Numelock II Polyaxial Locking System - Stryker

Numelock II Polyaxial Locking System - Stryker

Numelock II Polyaxial Locking System - Stryker

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Indications<br />

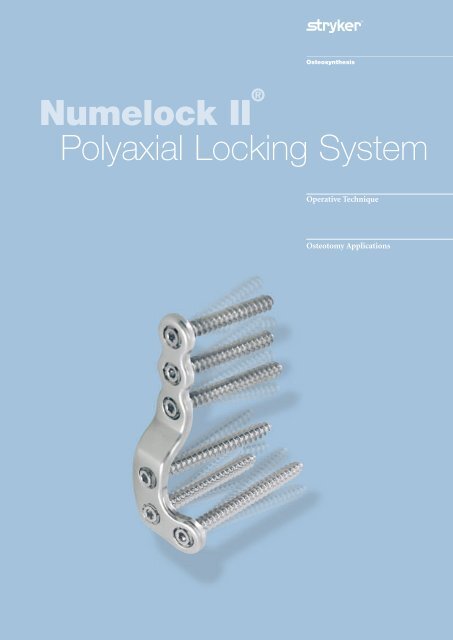

<strong>Numelock</strong> <strong>II</strong> ®<br />

<strong>Polyaxial</strong> <strong>Locking</strong> <strong>System</strong><br />

Operative Technique<br />

Osteotomy Applications

Contents<br />

Rationale 3<br />

Features and Benefits 4<br />

Indications 5<br />

Preoperative Planning 6<br />

Operative Technique<br />

• General Principles 6<br />

Ordering Information<br />

• Plates 9<br />

• Screws 10<br />

• Instruments 10<br />

• Cases and Trays 11<br />

Special acknowledgements are made to Professor Albert van Kampen, M.D., PhD<br />

and Dr. Robert Gaasbeek, M.D. of the University Medical Centre Nijmegen,<br />

the Netherlands, for sharing their technical and surgical expertise in the review of<br />

this Operative Technique.

Rationale<br />

The <strong>Numelock</strong> <strong>II</strong>® polyaxial locking mechanism provides the option of adjustability<br />

in the range of screw trajectories through a broad continuum of positions.<br />

This mechanism can be adjusted to meet the requirements of many osteotomies<br />

around the knee. This feature allows the <strong>Numelock</strong> <strong>II</strong>® plates to be correctly<br />

situated with respect to the patient’s anatomy, while each individual locking screw<br />

is accurately targeted to address the configuration of the osteotomy site and<br />

resulting bone segments.<br />

Plates<br />

The <strong>Numelock</strong> <strong>II</strong>® polyaxial locking<br />

system is designed to facilitate<br />

treatment with high tibial and distal<br />

femoral osteotomies. The shape,<br />

material properties and surface quality<br />

of the implants take into account the<br />

stringent demands of surgeons for<br />

high fatigue strength, optimized<br />

transfer of loading forces and a<br />

straightforward, standardized operative<br />

technique with broad applicability.<br />

For the purposes of safety,<br />

traceability and convenience,<br />

all plates are packaged sterile.<br />

Material<br />

Composition<br />

The implants are produced from<br />

316LVM Stainless Steel. ASTM F138<br />

and F139/ISO 5832-1 material<br />

standards provide rigid specifications<br />

that define the chemical composition,<br />

microstructural characteristics and<br />

mechanical properties of implant<br />

quality Stainless Steel. These standards<br />

ensure that 316LVM Stainless Steel,<br />

even if provided by different suppliers,<br />

is consistent and compatible.<br />

The material used for all <strong>Numelock</strong> <strong>II</strong>®<br />

plates and screws meets these<br />

standards.<br />

<strong>Locking</strong> Screws<br />

The <strong>Numelock</strong> <strong>II</strong>® locking screws used<br />

with the <strong>Numelock</strong> <strong>II</strong>® Osteotomy<br />

Plates have a thread diameter of<br />

6.5mm. All <strong>Numelock</strong> <strong>II</strong>® locking<br />

screws are packaged sterile and are<br />

provided in lengths from 27mm to<br />

85mm (27mm – 45mm in 3mm<br />

increments and 50mm – 85mm in<br />

5mm increments). The locking screws<br />

have a unique core design and thread<br />

pattern in the head and tip areas.<br />

As the screw is threaded into the<br />

locking mechanism (see below),<br />

its conical head part engages with<br />

the corresponding threads in the ring,<br />

which then expands into the plate,<br />

securely locking the position of the<br />

screw at the chosen angle and<br />

direction.<br />

<strong>Polyaxial</strong> <strong>Locking</strong><br />

Mechanism<br />

Every hole of each osteotomy plate<br />

(except Ref. No. STP2Y76S) is<br />

equipped with an integral polyaxial<br />

locking mechanism which will accept<br />

6.5mm diameter <strong>Numelock</strong> <strong>II</strong>®<br />

locking screws.<br />

The screw securely locks into the plate<br />

at the desired angle and direction.<br />

Prior to final locking of the<br />

<strong>Numelock</strong> <strong>II</strong> ® screw within the<br />

mechanism, the ring is designed to<br />

rotate freely. This attribute can be used<br />

to pull a bone segment into alignment<br />

(see Operative Technique – General<br />

Principles, Step Six, for additional<br />

information on this feature).<br />

Instrumentation<br />

The <strong>Numelock</strong> <strong>II</strong>® instruments are<br />

designed for accuracy and ease of<br />

use and precisely engage with all<br />

<strong>Numelock</strong> <strong>II</strong>® implant components.<br />

The storage trays conveniently house<br />

the instrument set.<br />

This mechanism permits the screws to<br />

be targeted through a cone of up to 30°<br />

in all directions. This capability allows<br />

the surgeon to aim each screw at an<br />

optimal trajectory within the 30° cone.<br />

3

Features and Benefits<br />

Features<br />

Axially stable, locking fixation<br />

<strong>Polyaxial</strong> locking mechanism<br />

30º range of screw insertion angles<br />

All plates and screws packaged sterile<br />

Screws with unique thread and conical<br />

core design<br />

Ring Driver permits screw<br />

and bone segment adjustments<br />

<strong>Numelock</strong> screws accept<br />

standard hex drivers<br />

Rounded plate ends<br />

Drill guide constrains screw<br />

insertion angle<br />

<strong>Numelock</strong> <strong>II</strong> ® Screw Depth Gauge<br />

gives direct value<br />

Benefits<br />

• High stability; protection against<br />

primary and secondary losses of<br />

reduction; limited plate contact with<br />

periostium; reliable purchase in<br />

normal and osteoporotic bone.<br />

• Screws positioned according to<br />

osteotomy surface or to avoid another<br />

implant; plate positioned to meet<br />

needs of patient anatomy.<br />

• Adjustability in range of screw<br />

trajectories for optimized fixation.<br />

• Safety, traceability, convenience.<br />

• Low insertion torque and secure<br />

locking; reduced possibility of<br />

cross-threading and cold welding.<br />

• Distance of bone to plate can be<br />

accurately adjusted; bone segments<br />

may be pulled towards plate.<br />

• Screws can be removed with standard<br />

hex drivers at end of treatment, in case<br />

of plate extraction.<br />

• Reduced potential for soft tissue<br />

irritation.<br />

• Limits screw head protrusion<br />

for reduced soft tissue irritation;<br />

insures optimal surface contact of ring<br />

to plate.<br />

• No compensation required<br />

for <strong>Numelock</strong> <strong>II</strong> ® locking screws.<br />

4

Indications<br />

The <strong>Numelock</strong> <strong>II</strong> ® Osteotomy <strong>System</strong>’s<br />

implants and instruments facilitate<br />

performance of high tibial and distal<br />

femoral osteotomies using the opening<br />

and closing wedge techniques.<br />

Specific indications include the<br />

following:<br />

• Unicompartmental osteoarthritis.<br />

• Congenital and post traumatic<br />

varus or valgus deformities and<br />

malalignments.<br />

• Posterolateral knee instability.<br />

The physician’s education, training<br />

and professional judgment must be<br />

relied upon to choose the most<br />

appropriate device and treatment<br />

option. Conditions presenting an<br />

increased risk of failure include:<br />

• Presence of inflammatory arthritis.<br />

• Severe joint instability cannot be<br />

treated through osteotomy alone;<br />

additional ligament reconstruction<br />

is required.<br />

• Any active or suspected latent<br />

infection or marked local inflammation<br />

in or about the affected area.<br />

• Compromised vascularity that would<br />

inhibit adequate blood supply to the<br />

osteotomy or the operative site.<br />

• Bone stock compromised by disease,<br />

infection or prior implantation that<br />

cannot provide adequate support<br />

and/or fixation of the devices.<br />

• Material sensitivity documented or<br />

suspected.<br />

• Obesity. An overweight or obese<br />

patient can produce loads on the<br />

implant which can lead to failure of<br />

the fixation of the device or to failure<br />

of the device itself.<br />

• Patients having inadequate tissue<br />

coverage over the operative site.<br />

• Implant utilization that would<br />

interfere with anatomical structures<br />

or physiological performance.<br />

• Any mental or neuromuscular<br />

disorder which could create an<br />

unacceptable risk of fixation<br />

failure or complications in<br />

postoperative care.<br />

• Other medical or surgical<br />

conditions which would preclude<br />

the potential benefit of surgery.<br />

5

Operative Technique<br />

Preoperative Planning<br />

The surgeon must first determine and<br />

clearly characterize the nature and<br />

extent of the deformity being<br />

corrected. For this purpose, full-length,<br />

standing (long axial alignment) AP<br />

radiographs need to be obtained.<br />

The x-rays must include the hip,<br />

knee and talus, standing in extension.<br />

The x-ray beam should be centered<br />

on the knee in question. It is also<br />

recommended that a standing lateral<br />

view and an anteroposterior view of<br />

the knee bent at 45° be obtained.<br />

These x-rays are then used to classify<br />

the orientation and magnitude of the<br />

deformity to be corrected using<br />

standard methods as described in the<br />

literature. The mechanical axis of the<br />

patient is defined by a line drawn from<br />

the center of the femoral head to the<br />

center of the tibial-talar joint.<br />

The radiographic evaluation is also<br />

used to determine the site of the<br />

osteotomy, the method of correction<br />

(opening or closing wedge)<br />

and positioning of the plate.<br />

General Principles<br />

It is recommended that any osteotomy<br />

be performed on a radiolucent table<br />

to allow visualization of the hip, knee<br />

and ankle. During the procedure,<br />

it is necessary for the surgeon to have<br />

a clear view of the entire extremity<br />

from the iliac crest to the talus.<br />

A choice of incision consistent with the<br />

anatomical region in question is made<br />

by the surgeon, based on personal<br />

experience and patient considerations.<br />

When treating a tibial deformity<br />

with a closing wedge osteotomy,<br />

the tibiofibular joint will prevent<br />

correction unless the fibula or the<br />

tibiofibular ligaments are cut.<br />

One option is to perform an oblique<br />

fibular osteotomy through a small<br />

incision in the proximal middle third<br />

of the fibula.<br />

Step One – Closing Wedge<br />

Osteotomy and Opening<br />

Osteotomy Wedge Sizing<br />

• The Cutting Guide (Ref. No. GCTP)<br />

in conjunction with fluoroscopic<br />

control permits accurate incisions to<br />

be made for closing wedge osteotomies.<br />

The first cut is made parallel to the<br />

joint line without the Cutting Guide.<br />

Insertion of two K-wires may be<br />

helpful in establishing the plane<br />

and location of the first cut.<br />

• After completion of the first cut, the<br />

Cutting Guide’s flange (see Fig. 1) is<br />

placed into this incision. Adjustment<br />

of the graduated scale allows for<br />

precise angulation of the second<br />

cutting line. For right leg osteotomies,<br />

use the side of the scale indicated by<br />

the letter “D.” For left leg osteotomies<br />

use the side of the scale marked “G.”<br />

Note: The “D” represents “Droite”<br />

(Right) and the “G” represents<br />

“Gauche” (Left) in French.<br />

• When performing an opening wedge<br />

osteotomy, a bone spreader can be<br />

used to pry open the osteotomy site<br />

and keep it from collapsing, while<br />

a bone clamp is used to secure the<br />

opposite aspect so that it does not<br />

displace. It is often useful to keep<br />

a small corner of the far cortex intact<br />

to help maintain stability.<br />

• Use the Trial Wedges (Ref. No.<br />

10CALES) to ensure that the correct<br />

angular position is maintained and<br />

also to help open the osteotomy gap.<br />

If bone filler is used, these Trial<br />

Wedges can also help in determining<br />

the correct size and shape of the<br />

actual wedge to be implanted in the<br />

gap. The Trial Wedges are conveniently<br />

held and manipulated into position<br />

with the Holder (Ref. No. PRCAL).<br />

The Trial Wedge is removed after<br />

stabilization of the osteotomy site.<br />

Flange<br />

Graduated Scale<br />

Figure 1<br />

6

Operative Technique<br />

Step Two – Plate Contouring<br />

• The selected plate may require some<br />

contouring. When shaping the<br />

implant, the <strong>Numelock</strong> <strong>II</strong>® polyaxial<br />

mechanisms must be protected by<br />

grasping the plate with two Bending<br />

Forceps (Ref. No. PFTP3I), ensuring<br />

that the single rounded knob of each<br />

of the Bending Forceps is securely<br />

seated in the holes adjacent to the<br />

area of the plate that is being bent<br />

(See Figure 2). If twisting of the plate<br />

is required, a single Forceps, in<br />

combination with a Plate Bending<br />

Iron (Ref. No. TRTP3), may be used.<br />

Step Three – Pre-drilling for<br />

<strong>Locking</strong> Screw Placement<br />

• Once the required shape has been<br />

fashioned, the plate should be<br />

positioned on the bone for optimal<br />

stability and ultimate fixation.<br />

• Make certain that the locking<br />

mechanisms are correctly oriented:<br />

The slotted sides of the rings must all<br />

be turned to face upwards (away from<br />

the underside of the plate).<br />

• The <strong>Numelock</strong> <strong>II</strong>® Drill Guide<br />

(Ref. No. GM35 for use with a 3.5mm<br />

drill bit or Ref. No. GM45 for use<br />

with a 4.5mm drill bit) is threaded<br />

into the locking mechanism of one of<br />

the holes (See Figure 3). The 3.5mm<br />

drill bit is recommended for normal<br />

bone. The Drill Guide is then<br />

positioned at the required angle and<br />

the appropriate diameter drill bit is<br />

used to create a pilot hole for screw<br />

insertion. The Drill Guide constrains<br />

the drilling angle to within 30°,<br />

ensuring optimal screw head profile<br />

to minimize possible soft tissue<br />

irritation.<br />

• If hard cortical bone is encountered,<br />

use the tip of the Cutting Screwdriver<br />

(Ref. No. TASH7) to incise the near<br />

cortex. Additionally, a 4.5mm drill bit<br />

may be used to overdrill the near<br />

cortex in case of hard bone. The Tap<br />

(Ref. No. TVSH7) may be used to<br />

further prepare a pilot hole that was<br />

drilled using the 4.5mm drill bit.<br />

Step Four – Depth Measurement<br />

• Using the Depth Gauge (Ref. No. JA65),<br />

measure the depth of the pilot holes<br />

directly through the plate<br />

(See Figure 4).<br />

Figure 2<br />

Note: Special care must be taken to<br />

prevent damage to the locking<br />

mechanism. To protect the<br />

mechanism from damage, apply<br />

bending only between the locking<br />

holes. Do not back bend the plate.<br />

The Bending Forceps<br />

(Ref. No. PFTP3I) and Plate<br />

Bending Irons (Ref. No. TRTP3)<br />

must not be used to bend the<br />

femoral plates as they are already<br />

pre-contoured in an optimal<br />

manner.<br />

Figure 3<br />

• It is important to preplan the angles<br />

of inclination for each of the locking<br />

screws to optimize the fixation<br />

of both osteotomy segments.<br />

Extreme caution needs to be exercised<br />

to avoid collision of any screws inside<br />

the bone and to avoid penetration<br />

of the joint surfaces.When feasible,<br />

to avoid such intersection of the<br />

<strong>Numelock</strong> <strong>II</strong>® screws within the bone,<br />

it is desirable to place them at<br />

divergent angles to each other.<br />

Figure 4<br />

The Depth Gauge provides the actual<br />

length of the screw required.<br />

Note that the “Y” Shaped Plate with<br />

Compression Hole (Ref. No. STP2Y76S)<br />

uses standard 4.5mm SPS cortical<br />

screws in the shaft. Use the Depth<br />

Gauge from the Basic Fragment SPS<br />

set (Ref. No. 702878) for correct<br />

measurement of the diaphyseal screws<br />

in this plate.<br />

7

Operative Technique<br />

Step Five – <strong>Locking</strong> Screw<br />

Placement<br />

• Using the Cutting Screwdriver<br />

(Ref. No. TASH7), insert the<br />

<strong>Numelock</strong>® locking screw as far as<br />

possible without locking the ring<br />

mechanism. Prevent rotation of the<br />

ring mechanism by engaging the<br />

Holding Spanner’s (Ref. No. CESH7)<br />

teeth with the corresponding slots in<br />

the ring (See Figure 5).<br />

Step Six – Final Adjustments/<br />

Repositioning/Transport<br />

• To adjust the position of the bone<br />

with respect to the plate or to pull<br />

a bone segment closer to the plate,<br />

use the Ring Driver (Ref. No. TVESH7).<br />

By turning the ring clockwise with<br />

the Ring Driver, the bone is moved<br />

closer to the plate as required.<br />

Note: If using this feature to realign<br />

two bone segments, the<br />

orientation of screw placement<br />

must be parallel to the plane of<br />

the osteotomy line associated<br />

with these two segments.<br />

Step Seven – Final <strong>Locking</strong><br />

• When all desired adjustments are<br />

complete, lock each <strong>Numelock</strong> <strong>II</strong>®<br />

screw with the Screwdriver while<br />

holding the ring steady with the<br />

Holding Spanner. Firm tightening<br />

of the screws ensures stability.<br />

After locking, it is no longer possible<br />

to rotate the ring without damaging<br />

the locking mechanism.<br />

Figure 5<br />

Repeat Steps Three through Five<br />

for all screw positions. If transport<br />

or repositioning of a bone segment<br />

is required, see Step Six.<br />

Note: To guarantee maximum stability,<br />

fill all <strong>Numelock</strong> <strong>II</strong>® holes with<br />

a locking screw of appropriate<br />

length.<br />

Postoperative Care<br />

The physician’s education, training and<br />

professional judgment must be relied<br />

upon to establish the most appropriate<br />

postoperative care regimen for each<br />

individual patient. The following<br />

recommendations may be considered<br />

at the surgeon’s discretion:<br />

• Some patients may need to spend<br />

several days in the hospital after an<br />

osteotomy procedure. Deep muscle<br />

compartment drains may need to be<br />

considered postoperatively as well as a<br />

suitable pain management protocol.<br />

• If warranted, continuous passive<br />

motion may begin during the second<br />

postoperative day to help restore<br />

mobility. When appropriate,<br />

toe-touch weight-bearing with<br />

crutches may follow.<br />

• Follow-up radiographs are<br />

recommended at six weeks after<br />

surgery. Weight-bearing may be<br />

gradually increased at the surgeon’s<br />

discretion or when there is<br />

radiographic evidence of union.<br />

Full weight-bearing may begin when<br />

there is full consolidation of the<br />

osteotomy site, typically at around<br />

eight to ten weeks for men and ten<br />

to twelve weeks for women.<br />

8

Ordering Information – Osteotomy Plates<br />

Stainless Steel, Packaged Sterile<br />

MEDIAL DISTAL FEMORAL, CLOSING<br />

<strong>Locking</strong> Screws Diameter 6.5mm<br />

MEDIAL PROXIMAL TIBIAL “Y” SHAPED, OPENING<br />

<strong>Locking</strong> Screws Diameter 6.5mm<br />

StSt Length Side <strong>Locking</strong> Shaft<br />

REF mm Holes Holes<br />

SFBIPOSTDS 91 Right 6 3<br />

SFBIPOSTGS 91 Left 6 3<br />

StSt Length Side <strong>Locking</strong> Shaft<br />

REF mm Holes Holes<br />

STP2Y70S 69 Sym 4 2<br />

STP2Y94S 94 Sym 4 2<br />

STP2Y114S 114 Sym 4 2<br />

LATERAL PROXIMAL TIBIAL “L” SHAPED, CLOSING<br />

<strong>Locking</strong> Screws Diameter 6.5mm<br />

MEDIAL PROXIMAL TIBIAL “L” SHAPED, OPENING<br />

<strong>Locking</strong> Screws Diameter 6.5mm<br />

StSt Length Side <strong>Locking</strong> Shaft<br />

REF mm Holes Holes<br />

STP2L61FDS 59 Right 4 2<br />

STP2L61FGS 59 Left 4 2<br />

StSt Length Side <strong>Locking</strong> Shaft<br />

REF mm Holes Holes<br />

STP2L64ODS 63 Right 4 2<br />

STP2L64OGS 63 Left 4 2<br />

59mm<br />

StSt Length Side <strong>Locking</strong> Shaft<br />

REF mm Holes Holes<br />

STP2L64FDS 63 Right 4 2<br />

STP2L64FGS 63 Left 4 2<br />

MEDIAL PROXIMAL TIBIAL “Y” SHAPED,<br />

OPENING WITH COMPRESSION HOLE<br />

<strong>Locking</strong> Screws Diameter 6.5mm<br />

Standard Screws Diameter 4.5mm (for shaft holes only)<br />

StSt Length Side <strong>Locking</strong> Shaft<br />

REF mm Holes Holes<br />

STP2Y76S 77 Sym 2 3<br />

63mm<br />

9

Ordering Information – Screws / Instruments<br />

6.5mm diameter <strong>Locking</strong> Screws,<br />

Stainless Steel, Packaged Sterile<br />

StSt<br />

Length<br />

REF<br />

mm<br />

S7SH27S 27<br />

S7SH30S 30<br />

S7SH33S 33<br />

S7SH36S 36<br />

S7SH39S 39<br />

S7SH42S 42<br />

S7SH45S 45<br />

S7SH50S 50<br />

S7SH55S 55<br />

S7SH60S 60<br />

S7SH65S 65<br />

S7SH70S 70<br />

S7SH75S 75<br />

S7SH80S 80<br />

S7SH85S 85<br />

6.5mm Instrumentation<br />

REF<br />

GCTP<br />

PRCAL<br />

10CALES<br />

PFTP3I<br />

TRTP3<br />

GM35<br />

MCA35195<br />

GM45<br />

MCA45195<br />

TVSH7<br />

JA65<br />

CESH7<br />

Description<br />

Cutting Guide<br />

Holder for Trial Wedges<br />

Set of 10 Trial Wedges<br />

Bending Forceps (Two Required)<br />

Plate Bending Iron<br />

Drill Guide for 3.5mm Drill Bit<br />

3.5mm Drill Bit<br />

Drill Guide for 4.5mm Drill Bit<br />

4.5mm Drill Bit<br />

Tap<br />

Depth Gauge<br />

Holding Spanner<br />

TASH7<br />

TVESH7<br />

Cutting Screwdriver<br />

Ring Driver<br />

10

Ordering Information – Cases and Trays<br />

REF<br />

Description<br />

Metal Case configuration<br />

CSA2F240 Storage Case, Instruments<br />

11

Trauma, Extremities & Deformities<br />

Trauma, Extremities & Deformities<br />

Biologics<br />

Biologics<br />

Surgical Products<br />

Surgical Products<br />

Neuro & ENT<br />

Neuro & ENT<br />

<strong>Stryker</strong> Trauma AG<br />

Bohnackerweg 1<br />

CH-2545 Selzach<br />

Switzerland<br />

www.osteosynthesis.stryker.com<br />

The information presented in this brochure is intended to demonstrate a <strong>Stryker</strong> product. Always refer to the package<br />

insert, product label and/or user instructions before using any <strong>Stryker</strong> product. Surgeons must always rely on their own<br />

clinical judgment when deciding which products and techniques to use with their patients. Products may not be available<br />

in all markets. Product availability is subject to the regulatory or medical practices that govern individual markets. Please<br />

contact your <strong>Stryker</strong> representative if you have questions about the availability of <strong>Stryker</strong> products in your area.<br />

<strong>Stryker</strong> Corporation or its subsidiary owns the registered trademark: <strong>Stryker</strong><br />

<strong>Stryker</strong> Corporation or its subsidiary owns, uses or has applied for the following trademarks: <strong>Numelock</strong> <strong>II</strong><br />

Literature Number: 982196<br />

LOT A4106<br />

Copyright © 2006 <strong>Stryker</strong><br />

Printed in Switzerland