TFT MID DUAL FORCE MANUAL.pdf - Los Angeles County ...

TFT MID DUAL FORCE MANUAL.pdf - Los Angeles County ...

TFT MID DUAL FORCE MANUAL.pdf - Los Angeles County ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

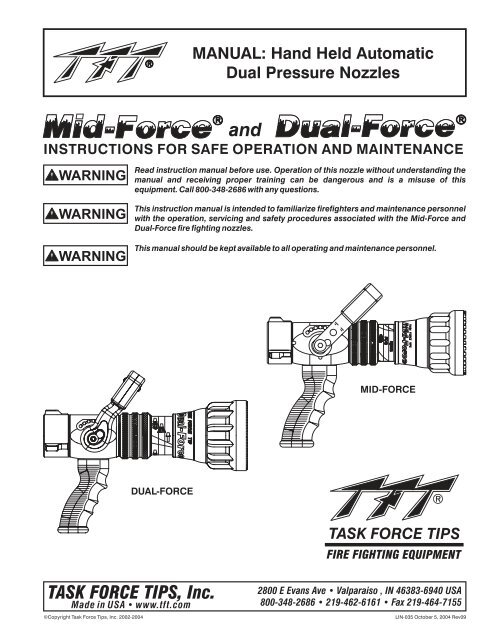

<strong>MANUAL</strong>: Hand Held Automatic<br />

Dual Pressure Nozzles<br />

and<br />

INSTRUCTIONS FOR SAFE OPERATION AND MAINTENANCE<br />

WARNING<br />

WARNING<br />

WARNING<br />

Read instruction manual before use. Operation of this nozzle without understanding the<br />

manual and receiving proper training can be dangerous and is a misuse of this<br />

equipment. Call 800-348-2686 with any questions.<br />

This instruction manual is intended to familiarize firefighters and maintenance personnel<br />

with the operation, servicing and safety procedures associated with the Mid-Force and<br />

Dual-Force fire fighting nozzles.<br />

This manual should be kept available to all operating and maintenance personnel.<br />

<strong>MID</strong>-<strong>FORCE</strong><br />

<strong>DUAL</strong>-<strong>FORCE</strong><br />

®<br />

TASK <strong>FORCE</strong> TIPS, Inc.<br />

MadeinUSA•www.tft.com<br />

©Copyright Task Force Tips, Inc. 2002-2004<br />

2800 E Evans Ave • Valparaiso , IN 46383-6940 USA<br />

800-348-2686 • 219-462-6161 • Fax 219-464-7155<br />

LIN-035 October 5, 2004 Rev09

1.0 GENERAL INFORMATION<br />

The Task Force Tips <strong>MID</strong>-<strong>FORCE</strong> and <strong>DUAL</strong>-<strong>FORCE</strong> nozzles are designed to provide excellent performance under most<br />

fire fighting conditions. Their rugged construction is compatible with the use of fresh water (see section 5.0 for saltwater<br />

use) as well as fire fighting foam solutions. Other important operating features are:<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

-<br />

Switchable from standard operation to low pressure<br />

Automatic pressure regulation at (meets NFPA 1964 automatic nozzle pressure requirements)<br />

Slide valve with valve handle detent flow control for excellent stream quality at all valve positions<br />

Quick-acting pattern control from straight stream to wide fog<br />

"Power fog teeth" for full-fill fog<br />

"Gasket grabber" inlet screen to keep large debris from entering nozzle<br />

Easily flushable while flowing to clear trapped debris<br />

<strong>TFT</strong>'s five-year warranty and unsurpassed customer service<br />

1.1 VARIOUS MODELS AND TERMS<br />

The <strong>TFT</strong> <strong>MID</strong>-<strong>FORCE</strong> and <strong>DUAL</strong>-<strong>FORCE</strong> nozzles are available in several different models. Some common models<br />

and operating features are shown in figure 1.<br />

SERIES FLOW RANGE NOMINAL PRESSURE STANDARD COUPLING*<br />

GPM l/min PSI BAR<br />

<strong>MID</strong>-<strong>FORCE</strong> 70-200 265-760 100 7 1-1/2 NH<br />

<strong>MID</strong>-<strong>FORCE</strong> 70-200 265-760 75 5 1-1/2 NH<br />

<strong>DUAL</strong>-<strong>FORCE</strong> 95-300 360-1150 100 7 1-1/2 NH<br />

<strong>DUAL</strong>-<strong>FORCE</strong> 95-250 360-950 75 5 1-1/2 NH<br />

* Other threads, coupling sizes, or connector styles can be specified at time of order.<br />

COUPLING<br />

ON<br />

FLOW CONTROL<br />

OFF<br />

STREAM<br />

SHAPER<br />

BARREL LABEL<br />

NAME LABEL<br />

RUBBER<br />

GASKET<br />

PRESSURE<br />

CONTROL<br />

KNOB<br />

PISTOL<br />

GRIP<br />

NOZZLE WITH VALVE<br />

and INTEGRAL PISTOL GRIP<br />

TIP ONLY NOZZLE<br />

DETENTS<br />

VALVE HANDLE<br />

VALVE POSITION<br />

LABEL<br />

VALVE RING<br />

GASKET<br />

GRABBER<br />

INLET<br />

SCREEN<br />

NOZZLE WITH VALVE<br />

TIP ONLY NOZZLE<br />

WITH TWIST SHUTOFF<br />

2<br />

FIGURE 1 - COMMON MODELS AND TERMS

1.2 COLOR CODED VALVE HANDLE COVERS<br />

The <strong>TFT</strong> <strong>MID</strong>-<strong>FORCE</strong> and <strong>DUAL</strong>-<strong>FORCE</strong> with lever type valve handles are supplied with black valve handle covers. The<br />

handle covers are available from <strong>TFT</strong> in various colors for those departments wishing to color code the nozzle to the<br />

discharge controls. A colored handle cover set will be sent upon receipt of the warranty card by <strong>TFT</strong>. Your department's<br />

name can also be engraved on the covers (see warranty card for more information).<br />

Handle covers are replaceable by removing the four screws that hold the handle covers in place. Use a 3/32” allen<br />

wrench when replacing screws.<br />

For standardization NFPA 1901 (A-4-9.3) recommends the following color code scheme:<br />

Preconnect #1 or Bumper Jump Line Orange<br />

Preconnect or discharge #5 Blue<br />

Preconnect or discharge #2<br />

Red<br />

Preconnect or discharge #6 Black<br />

Preconnect or discharge #3<br />

Yellow<br />

Preconnect or discharge #7 Green<br />

Preconnect or discharge #4<br />

White<br />

Foam Lines<br />

Red w/ White border<br />

(Red/White)<br />

1.3 NOZZLE COUPLING<br />

Rocker lug 1-1/2" NH full-time swivel is standard on models with lever type flow control. The coupling is the same on<br />

other models except it does not swivel. Other threads such as 1-1/2" NPSH can be specified at time of order.<br />

CAUTION<br />

Nozzle must be mated to a hose line with matched threads. Mismatched or damaged<br />

threads may cause nozzle to leak or uncouple from hose under pressure and could cause<br />

injury.<br />

2.0 FLOW CHARACTERISTICS<br />

The graphs in figure 2 show the typical performance of <strong>MID</strong>-<strong>FORCE</strong> and <strong>DUAL</strong>-<strong>FORCE</strong> nozzles.<br />

meets NFPA flow requirements.<br />

Pressure (PSI)<br />

120<br />

110<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

<strong>MID</strong>-<strong>FORCE</strong> 100/55 PSI (7/4 BAR)<br />

STANDARD 100 PSI LOW 55 PSI NFPA 100 PSI<br />

115 PSI<br />

85 PSI<br />

70 GPM<br />

STANDARD PRESSURE MODE<br />

70 - 200 GPM (265 - 760 L/min)<br />

FLOW RANGE<br />

LOW PRESSURE MODE<br />

0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320<br />

Flow (GPM)<br />

200 GPM<br />

The charts in section 8.0 of this document<br />

give specific examples of maximum flow<br />

rates for particular situations. Friction<br />

losses may vary due to differences in hose<br />

construction resulting in flows different<br />

than those shown. For situations or<br />

lengths of hose not listed on the chart,<br />

approximate flows can be calculated<br />

using conventional hydraulics. NOTE:<br />

Within the flow range, the nozzle inlet<br />

pressure may be approximated to be<br />

100 PSI when used in the standard<br />

pressure mode.<br />

120<br />

<strong>MID</strong>-<strong>FORCE</strong> 75/45 PSI (5/3 BAR)<br />

STANDARD 75PSI LOW 45PSI NFPA 75 PSI<br />

110<br />

100<br />

90<br />

90 PSI<br />

70 GPM<br />

200 GPM<br />

Pressure (PSI)<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

STANDARD PRESSURE MODE<br />

70 - 200 GPM (265 - 760 L/min)<br />

FLOW RANGE<br />

LOW PRESSURE MODE<br />

20<br />

10<br />

0<br />

0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320<br />

Flow (GPM)<br />

3

meets NFPA flow requirements.<br />

For Nozzles Manufactured<br />

After December 1, 2003<br />

New <strong>DUAL</strong>-<strong>FORCE</strong> 100/55 PSI (7/4 BAR) meets NFPA - For Nozzles M anufactured After December 1, 2003<br />

Pressure (PSI)<br />

120<br />

110<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

STANDRAD 100 PSI LOW 55 PSI NFPA 100 PSI<br />

115 PSI<br />

85 PSI<br />

95 GPM<br />

STANDARD PRESSURE MODE<br />

95 - 300 GPM (360 - 1150 L/min)<br />

FLOW RANGE<br />

LOW PRESSURE MODE<br />

95 - 225 GPM (360 - 850 L/min)<br />

FLOW RANGE<br />

300 GPM<br />

30<br />

20<br />

10<br />

0<br />

0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320<br />

Flow (GPM)<br />

120<br />

New <strong>DUAL</strong>-<strong>FORCE</strong> 75/45 PSI (5/3 BAR) meets NFPA - For Nozzles M anufactured after December 1, 2003<br />

STANDRAD 75PSI LOW 45PSI NFPA 75 PSI<br />

110<br />

100<br />

90<br />

90 PSI<br />

95 GPM<br />

250 GPM<br />

Pressure (PSI)<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

STANDARD PRESSURE MODE<br />

95 - 250 GPM (360 - 950 L/min)<br />

FLOW RANGE<br />

LOW PRESSURE MODE<br />

95 - 225 GPM (360 - 850 L/min)<br />

FLOW RANGE<br />

0<br />

0 20 40 60 80 100 120 140 160 180 200 220 240 260 280 300 320<br />

Flow (GPM)<br />

FIGURE 2 - NOZZLE PERFORMANCE<br />

4<br />

DANGER<br />

WARNING<br />

WARNING<br />

CAUTION<br />

An inadequate supply of nozzle pressure and/or flow will cause an ineffective stream and<br />

can result in injury, death or loss of property. See flow chart in section 8.0 or call 800-348-<br />

2686 for assistance.<br />

Failure to restrain nozzle reaction can cause firefighter injury from loss of footing and/or<br />

stream protection. Nozzle reaction will vary as supply conditions change: such as<br />

opening or closing other nozzles, hose line kinks, changes in pump settings, etc.<br />

Changes in spray pattern, flushing, or pressure control knob will also affect nozzle<br />

reaction. The nozzle operator must always be positioned to restrain the nozzle reaction<br />

in the event of those changes.<br />

Injury from whipping can occur. If nozzle gets out of control or away from operator, retreat<br />

from nozzle immediately. Do not attempt to regain control of nozzle while flowing water.<br />

Fire streams are capable of injury and damage. Do not direct water stream to cause injury<br />

or damage to persons or property.

3.0 NOZZLE CONTROLS<br />

3.1 FLOW CONTROL<br />

3.1.1 LEVER TYPE FLOW CONTROL<br />

On models that use a lever type valve handle, the nozzle is shut off when the handle is fully forward. The valve handle has<br />

six detent flow positions. These detent positions allow the nozzle operator to regulate the flow of the nozzle depending on<br />

the need or what can be safely and effectively handled. <strong>TFT</strong> recommends the use of a pistol grip for easier handling. For<br />

additional stress reduction, a hose rope or strap may also be used. This permits more effective use and ease of<br />

advancement, while minimizing strain and fatigue.<br />

3.1.2 TWIST SHUTTOFF<br />

On models that use a twist flow control. The valve is opened or closed by rotating the valve ring. Rotating the ring<br />

clockwise (as seen from the operating position behind the nozzle) closes the valve, while counterclockwise rotation<br />

opens it. Detents are provided at four intermediate positions and the position of the valve is shown by the exposed valve<br />

position label.<br />

3.1.3 TIP ONLY NOZZLES<br />

Tip only nozzles have NO shut off valve contained within the nozzle and MUST be used with a separate ball valve<br />

attached to the nozzle.<br />

3.2 PATTERN AND FLUSH CONTROL<br />

3.2.1 PATTERN CONTROL<br />

The <strong>TFT</strong>'s <strong>MID</strong>-<strong>FORCE</strong> and <strong>DUAL</strong>-<strong>FORCE</strong> have full pattern control from straight stream to wide fog. Turning the STREAM<br />

SHAPER clockwise (as seen from the operating position behind the nozzle) moves the SHAPER to the straight stream<br />

position. Turning the SHAPER counterclockwise will result in an increasingly wider pattern.<br />

Since the stream trim point varies with the flow, the stream should be "trimmed" after changing the flow to obtain the<br />

straightest and farthest reaching stream. To properly trim a stream, first open the pattern to a narrow fog. Then close the<br />

stream to parallel to give maximum reach. NOTE: Turning the shaper further forward will cause stream crossover<br />

and reduce the effective reach of the nozzle.<br />

The nozzle reaction is greatest when the shaper is in the straight stream position. The nozzle operator must be prepared<br />

for a change in reaction as the pattern is changed.<br />

3.2.2 FLUSH CONTROL<br />

Small debris passes through the gasket grabber and may get caught inside the nozzle. This trapped material will cause<br />

poor stream quality, shortened reach and reduced flow. To remove this trapped debris the nozzle can be flushed as<br />

follows; while still flowing water, turn the SHAPER counterclockwise past the full fog position (increased resistance will be<br />

felt on the SHAPER as the nozzle goes into flush). This will open the nozzle allowing debris to pass through. Rotate the<br />

SHAPER clockwise and out of flush to continue normal operation. During flush the nozzle reaction will decrease as the<br />

pattern becomes wider and the pressure drops. The nozzle operator must be prepared for an increase of nozzle reaction<br />

when returning the nozzle from the flush position to retain control of the nozzle.<br />

WARNING<br />

Large amounts of debris can reduce the flow of the<br />

nozzle resulting in an ineffective flow. In the event<br />

of a blockage it may be necessary to retreat to a<br />

safe area, uncouple nozzle and remove debris.<br />

3.3 STANDARD/LOW PRESSURE KNOB<br />

FIGURE 3 - GASKET GRABBER<br />

For situations where the standard pressure setting at the nozzle is impractical, the <strong>MID</strong>-<strong>FORCE</strong> or <strong>DUAL</strong>-<strong>FORCE</strong> may be<br />

switched to an low pressure mode. In the low pressure mode the nozzle pressure is reduced by about 50% while<br />

maintaining a usable stream and increasing the flow. The nozzle operator must be prepared for a change in reaction<br />

when changing modes. See figure 2 or the flow chart in section 8.0 for actual performance.<br />

To switch to the low pressure mode, shut off water flow with valve and turn knob at front of nozzle (see figure 4)<br />

counterclockwise (when viewed from front). Reopen valve to flow water at reduced pressure. Repeat the process,<br />

except turn knob clockwise, to return to standard pressure operation.<br />

5

To obtain dual pressure capability, a knob is added<br />

to the front end of the baffle. This knob protrudes<br />

past the end of the nozzle when the shaper is<br />

rotated back. As a consequence, the knob and<br />

baffle may be damaged if subjected to impact<br />

such as from a drop. The knob and baffle portion<br />

of the nozzle does NOT meet NFPA 1964's rough<br />

usage requirement of a six foot drop onto concrete<br />

(paragraph 4-7.1). In the event of damage to this<br />

section the stream quality may be affected as well<br />

as nozzle pressure regulation.<br />

Knob In<br />

Standard Operating Mode<br />

FIGURE 4<br />

Knob In<br />

Low Pressure Mode<br />

4.0 USE OF <strong>MID</strong>-<strong>FORCE</strong> and <strong>DUAL</strong>-<strong>FORCE</strong> NOZZLES<br />

Many factors contribute to the extinguishment of a fire. Among the most important is delivering water at a flow rate<br />

sufficient to absorb heat faster than it is being generated. The flow rate depends largely on the pump discharge pressure<br />

and hose friction loss. The pump discharge pressure may be found by use of the chart in section 8.0. It can also be<br />

calculated using a hydraulic equation such as:<br />

IT IS THE RESPONSIBILITY OF THE INDIVI<strong>DUAL</strong> FIRE DEPARTMENT OR AGENCY TO DETERMINE<br />

PHYSICAL CAPABILITIES AND SUITABILITY FOR AN INDIVI<strong>DUAL</strong>'S USE OF THIS EQUIPMENT.<br />

Within its flow range, the nozzle pressure (NP) of the <strong>MID</strong>-<strong>FORCE</strong><br />

or <strong>DUAL</strong>-<strong>FORCE</strong> nozzle may be approximated as 100 or 75 PSI in<br />

the standard mode. For additional information on calculating<br />

specific hose layouts, consult an appropriate fire service training<br />

manual, A Guide to Automatic Nozzles, or call <strong>TFT</strong>'s "Hydraulics<br />

Hotline" at 800-348-2686.<br />

PDP = NP+FL+DL+EL<br />

PDP = Pump discharge pressure in PSI<br />

NP = Nozzle pressure in PSI<br />

FL = Hose friction loss in PSI<br />

DL = Device loss in PSI<br />

EL = Elevation loss in PSI<br />

5.0 FIELD INSPECTION<br />

<strong>TFT</strong>'s <strong>MID</strong>-<strong>FORCE</strong> and <strong>DUAL</strong>-<strong>FORCE</strong> are designed and manufactured to be damage resistant and require minimal<br />

maintenance. However, as the primary fire fighting tools upon which your life depends, they should be treated<br />

accordingly. Use with saltwater is permissible provided nozzle is thoroughly cleaned with fresh water after each use. The<br />

service life of the nozzle may be shortened due to the effects of corrosion and is not covered under warranty.<br />

WARNING<br />

Nozzle must be inspected for proper operation and function according to inspection<br />

checklist on the last page before each use. Any nozzle that fails inspection is dangerous<br />

to use and must be repaired before using.<br />

Performance tests shall be conducted on the Mid-Force and Dual-Force nozzle after a repair, or anytime a problem is<br />

reported to verify operation in accordance with <strong>TFT</strong> test procedures. Consult factory for the procedure that corresponds<br />

to the model and serial number of the nozzle. Any equipment which fails the related test criteria should be removed from<br />

service immediately. Troubleshooting guides are available with each test procedure or equipment can be returned to the<br />

factory for service and testing. Factory service is available with repair time seldom exceeding one day in our facility.<br />

6

Factory serviced nozzles are repaired by experienced technicians to original specifications, fully tested and promptly<br />

returned. Any returns should include a note as to the nature of the problem, who to reach in case of questions and if a<br />

repair estimate is required.<br />

Repair parts and service procedures are available for those wishing to perform their own repairs.<br />

<strong>TFT</strong> Item#<br />

LHM-020<br />

LHD-020<br />

Title<br />

Mid-Matic & Mid-Force Service Procedure<br />

Handline & Dual-Force Service Procedure<br />

CAUTION<br />

Any alterations to the nozzle and its markings could diminish safety and constitutes a<br />

misuse of this product.<br />

All Task Force Tip nozzles are factory lubricated with high quality silicone grease. This lubricant has excellent washout<br />

resistance and long term performance. If your department has unusually hard or sandy water, the moving parts may be<br />

affected. Foam agents and water additives contain soaps and chemicals that may break down the factory lubrication.<br />

The moving parts of the nozzle should be checked on a regular basis for smooth and free operation, and signs of<br />

damage. IF THE NOZZLE IS OPERATING CORRECTLY, THEN NO ADDITIONAL LUBRICATION IS NEEDED. Any<br />

nozzle that is not operating correctly should be immediately removed from service and the problem corrected.<br />

6.0 WARRANTY<br />

Task Force Tips, Inc., 2800 East Evans Avenue, Valparaiso, Indiana 46383 ("<strong>TFT</strong>") warrants to the original purchaser of its<br />

Dual-Force and Mid-Force nozzles and other equipment ("equipment"), and to anyone to whom it is transferred, that the<br />

equipment shall be free from defects in material and workmanship during the five (5) year period from the date of<br />

purchase.<br />

<strong>TFT</strong>'s obligation under this warranty is specifically limited to replacing or repairing the equipment (or its parts) which<br />

are shown by <strong>TFT</strong>'s examination to be in a defective condition attributable to <strong>TFT</strong>. To qualify for this limited warranty,<br />

the claimant must return the equipment to <strong>TFT</strong>, at 2800 East Evans Avenue, Valparaiso, Indiana 46383, within a<br />

reasonable time after discovery of the defect. <strong>TFT</strong> will examine the equipment. If <strong>TFT</strong> determines that there is a<br />

defect attributable to it, <strong>TFT</strong> will correct the problem within a reasonable time. If the equipment is covered by this<br />

limited warranty, <strong>TFT</strong> will assume the expenses of repair.<br />

If any defect attributable to <strong>TFT</strong> under this limited warranty cannot be reasonably cured by repair or replacement, <strong>TFT</strong><br />

may elect to refund the purchase price of the equipment, less reasonable depreciation, in complete discharge of its<br />

obligations under this limited warranty. If <strong>TFT</strong> makes this election, claimant shall return the equipment to <strong>TFT</strong> free and<br />

clear of any liens and encumbrances.<br />

This is a limited warranty. The original purchaser of the equipment, any person to whom it is transferred, and any person<br />

who is an intended or unintended beneficiary of the equipment, shall not be entitled to recover from <strong>TFT</strong> any<br />

consequential or incidental damages for injury to person and/or property resulting from any defective equipment<br />

manufactured or assembled by <strong>TFT</strong>. It is agreed and understood that the price stated for the equipment is in part<br />

consideration for limiting <strong>TFT</strong>'s liability. Some states do not allow the exclusion or limitation of incidental or consequential<br />

damages, so the above may not apply to you.<br />

<strong>TFT</strong> shall have no obligation under this limited warranty if the equipment is, or has been, misused or neglected (including<br />

failure to provide reasonable maintenance) or if there have been accidents to the equipment or if it has been repaired or<br />

altered by someone else.<br />

THIS IS A LIMITED EXPRESS WARRANTY ONLY. <strong>TFT</strong> EXPRESSLY DISCLAIMS WITH RESPECT TO THE<br />

EQUIPMENT ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND ALL IMPLIED WARRANTIES OF FITNESS<br />

FOR A PARTICULAR PURPOSE. THERE IS NO WARRANTY OF ANY NATURE MADE BY <strong>TFT</strong> BEYOND THAT<br />

STATED IN THIS DOCUMENT.<br />

This limited warranty gives you specific legal rights, and you may also have other rights which vary from state to state.<br />

7.0 ANSWERS TO YOUR QUESTIONS<br />

We appreciate the opportunity of serving you and making your job easier. If you have any problems or questions, our tollfree<br />

"Hydraulics Hotline", 800-348-2686, is normally available to you 24 hours a day, 7 days a week.<br />

7

8.0 NOZZLE FLOW CHARTS<br />

8<br />

100/55 PSI<br />

=STANDARDPRESSUREMODE<br />

= LOW PRESSURE MODE<br />

STD<br />

LP<br />

Flow And Nozzle Reaction Chart<br />

1 1/2" HOSE 1 3/4" HOSE 2" HOSE<br />

FLOW (GPM)<br />

REACTION<br />

(LBS)<br />

250 ft.<br />

150 ft. 200 ft. 250 ft. 150 ft. 200 ft. 250 ft.<br />

150 ft.<br />

200 ft.<br />

LP<br />

STD LP STD LP STD LP STD LP STD LP STD LP STD LP STD LP STD<br />

68<br />

22<br />

75<br />

22<br />

82<br />

22<br />

54<br />

21<br />

60<br />

21<br />

65<br />

21<br />

46<br />

21<br />

50<br />

21<br />

55<br />

21<br />

22<br />

8<br />

24<br />

8<br />

27<br />

8<br />

17<br />

7<br />

19<br />

8<br />

21<br />

8<br />

14<br />

7<br />

16<br />

7<br />

17<br />

8<br />

50<br />

119<br />

34<br />

128<br />

35<br />

141<br />

36<br />

91<br />

31<br />

100<br />

32<br />

111<br />

32<br />

75<br />

28<br />

83<br />

29<br />

93<br />

31<br />

41<br />

15<br />

45<br />

15<br />

51<br />

15<br />

30<br />

13<br />

33<br />

14<br />

38<br />

14<br />

24<br />

12<br />

27<br />

12<br />

31<br />

13<br />

75<br />

153<br />

75<br />

167<br />

79<br />

184<br />

84<br />

117<br />

63<br />

129<br />

67<br />

143<br />

72<br />

97<br />

55<br />

107<br />

59<br />

121<br />

65<br />

56<br />

36<br />

63<br />

38<br />

72<br />

41<br />

40<br />

29<br />

45<br />

32<br />

52<br />

34<br />

32<br />

25<br />

36<br />

27<br />

42<br />

30<br />

100<br />

182<br />

113<br />

198<br />

122<br />

213<br />

135<br />

138<br />

91<br />

152<br />

97<br />

172<br />

108<br />

114<br />

77<br />

126<br />

84<br />

143<br />

93<br />

70<br />

57<br />

79<br />

62<br />

90<br />

69<br />

50<br />

44<br />

56<br />

48<br />

65<br />

54<br />

39<br />

37<br />

44<br />

40<br />

52<br />

45<br />

125<br />

205<br />

151<br />

220<br />

168<br />

---<br />

196<br />

158<br />

114<br />

174<br />

125<br />

195<br />

141<br />

130<br />

96<br />

143<br />

105<br />

163<br />

117<br />

84<br />

78<br />

95<br />

87<br />

---<br />

101<br />

58<br />

57<br />

66<br />

63<br />

77<br />

72<br />

46<br />

47<br />

52<br />

52<br />

61<br />

59<br />

150<br />

223<br />

187<br />

---<br />

212<br />

---<br />

---<br />

175<br />

136<br />

192<br />

151<br />

213<br />

174<br />

143<br />

112<br />

159<br />

124<br />

180<br />

140<br />

98<br />

97<br />

---<br />

109<br />

---<br />

---<br />

66<br />

70<br />

76<br />

78<br />

90<br />

90<br />

52<br />

57<br />

59<br />

63<br />

69<br />

72<br />

175<br />

---<br />

222<br />

---<br />

---<br />

---<br />

---<br />

189<br />

157<br />

207<br />

175<br />

228<br />

204<br />

156<br />

128<br />

173<br />

141<br />

196<br />

162<br />

---<br />

113<br />

---<br />

---<br />

---<br />

---<br />

75<br />

81<br />

86<br />

91<br />

102<br />

105<br />

58<br />

65<br />

66<br />

73<br />

78<br />

84<br />

200<br />

---<br />

---<br />

---<br />

---<br />

---<br />

---<br />

203<br />

176<br />

221<br />

198<br />

---<br />

---<br />

168<br />

142<br />

186<br />

158<br />

209<br />

183<br />

---<br />

---<br />

---<br />

---<br />

83<br />

91<br />

96<br />

102<br />

---<br />

---<br />

63<br />

73<br />

72<br />

82<br />

87<br />

94<br />

225<br />

PUMP DISCHARGE PRESSURE (PSI)<br />

---<br />

---<br />

CAUTION: Changing to Low Pressure mode will typically increase nozzle reaction.<br />

(1) Number on top in each box indicates flow (GPM), and number on bottom indicates nozzle reaction (LBS). (2) In Standard mode, the average nozzle pressure is 100 PSI. (3) Flows may vary with brand or condition of hose. (4)<br />

Flows are approximate and do not reflect losses in preconnect piping.

7/4 BAR<br />

=STANDARDPRESSUREMODE<br />

= LOW PRESSURE MODE<br />

7 bar<br />

LP<br />

Flow And Nozzle Reaction Chart<br />

38mm HOSE 45mm HOSE 50mm HOSE<br />

FLOW (LPM)<br />

REACTION<br />

(KG)<br />

45M 60M 75M 45M 60M 75M 45M 60M 75M<br />

LP<br />

7 bar LP 7 bar LP 7 bar LP 7 bar LP 7 bar LP 7 bar LP 7 bar LP 7 bar LP 7 bar<br />

225<br />

85<br />

285<br />

85<br />

310<br />

85<br />

205<br />

80<br />

225<br />

80<br />

245<br />

80<br />

175<br />

80<br />

190<br />

80<br />

210<br />

80<br />

10<br />

4<br />

11<br />

4<br />

12<br />

4<br />

8<br />

3<br />

9<br />

4<br />

10<br />

4<br />

6<br />

3<br />

7<br />

3<br />

8<br />

4<br />

3.5<br />

450<br />

130<br />

485<br />

130<br />

535<br />

135<br />

345<br />

115<br />

380<br />

120<br />

420<br />

85<br />

285<br />

105<br />

315<br />

110<br />

350<br />

115<br />

19<br />

7<br />

20<br />

7<br />

23<br />

175<br />

14<br />

6<br />

15<br />

6<br />

17<br />

6<br />

11<br />

5<br />

12<br />

5<br />

14<br />

6<br />

5.2<br />

580<br />

285<br />

630<br />

300<br />

695<br />

320<br />

445<br />

240<br />

490<br />

255<br />

540<br />

275<br />

365<br />

210<br />

405<br />

225<br />

460<br />

245<br />

25<br />

16<br />

29<br />

17<br />

33<br />

19<br />

18<br />

13<br />

20<br />

15<br />

24<br />

15<br />

15<br />

11<br />

16<br />

12<br />

19<br />

14<br />

7.0<br />

690<br />

430<br />

750<br />

460<br />

805<br />

510<br />

520<br />

345<br />

575<br />

365<br />

650<br />

410<br />

430<br />

290<br />

475<br />

320<br />

540<br />

350<br />

32<br />

26<br />

36<br />

28<br />

41<br />

31<br />

23<br />

20<br />

25<br />

22<br />

30<br />

25<br />

18<br />

17<br />

20<br />

18<br />

24<br />

20<br />

8.6<br />

775<br />

570<br />

---<br />

635<br />

---<br />

740<br />

600<br />

430<br />

660<br />

475<br />

740<br />

535<br />

490<br />

365<br />

540<br />

395<br />

615<br />

445<br />

38<br />

35<br />

--<br />

40<br />

---<br />

46<br />

26<br />

26<br />

30<br />

29<br />

35<br />

33<br />

21<br />

21<br />

24<br />

24<br />

28<br />

27<br />

10.0<br />

845<br />

710<br />

---<br />

800<br />

---<br />

---<br />

660<br />

515<br />

725<br />

570<br />

805<br />

660<br />

540<br />

425<br />

600<br />

470<br />

680<br />

530<br />

45<br />

44<br />

---<br />

50<br />

---<br />

---<br />

30<br />

32<br />

35<br />

35<br />

41<br />

41<br />

24<br />

26<br />

27<br />

29<br />

31<br />

33<br />

12.0<br />

---<br />

840<br />

---<br />

---<br />

---<br />

---<br />

715<br />

595<br />

785<br />

660<br />

---<br />

770<br />

590<br />

485<br />

655<br />

535<br />

740<br />

615<br />

---<br />

51<br />

---<br />

---<br />

---<br />

---<br />

34<br />

37<br />

39<br />

41<br />

---<br />

48<br />

26<br />

30<br />

30<br />

33<br />

35<br />

38<br />

14.0<br />

---<br />

---<br />

---<br />

---<br />

---<br />

---<br />

770<br />

665<br />

835<br />

750<br />

---<br />

---<br />

635<br />

535<br />

705<br />

600<br />

790<br />

695<br />

---<br />

---<br />

---<br />

---<br />

---<br />

38<br />

41<br />

44<br />

46<br />

---<br />

---<br />

29<br />

33<br />

33<br />

37<br />

40<br />

43<br />

15.5<br />

PUMP DISCHARGE PRESSURE (BAR)<br />

---<br />

CAUTION: Changing to Low Pressure mode will typically increase nozzle reaction.<br />

(1) Number on top in each box indicates flow (LPM), and number on bottom indicates nozzle reaction (KG). (2) In Standard mode, the average nozzle pressure is 7 bar. (3) Flows may vary with brand or condition of hose. (4) Flows are<br />

approximate and do not reflect losses in preconnect piping.<br />

9

10<br />

75/45 PSI<br />

=STANDARDPRESSUREMODE<br />

= LOW PRESSURE MODE<br />

STD<br />

LP<br />

Flow And Nozzle Reaction Chart<br />

1 1/2" HOSE 1 3/4" HOSE 2" HOSE<br />

FLOW (GPM)<br />

REACTION<br />

(LBS)<br />

250 ft.<br />

150 ft. 200 ft. 250 ft. 150 ft. 200 ft. 250 ft.<br />

150 ft.<br />

200 ft.<br />

LP<br />

STD LP STD LP STD LP STD LP STD LP STD LP STD LP STD LP STD<br />

89<br />

45<br />

97<br />

45<br />

84<br />

45<br />

67<br />

43<br />

74<br />

44<br />

84<br />

45<br />

57<br />

42<br />

62<br />

43<br />

69<br />

43<br />

26<br />

15<br />

29<br />

16<br />

25<br />

15<br />

19<br />

14<br />

21<br />

15<br />

25<br />

15<br />

16<br />

13<br />

18<br />

14<br />

20<br />

14<br />

50<br />

128<br />

60<br />

140<br />

62<br />

155<br />

64<br />

101<br />

55<br />

110<br />

57<br />

121<br />

59<br />

83<br />

51<br />

92<br />

53<br />

104<br />

55<br />

42<br />

25<br />

47<br />

26<br />

53<br />

27<br />

30<br />

22<br />

34<br />

23<br />

39<br />

24<br />

24<br />

20<br />

27<br />

21<br />

32<br />

22<br />

75<br />

162<br />

97<br />

171<br />

105<br />

182<br />

122<br />

123<br />

77<br />

136<br />

82<br />

153<br />

91<br />

103<br />

68<br />

113<br />

72<br />

127<br />

78<br />

56<br />

44<br />

63<br />

48<br />

71<br />

56<br />

40<br />

34<br />

45<br />

37<br />

52<br />

41<br />

31<br />

29<br />

35<br />

32<br />

42<br />

35<br />

100<br />

181<br />

146<br />

192<br />

166<br />

204<br />

203<br />

145<br />

105<br />

159<br />

118<br />

174<br />

134<br />

119<br />

86<br />

131<br />

96<br />

149<br />

108<br />

70<br />

67<br />

79<br />

75<br />

89<br />

89<br />

48<br />

48<br />

55<br />

54<br />

65<br />

62<br />

38<br />

39<br />

43<br />

43<br />

50<br />

50<br />

125<br />

199<br />

189<br />

210<br />

210<br />

—<br />

—<br />

162<br />

132<br />

174<br />

148<br />

191<br />

173<br />

134<br />

106<br />

148<br />

119<br />

166<br />

136<br />

85<br />

85<br />

95<br />

95<br />

—<br />

—<br />

57<br />

60<br />

66<br />

68<br />

78<br />

78<br />

44<br />

49<br />

50<br />

54<br />

60<br />

63<br />

150<br />

214<br />

215<br />

—<br />

—<br />

—<br />

—<br />

175<br />

155<br />

189<br />

175<br />

206<br />

206<br />

147<br />

124<br />

163<br />

138<br />

180<br />

162<br />

99<br />

99<br />

—<br />

—<br />

—<br />

—<br />

66<br />

71<br />

77<br />

79<br />

91<br />

91<br />

50<br />

57<br />

57<br />

64<br />

70<br />

73<br />

175<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

188<br />

176<br />

202<br />

201<br />

220<br />

220<br />

160<br />

140<br />

174<br />

157<br />

192<br />

183<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

76<br />

80<br />

87<br />

88<br />

104<br />

104<br />

55<br />

64<br />

65<br />

72<br />

79<br />

82<br />

200<br />

—<br />

—<br />

—<br />

—<br />

---<br />

—<br />

199<br />

196<br />

214<br />

214<br />

---<br />

---<br />

170<br />

155<br />

184<br />

174<br />

204<br />

204<br />

225<br />

PUMP DISCHARGE PRESSURE (PSI)<br />

---<br />

---<br />

---<br />

---<br />

---<br />

---<br />

85<br />

86<br />

98<br />

98<br />

---<br />

---<br />

62<br />

71<br />

73<br />

79<br />

89<br />

90<br />

CAUTION: Changing to Low Pressure mode will typically increase nozzle reaction.<br />

(1) Number on top in each box indicates flow (GPM), and number on bottom indicates nozzle reaction (LBS). (2) In Standard mode, the average nozzle pressure is 100 PSI. (3) Flows may vary with brand or condition of hose. (4)<br />

Flows are approximate and do not reflect losses in preconnect piping.

5/3 BAR<br />

=STANDARDPRESSUREMODE<br />

= LOW PRESSURE MODE<br />

7 bar<br />

LP<br />

Flow And Nozzle Reaction Chart<br />

38mm HOSE 45mm HOSE 50mm HOSE<br />

FLOW (LPM)<br />

REACTION<br />

(KG)<br />

45M 60M 75M 45M 60M 75M 45M 60M 75M<br />

LP<br />

5 bar LP 5 bar LP 5 bar LP 5 bar LP 5 bar LP 5 bar LP 5 bar LP 5 bar LP 5 bar<br />

337<br />

170<br />

367<br />

170<br />

318<br />

170<br />

254<br />

163<br />

280<br />

167<br />

318<br />

170<br />

216<br />

159<br />

235<br />

163<br />

261<br />

163<br />

12<br />

7<br />

13<br />

7<br />

11<br />

7<br />

9<br />

6<br />

10<br />

11<br />

7<br />

7<br />

6<br />

8<br />

6<br />

9<br />

6<br />

3.5<br />

484<br />

227<br />

530<br />

235<br />

587<br />

242<br />

382<br />

208<br />

416<br />

216<br />

458<br />

223<br />

314<br />

193<br />

348<br />

201<br />

394<br />

208<br />

19<br />

11<br />

21<br />

12<br />

24<br />

12<br />

14<br />

10<br />

15<br />

18<br />

11<br />

11<br />

9<br />

12<br />

10<br />

15<br />

10<br />

5.2<br />

613<br />

367<br />

647<br />

397<br />

689<br />

462<br />

466<br />

291<br />

515<br />

310<br />

579<br />

344<br />

390<br />

257<br />

428<br />

273<br />

481<br />

295<br />

25<br />

20<br />

29<br />

22<br />

32<br />

25<br />

18<br />

15<br />

20<br />

24<br />

19<br />

14<br />

13<br />

16<br />

15<br />

19<br />

16<br />

7.0<br />

685<br />

553<br />

727<br />

628<br />

772<br />

768<br />

549<br />

397<br />

602<br />

447<br />

659<br />

507<br />

450<br />

326<br />

496<br />

363<br />

564<br />

409<br />

32<br />

30<br />

36<br />

34<br />

40<br />

40<br />

22<br />

22<br />

25<br />

29<br />

28<br />

17<br />

18<br />

20<br />

20<br />

23<br />

23<br />

8.6<br />

753<br />

715<br />

795<br />

795<br />

—<br />

—<br />

613<br />

500<br />

659<br />

560<br />

723<br />

655<br />

507<br />

401<br />

560<br />

450<br />

628<br />

515<br />

39<br />

39<br />

43<br />

43<br />

—<br />

—<br />

26<br />

27<br />

30<br />

35<br />

35<br />

20<br />

22<br />

23<br />

24<br />

27<br />

29<br />

10.0<br />

810<br />

814<br />

—<br />

—<br />

—<br />

—<br />

662<br />

587<br />

715<br />

662<br />

780<br />

780<br />

556<br />

469<br />

617<br />

522<br />

681<br />

613<br />

45<br />

45<br />

—<br />

—<br />

—<br />

—<br />

30<br />

32<br />

35<br />

41<br />

41<br />

23<br />

26<br />

26<br />

29<br />

32<br />

33<br />

12.0<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

712<br />

666<br />

765<br />

761<br />

833<br />

833<br />

606<br />

530<br />

659<br />

594<br />

727<br />

693<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

34<br />

36<br />

39<br />

47<br />

47<br />

25<br />

29<br />

29<br />

33<br />

36<br />

37<br />

14.0<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

753<br />

742<br />

810<br />

810<br />

---<br />

---<br />

643<br />

587<br />

696<br />

659<br />

772<br />

772<br />

15.5<br />

PUMP DISCHARGE PRESSURE (BAR)<br />

—<br />

---<br />

---<br />

---<br />

---<br />

---<br />

39<br />

39<br />

44<br />

---<br />

---<br />

28<br />

32<br />

33<br />

36<br />

40<br />

41<br />

CAUTION: Changing to Low Pressure mode will typically increase nozzle reaction.<br />

(1) Number on top in each box indicates flow (LPM), and number on bottom indicates nozzle reaction (KG). (2) In Standard mode, the average nozzle pressure is 7 bar. (3) Flows may vary with brand or condition of hose. (4) Flows are<br />

approximate and do not reflect losses in preconnect piping.<br />

11

12<br />

For Nozzles with: Serial # <strong>TFT</strong>-H465101 and over or Manufactured after 12/01/2003<br />

100/55 PSI<br />

=STANDARDPRESSUREMODE<br />

= LOW PRESSURE MODE<br />

STD<br />

LP<br />

Flow And Nozzle Reaction Chart<br />

2 1/2" HOSE<br />

1 1/2" HOSE 1 3/4" HOSE 2" HOSE<br />

150 ft. 200 ft 250 ft.<br />

150 ft. 200 ft 250 ft. 150 ft. 200 ft 250 ft. 150 ft.<br />

200 ft<br />

250 ft.<br />

STD LP STD LP STD LP<br />

STD LP STD LP STD LP STD LP STD LP STD LP STD LP STD LP STD LP<br />

FLOW<br />

(GPM)<br />

REACTION<br />

(LBS)<br />

97<br />

53<br />

102<br />

53<br />

107<br />

53<br />

65<br />

50<br />

70<br />

51<br />

76<br />

51<br />

53<br />

48<br />

56<br />

49<br />

62<br />

50<br />

47<br />

45<br />

50<br />

47<br />

54<br />

48<br />

33<br />

19<br />

35<br />

19<br />

37<br />

19<br />

21<br />

17<br />

23<br />

17<br />

25<br />

18<br />

17<br />

15<br />

18<br />

16<br />

20<br />

17<br />

14<br />

14<br />

15<br />

15<br />

17<br />

16<br />

50<br />

184<br />

65<br />

194<br />

65<br />

206<br />

65<br />

116<br />

61<br />

127<br />

62<br />

141<br />

63<br />

89<br />

59<br />

98<br />

60<br />

110<br />

61<br />

72<br />

56<br />

80<br />

57<br />

91<br />

59<br />

71<br />

28<br />

76<br />

28<br />

82<br />

28<br />

40<br />

25<br />

45<br />

26<br />

51<br />

27<br />

30<br />

23<br />

33<br />

24<br />

38<br />

25<br />

24<br />

21<br />

27<br />

22<br />

31<br />

23<br />

75<br />

242<br />

122<br />

254<br />

128<br />

265<br />

135<br />

452<br />

86<br />

166<br />

91<br />

185<br />

99<br />

116<br />

73<br />

128<br />

77<br />

144<br />

83<br />

94<br />

65<br />

104<br />

69<br />

118<br />

74<br />

103<br />

59<br />

110<br />

62<br />

119<br />

66<br />

56<br />

40<br />

62<br />

43<br />

71<br />

47<br />

40<br />

33<br />

45<br />

35<br />

52<br />

38<br />

32<br />

28<br />

36<br />

30<br />

41<br />

33<br />

100<br />

279<br />

207<br />

288<br />

223<br />

299<br />

245<br />

182<br />

126<br />

199<br />

136<br />

221<br />

152<br />

138<br />

98<br />

152<br />

107<br />

172<br />

119<br />

112<br />

82<br />

124<br />

89<br />

141<br />

100<br />

130<br />

106<br />

139<br />

115<br />

149<br />

128<br />

70<br />

61<br />

78<br />

67<br />

90<br />

76<br />

50<br />

46<br />

56<br />

51<br />

65<br />

58<br />

39<br />

38<br />

44<br />

42<br />

51<br />

47<br />

125<br />

306<br />

283<br />

315<br />

312<br />

326<br />

328<br />

208<br />

160<br />

227<br />

176<br />

252<br />

198<br />

157<br />

122<br />

174<br />

134<br />

196<br />

151<br />

128<br />

100<br />

141<br />

110<br />

160<br />

124<br />

156<br />

149<br />

167<br />

166<br />

179<br />

179<br />

80<br />

80<br />

93<br />

89<br />

108<br />

101<br />

58<br />

59<br />

66<br />

66<br />

77<br />

75<br />

45<br />

47<br />

51<br />

53<br />

60<br />

60<br />

150<br />

329<br />

331<br />

340<br />

340<br />

—<br />

—<br />

230<br />

190<br />

251<br />

210<br />

274<br />

238<br />

175<br />

143<br />

193<br />

158<br />

217<br />

179<br />

142<br />

116<br />

157<br />

128<br />

178<br />

146<br />

182<br />

183<br />

195<br />

195<br />

—<br />

—<br />

95<br />

97<br />

108<br />

108<br />

126<br />

124<br />

66<br />

71<br />

75<br />

79<br />

88<br />

91<br />

51<br />

56<br />

58<br />

63<br />

68<br />

72<br />

175<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

250<br />

217<br />

270<br />

240<br />

294<br />

273<br />

190<br />

162<br />

210<br />

179<br />

237<br />

204<br />

154<br />

131<br />

171<br />

145<br />

194<br />

165<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

108<br />

112<br />

123<br />

125<br />

144<br />

144<br />

74<br />

81<br />

84<br />

91<br />

99<br />

105<br />

57<br />

64<br />

64<br />

72<br />

76<br />

83<br />

200<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

268<br />

242<br />

287<br />

268<br />

311<br />

307<br />

205<br />

179<br />

226<br />

199<br />

255<br />

227<br />

166<br />

144<br />

184<br />

160<br />

209<br />

183<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

121<br />

126<br />

138<br />

141<br />

163<br />

163<br />

81<br />

91<br />

93<br />

101<br />

110<br />

117<br />

62<br />

71<br />

71<br />

80<br />

84<br />

93<br />

225<br />

---<br />

---<br />

—<br />

—<br />

---<br />

---<br />

283<br />

264<br />

303<br />

293<br />

328<br />

329<br />

218<br />

195<br />

241<br />

216<br />

269<br />

248<br />

177<br />

157<br />

196<br />

174<br />

223<br />

199<br />

250<br />

PUMP DISCHARGE PRESSURE (PSI)<br />

---<br />

---<br />

---<br />

---<br />

---<br />

---<br />

134<br />

139<br />

154<br />

155<br />

181<br />

181<br />

89<br />

100<br />

102<br />

112<br />

122<br />

129<br />

67<br />

81<br />

77<br />

88<br />

91<br />

102<br />

CAUTION: Changing to Low Pressure mode will typically increase nozzle reaction.<br />

(1) Number on top of each box indicates flow (GPM), and number on bottom indicates nozzle reaction (LBS). (2) In Standard mode, the average nozzle pressure is 100<br />

PSI. (3) Flows may vary with brand or condition of hose. (4) Flows are approximate and do not reflect losses in preconnect piping.

For Nozzles with: Serial # <strong>TFT</strong>-H465101 and over or Manufactured after 12/01/2003<br />

7/4 BAR<br />

=STANDARDPRESSUREMODE<br />

= LOW PRESSURE MODE<br />

7 bar<br />

LP<br />

Flow And Nozzle Reaction Chart<br />

64mm HOSE<br />

38mm HOSE 45mm HOSE 50mm HOSE<br />

45M 60M 75M<br />

45M 60M 75M 45M 60M 75M 45M 60M 75M<br />

7 bar LP 7 bar LP 7 bar LP 7 bar LP 7 bar LP 7 bar LP 7 bar LP 7 bar LP 7 bar LP 7 bar LP 7 bar LP 7 bar LP<br />

FLOW<br />

(l/min)<br />

REACTION<br />

(KG)<br />

367<br />

201<br />

386<br />

201<br />

405<br />

201<br />

246<br />

189<br />

265<br />

193<br />

288<br />

193<br />

201<br />

182<br />

212<br />

185<br />

235<br />

189<br />

178<br />

170<br />

189<br />

178<br />

204<br />

182<br />

15<br />

9<br />

16<br />

9<br />

17<br />

9<br />

10<br />

8<br />

10<br />

8<br />

11<br />

8<br />

8<br />

7<br />

8<br />

7<br />

9<br />

8<br />

6<br />

6<br />

7<br />

7<br />

8<br />

7<br />

3.5<br />

696<br />

246<br />

734<br />

246<br />

780<br />

246<br />

439<br />

231<br />

481<br />

235<br />

534<br />

238<br />

337<br />

223<br />

371<br />

227<br />

416<br />

231<br />

273<br />

212<br />

303<br />

216<br />

344<br />

223<br />

32<br />

13<br />

34<br />

13<br />

37<br />

13<br />

18<br />

11<br />

20<br />

12<br />

23<br />

12<br />

14<br />

10<br />

15<br />

11<br />

17<br />

11<br />

11<br />

10<br />

12<br />

10<br />

14<br />

10<br />

5.2<br />

916<br />

462<br />

961<br />

484<br />

1003<br />

511<br />

575<br />

326<br />

628<br />

344<br />

700<br />

375<br />

439<br />

276<br />

484<br />

291<br />

545<br />

314<br />

356<br />

246<br />

394<br />

261<br />

447<br />

280<br />

47<br />

27<br />

50<br />

28<br />

54<br />

30<br />

25<br />

18<br />

28<br />

20<br />

32<br />

21<br />

18<br />

15<br />

20<br />

16<br />

24<br />

17<br />

15<br />

13<br />

16<br />

14<br />

19<br />

15<br />

7.0<br />

1056<br />

783<br />

1090<br />

844<br />

1132<br />

927<br />

689<br />

477<br />

753<br />

515<br />

836<br />

575<br />

522<br />

371<br />

575<br />

405<br />

651<br />

450<br />

424<br />

310<br />

469<br />

337<br />

534<br />

379<br />

59<br />

48<br />

63<br />

52<br />

68<br />

58<br />

32<br />

28<br />

35<br />

30<br />

41<br />

34<br />

23<br />

21<br />

25<br />

23<br />

29<br />

26<br />

18<br />

17<br />

20<br />

19<br />

23<br />

21<br />

8.6<br />

1158<br />

1071<br />

1192<br />

1181<br />

1234<br />

1241<br />

787<br />

606<br />

859<br />

666<br />

954<br />

749<br />

594<br />

462<br />

659<br />

507<br />

742<br />

572<br />

484<br />

379<br />

534<br />

416<br />

606<br />

469<br />

71<br />

68<br />

76<br />

75<br />

81<br />

81<br />

38<br />

36<br />

42<br />

40<br />

49<br />

46<br />

26<br />

27<br />

30<br />

30<br />

35<br />

34<br />

20<br />

21<br />

23<br />

24<br />

27<br />

27<br />

10.0<br />

1245<br />

1253<br />

1287<br />

1287<br />

—<br />

—<br />

871<br />

719<br />

950<br />

795<br />

1037<br />

901<br />

662<br />

541<br />

731<br />

598<br />

821<br />

678<br />

537<br />

439<br />

594<br />

484<br />

674<br />

553<br />

83<br />

83<br />

88<br />

88<br />

—<br />

—<br />

43<br />

44<br />

49<br />

49<br />

57<br />

56<br />

30<br />

32<br />

34<br />

36<br />

40<br />

41<br />

23<br />

25<br />

26<br />

29<br />

31<br />

33<br />

12.0<br />

—<br />

—<br />

—<br />

---<br />

—<br />

—<br />

946<br />

821<br />

1022<br />

908<br />

1113<br />

1033<br />

719<br />

613<br />

795<br />

678<br />

897<br />

772<br />

583<br />

496<br />

647<br />

549<br />

734<br />

625<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

49<br />

51<br />

56<br />

57<br />

65<br />

65<br />

34<br />

37<br />

38<br />

41<br />

45<br />

48<br />

26<br />

29<br />

29<br />

33<br />

34<br />

38<br />

14.0<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

1014<br />

916<br />

1086<br />

1014<br />

1177<br />

1162<br />

776<br />

678<br />

855<br />

753<br />

965<br />

859<br />

628<br />

545<br />

696<br />

606<br />

791<br />

693<br />

—<br />

—<br />

—<br />

—<br />

—<br />

—<br />

55<br />

57<br />

63<br />

64<br />

74<br />

74<br />

37<br />

41<br />

42<br />

46<br />

50<br />

53<br />

28<br />

32<br />

32<br />

36<br />

38<br />

42<br />

15.5<br />

---<br />

---<br />

—<br />

---<br />

---<br />

—<br />

1071<br />

999<br />

1147<br />

1109<br />

1241<br />

1245<br />

825<br />

738<br />

912<br />

818<br />

1018<br />

939<br />

670<br />

594<br />

742<br />

659<br />

844<br />

753<br />

17.0<br />

PUMP DISCHARGE PRESSURE (bar)<br />

---<br />

---<br />

---<br />

---<br />

---<br />

---<br />

61<br />

63<br />

70<br />

70<br />

82<br />

82<br />

40<br />

45<br />

46<br />

51<br />

55<br />

59<br />

30<br />

35<br />

35<br />

40<br />

41<br />

46<br />

CAUTION: Changing to Low Pressure mode will typically increase nozzle reaction.<br />

(1) Number on top of each box indicates flow (GPM), and number on bottom indicates nozzle reaction (LBS). (2) In Standard mode, the average nozzle pressure is 100<br />

PSI. (3) Flows may vary with brand or condition of hose. (4) Flows are approximate and do not reflect losses in preconnect piping.<br />

13

14<br />

For Nozzles with: Serial # <strong>TFT</strong>-H465101 and over or Manufactured after 12/01/2003<br />

75/45 PSI<br />

=STANDARDPRESSUREMODE<br />

= LOW PRESSURE MODE<br />

STD<br />

LP<br />

Flow And Nozzle Reaction Chart<br />

2 1/2" HOSE<br />

1 1/2" HOSE 1 3/4" HOSE 2" HOSE<br />

150 ft. 200 ft 250 ft.<br />

150 ft. 200 ft 250 ft. 150 ft. 200 ft 250 ft. 150 ft.<br />

200 ft<br />

250 ft.<br />

STD LP STD LP STD LP<br />

STD LP STD LP STD LP STD LP STD LP STD LP STD LP STD LP STD LP<br />

FLOW<br />

(GPM)<br />

REACTION<br />

(LBS)<br />

140<br />

53<br />

148<br />

53<br />

157<br />

53<br />

88<br />

50<br />

96<br />

51<br />

107<br />

51<br />

70<br />

48<br />

75<br />

49<br />

84<br />

50<br />

60<br />

45<br />

65<br />

47<br />

71<br />

48<br />

45<br />

18<br />

48<br />

19<br />

52<br />

19<br />

26<br />

17<br />

29<br />

17<br />

33<br />

18<br />

20<br />

15<br />

22<br />

16<br />

25<br />

17<br />

16<br />

14<br />

18<br />

15<br />

20<br />

16<br />

50<br />

212<br />

111<br />

221<br />

116<br />

230<br />

123<br />

133<br />

76<br />

145<br />

81<br />

162<br />

88<br />

101<br />

63<br />

112<br />

67<br />

126<br />

73<br />

82<br />

58<br />

91<br />

60<br />

104<br />

64<br />

77<br />

46<br />

83<br />

49<br />

89<br />

52<br />

42<br />

31<br />

47<br />

33<br />

54<br />

36<br />

30<br />

25<br />

34<br />

26<br />

39<br />

29<br />

24<br />

22<br />

27<br />

23<br />

31<br />

25<br />

75<br />

251<br />

206<br />

260<br />

224<br />

269<br />

252<br />

166<br />

121<br />

182<br />

132<br />

203<br />

148<br />

126<br />

93<br />

139<br />

103<br />

157<br />

115<br />

103<br />

77<br />

114<br />

85<br />

130<br />

96<br />

105<br />

92<br />

112<br />

101<br />

120<br />

114<br />

56<br />

51<br />

63<br />

57<br />

72<br />

64<br />

39<br />

38<br />

44<br />

42<br />

52<br />

48<br />

31<br />

31<br />

35<br />

34<br />

41<br />

39<br />

100<br />

281<br />

282<br />

290<br />

290<br />

300<br />

300<br />

194<br />

158<br />

212<br />

173<br />

232<br />

197<br />

147<br />

119<br />

162<br />

131<br />

183<br />

149<br />

120<br />

98<br />

133<br />

108<br />

151<br />

122<br />

131<br />

131<br />

140<br />

140<br />

150<br />

150<br />

68<br />

69<br />

77<br />

76<br />

90<br />

88<br />

48<br />

50<br />

54<br />

56<br />

63<br />

64<br />

37<br />

40<br />

42<br />

45<br />

49<br />

52<br />

125<br />

307<br />

307<br />

335<br />

317<br />

341<br />

343<br />

218<br />

189<br />

234<br />

210<br />

256<br />

239<br />

165<br />

141<br />

182<br />

156<br />

206<br />

177<br />

135<br />

115<br />

149<br />

124<br />

170<br />

145<br />

157<br />

157<br />

173<br />

167<br />

185<br />

185<br />

81<br />

84<br />

92<br />

94<br />

108<br />

108<br />

55<br />

61<br />

63<br />

68<br />

74<br />

78<br />

43<br />

48<br />

48<br />

54<br />

57<br />

63<br />

150<br />

342<br />

343<br />

348<br />

349<br />

355<br />

356<br />

236<br />

217<br />

255<br />

242<br />

276<br />

276<br />

182<br />

160<br />

201<br />

178<br />

225<br />

203<br />

148<br />

130<br />

164<br />

144<br />

187<br />

165<br />

186<br />

186<br />

197<br />

198<br />

209<br />

210<br />

94<br />

98<br />

108<br />

109<br />

127<br />

127<br />

63<br />

70<br />

71<br />

79<br />

86<br />

91<br />

48<br />

56<br />

55<br />

62<br />

65<br />

72<br />

175<br />

354<br />

356<br />

361<br />

362<br />

368<br />

369<br />

254<br />

243<br />

272<br />

270<br />

295<br />

295<br />

197<br />

178<br />

217<br />

198<br />

241<br />

227<br />

160<br />

144<br />

178<br />

160<br />

202<br />

183<br />

209<br />

210<br />

221<br />

222<br />

234<br />

235<br />

107<br />

110<br />

123<br />

123<br />

145<br />

145<br />

70<br />

79<br />

80<br />

88<br />

98<br />

102<br />

53<br />

62<br />

61<br />

70<br />

72<br />

81<br />

200<br />

367<br />

368<br />

373<br />

375<br />

—<br />

—<br />

269<br />

266<br />

288<br />

289<br />

313<br />

312<br />

211<br />

195<br />

231<br />

216<br />

257<br />

249<br />

172<br />

157<br />

190<br />

174<br />

216<br />

200<br />

232<br />

232<br />

245<br />

245<br />

—<br />

—<br />

120<br />

121<br />

138<br />

138<br />

163<br />

163<br />

77<br />

87<br />

90<br />

97<br />

109<br />

113<br />

58<br />

68<br />

66<br />

77<br />

80<br />

89<br />

225<br />

378<br />

380<br />

—<br />

—<br />

---<br />

---<br />

284<br />

284<br />

304<br />

304<br />

336<br />

329<br />

223<br />

210<br />

244<br />

234<br />

271<br />

269<br />

182<br />

169<br />

202<br />

188<br />

229<br />

216<br />

250<br />

PUMP DISCHARGE PRESSURE (PSI)<br />

255<br />

255<br />

---<br />

---<br />

---<br />

---<br />

134<br />

133<br />

154<br />

154<br />

180<br />

181<br />

85<br />

94<br />

99<br />

106<br />

122<br />

123<br />

63<br />

74<br />

72<br />

83<br />

88<br />

97<br />

CAUTION: Changing to Low Pressure mode will typically increase nozzle reaction.<br />

(1) Number on top of each box indicates flow (GPM), and number on bottom indicates nozzle reaction (LBS). (2) In Standard mode, the average nozzle pressure is 100<br />

PSI. (3) Flows may vary with brand or condition of hose. (4) Flows are approximate and do not reflect losses in preconnect piping.

For Nozzles with: Serial # <strong>TFT</strong>-H465101 and over or Manufactured after 12/01/2003<br />

5/3 BAR<br />

=STANDARDPRESSUREMODE<br />

= LOW PRESSURE MODE<br />

7 bar<br />

LP<br />

Flow And Nozzle Reaction Chart<br />

64mm HOSE<br />

38mm HOSE 45mm HOSE 50mm HOSE<br />

45M 60M 75M<br />

45M 60M 75M 45M 60M 75M 45M 60M 75M<br />

5 bar LP 5 bar LP 5 bar LP 5 bar LP 5 bar LP 5 bar LP 5 bar LP 5 bar LP 5 bar LP 7 bar LP 5 bar LP 5 bar LP<br />

FLOW<br />

(l/min)<br />

REACTION<br />

(KG)<br />

530<br />

201<br />

560<br />

201<br />

594<br />

201<br />

333<br />

189<br />

363<br />

193<br />

405<br />

193<br />

265<br />

182<br />

284<br />

185<br />

318<br />

189<br />

227<br />

170<br />

246<br />

178<br />

269<br />

182<br />

20<br />

8<br />

22<br />

9<br />

24<br />

9<br />

12<br />

8<br />

13<br />

8<br />

15<br />

8<br />

9<br />

7<br />

10<br />

7<br />

11<br />

8<br />

7<br />

6<br />

8<br />

7<br />

8<br />

7<br />

3.5<br />

802<br />

420<br />

836<br />

439<br />

871<br />

466<br />

503<br />

288<br />

549<br />

307<br />

613<br />

333<br />

382<br />

238<br />

424<br />

254<br />

477<br />

276<br />

310<br />

220<br />

344<br />

227<br />

394<br />

242<br />

35<br />

21<br />

38<br />

22<br />

40<br />

24<br />

19<br />

14<br />

21<br />

15<br />

24<br />

16<br />

14<br />

11<br />

15<br />

12<br />

18<br />

13<br />

11<br />

10<br />

12<br />

10<br />

14<br />

11<br />

5.2<br />

950<br />

780<br />

984<br />

848<br />

1018<br />

954<br />

628<br />

458<br />

689<br />

500<br />

768<br />

560<br />

477<br />

352<br />

526<br />

390<br />

594<br />

435<br />

390<br />

291<br />

431<br />

322<br />

492<br />

363<br />

48<br />

42<br />

51<br />

46<br />

54<br />

52<br />

25<br />

23<br />

29<br />

26<br />

33<br />

29<br />

18<br />

17<br />

20<br />

19<br />

24<br />

22<br />

14<br />

14<br />

16<br />

15<br />

19<br />

18<br />

7.0<br />

1064<br />

1067<br />

1098<br />

1098<br />

1136<br />

1136<br />

734<br />

598<br />

802<br />

655<br />

878<br />

746<br />

556<br />

450<br />

613<br />

496<br />

693<br />

564<br />

454<br />

371<br />

503<br />

409<br />

572<br />

462<br />

59<br />

59<br />

64<br />

64<br />

68<br />

68<br />

31<br />

31<br />

35<br />

34<br />

41<br />

40<br />

22<br />

23<br />

24<br />

25<br />

29<br />

29<br />

17<br />

18<br />

19<br />

20<br />

23<br />

24<br />

8.6<br />

1162<br />

1162<br />

1268<br />

1200<br />

1291<br />

1298<br />

825<br />

715<br />

886<br />

795<br />

969<br />

905<br />

625<br />

534<br />

689<br />

590<br />

780<br />

670<br />

511<br />

435<br />

564<br />

481<br />

643<br />

549<br />

71<br />

71<br />

78<br />

76<br />

84<br />

84<br />

37<br />

38<br />

42<br />

43<br />

49<br />

49<br />

25<br />

28<br />

29<br />

31<br />

34<br />

35<br />

20<br />

22<br />

22<br />

24<br />

27<br />

29<br />

10.0<br />

1294<br />

1298<br />

1317<br />

1321<br />

1344<br />

1347<br />

893<br />

821<br />

965<br />

916<br />

1045<br />

1045<br />

689<br />

606<br />

761<br />

674<br />

852<br />

768<br />

560<br />

492<br />

621<br />

545<br />

708<br />

625<br />

84<br />

84<br />

89<br />

90<br />

95<br />

95<br />

43<br />

44<br />

49<br />

49<br />

58<br />

58<br />

29<br />

32<br />

32<br />

36<br />

39<br />

41<br />

22<br />

25<br />

25<br />

28<br />

31<br />

33<br />

12.0<br />

1340<br />

1347<br />

1366<br />

1370<br />

1393<br />

1397<br />

961<br />

920<br />

1030<br />

1022<br />

1117<br />

1117<br />

746<br />

674<br />

821<br />

749<br />

912<br />

859<br />

606<br />

545<br />

674<br />

606<br />

765<br />

693<br />

95<br />

95<br />

100<br />

101<br />

106<br />

107<br />

49<br />

50<br />

56<br />

56<br />

66<br />

66<br />

32<br />

36<br />

36<br />

40<br />

44<br />

46<br />

24<br />

28<br />

28<br />

32<br />

34<br />

37<br />

14.0<br />

1389<br />

1393<br />

1412<br />

1419<br />

—<br />

—<br />

1018<br />

1007<br />

1090<br />

1094<br />

1185<br />

1181<br />

799<br />

738<br />

874<br />

818<br />

973<br />

942<br />

651<br />

594<br />

719<br />

659<br />

818<br />

757<br />

105<br />

105<br />

111<br />

111<br />

—<br />

—<br />

54<br />

55<br />

63<br />

63<br />

74<br />

74<br />

35<br />

39<br />

41<br />

44<br />

49<br />

51<br />

26<br />

31<br />

30<br />

35<br />

38<br />

40<br />

15.5<br />

1431<br />

1438<br />

—<br />

---<br />

---<br />

—<br />

1075<br />

1075<br />

1151<br />

1151<br />

1272<br />

1245<br />

844<br />

795<br />

924<br />

886<br />

1026<br />

1018<br />

689<br />