Haubenschild Farms Final Report - The Minnesota Project

Haubenschild Farms Final Report - The Minnesota Project

Haubenschild Farms Final Report - The Minnesota Project

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>The</strong> <strong>Minnesota</strong> <strong>Project</strong> August 2002<br />

Plug-Flow Digester<br />

Plug-flow digesters are suitable for ruminant animal manure having a solids concentration<br />

of 11 to 14 percent, such as cow manure collected by scraping. A flush system for manure<br />

collection is not appropriate for this system, since this would reduce the total solids content<br />

of the manure below specified levels. In manure with lower solids concentrations, such as<br />

swine manure, solids cannot stay in solution and tend to settle to the bottom of the tank,<br />

limiting their digestion. A plug-flow digester has few moving parts and requires minimal<br />

maintenance.<br />

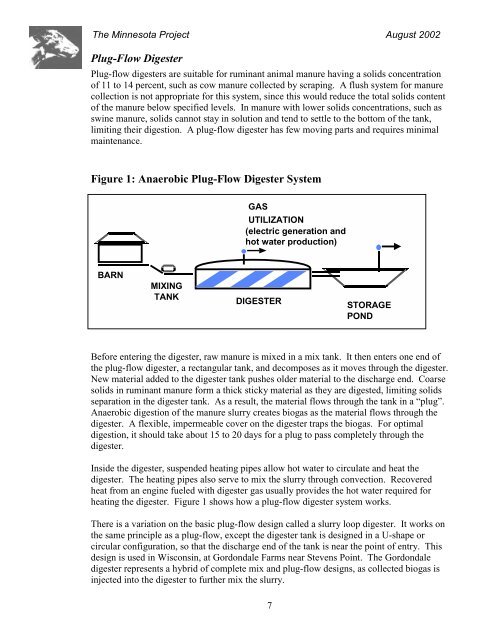

Figure 1: Anaerobic Plug-Flow Digester System<br />

GAS<br />

UTILIZATION<br />

(electric generation and<br />

hot water production)<br />

BARN<br />

MIXING<br />

TANK<br />

DIGESTER<br />

STORAGE<br />

POND<br />

Before entering the digester, raw manure is mixed in a mix tank. It then enters one end of<br />

the plug-flow digester, a rectangular tank, and decomposes as it moves through the digester.<br />

New material added to the digester tank pushes older material to the discharge end. Coarse<br />

solids in ruminant manure form a thick sticky material as they are digested, limiting solids<br />

separation in the digester tank. As a result, the material flows through the tank in a “plug”.<br />

Anaerobic digestion of the manure slurry creates biogas as the material flows through the<br />

digester. A flexible, impermeable cover on the digester traps the biogas. For optimal<br />

digestion, it should take about 15 to 20 days for a plug to pass completely through the<br />

digester.<br />

Inside the digester, suspended heating pipes allow hot water to circulate and heat the<br />

digester. <strong>The</strong> heating pipes also serve to mix the slurry through convection. Recovered<br />

heat from an engine fueled with digester gas usually provides the hot water required for<br />

heating the digester. Figure 1 shows how a plug-flow digester system works.<br />

<strong>The</strong>re is a variation on the basic plug-flow design called a slurry loop digester. It works on<br />

the same principle as a plug-flow, except the digester tank is designed in a U-shape or<br />

circular configuration, so that the discharge end of the tank is near the point of entry. This<br />

design is used in Wisconsin, at Gordondale <strong>Farms</strong> near Stevens Point. <strong>The</strong> Gordondale<br />

digester represents a hybrid of complete mix and plug-flow designs, as collected biogas is<br />

injected into the digester to further mix the slurry.<br />

7