REFINERY NEWS May 2012

REFINERY NEWS May 2012

REFINERY NEWS May 2012

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

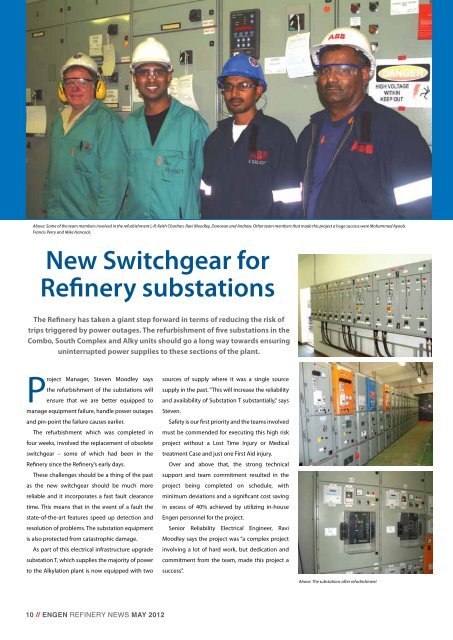

Above: Some of the team members involved in the refurbishment L-R: Keith Charlton, Ravi Moodley, Donovan and Andrew. Other team members that made this project a huge success were Mohammed Ayoob,<br />

Francis Perry and Mike Hancock.<br />

New Switchgear for<br />

Refinery substations<br />

The Refinery has taken a giant step forward in terms of reducing the risk of<br />

trips triggered by power outages. The refurbishment of five substations in the<br />

Combo, South Complex and Alky units should go a long way towards ensuring<br />

uninterrupted power supplies to these sections of the plant.<br />

Project Manager, Steven Moodley says<br />

the refurbishment of the substations will<br />

ensure that we are better equipped to<br />

manage equipment failure, handle power outages<br />

and pin-point the failure causes earlier.<br />

The refurbishment which was completed in<br />

four weeks, involved the replacement of obsolete<br />

switchgear – some of which had been in the<br />

Refinery since the Refinery’s early days.<br />

These challenges should be a thing of the past<br />

as the new switchgear should be much more<br />

reliable and it incorporates a fast fault clearance<br />

time. This means that in the event of a fault the<br />

state-of-the-art features speed up detection and<br />

resolution of problems. The substation equipment<br />

is also protected from catastrophic damage.<br />

As part of this electrical infrastructure upgrade<br />

substation T, which supplies the majority of power<br />

to the Alkylation plant is now equipped with two<br />

sources of supply where it was a single source<br />

supply in the past. “This will increase the reliability<br />

and availability of Substation T substantially,” says<br />

Steven.<br />

Safety is our first priority and the teams involved<br />

must be commended for executing this high risk<br />

project without a Lost Time Injury or Medical<br />

treatment Case and just one First Aid injury.<br />

Over and above that, the strong technical<br />

support and team commitment resulted in the<br />

project being completed on schedule, with<br />

minimum deviations and a significant cost saving<br />

in excess of 40% achieved by utilizing in-house<br />

Engen personnel for the project.<br />

Senior Reliability Electrical Engineer, Ravi<br />

Moodley says the project was “a complex project<br />

involving a lot of hard work, but dedication and<br />

commitment from the team, made this project a<br />

success”.<br />

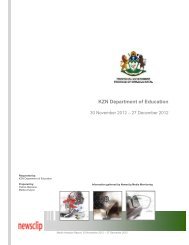

Above: The substations after refurbishment<br />

10 // engen Refinery news <strong>May</strong> <strong>2012</strong>