compact brazed heat exchanger b65 - Lyngson AS

compact brazed heat exchanger b65 - Lyngson AS compact brazed heat exchanger b65 - Lyngson AS

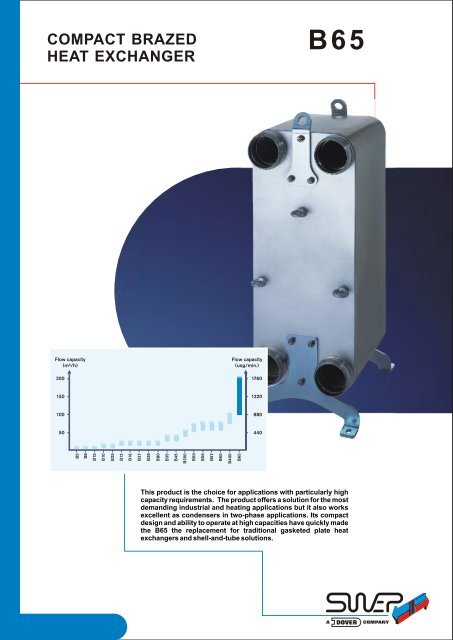

COMPACT BRAZED HEAT EXCHANGER B65 Flow capacity (m³/h) 200 Flow capacity (usg/min.) 1760 150 1320 100 880 50 440 B5 B8 B15 B10 B25 B12 B16 B27 B28 B80 B35 B45 B200 B50 B56 B57 B60 B400 B65 This product is the choice for applications with particularly high capacity requirements. The product offers a solution for the most demanding industrial and heating applications but it also works excellent as condensers in two-phase applications. Its compact design and ability to operate at high capacities have quickly made the B65 the replacement for traditional gasketed plate heat exchangers and shell-and-tube solutions.

COMPACT BRAZED<br />

HEAT EXCHANGER<br />

B65<br />

Flow capacity<br />

(m³/h)<br />

200<br />

Flow capacity<br />

(usg/min.)<br />

1760<br />

150<br />

1320<br />

100<br />

880<br />

50<br />

440<br />

B5<br />

B8<br />

B15<br />

B10<br />

B25<br />

B12<br />

B16<br />

B27<br />

B28<br />

B80<br />

B35<br />

B45<br />

B200<br />

B50<br />

B56<br />

B57<br />

B60<br />

B400<br />

B65<br />

This product is the choice for applications with particularly high<br />

capacity requirements. The product offers a solution for the most<br />

demanding industrial and <strong>heat</strong>ing applications but it also works<br />

excellent as condensers in two-phase applications. Its <strong>compact</strong><br />

design and ability to operate at high capacities have quickly made<br />

the B65 the replacement for traditional gasketed plate <strong>heat</strong><br />

<strong>exchanger</strong>s and shell-and-tube solutions.

B65<br />

864 mm (34.02 inch)<br />

731 mm (28.78 inch)<br />

363 mm (14.29 inch)<br />

231 mm (9.09 inch)<br />

F1 F2<br />

17.0+2.32xNP* mm<br />

(0.67+0.09xNP* inch)<br />

54.2 mm<br />

(2.13 inch)<br />

F1<br />

F2<br />

F3<br />

F4<br />

P1<br />

P2<br />

P3<br />

P4<br />

THE B LINE<br />

– OUR B<strong>AS</strong>IC RANGE<br />

The majority of SWEP's CBEs<br />

are classified as B-types. The B-<br />

types are suitable for most<br />

applications. Although the B-<br />

type CBEs are "standard", there<br />

is a huge variety of plate sizes,<br />

port sizes, plate pattern combinations,<br />

connections etc. And<br />

SWEP's unique plate design<br />

enables a virtually unlimited<br />

number of combinations in any<br />

given plate package execution to<br />

precisely match the thermal<br />

transfer requirements of your<br />

application.<br />

F3<br />

F4<br />

STANDARD CONNECTIONS<br />

For specific dimensions, or information about other types of connections, please<br />

contact your SWEP sales representative.<br />

Easy to choose the right<br />

product solution<br />

Externally<br />

threaded<br />

TECHNICAL DATA<br />

Max flow rate<br />

200 m³/h (881 usg/min.)<br />

Max working pressure at 155°C (311°F) 30 bar (435 psi)<br />

Max working pressure at 225°C (437°F) 26 bar (377 psi)<br />

Min working temperature<br />

-196°C (-321°F)<br />

Test pressure<br />

49 bar (711 psi)<br />

Max. Number of plates 300<br />

CBE weight dry (approx.)<br />

57.5+1.080×NP* kg (126.77+2.38×NP* lb)<br />

Hold-up volume: inner circuit<br />

0.590×(NP*/2-1) litre (0.156x(NP*/2-1) gal.)<br />

Hold-up volume: outer circuit<br />

0.590×NP*/2 litre (0.156x(NP*/2) gal.)<br />

Standard connection size<br />

DN100C<br />

Connection height<br />

54.2 mm (2.13 inch) or 112.2 mm (4.42 Inch)<br />

*NP = Number of plates<br />

Internally<br />

threaded<br />

Soldering<br />

Victaulic<br />

DNC Flanges<br />

With SWEP's unique SSP CBE,<br />

the SWEP Software Package,<br />

you can do advanced <strong>heat</strong><br />

transfer calculations yourself,<br />

and choose the product solution<br />

that suits your application best.<br />

It's also easy to choose connections<br />

and generate drawings of<br />

the complete product. If you<br />

would like advice, or you would<br />

like to discuss different product<br />

solutions, SWEP offers all the<br />

service and support you need.<br />

If you would like more information<br />

about B65 or our other<br />

products, please contact your<br />

local SWEP representative.<br />

MATERIAL<br />

Plate material: EN 10028/7-1.4401 (AlSI 316)<br />

Brazing material:<br />

Pure copper<br />

Connection material:<br />

EN10272 - 1.4401 (AlSI316) or EN10222 - 1.0305 (A106)<br />

THIRD-PARTY APPROVALS (selection)<br />

Europe, Pressure Equipment Directive (PED 97/23/EC)<br />

USA, Underwriters Laboratories (UL)<br />

USA, American Society of Mechanical Engineers (<strong>AS</strong>ME)<br />

Canada, Canadian Standard Association (CSA)<br />

Japan, The High Pressure Gas Safety Institute of Japan (KHK)<br />

For additional information please contact your local SWEP representative.<br />

SWEP reserves the right to make changes without prior notice<br />

Copyright SWEP January 2003 MC0209-04<br />

SWEP INTERNATIONAL AB<br />

Box 105, SE-261 22 Landskrona, Sweden<br />

Phone +46 418 540 00<br />

Fax +46 418 292 95<br />

Internet: www.swep.se<br />

E-mail: info@swep.se