Development of High Temperature Fiber and ETFE Tight Buffered ...

Development of High Temperature Fiber and ETFE Tight Buffered ...

Development of High Temperature Fiber and ETFE Tight Buffered ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The test is used to examine the fiber’s resistance to rapid<br />

temperature changes, to determine the reliability <strong>and</strong> stability <strong>of</strong><br />

its optical performance, <strong>and</strong> to improve the product quality.<br />

Figure 1 <strong>and</strong> Figure 2 show induced attenuation changes at<br />

1310nm <strong>and</strong> 1550nm respectively during the thermal shock test.<br />

The maximum change <strong>of</strong> attenuation in the test at 1310nm<br />

wavelength is +0.008dB/km while that at 1550nm wavelength is<br />

+0.011dB/km.<br />

2.2 <strong>Temperature</strong> cycling test<br />

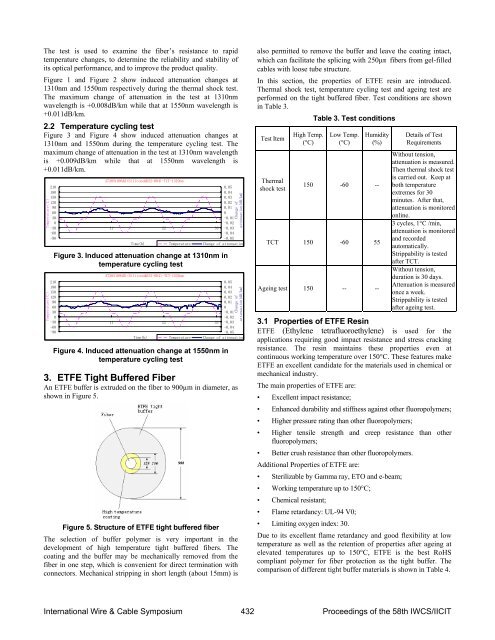

Figure 3 <strong>and</strong> Figure 4 show induced attenuation changes at<br />

1310nm <strong>and</strong> 1550nm during the temperature cycling test. The<br />

maximum change <strong>of</strong> attenuation in the test at 1310nm wavelength<br />

is +0.009dB/km while that at 1550nm wavelength is<br />

+0.011dB/km.<br />

<strong>Temperature</strong>(℃)<br />

<strong>Temperature</strong>(℃)<br />

A7305109AB1(Silicone&KS2-004)-TCT-1310nm<br />

210<br />

180<br />

0.05<br />

0.04<br />

150<br />

0.03<br />

120<br />

0.02<br />

90<br />

0.01<br />

60<br />

0<br />

30<br />

-0.01<br />

0<br />

-0.02<br />

-30 0 11 22 33 -0.03<br />

-60<br />

-0.04<br />

-90<br />

-0.05<br />

Time(h)<br />

<strong>Temperature</strong> Change <strong>of</strong> attenuation<br />

Figure 3. Induced attenuation change at 1310nm in<br />

temperature cycling test<br />

A7305109AB1(Silicone&KS2-004)-TCT-1550nm<br />

Change <strong>of</strong><br />

attenuation(dB/km)<br />

210<br />

180<br />

0.05<br />

0.04<br />

150<br />

0.03<br />

120<br />

0.02<br />

90<br />

0.01<br />

60<br />

0<br />

30<br />

-0.01<br />

0<br />

-0.02<br />

-30 0 11 22 33 -0.03<br />

-60<br />

-0.04<br />

-90<br />

-0.05<br />

Time(h)<br />

<strong>Temperature</strong> Change <strong>of</strong> attenuation<br />

Figure 4. Induced attenuation change at 1550nm in<br />

temperature cycling test<br />

3. <strong>ETFE</strong> <strong>Tight</strong> <strong>Buffered</strong> <strong>Fiber</strong><br />

An <strong>ETFE</strong> buffer is extruded on the fiber to 900µm in diameter, as<br />

shown in Figure 5.<br />

Figure 5. Structure <strong>of</strong> <strong>ETFE</strong> tight buffered fiber<br />

The selection <strong>of</strong> buffer polymer is very important in the<br />

development <strong>of</strong> high temperature tight buffered fibers. The<br />

coating <strong>and</strong> the buffer may be mechanically removed from the<br />

fiber in one step, which is convenient for direct termination with<br />

connectors. Mechanical stripping in short length (about 15mm) is<br />

Change <strong>of</strong><br />

attenuation(dB/km)<br />

also permitted to remove the buffer <strong>and</strong> leave the coating intact,<br />

which can facilitate the splicing with 250μm fibers from gel-filled<br />

cables with loose tube structure.<br />

In this section, the properties <strong>of</strong> <strong>ETFE</strong> resin are introduced.<br />

Thermal shock test, temperature cycling test <strong>and</strong> ageing test are<br />

performed on the tight buffered fiber. Test conditions are shown<br />

in Table 3.<br />

Table 3. Test conditions<br />

Test Item<br />

Thermal<br />

shock test<br />

<strong>High</strong> Temp.<br />

(°C)<br />

Low Temp.<br />

(°C)<br />

Humidity<br />

(%)<br />

150 -60 --<br />

TCT 150 -60 55<br />

Ageing test 150 -- --<br />

Details <strong>of</strong> Test<br />

Requirements<br />

Without tension,<br />

attenuation is measured.<br />

Then thermal shock test<br />

is carried out. Keep at<br />

both temperature<br />

extremes for 30<br />

minutes. After that,<br />

attenuation is monitored<br />

online.<br />

3 cycles, 1°C /min,<br />

attenuation is monitored<br />

<strong>and</strong> recorded<br />

automatically.<br />

Strippability is tested<br />

after TCT.<br />

Without tension,<br />

duration is 30 days.<br />

Attenuation is measured<br />

once a week.<br />

Strippability is tested<br />

after ageing test.<br />

3.1 Properties <strong>of</strong> <strong>ETFE</strong> Resin<br />

<strong>ETFE</strong> (Ethylene tetrafluoroethylene) is used for the<br />

applications requiring good impact resistance <strong>and</strong> stress cracking<br />

resistance. The resin maintains these properties even at<br />

continuous working temperature over 150°C. These features make<br />

<strong>ETFE</strong> an excellent c<strong>and</strong>idate for the materials used in chemical or<br />

mechanical industry.<br />

The main properties <strong>of</strong> <strong>ETFE</strong> are:<br />

• Excellent impact resistance;<br />

• Enhanced durability <strong>and</strong> stiffness against other fluoropolymers;<br />

• <strong>High</strong>er pressure rating than other fluoropolymers;<br />

• <strong>High</strong>er tensile strength <strong>and</strong> creep resistance than other<br />

fluoropolymers;<br />

• Better crush resistance than other fluoropolymers.<br />

Additional Properties <strong>of</strong> <strong>ETFE</strong> are:<br />

• Sterilizable by Gamma ray, ETO <strong>and</strong> e-beam;<br />

• Working temperature up to 150°C;<br />

• Chemical resistant;<br />

• Flame retardancy: UL-94 V0;<br />

• Limiting oxygen index: 30.<br />

Due to its excellent flame retardancy <strong>and</strong> good flexibility at low<br />

temperature as well as the retention <strong>of</strong> properties after ageing at<br />

elevated temperatures up to 150°C, <strong>ETFE</strong> is the best RoHS<br />

compliant polymer for fiber protection as the tight buffer. The<br />

comparison <strong>of</strong> different tight buffer materials is shown in Table 4.<br />

International Wire & Cable Symposium 432 Proceedings <strong>of</strong> the 58th IWCS/IICIT