, we focused on technology leadership on the<br />

one hand, and the latest manufacturing processes on the other.<br />

For a good three years, we were the only ones on the market to offer the<br />

double toggle joint system and hence achieved huge market growth with<br />

it. We were also the first to introduce CAD-CAM into manufacturing, and<br />

in the late <strong>80</strong>s and early 90s licensed manufacturing was started and<br />

implemented successfully in New Zealand and Canada. In the mid 90s,<br />

we were the largest knuckle-boom <strong>crane</strong> supplier worldwide in the area<br />

of military transport logistics. This business had more or less a projecttype<br />

of character. It brought in a great deal of money but was extremely<br />

risky due to the tendering process that is typical with the military.<br />

With the currency crisis in 1994, our products became 25 to 30% more<br />

expensive than those of our competitors overnight. It was the second<br />

time in our history it was touch and go whether we would survive as a<br />

company. Even our largest dealers no longer believed in a future with<br />

PALFINGER in this phase.<br />

We were able to make our way into the stock market with UIAG and<br />

recover the company. However, this was only because we relocated<br />

the majority of our manufacturing to locations in the east and sharply<br />

reduced our resources in Austria. That was a time I hope no one will ever<br />

have to experience. However, I suppose it is from that experience we<br />

were able to cope and work together to overcome this crisis.<br />

<strong>The</strong> success factors of our company are still the same today. My<br />

highest priority is on securing highly motivated employees followed by<br />

a per<strong>for</strong>mance-oriented and equally highly motivated dealer network.<br />

Seeing eye to eye, reliability, trust and pulling together in the same<br />

direction – these are the guarantees <strong>for</strong> our successful future.<br />

It goes without saying that technology and competitiveness are as<br />

important as they ever were, and that we can understand and interpret<br />

market developments, which means we have the right answers to the<br />

upcoming challenges.<br />

Hubert <strong>Palfinger</strong> sen.<br />

<strong>crane</strong>passion<br />

3

1971 Patent <strong>for</strong> hydraulic lifting<br />

moment control system<br />

Patent <strong>for</strong> cylinder placement<br />

on the extension boom system<br />

First export deliveries to<br />

Switzerland and France<br />

1972 Setup and expansion of<br />

the international sales<br />

organization<br />

1973 Patent <strong>for</strong> the jib gripper.<br />

4 <strong>crane</strong>passion

1974 Start-up of the assembly<br />

plant in Salzburg/Kasern<br />

1976 Expansion of business in<br />

the Pacific region<br />

Patent <strong>for</strong> foldable boom<br />

1977 Patent <strong>for</strong> cable drum gripper<br />

<strong>80</strong> YEARS OF PALFINGER<br />

A JOURNEY through time<br />

and ACROSS countries<br />

02 / 03 Editorial To be better than the others - our vision right from the<br />

start 04 / 05 Table of contents <strong>80</strong> years of <strong>Palfinger</strong> 06 / 07 Power link<br />

system France – le TOUR DE FRANCE 08 / 09 PALSOFT Australia –<br />

far, far away 10 / 11 AOS <strong>The</strong> Italian challenge 12 / 13 PAL 50 –<br />

Electronics on the truck-mounted <strong>crane</strong> Singapore - technology<br />

ambassador in the countries of the rising sun 14 / 15 CDP – <strong>The</strong> Russian<br />

bear 16 / 17 DPS – Dual Power System LIVING IN AMERICA 18 / 19 Functional<br />

Design Swiss precision work 20 / 21 SH / PAL 150 Germany – beautiful Anna<br />

22 / 23 HPSC Sweden – <strong>The</strong> winner takes it all<br />

<strong>crane</strong>passion<br />

5

1978 Enhancement of the patent <strong>for</strong><br />

cylinder placement on the extension<br />

boom system to include several boom<br />

extensions<br />

1981 Patent <strong>for</strong> compensated overload safety;<br />

patent <strong>for</strong> sequential console; entry into<br />

the market in North America<br />

Le<br />

tour de<br />

france<br />

Paris is worth the trip. But the rest of France shouldn‘t be<br />

overlooked either. That includes the chic Côte d’Azur, the<br />

elegance of the Bretagne, the charm of the Provence or the<br />

thrill of the French Alps. Hardly any other European country<br />

has so many facets.<br />

It doesn’t matter whether it is in industrial regions of the large cities, ports<br />

along the coasts, or at construction sites in the interior of the country.<br />

PALFINGER is everywhere, because a dense sales and service network<br />

supplies the Grand Nation seamlessly with loading, lifting and handling<br />

systems of the same name.<br />

As one of the first export markets ever, France has always been a shoe-in <strong>for</strong><br />

new opportunities and challenges. After establishing the truck-mounted <strong>crane</strong>,<br />

the first step in the direction of product diversification was taken by taking over<br />

the hook lift manufacturer GUIMA. PALFINGER stepped into the hook loader<br />

market and pressed <strong>for</strong>ward to become an attractive system provider.<br />

<strong>The</strong> development of <strong>Palfinger</strong> in France is closely connected to the name<br />

Vincent, or the family to be more precise. Armand Vincent, an old school<br />

pioneering business man, demonstrated handshake quality and good business<br />

sense throughout all the years.<br />

Today, his brother Francois, niece Emilie Fraisse, son Mathias and nephew<br />

Marco Mazzanti manage the business. “We grew up together. <strong>The</strong> working<br />

relationship with the different departments in the parent company such as<br />

Research & Development, Sales and Service is very intensive. It is based on<br />

trust. That is how it was in the past, and nothing is going to change in the<br />

future. We are market leaders in France in truck-mounted <strong>crane</strong>s and hook<br />

loaders. To strengthen this position and continue to develop it, we will tour<br />

right across France with our “Caravane” once again at the end of the year and<br />

properly promote our products. We have already had a very successful trip with<br />

this concept in 2007.” (Mathias Vincent)<br />

6 <strong>crane</strong>passion

1984 Opening of the plant in Lengau<br />

Milestone in <strong>crane</strong> development<br />

Introduction of the power link system<br />

power link<br />

<strong>The</strong> (double) lever that put(s)<br />

everything into motion<br />

Many laughed at the idea, and quite a few believed that<br />

PALFINGER would design their way out of a market. But just the<br />

opposite was true. And the triumphal march of the double toggle<br />

joint system (= POWER LINK) began.<br />

<strong>The</strong> toggle joint and knuckle boom were known. <strong>The</strong> new thing<br />

about the PALFINGER Power Link was the use of the toggle joint<br />

on the main boom as well. That way, an equally high lifting torque<br />

and the constant velocity curve could also be implemented on the<br />

main boom. This was an advantage that was to revolutionize the<br />

truck-mounted <strong>crane</strong> world.<br />

POWER LINK PLUS. This was also a PALFINGER invention that<br />

years later increased the operating range of the knuckle boom<br />

even further.<br />

Paul Reiter<br />

Design & Development<br />

La Caravane 2012/13<br />

PALFINGER Products on tour<br />

through all of France<br />

A different type of Tour de France: Once again,<br />

this year is completely inspired by a customeroriented<br />

demonstration of system solutions<br />

following the motto of “as close to the customer<br />

as possible” - “made by PALFINGER”.<br />

In cooperation with <strong>Palfinger</strong> France and Guima<br />

<strong>Palfinger</strong>, all PALFINGER products - above all<br />

truck-mounted <strong>crane</strong>s and hook loaders - will<br />

travel through all of France making them “close<br />

enough to touch” <strong>for</strong> end customers. Set-up<br />

on seven vehicles from the most reputable<br />

commercial vehicle manufacturers, the products<br />

will demonstrate the solution competence that<br />

they possess, especially in industry-specific<br />

product combinations. <strong>The</strong> “moving show” will<br />

stop at a total of 38 destinations. <strong>The</strong> product<br />

demonstrations will be held at the facilities of<br />

the Guima and PALFINGER Sales and Service<br />

Partners throughout France.<br />

<strong>crane</strong>passion<br />

7

1989 Export rate EXCEEDS 90%<br />

market presence in more<br />

than 70 countries<br />

1992 Opening of the plant in Köstendorf<br />

patent <strong>for</strong> automatic swing-up stabilizers<br />

Introduction of the Paltronic 100 electronics<br />

Introduction of return oil utilization on the<br />

truck-mounted <strong>crane</strong><br />

Start of simultaneous engineering<br />

Introduction of “functional design”<br />

far,<br />

far<br />

Longing <strong>for</strong> Australia. This continent has a special fascination about<br />

it, especially <strong>for</strong> Europeans. Who hasn’t dreamed of travelling around<br />

this country or even emigrating there? Perhaps that is the reason why<br />

PALFINGER settled into terra australis (= southern land) as early as in<br />

the 70s. <strong>The</strong> first PALFINGER <strong>crane</strong> was sold ‘down under’ in August<br />

1977. It was the beginning of a consuming passion.<br />

Steve Lloyd was there from day one - an original Australian and<br />

professing PALFINGER fan: “PALFINGER is a synonym <strong>for</strong> products<br />

with quality and technical features that actually make customers more<br />

successful in their everyday business. It is a great honour <strong>for</strong> us to be a<br />

sales partner and part of the worldwide PALFINGER family.”<br />

away.<br />

8 <strong>crane</strong>passion

1992 Introduction of PAC (software <strong>for</strong><br />

superstructure and stability calculations)<br />

and PATIS (digital spare parts catalogue)<br />

1993 Start of production in Marburg/Slovenia<br />

Patent <strong>for</strong> a range-optimized storage<br />

system <strong>for</strong> <strong>crane</strong>s without a toggle joint<br />

ISO certification of the Kasern plant<br />

PAC<br />

<strong>The</strong> hour when<br />

PALSOFT was born<br />

Calculations of loads, outreaches, axle loads and stability are part<br />

of the basics of the <strong>crane</strong> superstructure. At the end of the <strong>80</strong>s,<br />

PALFINGER took the first steps towards developing suitable software.<br />

Initially it was only used internally on the mainframe, however with the<br />

arrival of PCs, it was possible to make it available to dealers as well.<br />

<strong>The</strong> first version of PCA, still on the DOS operating system at that<br />

time, arrived on the market at the beginning of the 90s. - Its depth of<br />

data and operating com<strong>for</strong>t was clearly superior to other commercial<br />

calculation aids. Following further development in cooperation with<br />

well-known truck manufacturers, the third generation PACWin.NET is<br />

now in use. It is more user-friendly and attractive than ever.<br />

Paul Kübler<br />

One of the first <strong>Palfinger</strong> software developers<br />

Professional <strong>for</strong> interfaces and user interfaces<br />

“<strong>The</strong> PALFINGER family is a global family. We are there <strong>for</strong> our customers<br />

on five continents whenever they need us - with the certainty that their<br />

concerns are always our highest priorities.”<br />

Service is our success<br />

PALFINGER offers a comprehensive and far-reaching scope of services<br />

that covers the entire product life cycle. <strong>The</strong>re<strong>for</strong>e, there is good reason<br />

to say “service is our success” in Australia. Whether superstructure<br />

calculations, support in daily business with practical online support, or<br />

quick help <strong>for</strong> unpleasant downtime by extremely well-trained service<br />

technicians and a quick supply of spare parts - customers ought to<br />

expect first class service from the market and technology leader.<br />

Comment on the side<br />

It is interesting that this large country is<br />

the biggest consumer of our smallest<br />

models of <strong>crane</strong>, the PC <strong>crane</strong> series, with<br />

several hundred purchases per year.<br />

“<strong>The</strong> country is extensive. <strong>The</strong> land is often unpredictable. Regardless<br />

of where and when our customers need help, we give it our best - with<br />

commitment and enthusiasm.” (Steve Lloyd)<br />

<strong>crane</strong>passion<br />

9

1995 Construction of the plant in cadelbosco di Sopra/Italy<br />

1996 Innovation Prize <strong>for</strong> computer-based method<br />

system <strong>for</strong> optimization of welded structures<br />

PALFINGER <strong>crane</strong>s in Italy. A great challenge since their first appearance in 1991 at the<br />

Samoter Verona. A multitude of domestic manufacturers battled <strong>for</strong> market share.<br />

<strong>The</strong>re were more <strong>crane</strong> manufacturers in Italy than in any other country. Furthermore, life<br />

was made difficult <strong>for</strong> international competitors through expensive and complex approval<br />

procedures. Nevertheless, Orlando Ferrari knew the market and was confident that<br />

quality would also prevail south of the Brenner Pass.<br />

the<br />

italian<br />

Challenge<br />

And he was right on the money. Very quickly PALFINGER <strong>crane</strong>s met<br />

the demands and good taste of Italian customers. Competitors soon<br />

recognized the merits of the <strong>crane</strong>s from Austria and unabashedly<br />

began to copy them. Many products that looked similar at first<br />

glance appeared on the market at lower prices.<br />

“PALFINGER stands not only <strong>for</strong> quality and reliability, but also<br />

<strong>for</strong> technologically leading truck-mounted <strong>crane</strong> concepts. This<br />

not only applies in the classic truck segment, but also <strong>for</strong> wood<br />

loading and handling recycled material. <strong>The</strong>re was good reason <strong>for</strong><br />

competitors to adopt one highlight or another after taking a good<br />

look at PALFINGER. But only a PALFINGER is a PALFINGER. It is<br />

more expensive than competitors’ products at first glance. But<br />

after taking a closer look, it is the most cost-effective purchase<br />

based on its service life. Especially in economically difficult times,<br />

business owners are required to make clever, <strong>for</strong>ward-looking and<br />

sustainable investment decisions. <strong>The</strong> same is true in Italy. <strong>The</strong>re is<br />

wisdom behind the saying: “it is expensive to buy cheap.”<br />

10 <strong>crane</strong>passion

1998 Patent <strong>for</strong> the AOS active oscillation suppression SYstem<br />

AOS<br />

Only available<br />

from PALFINGER<br />

“If something is methodologically doable, it must also<br />

be possible to implement it electronically.” Those were<br />

the thoughts of Erich Wimmer as he observed a test<br />

bench employee as he was able to stop the strong postoscillations<br />

of the <strong>crane</strong> boom through skilful use of the<br />

hydraulic lever.<br />

<strong>The</strong> benefits of the system are obvious. <strong>The</strong> AOS<br />

active oscillation suppression system reduces natural<br />

oscillations that occur, thereby reducing dynamic<br />

loading. Post-oscillations caused by rapid braking or a<br />

quick load change can be avoided. This increases the<br />

precision of load positioning and thereby increases the<br />

safety and fine controllability of daily <strong>crane</strong> work. <strong>The</strong><br />

AOS active oscillation suppression system is patented. So<br />

far, no competitor has launched any comparable system<br />

on the market.<br />

PALFINGER ITALIA<br />

Official PALFINGER<br />

dealer since 1990<br />

erich Wimmer<br />

Manager of R&D Electronics<br />

ALWAYS MANAGED TO TEACH OLD DOGS SOME NEW TRICKS<br />

Milena Bartoli<br />

Charming business WOMAN<br />

who knows how to prevail<br />

in a <strong>crane</strong> world dominated<br />

by men.<br />

Comment on the side<br />

At the world premiere of the new PALFINGER SH<br />

<strong>crane</strong> series at the Bauma 2010, the public tipped<br />

their hats to the new truck-mounted <strong>crane</strong><br />

concept. You don’t have to be a prophet to <strong>for</strong>esee<br />

that competitors will once again pick up the<br />

inspiration of one idea or another. That is a<br />

compliment <strong>for</strong> the inventor. Competition<br />

stimulates business and ultimately benefits the<br />

user. Only one thing is certain. PALFINGER will<br />

continue to raise the bar on its competitors in the<br />

future as well.<br />

<strong>crane</strong>passion<br />

11

1999 PALTRONIC 50 AM SERIEs cRANe 1999 IPO<br />

100,000th <strong>Palfinger</strong> <strong>crane</strong> leaves the plant<br />

Patent <strong>for</strong> hydraulic overload safety device<br />

PAL 50<br />

PALFINGER makes electronics<br />

socially acceptable on a<br />

truck-mounted <strong>crane</strong><br />

Beginning of the 90s. PALFINGER recognizes<br />

the necessity <strong>for</strong> electronic control systems and<br />

develops the Paltronic (PAL 100). <strong>The</strong> new trend<br />

rapidly gains momentum in the railway business.<br />

<strong>The</strong> truck-mounted <strong>crane</strong> market initially shows<br />

its sceptical side and only warms up to the idea<br />

of electronic solutions slowly.<br />

1999. PALFINGER profits from its positive<br />

experience in the railway sector and brings the<br />

PAL 50, a system <strong>for</strong> overload cut-off <strong>for</strong> series<br />

<strong>crane</strong>s, to the market. <strong>The</strong> PAL 50 is still proving<br />

its worth today and controls numerous functions<br />

on the modern truck-mounted <strong>crane</strong>.<br />

Wolfgang Kinz<br />

Success factor in <strong>crane</strong><br />

application programming<br />

12 <strong>crane</strong>passion

2000 RAP Rapid Process (order-based manufacturing)<br />

2001 Power Link Plus (UPWARDLY TILTABLE KNUCKLE BOOM)<br />

TechnologY<br />

ambassador<br />

<strong>for</strong> the countries of the rising sun<br />

Singapore. Asian flair mixed with a European influence.<br />

International shipment centre between east and west.<br />

Financial metropolis and port city. <strong>The</strong> head office of<br />

Wong Fong Engineering is located in the “Fine City”, one<br />

of the cleanest cities in the world and has taken the lead<br />

since 1996 in sales of “Fine PALFINGER Crane <strong>Technology</strong>”.<br />

Pioneer work in the establishment of innovative <strong>crane</strong> solutions. As a<br />

<strong>for</strong>erunner in the use of knuckle-boom <strong>crane</strong>s, Singapore is also the<br />

showcase <strong>for</strong> the merits of these applications <strong>for</strong> the entire Asia Pacific<br />

region. In contrast to other Southeast Asian countries in which the<br />

telescopic <strong>crane</strong> still dominates the truck <strong>crane</strong> market, the knuckleboom<br />

<strong>crane</strong> concept has been established here <strong>for</strong> a number of years.<br />

With an annual market potential of about 400 new <strong>crane</strong>s and a<br />

surface area of only 400 km 2 , the tiger state is among the countries<br />

with the highest density of <strong>crane</strong>s. Sixty percent of the <strong>crane</strong>s used in<br />

Singapore are attributed to the heavy-duty <strong>crane</strong> league. In the<br />

segment of 85 to 150 mt <strong>crane</strong>s, Singapore is among the countries with the<br />

most users worldwide. Many years of industry and service know-how have<br />

contributed to making the PALFINGER brand into a permanent part of the<br />

cityscape of Singapore.<br />

Bestseller. <strong>The</strong> very successful product launch of the PK 50002 EH<br />

High Per<strong>for</strong>mance truck-mounted <strong>crane</strong> in 2010 is just one representative<br />

example of the typical preference that Singapore shows <strong>for</strong> high-tech large<br />

<strong>crane</strong>s. Twenty <strong>crane</strong>s were ordered just in the first three months.<br />

“Innovations from PALFINGER are always radical and trendsetting in the<br />

truck-mounted <strong>crane</strong> business. Whether it is Power Link Plus, CDP or AOS,<br />

we profit from it tremendously. It is easy to convince customers of the<br />

excellent per<strong>for</strong>mance of a PALFINGER <strong>crane</strong>. That is motivating and<br />

makes us proud.”<br />

Jimmy lew<br />

wong fong engineering<br />

<strong>crane</strong>passion<br />

13

2002 Introduction of cathodic dip painting (CDP)<br />

Interlock outrigger safety system<br />

KTL<br />

Keeps <strong>crane</strong>s young<br />

Cathodic dip painting, a coating process that<br />

is state of the art <strong>for</strong> cars and trucks, is also<br />

making its way into the truck-mounted <strong>crane</strong><br />

industry thanks to PALFINGER. That’s good<br />

news <strong>for</strong> our customers, because CDP does<br />

more than just make PALFINGER <strong>crane</strong>s look<br />

better. <strong>The</strong> abrasion-resistant and UV-resistant<br />

coating ensures lasting surface protection to<br />

guarantee value retention <strong>for</strong> years. A perfect<br />

look - <strong>for</strong> the life of the <strong>crane</strong> - and high resale<br />

values speak in favour of the sophisticated<br />

anti-aging program. Sixteen operations, a<br />

precision electrostatic coating and uni<strong>for</strong>m paint<br />

application make PALFINGER <strong>crane</strong>s clearly<br />

more fit and superior to others.<br />

Walter Haberl<br />

Manager of Design & Development<br />

THE<br />

russiAN<br />

BEAR<br />

Entering into the new, very promising market was set<br />

in motion in the mid 90s by Hubert <strong>Palfinger</strong>. It was a<br />

challenging task to cover the vastness of the country<br />

with good partners and products even in climatically<br />

difficult regions. Today there is a dealer network with<br />

more than 50 partners throughout the land. And, the<br />

PALFINGER truck-mounted <strong>crane</strong> is no longer a<br />

stranger on Russia’s roads and construction sites.<br />

14 <strong>crane</strong>passion

<strong>The</strong>re is a good reason why the company’s headquarters are in the<br />

beautiful city of St. Petersburg - a city founded by Peter the Great as a<br />

“window to Europe”, a city that was built as a figurehead of the Tsars,<br />

and a city that presents itself as an important cultural and economic<br />

centre today.<br />

“We market and sell PALFINGER truck-mounted <strong>crane</strong>s with pleasure.<br />

We appreciate the high product quality, reliability and professional<br />

support from PALFINGER in the areas of marketing and training. If you<br />

take the tough climatic conditions in vast parts of our country into<br />

consideration, then high-quality products that can stand up to these<br />

conditions <strong>for</strong> the product’s entire service life become tremendously<br />

important. <strong>The</strong> lasting surface protection from “CDP” responds to this need<br />

and is a significant competitive edge on the Russian market long term.”<br />

Dmitriy R. Andreev<br />

Marketing Manager <strong>Palfinger</strong> Crane Rus<br />

<strong>The</strong> Russian Bear has awoken from its hibernation and we are excited<br />

about how everything will develop. <strong>The</strong> outlooks are very promising.<br />

<strong>The</strong> Olympic Winter Games in Sotschi in 2014 and the FIFA World Cup<br />

in 2018 are decisive sources of inspiration <strong>for</strong> the construction<br />

industry. And PALFINGER is there - live!<br />

Comment on the side<br />

Many know that it is “VERY” cold<br />

in Russia, especially in winter.<br />

However, not many know that the<br />

“white nights” in St. Petersburg<br />

are those nights in which you can<br />

ALWAYS leave the bars in daylight.<br />

Almost no one knows that the<br />

“snow” in St. Petersburg mainly<br />

consists of frozen spray water<br />

from the sea.<br />

<strong>crane</strong>passion<br />

15

2005 DPS – Dual Power System<br />

2006 ISC – Integrated Stability Control<br />

DPS PLUS<br />

Top per<strong>for</strong>mance up to<br />

the tip of the <strong>crane</strong><br />

Maximum outreach and maximum lifting power are the<br />

attributes of a perfect truck-mounted <strong>crane</strong>. Until now,<br />

<strong>crane</strong>s with a fly jib usually meant a reduction of the fly jib<br />

lifting power as of a specific outreach in order to protect<br />

the <strong>crane</strong> against overloading.<br />

a<br />

That had to be changed and posed a new challenge to<br />

the designers at PALFINGER.<br />

Hence, the developers at PALFINGER drew on some<br />

valuable knowledge from prior system testing and<br />

developed the Dual Power System Plus (DPS Plus). <strong>The</strong><br />

system makes it possible to use the full lifting power<br />

through the use of two pressure ranges on the fly jib. With<br />

it, the full lifting power of the fly jib can be utilized even<br />

<strong>for</strong> <strong>crane</strong>-jib combinations with very large outreaches, if<br />

the <strong>crane</strong>’ extension boom is not fully extended.<br />

Typical of PALFINGER, the system engages and<br />

disengages fully automatically and is characterized<br />

once again by being very user-friendly <strong>for</strong> the <strong>crane</strong><br />

operator.<br />

Eckhard Wimmer<br />

Manager Pre-Development<br />

and Calculations<br />

25 years with PALFINGER<br />

16 <strong>crane</strong>passion

Comment on the side<br />

To PALFINGER, the North American<br />

area also includes Central America<br />

and the South American countries of<br />

Columbia, Venezuela and Ecuador.<br />

<strong>The</strong> reason <strong>for</strong> this is that these<br />

countries traditionally handle their<br />

business with the “West” via Florida.<br />

LIVING IN<br />

meriCa<br />

When PALFINGER shipped its first truck-mounted <strong>crane</strong> across<br />

the Atlantic at the beginning of the <strong>80</strong>s, hope was inspired by<br />

the endless possibilities of this country. And rightly so, as it<br />

turned out in the subsequent years.<br />

Today the North American area is PALFINGER’s most extensively developed market<br />

besides Europe, with many different products and locations. Mark Woody has<br />

accompanied <strong>Palfinger</strong> Inc. in Niagara Falls <strong>for</strong> 20 years. He has made a significant<br />

contribution to the “rise” of PALFINGER in North America from a small dealer up to<br />

a large organization.<br />

Specific applications call <strong>for</strong> specific <strong>crane</strong> solutions. For example, wallboard and<br />

drywall <strong>crane</strong>s (special <strong>crane</strong>s <strong>for</strong> basement and <strong>for</strong>mwork construction and/or dry<br />

construction) are typical <strong>for</strong> the North American construction business.<br />

Service <strong>crane</strong>s also play an important role. <strong>The</strong> market is large and highly soughtafter.<br />

PALFINGER is currently represented with four models in the high-class<br />

segment. <strong>The</strong>ir technologically high-quality equipment (radio remote control as a<br />

standard, cable winch incl. shut-off device) ensures that these models are in very<br />

high demand.<br />

Attractive package solutions were successfully launched in the large <strong>crane</strong> segment<br />

with the “large <strong>crane</strong> project” as our own key account. Completely configured<br />

vehicles <strong>for</strong> specifically defined customer applications (e.g. petroleum industry)<br />

convinced customers of the merits of a knuckle-boom <strong>crane</strong>. Live demonstrations<br />

with demonstration vehicles won the hearts and minds of potential users.<br />

“<strong>The</strong> geometric benefits of the knuckle-boom <strong>crane</strong> result mainly from the POWER<br />

LINK and the POWER LINK PLUS system. Our customers appreciate the benefits of<br />

these systems. <strong>The</strong> use of the tried and proven double toggle joint system becomes<br />

even more efficient through the upward reverse linkage system. <strong>The</strong> 15 degree<br />

reverse linkage system makes it possible to do work in limited space with high<br />

precision. <strong>The</strong> <strong>crane</strong> also lifts loads through low windows and door openings.<br />

Cranes can be used easily in buildings.”<br />

Greg Sneek<br />

Product Manager, Crane Division North America<br />

<strong>crane</strong>passion<br />

17

2008 Market launch of the High Per<strong>for</strong>mance generation of<br />

truck-mounted <strong>crane</strong>s<br />

Maintenance-free extension boom system<br />

Material optimization<br />

Functional Design<br />

Opening of new hexagonal tube production in Lengau<br />

2009 DPS-Plus / Power Link Cable Winch / Single Link Plus<br />

Functional<br />

Design<br />

Makes <strong>crane</strong>s beautiful<br />

and owners proud<br />

A truck-mounted <strong>crane</strong> is a high-tech product with an<br />

image. Design is a must-have. People at PALFINGER have<br />

known that <strong>for</strong> a long time. Industrial designers have had<br />

a serious say in product development since the 90s. Good<br />

(industrial) design must fulfil a purpose. It must be simple,<br />

visually attractive and economical to implement. <strong>The</strong> art is<br />

to combine functionality and individuality in the choice of<br />

materials and the design of shapes, colours and solution<br />

details.<br />

Here is the basic principle: Something that looks good<br />

and contributes to more convenience will be a success.<br />

Heinrich Krug<br />

Industrial designer<br />

He has styled PALFINGER <strong>crane</strong>s <strong>for</strong> 20 years<br />

Precision<br />

work <strong>for</strong><br />

40<br />

YEARS<br />

18 <strong>crane</strong>passion

As precise as a Swiss watch. That is how the team at<br />

the Swiss general agency works. And it has done so <strong>for</strong><br />

40 years. Walser Schweiz AG took over as the general<br />

agent of PALFINGER in Switzerland in 1972 as the first<br />

export partner worldwide. Since then, the company has<br />

successfully sold the broad product range of PALFINGER.<br />

“PALFINGER is the world market leader. We are proud of this. With<br />

the PALFINGER brand, today we are certainly able to offer the most<br />

complete product range of high-quality lifting, loading and handling<br />

systems. Despite its role as a global player, PALFINGER has never<br />

lost sight of the importance of staying close to its dealers around the<br />

globe. We still maintain an intensive partnership with our friends from<br />

the neighbouring countries.<br />

PALFINGER clearly confirmed its role as a trendsetter with the launch<br />

of the High Per<strong>for</strong>mance <strong>crane</strong> generation. <strong>The</strong> innovative <strong>crane</strong><br />

concept became quickly established on the Swiss market. Today, all<br />

the technical features are indispensable <strong>for</strong> the very demanding and<br />

quality-aware Swiss customers. <strong>The</strong> SH <strong>crane</strong> series in particular,<br />

which is the crown of the High Per<strong>for</strong>mance <strong>crane</strong> generation, sells<br />

very well in Switzerland. Within just a few weeks, we were able to<br />

congratulate several customers on their purchase of a PK 92002 SH.<br />

It was a very promising start in the large <strong>crane</strong> segment with the new<br />

SH models compared to the size of our small country.<br />

Thanks to the optimized lightweight construction, the High<br />

Per<strong>for</strong>mance <strong>crane</strong> generation is primarily characterized by the<br />

optimum balance between its net weight and lifting power. Our often<br />

quite meticulous Swiss customers really appreciate that everything is<br />

“very orderly” around the truck-mounted <strong>crane</strong> and that the <strong>crane</strong>s<br />

look attractive.<br />

With the functional design, PALFINGER has reduced a modern design<br />

and the highest level of functionality to a common denominator.<br />

Refined detailed solutions and high-quality plastic coverings that not<br />

only look nice, but also serve their purpose, make a lot of sense.<br />

Ultimately, day to day work is simply more fun, and the company<br />

benefits at the same time by the positive effects on its image.”<br />

Ruedi Sutter<br />

Managing Director Walser Schweiz AG<br />

A successful partnership<br />

in Switzerland <strong>for</strong> 40 years<br />

www.walserag.ch<br />

<strong>crane</strong>passion<br />

19

BEAUTIFU<br />

Professionals know<br />

what looks good!<br />

<strong>The</strong> new intelligent<br />

<strong>crane</strong>s of the SH series<br />

www.palfinger-sh.de<br />

It is literally German thoroughness. <strong>The</strong> successful<br />

market launch concept of the new “SH <strong>crane</strong> series” is<br />

based on this thoroughness, and it is emotionally<br />

likeable at the same time.<br />

Even after the first tests in practice, we knew that the new SH <strong>crane</strong><br />

series could really be a hit on the market. <strong>The</strong> requirement was to<br />

successfully communicate the higher price compared to the competition.<br />

<strong>The</strong>re<strong>for</strong>e, a decision was made to have a market launch that went in a<br />

different direction than be<strong>for</strong>e.<br />

<strong>The</strong> media image was to be simple but emotional. Something that would<br />

appeal to customers immediately. With the slogan “Professionals know<br />

what looks good!” and the face of “beautiful Anna” we wanted to visualise<br />

what our customers keep telling us: “Your units simply look great.”<br />

This subject was published everywhere in German trade journals in the<br />

first six months of 2011. A separate website was designed and combined<br />

with a mailing campaign in order to be able to measure the response.<br />

20 <strong>crane</strong>passion

2010 SH/PAL 150<br />

Convenience and safety initiative according to<br />

EN 12999:2011<br />

SH / PAL 150<br />

Truck-mounted<br />

<strong>crane</strong> technology<br />

Next Generation<br />

Keeping an eye on increasing automation in the industry,<br />

PALFINGER freed up tremendous resources <strong>for</strong> the design<br />

of the new electronic control system. <strong>The</strong> electronics<br />

department grew to more than 20 specialists during the<br />

course of the intensive development period. <strong>The</strong> first<br />

thoughts about a successor generation of electronics<br />

- the PALTRONIC 50 – came up in 2002.<br />

“Continuous improvement. Our daily job.” A clear<br />

message placed boldly in the department was<br />

instrumental to the work of the entire team. <strong>The</strong> result<br />

was “SH”, a control system concept with a new level of<br />

functionality and safety.<br />

With the new PALTRONIC 150 as the centrepiece, a<br />

new era in truck-mounted <strong>crane</strong> technology began.<br />

paul handlechner<br />

Manager of Control System Electronics<br />

Electronic all-rounder<br />

L “ANNA”<br />

Our customers were able to get into the new “SH site”<br />

with a personal code and learn about the new series. <strong>The</strong><br />

opportunity to win a miniature model of the PK 53002 SH<br />

made the promotion even more attractive. <strong>The</strong> analysis<br />

that we carried out showed that we were on the right<br />

track. We knew who logged in and <strong>for</strong> how long and which<br />

features they learned about. Based on this in<strong>for</strong>mation,<br />

nothing stood in the way <strong>for</strong> our sales <strong>for</strong>ce to efficiently<br />

address our customers.<br />

In addition, all 200 of our partners were given intensive<br />

training on the products. An adequate dealer package took<br />

the campaign to the point of sale. To do something new,<br />

all <strong>for</strong>emen and assemblers were addressed during the<br />

course of the campaign. This group of people in particular<br />

have made an unbelievably strong contribution to the sale<br />

of a product. Not only the sales staff, but all employees<br />

should be thrilled by the new series. We also offered all<br />

employees the possibility to control an SH <strong>crane</strong>, i.e.<br />

to “understand it”.<br />

“All our demonstration vehicles were equipped with the SH<br />

motif. This was so popular that several customers continued<br />

travelling with the motif even after the vehicle was sold, thus<br />

providing advertising <strong>for</strong> us on the roads nation wide.”<br />

Franz Ebner<br />

Marketing Manager <strong>Palfinger</strong> Deutschland<br />

“This is a highly sought-after market. Price pressure is increasing.<br />

But PALFINGER is more than optimistic as it looks to the future.<br />

We score points through our edge in design and technology.<br />

And we also score points by focusing on industry segments and<br />

having a impeccable service network. With the “Best Price Deal”,<br />

we show our customers where their entire personal cost-saving<br />

potential is and where profitable business segments are.”<br />

Thomas Moucka<br />

Managing Director PALFINGER Deutschland<br />

<strong>crane</strong>passion<br />

21

2011 HPSC (High Per<strong>for</strong>mance Stability Control)<br />

HPSC<br />

Couldn’t be<br />

more intelligent<br />

<strong>The</strong> requirements <strong>for</strong> the new stability control system<br />

“HPSC” were clear: <strong>The</strong> control system was to calculate the<br />

stability as realistically as possible <strong>for</strong> any support situation -<br />

and do it in real time.<br />

When dealing with stability, de<strong>for</strong>mation of the vehicle plays<br />

a dominant role. Hence, the theoretical, non-de<strong>for</strong>med<br />

structure cannot <strong>for</strong>m the basis <strong>for</strong> an accurate calculation.<br />

Extensive simulations with the help of finite element<br />

programs, numerous practical tests and the development<br />

of a highly complex real data algorithm were ultimately the<br />

ingredients <strong>for</strong> what currently is the most intelligent stability<br />

control system.<br />

Alexander Schalber<br />

Computation Engineer<br />

<strong>The</strong><br />

winner<br />

takes it<br />

All<br />

22 <strong>crane</strong>passion

Love at first sight. Confronted with a PALFINGER <strong>crane</strong> on the test bench, Bertil Hinz - at that time a highly<br />

qualified employee of a Scandinavian competitor - immediately recognized the advantages of “the red <strong>crane</strong><br />

from Austria.” HINZ has sold PALFINGER products successfully in Sweden since 1974. Today, Magnus Hinz is<br />

part of the second generation managing the fate of HINZ FÖRSÄLJNINGS AB in BORLÄNGE, Sweden. Born in<br />

1973, he picked the PALFINGER spirit up right from the beginning.<br />

“If you uphold your own standard, then customers will follow.”<br />

“<strong>The</strong> most important thing in a working relationship that spans decades<br />

or even generations is the certainty that you can always rely on your<br />

partner in day to day business. After so many years of having a business<br />

relationship with PALFINGER, you are part of the family. People know each<br />

other. Personal and direct contact simplifies the working relationship and<br />

creates a relaxed atmosphere among partners. <strong>The</strong> people at PALFINGER<br />

are well qualified <strong>for</strong> this. <strong>The</strong>y know their business. <strong>The</strong>y know what it<br />

is all about and take care of our concerns every day. And as long as the<br />

majority of the shares are held by the <strong>Palfinger</strong> family, we are confident<br />

and motivated <strong>for</strong> the future!<br />

“To be better than the others” was the goal of PALFINGER right from the<br />

start, and was certainly the basis <strong>for</strong> success on the Scandinavian market.<br />

Specifically, it was the <strong>crane</strong>s with the double toggle joint system that<br />

once revolutionized the truck-mounted <strong>crane</strong> market, and thanks to their<br />

numerous innovations, they thrill customers time and time again.<br />

Just think about the lightweight construction, the overall <strong>crane</strong><br />

per<strong>for</strong>mance and the perfect after-sales service. <strong>The</strong> list is long. All<br />

of this has made PALFINGER into that what it is today - a premium<br />

brand with power, status and esprit. And it made us number one<br />

in Sweden! System partners in the industry notice this spirit and<br />

strength. Ultimately, they also want to work together with winners.”<br />

Magnus Hinz<br />

Director of the Management board and<br />

vice general manager<br />

<strong>The</strong> new stability control system “HPSC”, which by the way was<br />

tested <strong>for</strong> its practicality in an extensive field test in Sweden, is a<br />

guarantee <strong>for</strong> continuing on the road to success.<br />

<strong>crane</strong>passion<br />

23

2011 A new generation in the Supervisory Board<br />

New edition A close look at the product life-cycle<br />

of a <strong>Palfinger</strong> truck-mounted <strong>crane</strong>.<br />

statements<br />

“PALFINGER is an Austrian company with an international<br />

profile. Expansion of existing dealer partnerships and joint<br />

ventures with the largest Chinese construction machinery and<br />

equipment manufacturer secure our position on the world<br />

market <strong>for</strong> the coming decade.”<br />

Hubert <strong>Palfinger</strong> jun.<br />

Deputy Chairman of the Supervisory Board<br />

“PALFINGER is aware of its ecological responsibility. <strong>The</strong>re<strong>for</strong>e we<br />

focus on eco-efficient manufacturing and environmentally friendly<br />

innovations. In addition, we are also focusing on sustainable product<br />

areas and are strengthening our market position in the offshore and<br />

wind power sectors as well.”<br />

Hannes <strong>Palfinger</strong><br />

Member of the Supervisory Board<br />

24 <strong>crane</strong>passion