Vaderstad Rollers Brochure - LiveUpdater

Vaderstad Rollers Brochure - LiveUpdater

Vaderstad Rollers Brochure - LiveUpdater

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

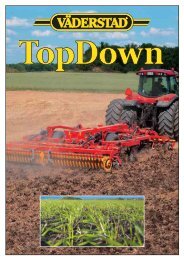

Better tillage methods<br />

The main operations of the Rexius roller are crushing clods<br />

and levelling ploughed land. By equipping the Rexius roller<br />

with Crosskill rings and the Crossboard you are in command<br />

of a superior soil preparation system of the highest calibre<br />

available. Even on the toughest soils the Rexius roller still<br />

creates an excellent tilth as a part of various tillage combinations.<br />

In these extreme conditions it is highly recommended<br />

to use the stabilising rod for producing the best level finish<br />

possible. The heavy duty Crossboard levelling board can be<br />

locked together with stabilising rod and can be equipped<br />

with Single-Knife.<br />

Levelling efficiency<br />

The Rexius rollers and tool-bars have been developed with<br />

the Rapid tillage concept in mind and versatility available<br />

with this range will virtually suit all of your requirements.<br />

Hook your Rexius Roller behind your cultivator and you<br />

have a valuable tillage train.

Hang the roller on behind<br />

A following Crosskill roller combines<br />

efficient tillage with uniform<br />

soil firming and few passes, equally<br />

relevant in both spring and<br />

autumn. Thanks to the Crosskill<br />

rings, the roller has a unique ability<br />

to keep clean even when the soil is<br />

relatively wet, as is often the case<br />

immediately after cultivator, stubbble<br />

cultivator or disc tillage. This<br />

makes the roller a versatile multitasker.<br />

Roll after spring sowing<br />

Rolling in the spring after drilling<br />

with the Rexius roller equipped<br />

with Crosskill rings ensures stones<br />

are pushed down into the soil, and<br />

that optimal conditions are created<br />

for germination around the seed.<br />

The surface is also left in a porous<br />

state, which prevents silting-up<br />

after heavy rain.<br />

Roll autumn-sown crops in<br />

spring<br />

The unique design of the Crosskill<br />

rings helps to break up capped<br />

autumn drilled soils in the spring,<br />

and exposes delicate root systems<br />

to the air to stimulate growth.<br />

Stones are also pushed beneath the<br />

soil surface.<br />

Large stone trays<br />

With two stone trays on each side,<br />

rolling can be accompanied by efficient<br />

stone lifting. The stone trays<br />

are very roomy since each can hold<br />

more than 1000 litres. This allows<br />

the driver to concentrate on the<br />

task of rolling rather on constantly<br />

reversing out to the edge of the<br />

field to empty the stone trays. A<br />

small detail that further increases<br />

capacity on busy days. When the<br />

stone trays eventually fill up, the<br />

entire roller is simply tipped back<br />

in a suitable spot and the trays are<br />

emptied. All this is done hydraulically<br />

from the tractor cab.

Folding or unfolding<br />

– both are easy<br />

The change between transport<br />

and field work is strikingly<br />

simple and can be<br />

effected without the driver<br />

having to leave the tractor<br />

cab. The transport locks on<br />

the rollers are automatically<br />

engaged and released during<br />

folding and unfolding.<br />

Unfolding to working mode<br />

1. The central section is lowered<br />

and the transport locks released<br />

2. The tractor is reversed<br />

3. After a few metres, the roller is<br />

unfolded and lowered forward<br />

4. Ready for work<br />

8. The roller is automatically locked<br />

and is ready for transport<br />

7. Drive the tractor forwards 6.Tilt the roller 90° backwards 5. Stop the tractor<br />

and back to transport mode

Rexius Packer broadens the horizon<br />

A Rexius Packer after a Cultus stubble cultivator or an NZ-cultivator<br />

crushes clods and firms the soil efficiently. In stubble tillage,<br />

this soil firming produces optimal conditions for the germination<br />

of weeds and volunteer plants. In a second pass with a<br />

stubble implement, these are effectively eliminated. On ploughed<br />

soil, Rexius Packer crushes clods and levels the surface so<br />

that the best possible conditions are created for the new crop.<br />

Attached by its long towbar, the Rexius Packer follows<br />

smoothly behind the toolbar during work and transport.<br />

Thanks to Väderstad’s patented folding system, the Rexius<br />

Packer has a transport width of only 3 m.<br />

Rexius Packer is available in 5.0 and 6.0 m widths.<br />

Attached by its long towbar, the Rexius Packer follows<br />

smoothly behind the toolbar during work and transport.<br />

Thanks to Väderstad’s patented folding system, the<br />

Rexius Packer has a transport width of only 3 m.

Rollex rollers are among the vanguard in<br />

Väderstad’s comprehensive range of soil<br />

tillage and drilling equipment<br />

The first Väderstad rollers were manufactured back in 1977<br />

and the Rollex range saw the light of day in 1986.<br />

Simple and ingenious<br />

Since 1977 there has been a continuous stream of improvements.<br />

The construction of the Rollex rollers has been refined<br />

over the years and is now both simple and ingenious at<br />

the same time. Rollex rollers are of the highest quality. The<br />

rubber mounted bearings give the rollers a gentle and<br />

smooth ride while increasing the lifetime compared to<br />

rollers that do not have this rubber based suspension<br />

system.<br />

Even rolling performance<br />

The loading is uniform on each section of the roller, which<br />

produces a rolling effect that is even across the entire<br />

working width. The Rollex roller provides the foundation on<br />

which to build the harvest!

Broad area of use<br />

The Rexius roller is a heavy and universal roller with a<br />

broad area of use. The roller can be used with the<br />

equipment Crossboard levelling board both in spring<br />

and autumn for preparing a seedbed or as an ordinary<br />

roller after spring drilling. Hook your roller behind the<br />

cultivator, disc implement or the stubble cultivator -<br />

there are a lot of combination possibilities.<br />

Economical and biological advantages<br />

The Rexius roller is complimentary to most other<br />

implements. This provides a greater level of intensity<br />

and productivity with every pass across the field creating<br />

extensive savings of time and costly energy while<br />

also reducing traffic.The reduction of passes from the<br />

time of combining through to establishing a new crop is<br />

biologically and economically advantageous. Not only<br />

is the cost of tillage reduced but also the time requirement.<br />

The soil is therefore less compacted and both<br />

spring and autumn sowing can often take place earlier.<br />

This will also result in increased permeability of water<br />

due to greater pores, which are invaluable in early<br />

droughts.

The Rexius 1230 is a large roller ideal for farmers who<br />

place high demands on capacity and work rate, but<br />

who are not prepared to compromise on the quality of<br />

their rolling. The large roller is heavy and does a first<br />

class job even at high rolling speeds. Thanks to the<br />

unique rubber suspension in which every roller<br />

section is mounted, the roller has a ‘floating’ ride and<br />

unique stability and durability. The rubber suspension<br />

absorbs and ‘swallows’ impacts and vibrations that<br />

would otherwise be transmitted through the bearings<br />

and cause unnecessary wear, with breakages and<br />

stoppages as a result.<br />

The importance of rolling for many farmers is well documented<br />

through years of experience. Rolling is effective<br />

in giving uniform emergence after spring drilling, firming<br />

in winter crops in the spring, producing good soil/root<br />

contact and pressing down stones that can otherwise<br />

cause problems for the combine during harvesting.<br />

Rolling direct after ploughing is another task for a powerful<br />

roller that can save many later passes with other<br />

tillage implements. With the new working width of over<br />

12 metres, the Rexius 1230 fits in perfectly on farms<br />

where 12 or 24 metre tramlines are being used in field<br />

operations.<br />

The Rexius 1230 is constructed on the same principles as<br />

the other members of the Rexius range. This means a<br />

very robust and powerful construction with strong joints<br />

and framework. The weight is over 450 kg per metre<br />

working width, compared with 400 kg/m for previous<br />

Rexius rollers.

Contouring<br />

The roller sections are freely jointed relative to each<br />

other and the construction allows large ruts in the field<br />

to be dealt with while still maintaining the good contouring<br />

ability. The weight of the roller also contributes to<br />

the excellent contouring at high driving speeds.

Protect emergence<br />

Crop production advisor Henrik Lillje in a trial on hard crusts at<br />

Brunnby Research Farm outside Västerås, Sweden, at the boundary<br />

between an untreated plot and a plot where the crust was<br />

broken using a Rexius roller with Double-Knife attachment.<br />

Rain between drilling and emergence can completely<br />

compromise crop emergence if a crust forms. In that<br />

event, a rapid and determined response is needed to<br />

protect emergence and ensure crop survival. Two<br />

trials at Brunnby Research Farm in Sweden in 2003<br />

showed the importance of always breaking up a crust.<br />

The spring began well at Brunnby and the barley on<br />

both fields was drilled on 23 and 25 of April. The foundations<br />

were laid for a good harvest. Then came the<br />

rain and within the space of 10 days over 50 mm of rain<br />

had fallen.<br />

Two types of crust<br />

On soils with a silt component, a crust always develops<br />

as a predictable reaction to rain after drilling.<br />

Everyone knows that. But few actually know how much<br />

yield loss this crust causes, since it is difficult to get<br />

reliable measurements. Therefore during an advisory<br />

field visit at the beginning of May, the idea arose of<br />

measuring the impeding effects of such a crust. Two<br />

trials were laid out on different soils. One of these was<br />

a heavy clay with 3.4% humus. On this, the crust that<br />

developed was brittle and crisp.<br />

‘You could see footprints when someone walked on the<br />

soil’, explains Henrik Lillje, crop production advisor for<br />

a Swedish agricultural advice service and the initiator<br />

of the trials.<br />

The other soil was a poor medium clay with only 1.9%<br />

humus but with a large silt fraction.<br />

‘Here the entire seedbed became a compact crust’ says<br />

Henrik Lillje.<br />

Four treatments<br />

Four treatments were applied in addition to the untreated<br />

plot. A Rexius roller with Crosskill rings was used<br />

with and without the crust-breaking Double-Knife<br />

attachments mounted on the levelling board. In addition,<br />

an ordinary NZ cultivator and a converted Wiberg<br />

cultivator with three rows of following harrow tines<br />

were tested. All treatments were carried out on 15 May<br />

and their effects were soon apparent.<br />

‘The trapped seedlings began to grow again when we<br />

aerated the soil with some form of treatment’, reports<br />

Henrik Lillje. And when the time came to harvest the<br />

barley, the summer recovery was apparent in the<br />

combine bins in the plots where the crust had been<br />

broken. In the trial with the brittle crust, all treatments<br />

produced a 14 - 15% yield increase.<br />

‘The yield outcome was better than we expected. The<br />

results show that one should always take action as<br />

soon as crusting is suspected’, advises Henrik Lillje.<br />

Crop failure prevented<br />

In the trial with the hard crust, the improvement was<br />

huge and the yield increased from the crop failure level<br />

to almost a normal level in some of the plots. The conclusion<br />

is that it is better to do something than to wait<br />

and do nothing at all.<br />

‘The essential thing is to improve gas exchange for the<br />

seedlings trapped under the crust’, explains Henrik<br />

Lillje.<br />

The best results were obtained with the crust breaking<br />

Double-Knife tool, which had to face this stiff challenge<br />

in only its first year on the market.<br />

‘The crust-breaker knife is an excellent crust-breaking<br />

tool. The advantage with Double-Knife is that it is<br />

possible to apply hard cultivation without ripping up<br />

the soil because the movement is directed frontwardsbackwards’<br />

comments Henrik Lillje.<br />

Rexius surprising<br />

The NZ cultivator was poorly set up and should have<br />

gone deeper, so it did not do itself justice. However, the<br />

excellent abilities of the Rexius roller emerged even<br />

without the crust-breaking Double-Knife on the levelling<br />

board.<br />

‘One pass with the Rexius roller only made faint tracks<br />

on the surface but more than doubled the yield!’<br />

The best advice for growers is to always react in some<br />

way and to never delay.<br />

‘Always break up a crust – hit it hard with whatever is<br />

available on the farm’, concludes Henrik Lillje.

– break soil crusts<br />

Yield, kg/ha<br />

5000<br />

4500<br />

4000<br />

3500<br />

3000<br />

2500<br />

2000<br />

1500<br />

1000<br />

500<br />

0<br />

Hard crust – from crop failure to normal harvest with Double-Knife<br />

340<br />

100<br />

1354 kg/ha<br />

Untreated<br />

216<br />

2931 kg/ha<br />

Rexius roller<br />

with Crosskill<br />

rings<br />

269<br />

3644 kg/ha<br />

Wiberg cultivator,<br />

3 rows of following<br />

harrow tines<br />

4605 kg/ha<br />

Rexius roller with<br />

the crust-breaking<br />

Double-Knife<br />

274<br />

3705 kg/ha<br />

NZ cultivator<br />

Yield, kg/ha<br />

5000<br />

4500<br />

4000<br />

3500<br />

3000<br />

2500<br />

2000<br />

1500<br />

1000<br />

500<br />

0<br />

100<br />

3924 kg/ha<br />

Untreated<br />

Brittle crust – surprisingly large end result<br />

114<br />

4471 kg/ha<br />

Rexius roller with<br />

Crosskill rings<br />

114<br />

4455 kg/ha<br />

Wiberg cultivator, 3<br />

rows of following<br />

harrow tines<br />

115<br />

4501 kg/ha<br />

Rexius roller with the<br />

crust-breaking<br />

Double-Knife

Rubber suspension<br />

The rubber suspension is a unique<br />

construction from Väderstad that<br />

gives the roller unbeatable durability<br />

through the ability of the<br />

rubber to absorb vibrations and<br />

impacts. The rubber suspension is<br />

very hard-wearing and maintenance<br />

free.<br />

Multiple sealed bearings<br />

The bearings are designed and<br />

manufactured for long life under<br />

tough conditions. The bearings are<br />

mounted in a rubber-sprung<br />

bearings chamber. The bearings<br />

have multiple seals and can be lubricated,<br />

for long life in dusty and<br />

demanding environments. The roller<br />

axle, which is 55 mm in diameter, is<br />

manufactured from microalloyed<br />

steel of high quality.<br />

Hard metal bushes in<br />

joints<br />

All wing joints are equipped with<br />

hard metal bushes and hardened<br />

joint bolts. The whole joint can also<br />

be lubricated for an unrivalled<br />

length of life. The joint is also wide,<br />

with large joint surfaces to reduce<br />

the load on the materials.<br />

Robust frame<br />

The basic frame is constructed<br />

around heavy rectangular profile<br />

steel with dimensions 200x100x6<br />

mm and with a high steel quality.<br />

The rigidity is impressive and<br />

imparts great stability to the<br />

construction. The entire frame is<br />

all-welded to avoid having loose<br />

bolt connections exposed to the<br />

wear that can occur during high<br />

speed work.<br />

200 mm<br />

100 mm 6 mm

BioDrill<br />

With BioDrill on a Väderstad roller,<br />

grass leys, catch crops and other<br />

small-seeded crops can be drilled.<br />

This saves passes, time and money.<br />

The seeds are metered out by the<br />

tried and tested Fenix system with<br />

great precision. The seed nozzles<br />

are placed in front of the roller unit<br />

and give uniform broadcasting. The<br />

seeds are buried by the roller in the<br />

upper 2 centimetres, where the<br />

conditions for germination are<br />

best.<br />

Automatic locking device<br />

The locks open automatically when the<br />

central section of the roller is lowered.<br />

During transport, when the central<br />

section is raised, the locks engage and<br />

prevent accidental unfolding of the<br />

roller during reversing.<br />

Rigid stabiliser<br />

The powerful Crossboard levelling<br />

board has a heavy stabiliser bar of<br />

very high spring steel quality with a<br />

breaking point of over 1100 N/mm2<br />

and provides a very thorough<br />

levelling effect on even the heaviest<br />

and most difficult clay soils.<br />

Single-Knife or<br />

Double-Knife<br />

To further enhance the cultivating<br />

and crushing effect of the<br />

Crossboard, it can be fitted with<br />

sharp, hardened steel blades called<br />

Single-Knife. The crust breaking<br />

Double-Knife blades break through<br />

the surface pans that readily develop<br />

on silty soils after heavy rain.<br />

The most efficient crust-breaker<br />

available for a very light surface<br />

‘cracking’ is a pass with only the<br />

Crosskill rings working.

Technical data:<br />

Model/ Transp. No. of Wt kg Wt kg HP Wheel Wheel Hydraulic<br />

working width sections Crossk./Camb. Heavy Duty with dim dim outlet<br />

width, cm m incl Crossb. incl Crossb. Crossb Cam/CK Heavy Duty excl CB incl CB<br />

RS 650 2,5 3 3700 4700 70 - 120 400×15,5” 400×15,5”<br />

°<br />

°°<br />

RS 820<br />

RS 940<br />

RS 1020<br />

RS 1230**<br />

2,5<br />

2,5<br />

2,5<br />

2,5<br />

5<br />

5<br />

5<br />

5<br />

4700<br />

5100<br />

5400<br />

5560***<br />

6100<br />

6800<br />

7100<br />

_<br />

90 - 150<br />

100 - 170<br />

110 - 190<br />

100 - 140<br />

400×15,5"<br />

400×15,5"<br />

400×15,5"x4<br />

400×15,5”x4<br />

400×15,5"x4*<br />

400×15,5"x4*<br />

400×15,5"x4*<br />

_<br />

°<br />

°<br />

°<br />

°<br />

°°<br />

°°<br />

°°<br />

***<br />

RX 620 2,8 3 2800 _ 70 - 110 10.0/75-15,3" _<br />

°<br />

°°<br />

Wt kg, excl. CB Wheel Hydraulic outlet<br />

RSP 500 *** 2,5 3 3100 _ – 11,5x15,5" _<br />

°<br />

***<br />

RSP 650 2,5 3 4100 _ – 400x15,5" _<br />

°<br />

°°<br />

*Wheels mounted on bogie.<br />

**RS-1230 is only supplied with Cambridge rings. ***Cannot be fitted with Crossboard<br />

All draught recommendations are based on the power output of the tractor.<br />

Local conditions, for example sloping fields, can increase the draught considerably.<br />

Key to symbols:<br />

°<br />

One double-acting takeoff<br />

∅ 55 mm<br />

∅ 60 mm<br />

Cambridge rings<br />

The conventional Cambridge rings are best utilised<br />

when the Rexius roller is mostly working as a traditional<br />

roller e.g. after drilling or when pressing down<br />

stones.<br />

Heavy Duty rings<br />

During autumn conditions a heavy duty ring is more<br />

suitable on heavy soils or when a high degree of consolidation<br />

is required. Heavy duty rings are widely used<br />

throughout the continental Europe.<br />

∅ 55 mm<br />

Crosskill rings<br />

Crosskill rings have become very common because they<br />

do not only have the same properties as the Cambridge<br />

rings, but they also possess a range of additional and<br />

unique characteristics such as: They leave a loose and<br />

crusting-resistant soil surface, they crush clods efficiently,<br />

they are less likely to become clogged by wet soil and<br />

they ‘swallow’ light soils much better without leaving a<br />

puffy seedbed.<br />

VÄDERSTAD-VERKEN AB<br />

SE-590 21 VÄDERSTAD • Sweden<br />

Tel. +46 142 820 00 • Fax +46 142 820 10<br />

www.vaderstad.com<br />

Steel ring for Rexius Packer<br />

The hardened steel ring on the Rexius Packer efficiently<br />

firms the heaviest soils. On ploughed soil, clods are<br />

crushed with impressive power and a levelled seedbed is<br />

produced. The ring has particularly good abilities in wet<br />

conditions thanks to efficient scrapers. The steel rings<br />

are tightly screwed together on the axles and each ring<br />

acts as an effective disc spring, which makes any subsequent<br />

adjustment unnecessary.<br />

The manufacturer retains the right to alter any specifications and design without notice. Patented and patents pending.<br />

990513-ENVV Mjölby Tryckeri AB/Desktopteknik AB 2005.10