NanoFlex™

NanoFlex™

NanoFlex™

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

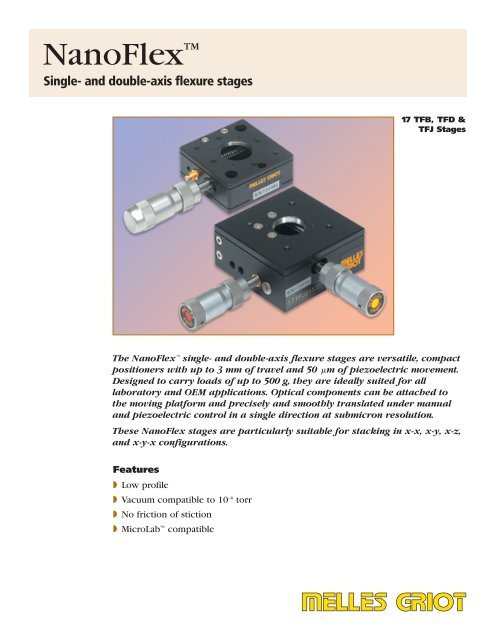

NanoFlex <br />

Single- and double-axis flexure stages<br />

17 TFB, TFD &<br />

TFJ Stages<br />

The NanoFlex single- and double-axis flexure stages are versatile, compact<br />

positioners with up to 3 mm of travel and 50 mm of piezoelectric movement.<br />

Designed to carry loads of up to 500 g, they are ideally suited for all<br />

laboratory and OEM applications. Optical components can be attached to<br />

the moving platform and precisely and smoothly translated under manual<br />

and piezoelectric control in a single direction at submicron resolution.<br />

These NanoFlex stages are particularly suitable for stacking in x-x, x-y, x-z,<br />

and x-y-x configurations.<br />

Features<br />

◗ Low profile<br />

◗ Vacuum compatible to 10 –6 torr<br />

◗ No friction of stiction<br />

◗ MicroLab compatible<br />

µ

NanoFlex Single-Axis Flexure Translation Stages<br />

Arcuate Resolution PZT PZT Load<br />

Travel Displacement (setting sensitivity) Travel Manual Pushing Force Capacity Weight PRODUCT NUMBER<br />

(mm) (mm) (nm) (mm) Drive (N) g (lb) g (lb) With PZT Without PZT<br />

1.5 15 50 25 Thumbscrew 50 300 (0.7) 90 (0.2) 17 TFB 001/T 17 TFB 011/T<br />

2 10 50 50 Thumbscrew 100 500 (1.1) 200 (0.4) 17 TFD 001/T –<br />

2 10 50 50 Differential Drive 100 500 (1.1) 200 (0.4) 17 TFD 001/D –<br />

3 35 2 50 Thumbscrew 100 500 (1.1) 425 (0.9) – –<br />

0.3 – 100 50 Differential Drive 100 500 (1) 425 (0.9) 17 TFJ 001/D 17 TFJ 011/D<br />

Optical Table Mounting Plate (3 counterbored holes at 25.4-mm spacing) 17 TFA 001<br />

Note: Piezoelectric drivers provided separately. NanoFlex stages are compatible with 17 PCS 001, 17 PCW 001, and 17 PCW 011 controllers.<br />

SMC<br />

connector<br />

3 x f4.5<br />

thru top<br />

5 x M2 x 2.5 deep<br />

in top<br />

SMC connector<br />

2 x f7.5 thru top<br />

34<br />

drive thread<br />

20<br />

M4 X 2.5 deep<br />

in top<br />

drive thread<br />

20<br />

6 x M4 x 4 deep<br />

both sides<br />

18 12.5<br />

20<br />

20<br />

M2 x 2 deep<br />

2 sides<br />

6 x M2 x 2.5 deep in base<br />

30<br />

2 x f4.3<br />

thru base<br />

4 x M2 x 3 deep<br />

both sides<br />

3 x f2.3 thru base<br />

dimensions in mm<br />

17 TFB 001/T NanoFlex single-axis compoundflexure<br />

stage<br />

dimensions in mm<br />

50<br />

RMS thread both sides<br />

VIEW A<br />

17 TFD 001/T NanoFlex single-axis flexure<br />

translation stage<br />

30<br />

3 x M6 x 3 deep<br />

2 sides<br />

34<br />

4 x M2 x 4.5<br />

deep both<br />

sides<br />

25<br />

RMS thread<br />

both sides<br />

65<br />

20<br />

VIEW A<br />

4 x M4 x 4.5<br />

deep<br />

both sides<br />

dimensions in mm<br />

17 TFJ 001/D NanoFlex dual-axis flexure<br />

translation stage<br />

µ<br />

www.mellesgriot.com<br />

USA 55 Science Parkway • Rochester, NY 14620 • 1-800-755-7558 • (585) 244-7220 • FAX (585) 244-6292 • E-mail: sales@rochester.mellesgriot.com<br />

Canada 2470 Don Reid Drive • Ottawa, ON K1H 1E1 • 1(800) 267-3497 • (613) 226-5880 • FAX (613) 226-5885 • E-mail: sales@canada.mellesgriot.com<br />

Europe St Thomas Place • Ely, Cambridgeshire CB7 4EX, UK • +44 (0)1353 654500 • FAX +44 (0)1353 654555 • E-mail: info.europe@mellesgriot.com<br />

Far East 3F Pine Building, 3-11-2 Shibuya • Shibuya-Ku, Tokyo 150-0002, Japan • +81 3-3407-3614 • FAX +81 3-3486-0923 • E-mail: sales@mgkk.com<br />

MELLES GRIOT ® is a registered trademark of Melles Griot Inc. in the United States and certain other countries.<br />

In France, Germany, Italy, Belgium, The Netherlands, and Luxembourg, MELLES GRIOT ® is a registered trademark of Melles Griot B.V.<br />

Melles Griot follows a policy of continuous product development. For this reason, specifications are subject to change without notice.<br />

PRINTED IN UK<br />

©2001 MELLES GRIOT<br />

MCE 1035 12/01

NanoFlex <br />

Single-axis compound-flexure translation stage<br />

17 TFC Series<br />

The NanoFlex single-axis compound-flexure stage provides ultrasmooth<br />

translation for optics and other component assemblies.<br />

Designed with compound linear flexures, the stage has no arcuate<br />

motion and provides highly stable, piezoelectric-controlled movement for<br />

interferometry, microscopy, biomedical, and other precision nanopositioning<br />

applications.<br />

The stability of the NanoFlex stage makes it suitable for stacking in x-x, and<br />

x-y configurations where precise planar movement is required.<br />

Features<br />

◗ 5-mm rectilinear manual travel<br />

◗ 20-mm piezoelectric travel<br />

◗ MicroLab compatible<br />

µ

Specifications:<br />

Construction<br />

Aluminum and steel athermalized design with<br />

silver satin finish; fully linearized compoundflexure<br />

construction<br />

Weight: 300 g (0.7 lb)<br />

Load Capacity: 1 kg (2.21 lb)<br />

Piezoelectric Pushing Force: 250 N maximum<br />

Travel (Rectilinear, Nonarcuate)<br />

Fine thread: 5 mm<br />

Differential: 300 mm<br />

Piezo actuator: 20 mm<br />

Resolution (Setting Sensitivity)<br />

Fine thread: 1 mm<br />

Differential: 50 nm<br />

Piezo actuator: 20 nm<br />

Piezo actuator with position feedback: 5nm<br />

Ordering Information<br />

Manual<br />

Drive<br />

UltraMike <br />

UltraMike <br />

UltraMike <br />

Piezo<br />

Actuator<br />

Yes<br />

Yes<br />

No<br />

Piezo<br />

Feedback<br />

No<br />

Yes<br />

No<br />

PRODUCT<br />

NUMBER<br />

17 TFC 001/MD<br />

17 TFC 003/MD<br />

17 TFC 011/MD<br />

Note: Controllers purchased separately. 17 TFC 001/MD compatible with<br />

17 PCS 001, 17 PCC 001, 17 PCW 001, and 17 PCW 011. 17 TFC 003/MD<br />

compatible with 17 PCZ 001.<br />

4 holes M3 for<br />

SMC<br />

connector 34<br />

4 holes<br />

M4 ! 10 deep<br />

25 50<br />

2 holes<br />

M6!10 deep<br />

2!f11<br />

thru top<br />

30<br />

4!M4!5 deep both sides<br />

*75<br />

2!f7 thru base<br />

dimensions: millimeters<br />

17 TFC 003/MD NanoFlex single-axis<br />

translation stage<br />

µ<br />

www.mellesgriot.com<br />

Europe St Thomas Place • Ely, Cambridgeshire CB7 4EX, UK • +44 (0)1353 654500 • FAX +44 (0)1353 654555 • E-mail: info.europe@mellesgriot.com<br />

USA 55 Science Parkway • Rochester, NY 14620 • 1-800-755-7558 • (585) 244-7220 • FAX (585) 244-6292 • E-mail: sales@rochester.mellesgriot.com<br />

Canada (613) 226-5880 France (01) 3012-0680 Germany (06251) 84060 Japan (03) 3407-3614 Netherlands (0316) 333041 Singapore 392-5368 Sweden (08) 544-4490<br />

MELLES GRIOT ® is a registered trademark of Melles Griot Inc. in the United States and certain other countries.<br />

In France, Germany, Italy, Belgium, The Netherlands, and Luxembourg, MELLES GRIOT ® is a registered trademark of Melles Griot B.V.<br />

Melles Griot follows a policy of continuous product development. For this reason, specifications are subject to change without notice.<br />

PRINTED IN UK<br />

©2002 MELLES GRIOT<br />

MCE 1036 02/02

vz<br />

Z<br />

Available in:<br />

✔ Production Quantities<br />

Y<br />

vy<br />

NanoBlock Four-, Five-,<br />

and Six-Axis Waveguide<br />

Manipulators<br />

These multiaxis positioning units are designed for the ultraprecise<br />

orientation of integrated optical and optoelectronic devices.<br />

They provide four, five, or six degrees of freedom and are available<br />

with a wide range of differential and piezoelectric drive options.<br />

These manipulators are designed for use with NanoBlock and<br />

NanoMax-TS three-axis nanopositioners, assembled in end-fire<br />

and butt-coupled configurations.<br />

These waveguide manipulators have flexure hinges for all motions<br />

except those along the x- and y-axes, which utilize bearing stages<br />

for longer travel. This design is effective for the applications for<br />

which these waveguide manipulators have been produced, but these<br />

manipulators are not optimized for dynamic operation. Consequently,<br />

although they are compatible with the NanoTrak <br />

autoalignment system, they do not provide performance comparable<br />

to a NanoMax – NanoTrak combination. It is recommended<br />

that for characterizing or pigtailing, NanoTrak control units should<br />

be used to servo-control the vertical and horizontal axes of the<br />

NanoBlock or NanoMax — controlling the input and output<br />

fiber— while vy (pitch) and vz (yaw) adjustments are made to the<br />

device mounted on the waveguide manipulator.<br />

These waveguide manipulators, all with a nominal 112.5-mm<br />

platform height above the tabletop, are designed to mount the wide<br />

range of component holders at an optical-axis height of 125 mm.<br />

When testing or fabricating integrated optical devices with<br />

multiple inputs and outputs using fiber arrays mounted in silicon<br />

V-grooves, vx (roll) must be added to the input and output fiber<br />

arrays. Alignment of the arrays is often achieved by precisely aligning<br />

one of the outermost fibers and then rolling the fiber array until<br />

the other outermost fiber is properly aligned. At this point, all<br />

fibers between the two outer fibers should be in alignment. In this<br />

type of system, it is common to configure two six-axis positioners<br />

to orient the fiber arrays with a simple y-z manipulator between them<br />

to orient the integrated optical device.<br />

EXTENSIVE RANGE OF OPTIONS<br />

The four-axis waveguide manipulator has four degrees of<br />

freedom, — y, z, vy, vz — with an unrestricted top-mounting surface,<br />

permitting large waveguide devices to be mounted and oriented.<br />

The vy (pitch) and vz (yaw) axes do not intersect; consequently,<br />

adjustments made about these axes must usually be<br />

accompanied by optimization of y and z. A manual or piezoelectric<br />

iterative procedure is required, or a NanoTrak can be used in<br />

combination with the accompanying NanoBlock to eliminate this<br />

problem. The five-axis waveguide manipulator has an additional<br />

degree of freedom along the optical axis (x).<br />

The six-axis waveguide manipulator has a special version of the<br />

MicroRoll mounted to the five-axis waveguide manipulator to<br />

add rotation about the optical axis (vx). It has two mounting<br />

surfaces: the standard top plate with five degrees of freedom (x, y,<br />

z, vy, vz) and the MicroRoll top plate with the addition of vx to<br />

give six degrees of freedom. The vy, vz, and vx axes do not intersect.<br />

A NanoBlock–NanoTrak combination is recommended to compensate<br />

automatically for the interactions between the axes.<br />

The waveguide manipulators have precision UltraMike <br />

differential micrometers with thumbscrew locking. They are available<br />

with or without piezoelectric actuators on all axes. In addition,<br />

piezoelectric actuators with feedback control and positional readout<br />

are available on the x-, y-, and z-axes.<br />

SPECIFICATIONS:<br />

NanoBlock FOUR-,FIVE-, AND<br />

SIX-AXIS WAVEGUIDE MANIPULATORS<br />

Construction: Aluminum and steel with black finish<br />

Weight: 1500 g (3.3 lb)<br />

Load Capacity: 500 g (1.1 lb)<br />

Piezoelectric Pushing Force: 250 N maximum<br />

Travel:<br />

Fine thread: 13 mm (x, y), 6 mm (z), 8 degrees (vx, vy, vz)<br />

Differential: 300 mm (x, y, z),<br />

10 arc minutes (vx, vz), 30 arc minutes (vy)<br />

Piezo actuator: 20 mm (x, y, z),<br />

45 arc seconds (vx, vz), 2 arc minutes (vy)<br />

Piezo actuator with feedback: 20 mm (x, y, z)<br />

Resolution (setting sensitivity):<br />

Fine thread: 1 mm (x, y, z),<br />

10 arc seconds (vx, vy, vz)<br />

Differential: 50 nm (x, y, z),<br />

1 arc seconds (vx, vy, vz)<br />

Piezo actuator: 40 nm (x, y, z),<br />

0.3 arc seconds (vx, vy, vz)<br />

Piezo actuator with feedback: 20 nm (x, y, z)

7.5<br />

20<br />

60 20 45<br />

9<br />

70<br />

61<br />

vz yaw<br />

rotational center<br />

14 holes threaded<br />

M3 x 4 deep<br />

135<br />

max<br />

70<br />

50.4<br />

NanoBlock Four-, Five-, and Six-Axis<br />

Waveguide Manipulators<br />

Number of<br />

Axes<br />

4<br />

4<br />

4<br />

5<br />

5<br />

5<br />

6<br />

6<br />

6<br />

Piezoelectric<br />

Actuators<br />

y, z, vy, vz<br />

“<br />

None<br />

x, y, z, vy, vz<br />

“<br />

None<br />

x, y, z, vx, vy, vz<br />

“<br />

None<br />

Piezoelectric<br />

Feedback<br />

N.A.<br />

y, z only<br />

N.A.<br />

N.A.<br />

x, y, z only<br />

N.A.<br />

N.A.<br />

x, y, z only<br />

N.A.<br />

PRODUCT<br />

NUMBER<br />

17 ANF 001/MD<br />

17 ANF 003/MD<br />

17 ANF 005/MD<br />

17 ANG 001/MD<br />

17 ANG 003/MD<br />

17 ANG 005/MD<br />

17 ANH 001/MD<br />

17 ANH 003/MD<br />

17 ANH 005/MD<br />

35<br />

40<br />

48<br />

60<br />

12 (vy pitch<br />

rotational<br />

center)<br />

4 holes threaded<br />

M3 x 4 deep on<br />

15 centers<br />

Six-Axis Waveguide<br />

Manipulator<br />

17 ANH series<br />

vx roll<br />

rotational center<br />

3W x 1.5D<br />

location slot 50<br />

$ x, y, z, vx, vy, vz<br />

alignment<br />

$ 25-nm resolution<br />

$ 0.2-arc-seconds<br />

resolution<br />

12.5<br />

23<br />

(vy pitch<br />

rotational<br />

center) 112.5 3<br />

159<br />

max<br />

25 3<br />

126<br />

142<br />

190 max<br />

17 ANF 005MD<br />

17 ANG 005MD<br />

17 ANH 005MD<br />

dimensions in mm

four-axis device manipulators<br />

17 AMT 001/D<br />

17 AMU 001/D<br />

MicroBlock <br />

MicroBlock four-axis device manipulators are compact and cost-effective,<br />

four-axis positioners designed for precise orientation of photonics and<br />

other planar devices.<br />

The four independent degrees of freedom — y, z, vy (pitch), and vz (yaw) —<br />

make them ideal for end-fire and butt-coupling applications where relatively<br />

large translations are required. A common point of rotation is located at the<br />

system optical-axis height of 75 mm, 12.5 mm above the platform surface.<br />

A component can then be translated in the y-z plane followed by precise<br />

control of the rotational adjustment about a point in the plane.<br />

These four-axis manipulators are equipped with UltraFine differential<br />

drives on all axes. The long transverse range allows easy adjustment<br />

across the full width of most devices, and the low profile 17 AMU 001/D is<br />

especially useful for large devices.<br />

µ

Specifications:<br />

Construction: Aluminum and steel with black finish<br />

Weight: 700–750 g (1.5–1.7 lb)<br />

Load Capacity: 500 g (1.1 lb)<br />

Ordering Information<br />

Fine Thread<br />

Differential<br />

Axis Travel Resolution Travel Resolution PRODUCT NUMBER<br />

y 13 mm 1 mm 300 mm 50 nm<br />

z 6 mm 1 mm 300 mm 50 nm<br />

vy 10 deg 10 arc sec 30 arc min 1 arc sec<br />

vz 10 deg 10 arc sec 30 arc min 1 arc sec<br />

y 13 mm 1 mm 300 mm 50 nm<br />

z 6 mm 1 mm 300 mm 50 nm<br />

vy 10 deg 10 arc sec 30 arc min 1 arc sec<br />

vz 10 deg 10 arc sec 12 arc min 1 arc sec<br />

17 AMT 001/D<br />

17 AMU 001/D<br />

14 holes threaded<br />

M3!5 deep<br />

15<br />

6.5<br />

15<br />

50.4<br />

4 holes f7 thru<br />

140<br />

max<br />

28.5<br />

165 maximum<br />

15 50.4<br />

1586<br />

91<br />

20<br />

45<br />

75.6<br />

60<br />

90<br />

10<br />

20<br />

75.6<br />

20<br />

7.5<br />

2 holes<br />

threaded<br />

M4!10 deep<br />

16 (vy pitch<br />

rotational<br />

center)<br />

11<br />

62.5<br />

83<br />

dimensions: millimeters<br />

40<br />

61<br />

70<br />

164 max<br />

3 wide!1.5 deep<br />

location slot<br />

20 50<br />

75<br />

12 (vy pitch<br />

rotational<br />

center)<br />

4.5<br />

30 (vz yaw<br />

rotational<br />

center)<br />

17 AMU 001/D<br />

90<br />

maximum<br />

145<br />

maximum<br />

4 holes<br />

f7 thru<br />

62.5<br />

83<br />

6<br />

40<br />

75<br />

57<br />

vy pitch<br />

and vz yaw<br />

rotational<br />

center<br />

3 wide!1.5 deep<br />

location slot<br />

17 AMT 001/D<br />

75<br />

MicroBlock four-axis device manipulators<br />

µ<br />

www.mellesgriot.com<br />

Europe St Thomas Place • Ely, Cambridgeshire CB7 4EX, UK • +44 (0)1353 654500 • FAX +44 (0)1353 654555 • E-mail: info.europe@mellesgriot.com<br />

USA 55 Science Parkway • Rochester, NY 14620 • 1-800-755-7558 • (585) 244-7220 • FAX (585) 244-6292 • E-mail: sales@rochester.mellesgriot.com<br />

Canada (613) 226-5880 France (01) 3012-0680 Germany (06251) 84060 Japan (03) 3407-3614 Netherlands (0316) 333041 Singapore 392-5368 Sweden (08) 544-4490<br />

MELLES GRIOT ® is a registered trademark of Melles Griot Inc. in the United States and certain other countries.<br />

In France, Germany, Italy, Belgium, The Netherlands, and Luxembourg, MELLES GRIOT ® is a registered trademark of Melles Griot B.V.<br />

Melles Griot follows a policy of continuous product development. For this reason, specifications are subject to change without notice.<br />

PRINTED IN UK<br />

©2002 MELLES GRIOT<br />

MCE 1045 02/02

x-y-z flexure stage<br />

17 AMB 003<br />

MicroBlock <br />

The MicroBlock is a versatile, low-cost, independent, three-axis<br />

nanopositioning stage developed to meet the stringent requirements<br />

needed for aligning fiber optics. The stage features a nominal working<br />

platform height of 62.5 mm and provides a common optical-axis height of<br />

75 mm with a wide range of accessories.<br />

The MicroBlock is ideal for aligning single-mode fibers and can be<br />

mounted directly on an optical table, breadboard, or other surface with a<br />

25-mm/1-inch or 50-mm/2-inch hole matrix.<br />

The top-mounting platform may be rotated through 90 degrees so that the<br />

user can arrange two MicroBlocks with respect to one another (or other<br />

positioners), locating the x-y-z drives to give the most convenient access.<br />

Features<br />

◗ 75-mm optical axis height<br />

◗ No friction or stiction<br />

◗ Increased stability and stiffness<br />

◗ Minimal thermal drift<br />

µ

Specifications:<br />

Travel:<br />

4 mm (mechanical)<br />

300 mm (differential)<br />

Load Capacity: 1 kg (2.2 lb)<br />

Vacuum Compatibility: >10 -4 Pa<br />

Arcuate Displacement: 85 mm<br />

Resolution:<br />

Thumbscrew: 1000 nm<br />

Differential micrometer: 50 nm<br />

Weight: 0.75 kg (1.65 lb)<br />

Platform: 60 mm ! 60 mm<br />

MicroBlock Fiber Launch Kit<br />

A popular configuration of the MicroBlock <br />

x-y-z flexure stage is the single-mode fiber<br />

launcher. For your convenience, this<br />

configuration can be ordered under one<br />

product number and simply requires the<br />

addition of an 04 OAS series microscope<br />

objective lens with the appropriate<br />

magnification and numerical aperture.<br />

Ordering Information<br />

MicroBlock with Thumbscrews 17 AMB 003/T<br />

MicroBlock with Differential<br />

Micrometers<br />

17 AMB 003/MD<br />

Fixed Platform Bracket (26-mm) 17 AMA 007<br />

Fixed Platform Bracket (56-mm) 17 AMA 009<br />

Moving World Bracket 17 AMA 011<br />

Spacer Block to Raise Optical-<br />

Axis Height to 125-mm 17 AMA 554<br />

MicroBlock Fiber Launch Kit<br />

With UltraMike <br />

X-Y-Z Adjusters<br />

17 AMB 003/MD/K<br />

System includes: X-Y-Z positioners (07 TMF 221), V-groove fiber<br />

holder (17 HFV 001), fixed work platform (17 AMA 009), and<br />

RMS threaded holder (17 HMO 001).<br />

top plate may be rotated<br />

through 90° by removing<br />

these four screws<br />

8 holes threaded M3!4 deep on 15 centers<br />

7 holes threaded M4 on 17 centers<br />

VIEW A<br />

117<br />

maximum<br />

) 60<br />

40<br />

) 75<br />

3 slots f7 thru<br />

4 holes threaded M2<br />

on 20 centers<br />

3 wide!1.5 deep<br />

location slot<br />

50.4<br />

7<br />

62.5<br />

82.0<br />

46.5<br />

48<br />

4 holes threaded<br />

M3!5 deep<br />

4<br />

50.4<br />

TOP VIEW<br />

7<br />

3<br />

51 6<br />

VIEW A<br />

6<br />

8.25<br />

dimensions: millimeters<br />

MicroBlock 3-axis stage<br />

µ<br />

www.mellesgriot.com<br />

Europe St Thomas Place • Ely, Cambridgeshire CB7 4EX, UK • +44 (0)1353 654500 • FAX +44 (0)1353 654555 • E-mail: info.europe@mellesgriot.com<br />

USA 55 Science Parkway • Rochester, NY 14620 • 1-800-755-7558 • (585) 244-7220 • FAX (585) 244-6292 • E-mail: sales@rochester.mellesgriot.com<br />

Canada (613) 226-5880 France (01) 3012-0680 Germany (06251) 84060 Japan (03) 3407-3614 Netherlands (0316) 333041 Singapore 392-5368 Sweden (08) 544-4490<br />

MELLES GRIOT ® is a registered trademark of Melles Griot Inc. in the United States and certain other countries.<br />

In France, Germany, Italy, Belgium, The Netherlands, and Luxembourg, MELLES GRIOT ® is a registered trademark of Melles Griot B.V.<br />

Melles Griot follows a policy of continuous product development. For this reason, specifications are subject to change without notice.<br />

PRINTED IN UK<br />

©2002 MELLES GRIOT<br />

MCE 1043 02/02

NanoRotator <br />

360-degree motorized rotation stage<br />

17 AMR 101<br />

The NanoRotator rotation stage provides 360 degrees of rotation and can<br />

be used in either a vertical or horizontal orientation. Powered by the same<br />

high-resolution stepper motor used in the NanoStep 1000 positioners, it is<br />

constructed with a thin-walled bearing design that provides highly accurate<br />

rotation with minimum wobble and eccentricity. A mechanical switch<br />

generates a reference signal for each complete rotation.<br />

The NanoRotator is particularly useful for rotating circular components,<br />

such as diode packages, under a laser welding station. It has a central<br />

50-mm-diameter access hole, which allows standard fiber connectors to be<br />

withdrawn following assembly operations.<br />

Adaptor plates can be attached to the mounting platform for mounting<br />

opto-mechanical or other nanopositioning accessories.<br />

The stepper motor can be controlled either with the master 17 MDU 001<br />

intelligent drive unit or the modular 17 MST 001 controller (sold separately).<br />

µ

Specifications:<br />

Construction<br />

Aluminum body and platform with black finish<br />

Weight: 1.4 kg (3.1 lb)<br />

Load Capacity: 50 kg (110 lb)<br />

Travel: 360 degrees of continuous rotation<br />

Resolution: 1 arc second<br />

4 holes 7.5 thru counterbored f11.5!f7.5 deep<br />

50.0<br />

114.0<br />

50.0 50.0<br />

32.0<br />

closed<br />

top plate 10.0<br />

13.0 50.0 4 holes M4 on<br />

26.0 100.0<br />

a f59.0 circle<br />

f50.0 clear aperture through center<br />

rotation platform<br />

34.5<br />

f98.0<br />

table<br />

adaptor 10.0 50.0<br />

2 holes M6<br />

on 3 sides<br />

dimensions: millimeters<br />

197.0<br />

17 AMR 101 NanoRotator 360-degree<br />

motorized rotation stage<br />

NanoRotator Accessories<br />

Optical Table Mounting Adaptor 17 AMA 043<br />

Adaptor Plate (inch pitch) 17 AMA 041<br />

Adaptor Plate (M6 pitch) 17 AMA 541<br />

Tongue-in-Groove Accessory<br />

Adaptor Plate 17 AMA 042<br />

Mounting Plate for NanoBlock 17 AMA 040<br />

Adaptor Plate for Horizontal<br />

Mounting to NanoStep Stage 17 AMA 037<br />

µ<br />

0°–360° in<br />

1° divisions<br />

42.2<br />

graduated knob<br />

5.5<br />

113.0<br />

7.5<br />

7.5<br />

6 holes fA thru<br />

50.4 34.0<br />

plate<br />

10.0 thick<br />

7 holes M6 thru<br />

11.9<br />

25.2<br />

12.5<br />

50.4<br />

4 holes<br />

f8.0 thru<br />

6.5<br />

50.0<br />

100.0<br />

25.0<br />

25.2<br />

f98.0<br />

mounting holes<br />

to nanorotator<br />

3.080.05<br />

wide!1.70<br />

30.0<br />

30.0<br />

45<br />

°<br />

17 AMA 040<br />

17 AMA 041/541<br />

4 holes M4 thru<br />

hole M16!1<br />

optional thru<br />

at center<br />

mounting holes<br />

to nanorotator<br />

17 AMA 042<br />

20.0<br />

20.0<br />

33.0<br />

50.4 37.1 8.0<br />

12.5 5.5<br />

9.5<br />

4 holes<br />

113.0<br />

f4.50 thru<br />

counterbored f7.80!5.0 deep<br />

equally spaced on 59 centers<br />

114.0<br />

101.0<br />

17 AMA 043<br />

10.0<br />

plate 13.25!3 13.25!3<br />

5.0 thick<br />

NanoRotator mounting and adaptor plates<br />

dimensions: millimeters<br />

NanoRotator mounting and adaptor plates<br />

Ordering Information<br />

NanoRotator 360-Degree<br />

Motorized Rotation Stage 17 AMR 101<br />

www.mellesgriot.com<br />

Europe St Thomas Place • Ely, Cambridgeshire CB7 4EX, UK • +44 (0)1353 654500 • FAX +44 (0)1353 654555 • E-mail: info.europe@mellesgriot.com<br />

USA 55 Science Parkway • Rochester, NY 14620 • 1-800-755-7558 • (585) 244-7220 • FAX (585) 244-6292 • E-mail: sales@rochester.mellesgriot.com<br />

Canada (613) 226-5880 France (01) 3012-0680 Germany (06251) 84060 Japan (03) 3407-3614 Netherlands (0316) 333041 Singapore 392-5368 Sweden (08) 544-4490<br />

MELLES GRIOT ® is a registered trademark of Melles Griot Inc. in the United States and certain other countries.<br />

In France, Germany, Italy, Belgium, The Netherlands, and Luxembourg, MELLES GRIOT ® is a registered trademark of Melles Griot B.V.<br />

Melles Griot follows a policy of continuous product development. For this reason, specifications are subject to change without notice.<br />

PRINTED IN UK<br />

©2002 MELLES GRIOT<br />

MCE 1041 02/02

NanoRoll <br />

Flexure rotation stages<br />

17 AMR Series<br />

The 17 AMR series ultrasmooth flexure rotation stages are ideally suited for<br />

precision roll movements about the longitudinal axis of a fiber. They can be<br />

used as stand-alone angular positioners, goniometers, or combined with<br />

three-axis translators to create four-axis, X-Y-Z-vx, stages.<br />

The 12 degrees of movement can be controlled manually with the UltraMike <br />

differential micrometer drive with 1-arc-second resolution, or automatically<br />

by stepper motors with less than 1-arc-second resolution, or piezoelectric<br />

actuators with 0.1-arc-second resolution.<br />

The stepper motor is controlled by either a 17 MDU 001 benchtop driver or<br />

a 17 MST 001 modular driver (sold separately). The piezoelectric actuator is<br />

controlled by any Melles Griot piezoelectric controller.<br />

Features<br />

◗ Differential and piezoelectric drives<br />

◗ Ideal for aligning polarization-preserving fibers<br />

◗ Standard 75-mm optical axis height<br />

µ

Specifications:<br />

Travel:<br />

Fine Thread: 12 degrees<br />

Motor: 8 degrees<br />

Differential: 10 arc minutes<br />

Piezo: 45 arc seconds<br />

Resolution:<br />

Fine Thread: 10 arc seconds<br />

Motor:

Pneumatic Linear Precision Stage<br />

17 PST Series<br />

The 17 PST series pneumatic linear precision stage provides fast, hassle-free<br />

movement of loads up to 50 kg. It is designed specifically for process<br />

automation applications in the manufacturing industry.<br />

With highly repeatable, easy-to-adjust end stops, this stage is perfectly<br />

suited for load/unload positioning and for driving accessories like glue<br />

dispensers and uv-curing equipment into the working space of precision<br />

positioning and alignment systems.<br />

Features<br />

◗ 75-mm maximum travel (40-mm minimum)<br />

◗ Precision adjustable end stops<br />

◗ 2-mm repeatability of end positions<br />

◗ Low-maintenance design<br />

µ

Specifications:<br />

Construction: Aluminum cross-roller stage<br />

Travel Range: 40–75 mm<br />

Repeatability: 2 mm RMS<br />

End-Stop Setting Sensitivity: 1 mm<br />

Weight: 2.5 kg<br />

Load Capacity:<br />

Mounted horizontally: 50 kg<br />

Mounted vertically: 5 kg<br />

Speed: 100 mm/second (maximum)<br />

Settling Time: < 3 seconds<br />

Air Line Pressure: 40 psi<br />

35 150<br />

35<br />

120<br />

35<br />

200<br />

f34<br />

27<br />

50<br />

dimensions: millimeters<br />

17 PST 101 pneumatic linear precision stage<br />

Ordering Information<br />

Pneumatic Linear Precision Stage 17 PST 001<br />

Pneumatic Linear Precision Stage<br />

with Solenoid Valve 17 PST 101<br />

µ<br />

www.mellesgriot.com<br />

Europe St Thomas Place • Ely, Cambridgeshire CB7 4EX, UK • +44 (0)1353 654500 • FAX +44 (0)1353 654555 • E-mail: info.europe@mellesgriot.com<br />

USA 55 Science Parkway • Rochester, NY 14620 • 1-800-755-7558 • (585) 244-7220 • FAX (585) 244-6292 • E-mail: sales@rochester.mellesgriot.com<br />

Canada (613) 226-5880 France (01) 3012-0680 Germany (06251) 84060 Japan (03) 3407-3614 Netherlands (0316) 333041 Singapore 392-5368 Sweden (08) 544-4490<br />

MELLES GRIOT ® is a registered trademark of Melles Griot Inc. in the United States and certain other countries.<br />

In France, Germany, Italy, Belgium, The Netherlands, and Luxembourg, MELLES GRIOT ® is a registered trademark of Melles Griot B.V.<br />

Melles Griot follows a policy of continuous product development. For this reason, specifications are subject to change without notice.<br />

PRINTED IN UK<br />

©2002 MELLES GRIOT<br />

MCE 1039 02/02

Linear Long-Travel Translation Stage<br />

17 LNR 001<br />

The 17 LNR 001 stage is an extremely versatile single-axis translation stage<br />

that provides high precision, high load-carrying capacity, and long travel.<br />

Stages can be bolted together to form x-y and x-y-z configurations. In<br />

addition, there is a wide range of drive options that simply bolt onto the<br />

side of the stage. Manual, stepper motor, and piezoelectric actuators can<br />

all be selected, and mounted in combinations of any two opposing drive<br />

options. The unique combination of long-travel actuators and high-precision<br />

piezoelectric elements is ideal for difficult applications such as assembly<br />

and laser welding of photonics products and microscopy of large samples.<br />

All drives must be specified and ordered separately to correspond with the<br />

intended application. Piezoelectric actuators can be selected from any of the<br />

17 PAS or 17 PAZ series of actuators.<br />

Features<br />

◗ Stable cross-roller-bearing design<br />

◗ Up to 50 mm of travel<br />

◗ Rapidly interchangeable drive modules<br />

◗ x-y-z configurations possible<br />

µ

Specifications:<br />

Construction<br />

Steel with phosphorous-nickel satin finish<br />

Load Capacity: 10 kg (22 lb)<br />

Travel: 50 mm<br />

Positive Return Force: 30 N<br />

25<br />

25<br />

Ordering Information<br />

VIEW A<br />

Linear Long-Travel Stage<br />

(Drive not included) 17 LNR 001<br />

Accessories<br />

Table Mounting Plate 17 AMA 061<br />

25<br />

3 holes<br />

M6<br />

100 30.4<br />

Veritcal Mounting Bracket 17 AMA 062<br />

Spacer (to allow x-y mounting) 17 AMA 063<br />

Mounting Adaptor for<br />

NanoMax300 to LNR Stage 17 AMA 562<br />

10 mm Packing Plate 17 AMA 566<br />

Mounting Adaptor for LNR<br />

to NanoStep Stage 17 AMA 567<br />

Mounting Adaptor for LNR<br />

to NanoRotator Stage 17 AMA 570<br />

25<br />

2 clearance holes<br />

f7.5 for mounting<br />

38 38<br />

25<br />

25<br />

25<br />

38<br />

25<br />

38<br />

25<br />

13 holes M6<br />

VIEW A<br />

dimensions: millimeters<br />

17 LNR 001 translation stage shown<br />

with stepper motor<br />

Modular Drives<br />

Travel Resolution PRODUCT<br />

(mm) (mm) NUMBER<br />

Micrometer Drive 25.0 1.0 17 DRV 010<br />

Micrometer Drive 50.0 1.0 17 DRV 011<br />

Micrometer Drive (Digital) 25.0 1.0 17 DRV 012<br />

Differential Drive 25.0 0.05 17 DRV 007<br />

Stepper Motor 25.0 0.05 17 DRV 013 or 113<br />

Stepper Motor 50.0 0.05 17 DRV 014 or 114<br />

Piezoelectric Actuators 0.001–0.1 0.01 17 PAS or PAZ<br />

µ<br />

www.mellesgriot.com<br />

Europe St Thomas Place • Ely, Cambridgeshire CB7 4EX, UK • +44 (0)1353 654500 • FAX +44 (0)1353 654555 • E-mail: info.europe@mellesgriot.com<br />

USA 55 Science Parkway • Rochester, NY 14620 • 1-800-755-7558 • (585) 244-7220 • FAX (585) 244-6292 • E-mail: sales@rochester.mellesgriot.com<br />

Canada (613) 226-5880 France (01) 3012-0680 Germany (06251) 84060 Japan (03) 3407-3614 Netherlands (0316) 333041 Singapore 392-5368 Sweden (08) 544-4490<br />

MELLES GRIOT ® is a registered trademark of Melles Griot Inc. in the United States and certain other countries.<br />

In France, Germany, Italy, Belgium, The Netherlands, and Luxembourg, MELLES GRIOT ® is a registered trademark of Melles Griot B.V.<br />

Melles Griot follows a policy of continuous product development. For this reason, specifications are subject to change without notice.<br />

PRINTED IN UK<br />

©2002 MELLES GRIOT<br />

MCE 1037 02/02

NanoMax300-TS <br />

x-y-z parallel flexure stage<br />

17 MAX 300<br />

Series<br />

The NanoMax-TS three-axis stage offers an unmatched combination of<br />

high stability and resolution from a three-axis positioner, with major<br />

improvements in performance, functionality, and robustness achieved from<br />

the patented parallel flexure design.<br />

Modular actuators are easily and quickly fitted to the stage at ergonomically<br />

sited locations. Stepper motor, manual differential micrometer, manual<br />

differential, and thumbscrew drives are all available. Any combination of<br />

these drives can be used on any axis of the stage.<br />

Rapid, ultra-high precision motion can be achieved by combining long-travel<br />

actuators with either internal or external piezoelectric actuators.<br />

Features<br />

◗ 75-mm optical axis height<br />

◗ Open- and closed-loop piezoelectric actuators<br />

◗ Modular drives<br />

◗ No friction or stiction<br />

◗ Ultimate stability and stiffness<br />

µ

Specifications:<br />

Travel:<br />

Fine thread: 4 mm (x, y, z)<br />

Piezo actuator: 20 mm (x, y, z)<br />

RMS repeatability: 15 nm<br />

Piezoelectric pushing force: 250 N maximum<br />

Load capacity: 1 kg<br />

Resonant frequency (f 0 : 8 10% Hz):<br />

No load: 375 Hz<br />

275 g: 200 Hz<br />

575 g: 150 Hz<br />

Total arcuate displacement: 80 mm<br />

Vacuum compatibility: >10 -4 Pa maximum<br />

Piezoelectric drive voltage: 0–75 Vdc<br />

Weight: 1 kg<br />

Platform size: 60 mm ! 60 mm<br />

Resolution:<br />

Fine thread: 1 mm (x,y,z)<br />

Differential: 50 nm (x,y,z)<br />

Piezo actuator: 20 nm (x,y,z)<br />

Piezo actuator with feedback: 5 nm (x,y,z)<br />

Ordering Information<br />

Three-Axis Flexure Stage with<br />

Active Position Feedback<br />

on All Axes 17 MAX 301<br />

Three-Axis Flexure Stage without<br />

Position Feedback 17 MAX 302<br />

NanoMax 3-Axis Stage without<br />

Piezoelectric Actuators 17 MAX 303<br />

Stepper Motor Drive Module 17 DRV 001<br />

Differential Micrometer Drive<br />

Module 17 DRV 002<br />

Thumbscrew Drive Module 17 DRV 004<br />

Mounting Plate to Fix<br />

17 MAX 300 Series Stages to<br />

17 NST Series Long-Travel Stages<br />

(125-mm Optical Axis Height) 17 AMA 555<br />

Spacer Block to Raise Optical-<br />

Axis Height to 125-mm 17 AMA 554<br />

105.6<br />

top plate may be rotated<br />

through 90° by removing<br />

these four screws<br />

87.0<br />

40.0<br />

34.0<br />

20.0<br />

y<br />

8 holes threaded<br />

M3!4 deep on 15 centers<br />

x<br />

z<br />

30.0<br />

42.6<br />

4 holes<br />

threaded M2<br />

on 20 centers<br />

7 holes threaded<br />

M4 on 17 centers<br />

SMC connectors<br />

62.5<br />

6 holes f8<br />

through base<br />

4.8<br />

17.4<br />

93.0<br />

105.6<br />

8.0<br />

VIEW A<br />

dimensions: millimeters<br />

VIEW A<br />

17 MAX 302 3-axis stage<br />

µ<br />

www.mellesgriot.com<br />

Europe St Thomas Place • Ely, Cambridgeshire CB7 4EX, UK • +44 (0)1353 654500 • FAX +44 (0)1353 654555 • E-mail: info.europe@mellesgriot.com<br />

USA 55 Science Parkway • Rochester, NY 14620 • 1-800-755-7558 • (585) 244-7220 • FAX (585) 244-6292 • E-mail: sales@rochester.mellesgriot.com<br />

Canada (613) 226-5880 France (01) 3012-0680 Germany (06251) 84060 Japan (03) 3407-3614 Netherlands (0316) 333041 Singapore 392-5368 Sweden (08) 544-4490<br />

MELLES GRIOT ® is a registered trademark of Melles Griot Inc. in the United States and certain other countries.<br />

In France, Germany, Italy, Belgium, The Netherlands, and Luxembourg, MELLES GRIOT ® is a registered trademark of Melles Griot B.V.<br />

Melles Griot follows a policy of continuous product development. For this reason, specifications are subject to change without notice.<br />

PRINTED IN UK<br />

©2002 MELLES GRIOT<br />

MCE 1042 03/02

apt System Six-Axis<br />

<br />

Alignment Stage<br />

17 APT 600<br />

Melles Griot introduces a new class of nanopositioning alignment stage<br />

based on a novel, patent-pending mechanism for multiaxis positioning. The<br />

APT (advanced positioning technology) system stage provides superior<br />

performance with six axes of motion, modular and interchangeable<br />

actuators, small footprint, and multiple functional surfaces.<br />

The 17 APT 600 multiaxis stage provides the user with exceptional levels<br />

of precision and accuracy as a result of its innovative, proprietary design.<br />

All APT system stages incorporate new GALPin technology, developed<br />

using guided alignment linkage pins and parallel interaction with a single<br />

moving platform. This technology provides much longer travel range<br />

compared to other compact six-axis positioners.<br />

Fixtures, cameras, holders, probes, and accessories can be mounted directly<br />

onto any of the available sides of the APT stage. This simplifies system<br />

setup, eliminating the need for posts, pillars, and brackets, saving time,<br />

space, and money.<br />

Features<br />

◗ Slim and compact<br />

◗ All drives mounted on one side<br />

◗ Kinematic device mounts<br />

◗ Increased travel<br />

◗ Modular actuators<br />

µ

Specifications:<br />

Load Capacity: 1000 g<br />

Travel:<br />

Fine thread:<br />

12 mm (x, y, z), 6 degrees (vx, vy, vz)<br />

Differential:<br />

150 mm (x, y, z), 9 arc minutes (vx, vy, vz)<br />

Piezoelectric actuator:<br />

30 mm (x, y, z), 1.2 arc minutes (vx, vy, vz)<br />

Fixed Points of Rotation: 2 (not common)<br />

Actuator Resolution:<br />

Fine thread:<br />

1 mm (x, y, z), 4 arc seconds (vx, vy, vz)<br />

Differential:<br />

100 nm (x, y, z), 0.6 arc seconds (vx, vy, vz)<br />

Piezoelectric actuator:<br />

10 nm (x, y, z), 0.1 arc seconds (vx, vy, vz)<br />

Stepper motor:<br />

80 nm (x, y, z), 0.6 arc seconds (vx, vy, vz)<br />

Resonant Frequency: >200 Hz<br />

100 g load: 220 Hz<br />

500 g load: 200 Hz<br />

Piezoelectric Pushing Force: 250 N minimum<br />

Thermal Stability (15–30°C): < 1 mm/ºC<br />

Vacuum Compatibility:<br />

> 10 –4 mbar maximum<br />

Piezoelectric Drive Voltage: 0–75 Vdc<br />

Weight: 7 kg<br />

Dimensions (W ! H ! D):<br />

Minimum: 60 ! 175 ! 150 mm<br />

(2.36 ! 6.9 ! 5.91 in.)<br />

Maximum: 60 ! 200 ! 300 mm<br />

(2.36 ! 7.88 ! 11.82 in.)<br />

Ordering Information<br />

APT System Six-Axis Stage 17 APT 600/*<br />

Left- or Right-Handed 1<br />

Piezoelectric Actuators 2<br />

Axis: x= y= z= vx= vy= vz=<br />

*Complete the product number using the following<br />

codes:<br />

1 Specify whether left- or right-handed stage is<br />

required by inserting the letter L or R.<br />

2 Specify piezoelectric actuator requirements on for<br />

each axis using the following codes:<br />

0 = no piezo<br />

1 = piezo<br />

2 = piezo with feedback<br />

For example: 17 APT 600/R222111 is a right-handed<br />

APT six-axis stage with piezoelectric actuators on all<br />

axes and feedback on x, y, and z axes.<br />

60 15<br />

135<br />

dimensions: millimeters<br />

APT series six-axis stage<br />

150<br />

175<br />

This product has been designed, tested, and manufactured<br />

in compliance with applicable European electrical safety<br />

standards.<br />

µ<br />

alignment.mellesgriot.com<br />

USA 1-800-410-9141 Europe +44 (0) 1353 654500 Asia +81 (3) 3407-3614 • nanopositioning@mellesgriot.com<br />

MELLES GRIOT ® is a registered trademark of Melles Griot Inc. in the United States and certain other countries.<br />

In France, Germany, Italy, Belgium, The Netherlands, and Luxembourg, MELLES GRIOT ® is a registered trademark of Melles Griot B.V.<br />

Melles Griot follows a policy of continuous product development. For this reason, specifications are subject to change without notice.<br />

PRINTED IN USA<br />

©2003 MELLES GRIOT<br />

3207 REV B 12/03

apt System Stepper Motor<br />

<br />

Controller<br />

17 BSC 002<br />

The benchtop APT (advanced positioning technology) system stepper-motor<br />

controller uses the latest high-speed digital signal processing (DSP)<br />

technology and low-noise analog electronics to drive up to two axes of<br />

motion. Additional axes can be driven by connecting one or more units<br />

via a standard USB hub.<br />

The 17 BSC 002 uses an intuitive graphical user interface which provides<br />

access to all motion controls and features, including velocity profiling, jog<br />

velocity and resolution, and self-diagnostics. Advanced software functions<br />

include both internal and external triggering, automatic positioning-error<br />

compensation, and programmable search and scan routines. All user inputs<br />

and outputs are digital and optically isolated for nongalvanic connection.<br />

A key feature of this controller is its open architecture, both in terms of its<br />

software and hardware. This means it can be upgraded in the future to meet<br />

changing requirements and that it can be used with encoded hardware.<br />

Features<br />

◗ Dual-channel bipolar synchronous control<br />

◗ Dynamic step-resolution control<br />

◗ 25,600 microsteps maximum per revolution<br />

◗ 25-W maximum average power<br />

◗ Optically isolated input/output<br />

µ

Specifications:<br />

Input/Output:<br />

Motor output connectors:<br />

2! 26-pin female D-type connectors<br />

Command signal connector:<br />

25-pin female D-type<br />

Feedback: 0–10 V<br />

Analog inputs (2): 0–10 Vdc<br />

Galvanic isolated I/O: 5 Vdc TTL<br />

Stepping:<br />

Cardinal steps: 200<br />

Microsteps: 25,600 (max)<br />

Power (maximum):<br />

Average: 25 W<br />

Peak: 75 W<br />

General:<br />

Power Input:<br />

Voltage: 85–264 Vac<br />

Power: 200 W<br />

Fuse: 3 A<br />

Dimensions (W ! D ! H):<br />

245 ! 130 ! 330 mm (9.6 ! 5.1 ! 13 in.)<br />

Weight: 6 kg (13 lb)<br />

Computer Interface and Software:<br />

USB interface<br />

ActiveX ® function library<br />

ActiveX ® virtual panel control<br />

Ordering Information<br />

APT system stepper motor<br />

controller 17 BSC 002<br />

This product has been designed, tested, and manufactured<br />

in compliance with applicable European electrical safety<br />

standards.<br />

Rear panel configuration<br />

µ<br />

alignment.mellesgriot.com<br />

USA 1-800-410-9141 Europe +44 (0) 1353 654500 Asia +81 (3) 3407-3614 • nanopositioning@mellesgriot.com

apt System Piezoelectric<br />

<br />

Controller<br />

17 BPC 002<br />

The APT (advanced positioning technology) system benchtop<br />

piezoelectric controller incorporates the latest high-speed digital signal<br />

processing technology and low-noise analog electronics to provide two<br />

high-voltage (0–75 V) output channels.<br />

The 17 BPC 002 controller is designed for use in critical alignment<br />

applications where submicron motion is required. The system is operated<br />

via an intuitive graphical user interface using a computer with a USB port.<br />

All actuator movement is determined by software embedded in the<br />

controller itself. The software includes functions for internal and external<br />

triggering, asynchronous moves, and external inputs.<br />

A key feature of the 17 BPC 002 controller is its open architecture, both in<br />

terms of its software and hardware. This means that the controller can be<br />

upgraded in the future to meet changing requirements.<br />

Features<br />

◗ Two piezoactuator output channels<br />

◗ Intuitive virtual panel software<br />

◗ Plug-and-play installation<br />

◗ Rear-panel connections<br />

◗ Bidirectional triggering<br />

◗ USB communication port<br />

µ

Specifications:<br />

Piezoelectric Output:<br />

Output connectors: 2! SMC male<br />

Voltage output: 0–75 Vdc/channel<br />

Voltage stability: 100 ppm over 24 hours<br />

Noise:

Available in:<br />

✔ Production Quantities<br />

Piezoelectric Drivers<br />

Piezoelectric Drivers<br />

The 17 PCS 001 driver allows simple yet precise hands-off<br />

adjustments to be made to piezoelectric actuators without active<br />

position feedback. Separate potentiometer knobs control three<br />

independent, low-noise outputs. Three BNC rear-panel inputs can<br />

be used to control the output voltage remotely. These limited-bandwidth<br />

inputs are effectively dc controls. The voltage on each output<br />

channel can be monitored on the liquid crystal display. The<br />

three SMC drive outputs are color coded red, yellow, and green.<br />

For dynamic, wide-bandwidth piezo controller and for position<br />

feedback options, please refer to pages 33.3 through 33.5.<br />

SPECIFICATIONS: PIEZOELECTRIC DRIVERS<br />

Output Voltage:<br />

3 channels, 0–75 Vdc, SMC screw connectors<br />

Internal control with 10-turn front-panel potentiometers or<br />

external control with 0–10 Vdc on 3 rear-panel BNC inputs<br />

Noise: < 3 mV<br />

Display: 3.5 digit LCD<br />

Power Input:<br />

Voltage: 100, 120, 220, and 240 V,<br />

rear-panel selector switch<br />

Frequency: 50–60 Hz<br />

Power: