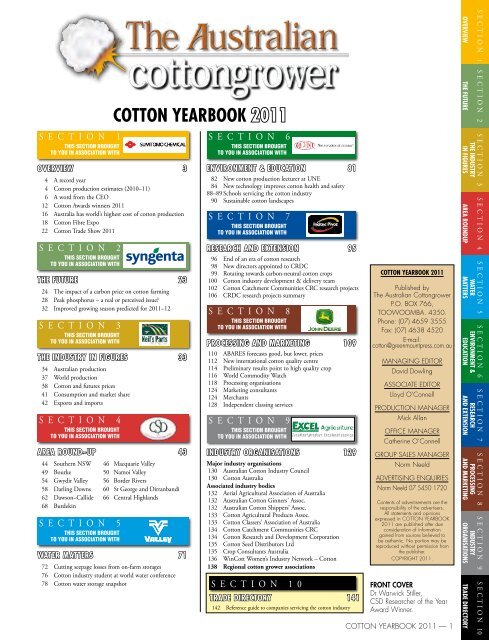

COTTON YEARBOOK 2011 - Greenmount Press

COTTON YEARBOOK 2011 - Greenmount Press

COTTON YEARBOOK 2011 - Greenmount Press

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

S E C T I O N 1<br />

OVERVIEW<br />

S e c t i o n 1<br />

THIS SECTION brought<br />

to you in asSociation with<br />

OVERVIEW 3<br />

4 A record year<br />

4 Cotton production estimates (2010–11)<br />

6 A word from the CEO<br />

12 Cotton Awards winners <strong>2011</strong><br />

16 Australia has world’s highest cost of cotton production<br />

18 Cotton Fibre Expo<br />

22 Cotton Trade Show <strong>2011</strong><br />

S e c t i o n 2<br />

THIS SECTION brought<br />

to you in asSociation with<br />

THE FUTURE 23<br />

24 The impact of a carbon price on cotton farming<br />

28 Peak phosphorus – a real or perceived issue?<br />

32 Improved growing season predicted for <strong>2011</strong>–12<br />

S e c t i o n 3<br />

THIS SECTION brought<br />

to you in asSociation with<br />

THE INDUSTRY IN FIGURES 33<br />

34 Australian production<br />

37 World production<br />

38 Cotton and futures prices<br />

41 Consumption and market share<br />

42 Exports and imports<br />

S e c t i o n 4<br />

THIS SECTION brought<br />

to you in asSociation with<br />

AREA ROUND~UP 43<br />

44 Southern NSW 46 Macquarie Valley<br />

49 Bourke 50 Namoi Valley<br />

54 Gwydir Valley 56 Border Rivers<br />

58 Darling Downs 60 St George and Dirranbandi<br />

62 Dawson–Callide 66 Central Highlands<br />

68 Burdekin<br />

S e c t i o n 5<br />

THIS SECTION brought<br />

to you in asSociation with<br />

WATER MATTERS 71<br />

72 Cutting seepage losses from on-farm storages<br />

76 Cotton industry student at world water conference<br />

78 Cotton water storage snapshot<br />

<strong>COTTON</strong> <strong>YEARBOOK</strong> <strong>2011</strong><br />

S e c t i o n 6<br />

THIS SECTION brought<br />

to you in asSociation with<br />

ENVIRONMENT & EDUCATION 81<br />

82 New cotton production lecturer at UNE<br />

84 New technology improves cotton health and safety<br />

88–89 Schools servicing the cotton industry<br />

90 Sustainable cotton landscapes<br />

S e c t i o n 7<br />

THIS SECTION brought<br />

to you in asSociation with<br />

RESEARCH AND EXTENSION 95<br />

96 End of an era of cotton research<br />

98 New directors appointed to CRDC<br />

99 Rotating towards carbon-neutral cotton crops<br />

100 Cotton industry development & delivery team<br />

102 Cotton Catchment Communities CRC research projects<br />

106 CRDC research projects summary<br />

S e c t i o n 8<br />

THIS SECTION brought<br />

to you in asSociation with<br />

PROCESSING AND MARKETING 109<br />

110 ABARES forecasts good, but lower, prices<br />

112 New international cotton quality centre<br />

114 Preliminary results point to high quality crop<br />

116 World Commodity Watch<br />

118 Processing organisations<br />

124 Marketing consultants<br />

124 Merchants<br />

128 Independent classing services<br />

S e c t i o n 9<br />

THIS SECTION brought<br />

to you in asSociation with<br />

INDUSTRY ORGANISATIONS 129<br />

Major industry organisations<br />

130 Australian Cotton Industry Council<br />

130 Cotton Australia<br />

Associated industry bodies<br />

132 Aerial Agricultural Association of Australia<br />

132 Australian Cotton Ginners’ Assoc.<br />

132 Australian Cotton Shippers’ Assoc.<br />

133 Cotton Agricultural Products Assoc.<br />

133 Cotton Classers’ Association of Australia<br />

134 Cotton Catchment Communities CRC<br />

134 Cotton Research and Development Corporation<br />

135 Cotton Seed Distributors Ltd<br />

135 Crop Consultants Australia<br />

136 WinCott Women’s Industry Network – Cotton<br />

138 Regional cotton grower associations<br />

S e c t i o n 1 0<br />

TRADE DIRECTORY 141<br />

142 Reference guide to companies servicing the cotton industry<br />

<strong>COTTON</strong> <strong>YEARBOOK</strong> <strong>2011</strong><br />

Published by<br />

The Australian Cottongrower<br />

P.O. BOX 766,<br />

TOOWOOMBA. 4350.<br />

Phone: (07) 4659 3555<br />

Fax: (07) 4638 4520<br />

E-mail:<br />

cotton@greenmountpress.com.au<br />

MANAGING EDITOR<br />

David Dowling<br />

ASSOCIATE EDITOR<br />

Lloyd O’Connell<br />

PRODUCTION MANAGER<br />

Mick Allan<br />

OFFICE MANAGER<br />

Catherine O’Connell<br />

GROUP SALES MANAGER<br />

Norm Neeld<br />

ADVERTISING ENQUIRIES<br />

Norm Neeld 07 5450 1720<br />

Contents of advertisements are the<br />

responsibility of the advertisers.<br />

All statements and opinions<br />

expressed in <strong>COTTON</strong> <strong>YEARBOOK</strong><br />

<strong>2011</strong> are published after due<br />

consideration of information<br />

gained from sources believed to<br />

be authentic. No portion may be<br />

reproduced without permission from<br />

the publisher.<br />

COPYRIGHT <strong>2011</strong>.<br />

FRONT COVER<br />

Dr Warwick Stiller,<br />

CSD Researcher of the Year<br />

Award Winner.<br />

<strong>COTTON</strong> <strong>YEARBOOK</strong> <strong>2011</strong> — 1<br />

THE FUTURE<br />

S E C T I O N 2<br />

S E C T I O N 3<br />

THE INDUSTRY<br />

IN FIGURES<br />

AREA ROUNDUP<br />

S E C T I O N 4<br />

S E C T I O N 5<br />

WATER<br />

MATTERS<br />

S E C T I O N 6<br />

ENVIRONMENT &<br />

EDUCATION<br />

S E C T I O N 7<br />

RESEARCH<br />

AND EXTENSION<br />

S E C T I O N 8<br />

PROCESSING<br />

AND MARKETING<br />

S E C T I O N 9<br />

INDUSTRY<br />

ORGANISATIONS<br />

TRADE DIRECTORY<br />

S E C T I O N 10

DRIVING YOUR<br />

<strong>COTTON</strong> HARVEST FURTHER<br />

BON © BERLET #5573<br />

Bonfiglioli's advanced design and quality drives<br />

deliver outstanding performance, cost-savings & flexibility<br />

Combined with their talented solutions orientated<br />

engineers and specialised Drive Service Centre the<br />

Heavy Duty (HD) bevel or parallel helical and its<br />

modular combinations are engineered to provide<br />

outstanding quality, performance and fl exibility.<br />

From the customised HD Drive Power Packs, to the<br />

NEW smarter HD Alignment Free Drives (capable<br />

of further reducing your drive costs) are the perfect<br />

choice for your demanding bulk handling requirements.<br />

Advanced design technologies and scrupulous<br />

attention to detail, place these units at the top of<br />

their class, perfectly complementing Bonfi glioli’s<br />

established industry approved A Series helical bevel<br />

and F Series shaft mounted helical gearboxes.<br />

In conjunction with substantial warehoused stock<br />

levels, there’s a team of highly qualifi ed technicians,<br />

safe-guarding assembly and quality control.<br />

All is united to provide second-to-none, quick<br />

deliveries, service and 24/7 support.<br />

PHONE 1300 656 757<br />

More Torque - More Action<br />

www.bonfiglioli.com.au

S e c t i o n 1<br />

overview<br />

THIS SECTION brought to you in asSociation with<br />

A record year 4<br />

Cotton production estimates 4<br />

A word from the CEO 6<br />

Cotton Awards winners <strong>2011</strong> 12<br />

Australia has world’s highest cost of cotton<br />

production 16<br />

Cotton Fibre Expo 18<br />

Cotton Trade Show <strong>2011</strong> 22<br />

3

• o v e r v i e w B Y S U M I T O M O C H E M I C A L • o v e r v i e w B Y S U M I T O M O C H E M I C A L • o v e r v i e w B Y S U M I T O M O C H E M I C A L •<br />

S E C T I O N 1<br />

OVERVIEW<br />

This section brought to<br />

you in association with<br />

David Dowling.<br />

The 2010–11 cotton season will go down as an<br />

exceptional year in more ways than one. The<br />

area planted to cotton was a record and total<br />

production was a record – and the turnaround in<br />

fortunes for the industry from the middle of 2010<br />

was nothing short of remarkable.<br />

After almost a decade of drought, we were looking<br />

at another year of severely depressed production<br />

before the rain started to fall and turned the whole<br />

thing around. The smiles on the faces of growers<br />

became wider and wider and the size of the crop kept<br />

increasing. After the loss of so many trained personnel<br />

and the run down in machinery stocks over the<br />

years, there were doubts about the ability of the<br />

industry to handle the logistics of such a big crop.<br />

But one way or another, growers found the people<br />

to plant and manage the crop, the machinery and<br />

expertise to grow it and the contractors necessary to<br />

get it off.<br />

It was a remarkable achievement. It was also the<br />

A record year<br />

By David Dowling<br />

longest season in history. From the time from when<br />

the first crops were planted in mid September 2010,<br />

to when the last crops were harvested, was close to<br />

12 months. And who knows when the final bale will<br />

be ginned.<br />

The other records of course – and the ones we<br />

didn’t want – were the record rainfall totals and<br />

flooding, especially in Central Queensland and the<br />

Darling Downs. Just as Australia is operating a ‘two<br />

speed’ economy at the moment, this cotton season<br />

had two speeds. For growers faced with floods and<br />

long periods of cloudy weather, it was a disaster in<br />

some cases.<br />

On the other hand, there were cases of record<br />

yields and record prices which added a much needed<br />

recharge to many bank accounts. With another<br />

record season in the offing for <strong>2011</strong>–12, let’s hope<br />

that the good fortune is shared around and the only<br />

records we are talking about next year are positive<br />

ones.<br />

Australian cotton production estimates 2010–11<br />

Hectares<br />

Irrigated Dryland Total<br />

Yield<br />

bales/ha<br />

Bales Hectares 5 Yield<br />

bales/ha<br />

Bales Hectares Bales<br />

Queensland<br />

Emerald 1 24,000 6.0 145,000 8,000 2.5 20,000 32,000 165,000<br />

Biloela/Theodore 3,800 6.1 23,000 1,000 2.5 2,500 4,800 25,500<br />

Burdekin 350 7.1 2,500 0 0 350 2,500<br />

Darling Downs 44,500 6.5 289,000 55,000 2.7 150,000 99,500 439,000<br />

St George 27,800 10.7 296,000 550 3.6 2,000 28,350 298,000<br />

Dirranbandi 31,000 10.7 330,000 1,100 3.6 4,000 32,100 334,000<br />

Total 131,450 8.3 1,085,500 65,650 2.7 178,500 197,100 1,264,000<br />

NSW<br />

Macintyre 2 72,000 9.8 703,000 33,500 3.1 105,000 105,500 808,000<br />

Gwydir 52,200 9.8 510,000 74,000 2.8 210,000 126,200 720,000<br />

Upper Namoi 16,000 9.4 150,000 15,000 2.9 44,000 31,000 194,000<br />

Lower Namoi 3 50,500 9.7 492,000 18,000 2.3 42,000 68,500 534,000<br />

Macquarie 16,800 9.3 156,000 0 0 16,800 156,000<br />

Bourke 10,300 10.2 105,000 0 0 10,300 105,000<br />

Southern NSW 4 23,000 9.6 220,000 0 0 23,000 220,000<br />

Total 244,900 9.7 2,377,000 140,500 2.9 401,000 385,400 2,778,000<br />

WA – Ord 980 7.1 7,000 0 0 980 7,000<br />

Aust. total 377,330 9.2 3,469,500 206,150 2.8 579,500 583,480 4,049,000<br />

Overall average yield: 6.94 bales/ha (1575 kg/ha).<br />

1<br />

Includes Mackenzie and Belyando.<br />

2<br />

About 40% of Macintyre cotton is grown in Queensland. Includes Mungindi.<br />

3<br />

Includes Walgett.<br />

4<br />

Lachlan, Murrumbidgee Valleys and Tandou.<br />

5<br />

Planted area is in field hectares, not green hectares.<br />

4 — <strong>COTTON</strong> <strong>YEARBOOK</strong> <strong>2011</strong>

Notice to all bugs & suckers<br />

PROTECTED<br />

BY SHIELD<br />

Now also registered<br />

for control of<br />

Green Vegetable Bug<br />

& Jassids<br />

For the control of Green mirids & susceptible Aphids<br />

Highly effective and economical<br />

Short 5 day withholding period<br />

www.sumitomo-chem.com.au<br />

Sumitomo Shield Systemic Insecticide ® is a registered trademark of Sumitomo Chemical Australia Pty Ltd.

• o v e r v i e w B Y S U M I T O M O C H E M I C A L • o v e r v i e w B Y S U M I T O M O C H E M I C A L • o v e r v i e w B Y S U M I T O M O C H E M I C A L •<br />

S E C T I O N 1<br />

OVERVIEW<br />

This section brought to<br />

you in association with<br />

A word from the CEO<br />

The production of a record Australian cotton<br />

crop of around four million bales created<br />

a really positive platform for our year and<br />

buoyed the industry, our growers and their families.<br />

It also came with its own set of challenges for Cotton<br />

Australia. Not only did we have hundreds of growers<br />

entering the industry who hadn’t grown cotton<br />

before, we also had to make sure we had the capacity<br />

to produce and harvest such a massive crop.<br />

In the middle of all that, some regions were hit<br />

with the worst flooding in a century, and we lost<br />

approximately 10 per cent of our area. For some<br />

cotton families this was devastating and has meant<br />

another year of lost income. The Cotton Australia<br />

team worked hard to support these growers during a<br />

very difficult time.<br />

When we weren’t dealing with issues from ‘left<br />

field’ this year, the team steadily worked through our<br />

detailed Annual Operating Plan. This plan has input<br />

from growers, is approved by the Board and is built<br />

on each year to ensure new areas of grower interest<br />

are covered.<br />

This plan sets out a number of goals; to help the<br />

Australian cotton industry be world competitive, sustainable<br />

and valued by the community. It drives the<br />

industry’s strategic direction, retains a strong focus<br />

on R&D, promotes the strengths of the industry,<br />

reports its environmental credentials and implements<br />

policy objectives.<br />

Cotton Australia’s advocacy work starts in the<br />

field, listening to grower concerns and issues, and<br />

By Adam Kay, CEO, Cotton Australia<br />

Adam Kay and CA Chairman Andrew Watson.<br />

ends in Parliament House in Canberra, Sydney and<br />

Brisbane where those messages are taken to the policy<br />

makers who can have a real impact on the business<br />

of growing cotton.<br />

Topics in the spotlight<br />

Relief for flood affected growers<br />

Unfortunately approximately 10 per cent of the<br />

planted area was inundated with flood waters, particularly<br />

in Central Queensland, Theodore, the Darling<br />

Downs and St George. For some cotton families<br />

this was devastating and meant another year of lost<br />

income. The Cotton Australia team did everything it<br />

could to help, working with government to get funds<br />

released and working with industry to provide support<br />

to these growers during a very difficult time. A<br />

6 — <strong>COTTON</strong> <strong>YEARBOOK</strong> <strong>2011</strong><br />

Members of the Cotton Australia Board.

• o v e r v i e w B Y S U M I T O M O C H E M I C A L<br />

• o v e r v i e w B Y S U M I T O M O C H E M I C A L • o v e r v i e w B Y S U M I T O M O C H E M I C A L •<br />

30 point plan based on grower needs was developed<br />

and implemented and the Cotton Flood Fund will<br />

see donations from industry delivered to growers to<br />

help them get started next season.<br />

Planning for a bumper crop<br />

Over a quarter of the cotton area in the 2010-11<br />

season was produced by dryland growers, a much<br />

larger percentage of the crop than ever before. A<br />

significant number of growers entered the industry<br />

for the first time, or hadn’t grown cotton for many<br />

years, and so there was a challenge to ensure these<br />

newcomers had access to the latest information and<br />

technology and were aware of their obligations to the<br />

environment, their fellow farmers and the industry.<br />

Early in the season, when a major increase in area<br />

was predicted, Cotton Australia developed a plan to<br />

ensure there were adequate supplies of inputs and<br />

a seamless production season for growers. Briefings<br />

were conducted with senior staff and credit management<br />

teams of most major banks, detailed forecasts<br />

were delivered to the chemical supply industry and<br />

Cotton Australia worked closely with John Deere<br />

on supplies of module wrap. The plan resulted in no<br />

major supply shortages despite a crop three times the<br />

size of the previous year.<br />

Murray-Darling Basin Plan – the story<br />

continues<br />

It was another big year in the ongoing development<br />

of the Murray-Darling Basin Plan, with<br />

Cotton Australia heavily involved in the process.<br />

The “Guide” to the Draft Plan recommended cuts<br />

in diversions across the Basin between 3000GL –<br />

4000GL, and predicted just 800 jobs would be lost.<br />

The balance was obviously tipped towards the<br />

environment, rather than fairly balancing social and<br />

economic considerations. Cotton Australia, many<br />

industry and community groups and thousands of<br />

individuals from Basin communities protested long<br />

and loud at this inequity and challenged the credibility<br />

of the Guide’s science and conclusions. The<br />

immediate impacts of these communities finding<br />

A packed Murray-Darling Basin Plan community<br />

meeting on the Darling Downs.<br />

S E C T I O N 1<br />

OVERVIEW<br />

This section brought to<br />

you in association with<br />

Extend the life of your Chemicals, Turn Chemical Resistent<br />

Weeds (Fleabane, Feather Top and Windmill grass) into Organic Matter<br />

Go-Devils (triple disc hillers)<br />

Larger disc hiller models available with disc sizes upto 28 inch<br />

PROVEN<br />

PERFORMER<br />

8-4 Series Triple-Flex Tandem Disc. Working<br />

Width from 21’–40’.<br />

8-4 Series Narrow Folding Tandem Disc. Working<br />

Width 10’–21’ 3 metres wide in transport.<br />

Also available:<br />

H Rotobucks H Rubber & steel rollers<br />

H Cultipackers H Grader sloper blades<br />

H Toolbars built to order<br />

Countrywide Industries<br />

Manufacturers of Agricultural Equipment & General Engineering<br />

Factory – Cnr River & Morgan Sts, Dubbo NSW 2830 – PO Box 1830, Dubbo NSW 2830<br />

Phone: (02) 6882 8933 Fax: (02) 6882 2106<br />

Email: cwi@hwy.com.au — www.countrywideindustries.com.au<br />

<strong>COTTON</strong> <strong>YEARBOOK</strong> <strong>2011</strong> — 7

• o v e r v i e w B Y S U M I T O M O C H E M I C A L • o v e r v i e w B Y S U M I T O M O C H E M I C A L • o v e r v i e w B Y S U M I T O M O C H E M I C A L •<br />

S E C T I O N 1<br />

OVERVIEW<br />

This section brought to<br />

you in association with<br />

their voice has set us on a path that, while not perfect<br />

and not yet certain, is more promising than the<br />

previous process.<br />

During this time, Cotton Australia leveraged its<br />

alliances to the full, working with NFF, QFF and the<br />

NSW Irrigators Council in particular to apply pressure<br />

to government and the Murray-Darling Basin<br />

Association. Cotton Australia also joined the newly<br />

formed National Irrigators Council and the Basin<br />

Communities Association to further strengthen our<br />

position in this critical debate.<br />

2,4D drift kept at bay<br />

For the third consecutive season Cotton Australia<br />

implemented a comprehensive campaign to reduce<br />

incidents of cotton crop damage due to phenoxy<br />

herbicide drift. The awareness campaign involved<br />

providing direct information on best management<br />

practice spray application, cotton crop field locations<br />

and adverse incident reporting procedures. Cotton<br />

Australia can report that there were no documented<br />

adverse incident reports of phenoxy herbicide damage<br />

to cotton crops this season.<br />

A critical element in this success was the continued<br />

development of cottonmap.com.au which was<br />

again very successful in alerting potential users of<br />

Phenoxy products to the proximity of cotton fields<br />

to any area requiring weed control over summer.<br />

Over 400 registered users mapped 5326 fields covering<br />

579,990 hectares.<br />

15th Australian Cotton Conference brings<br />

industry together<br />

The 15th Australian Conference was held on the<br />

Gold Coast in August, with the theme “Fashioning<br />

the Future.” The industry showcase had close to<br />

1000 delegates including a large contingent of growers,<br />

and covered wide ranging topics from global<br />

marketing issues down to detailed research data on<br />

plant nutrition, water and soil health.<br />

Tristan Petty, James Houlahan and Dean Hamblin.<br />

Key Wins for GROWERS<br />

• The Cotton Australia Board and Staff have<br />

fought hard to get positive outcomes for<br />

growers during the year. Some of the wins<br />

achieved in 2010–11 include:<br />

• A major change of direction in planning for<br />

the Murray-Darling Basin, allowing more time<br />

and more pressure to be applied at local and<br />

Federal levels.<br />

• Water buy-backs to only come from willing<br />

sellers.<br />

• Prohibitive ‘capacity to pay’ and ‘rates of<br />

return’ aspects overturned in water price setting<br />

negotiations in Queensland.<br />

• Reduction in 2,4D spray drift incidence from<br />

nearly 16,000 hectares of cotton affected in<br />

the 2009–10 season, (costing the industry $9<br />

million) to virtually no problems this year.<br />

• Despite a cotton area three times the size,<br />

no major issues with input supply shortages<br />

this season due to Cotton Australia’s efforts in<br />

briefing all major players.<br />

• First industry group on the scene during the<br />

flood crisis, establishing grower and community<br />

needs and taking these to government. The<br />

Cotton Flood Fund to be established with a $2<br />

million pledge from Monsanto.<br />

• Cotton Australia lobbied for a joint Federal/<br />

Queensland decision to extend Category<br />

D assistance, extending concessional loans<br />

across 33 local government areas, including<br />

cotton communities.<br />

• Negotiated far better outcomes for cotton<br />

module and equipment movement, alleviating<br />

restrictions placed on growers during the<br />

critical harvest period.<br />

• Over 1000 delegates attend the Cotton<br />

Conference on the Gold Coast in August<br />

2010, sharing the latest research, innovations<br />

and best practice as well as uniting the<br />

industry.<br />

• Cotton Australia convened 26 agricultural<br />

industries to develop a joint-submission to<br />

the Productivity Commission Inquiry into rural<br />

R&D, providing a strong and united voice for<br />

agriculture<br />

• Following Cotton Australia’s intensive<br />

lobbying campaign the Agriculture Minister<br />

has pledged not to change funding<br />

arrangements for Research and Development<br />

Corporations, including the CRDC, despite<br />

a recommendation to the contrary from the<br />

Productivity Commission Review into rural R&D.<br />

• Revised myBMP program launched, a webbased<br />

system making it easier for growers to use<br />

and bringing all of the industry’s sustainability<br />

resources and knowledge together.<br />

• Negotiated for better conditions than those<br />

originally proposed in the new Pastoral Award,<br />

making it more cost effective for growers to<br />

implement.<br />

• Cotton Australia successfully applied to the<br />

APVMA for a number of special permits for<br />

a range of insecticides to control locusts and<br />

mealybugs that posed major biosecurity threats<br />

during the season.<br />

8 — <strong>COTTON</strong> <strong>YEARBOOK</strong> <strong>2011</strong>

Cotton Champions<br />

Pictured L-R: Bill Willis, Ed Willis, Peter O’Keeffe from Monsanto & Von Warner<br />

Winners Tony Taylor and John Norman<br />

We’d like to congratulate the winners of this year’s<br />

Monsanto Grower of the Year Award, Bill Willis, Ed Willis<br />

and Von Warner from Bullamon Plains Pastoral, in<br />

Thallon, Queensland.<br />

The Australian cotton industry is filled with lots of dedicated farmers,<br />

but the Bullamon Plains Pastoral growers won because of their<br />

consistent yields of around 11 bales/ha and their excellent teamwork<br />

in developing a coordinated irrigation and cropping system.<br />

We’d also like to congratulate the runners up, Donald and Douglas<br />

Crothers from ‘Booligar’, Dirranbandi, Queensland and Hamish<br />

Johnstone, Macintyre Downs, Goondiwindi, Queensland.

• o v e r v i e w B Y S U M I T O M O C H E M I C A L • o v e r v i e w B Y S U M I T O M O C H E M I C A L • o v e r v i e w B Y S U M I T O M O C H E M I C A L •<br />

S E C T I O N 1<br />

OVERVIEW<br />

This section brought to<br />

you in association with<br />

Rural R&D<br />

Rural R&D was put under the spotlight this year<br />

with a Productivity Commission Review looking at<br />

the government’s return on investment in this area.<br />

Cotton Australia led the cotton industry’s submission<br />

and also coordinated a cross-sectoral group including<br />

over 20 commodity groups in compiling a joint submission.<br />

Cotton Australia was disappointed in the<br />

draft findings that suggested major funding cuts, and<br />

has geared up for a sustained fight to ensure research<br />

dollars continue to flow.<br />

myBMP<br />

In the area of sustainability, the revised myBMP<br />

program was launched to industry, following extensive<br />

grower feedback and improvements to this<br />

industry sustainability flagship. The improved system<br />

has removed impediments to grower uptake,<br />

encouraging greater on-ground adoption of sound<br />

environmental practices and giving the community<br />

confidence that the cotton industry is managing its<br />

natural assets efficiently. A new Human Resources<br />

module was added to ensure a better and safer workplace<br />

environment on cotton farms, with the benefits<br />

set to filter through to the wider community.<br />

myBMP basically takes the original BMP manual<br />

and replaces it with a user friendly, up to the minute<br />

web based tool. The program is designed to be a one<br />

stop shop for growers and industry people to access<br />

the latest information and research, find solutions to<br />

challenges that may arise and provide a wide variety<br />

of tools and features to help industry members operate<br />

at optimal efficiency.<br />

The Queensland floods produced all the wrong sort of<br />

publicity.<br />

Jim Wark explaining the myBMP system.<br />

The 2010 Cotton Conference organising committee.<br />

10 — <strong>COTTON</strong> <strong>YEARBOOK</strong> <strong>2011</strong>

Series lll model available now with upgraded horizontal<br />

pivot bolt & tool bar mount<br />

Eliminate disc flips or block ups<br />

Full independent horizontal & vertical adjustment of<br />

unit height & spindle pitch<br />

Fits most mulchers & toolbar configurations up to 12m<br />

Patent No AU 2004203623<br />

Our unique row crop flail pattern improves flail life &<br />

maintains rotor balance throughout the life of the flail<br />

Mulcher can be fully lifted while still running<br />

Bisalloy replaceable wear skins<br />

Broad-acre capable<br />

TTQ can refurbish your mulcher at our workshop.<br />

We supply flails, pins, bearings & can advise on repairs or modifications<br />

so you can do it yourself.<br />

Our portable balancing kit enables us to balance your mulcher onsite.<br />

TTQ manufactures toolbars to<br />

suit all your farming needs e.g.<br />

Centre Buster<br />

Side Buster<br />

Fertiliser Rigs<br />

Parallelograms<br />

GPS Steerable coulter<br />

adapter<br />

Introducing new multi<br />

shank system capable<br />

of fitting ripper boots,<br />

50 degree standard<br />

sweeps ( 2¼” bolt<br />

centres ) and chisel<br />

points, all on the one<br />

shank. 32mm thick and<br />

I” shear pins.<br />

TTQ is the home of tungsten hardfacing and all your wear & tear components !<br />

Tillage Traders Qld<br />

511 Boundary St Torrington Toowoomba Qld<br />

www.ttq.net.au<br />

Sales & Service 07 4634 0800<br />

Lindon Smith 0427 304 805<br />

<strong>COTTON</strong> <strong>YEARBOOK</strong> <strong>2011</strong> — 11

• o v e r v i e w B Y S U M I T O M O C H E M I C A L • o v e r v i e w B Y S U M I T O M O C H E M I C A L • o v e r v i e w B Y S U M I T O M O C H E M I C A L •<br />

S E C T I O N 1<br />

OVERVIEW<br />

This section brought to<br />

you in association with<br />

Watched on by their cotton industry peers,<br />

friends and the broad cotton family, winners<br />

in the Australian Cotton Industry<br />

Awards were announced in Narrabri on Wednesday,<br />

August 10.<br />

As the last official function for this year’s Cotton<br />

Collective, the awards recognise those talented and<br />

dedicated people who have made an outstanding<br />

contribution to the cotton industry.<br />

Accepting Australian Cotton Industry Awards<br />

were:<br />

CSD Researcher of the Year Award<br />

Winner<br />

Dr Warwick Stiller<br />

CSIRO Plant Industry,<br />

Narrabri, NSW<br />

Dr Warwick Stiller is a cotton breeder who joined<br />

CSIRO Plant Industry in 1995 as a post graduate<br />

student, and has developed into a committed scientist<br />

and plant breeder who is globally recognised for<br />

his work.<br />

Warwick has spent the past 16 years of his life<br />

Dr Warwick Stiller.<br />

Cotton Awards winners<br />

<strong>2011</strong><br />

in the cotton breeding scheme that was established<br />

to produce varieties for dryland productivity, stress<br />

tolerance and water use efficiency and he has played<br />

a leading role in delivering new varieties to the<br />

Australian cotton industry that deliver exceptional<br />

yield and quality and are the envy of our competitors.<br />

Chris Lehman Trust<br />

Young Achiever of the Year Winner<br />

Sponsored by Bayer CropScience<br />

Fleur Anderson<br />

President Dawson Valley Cotton Grower<br />

Association, Theodore, Queensland<br />

Born into a cotton growing family on the Darling<br />

Downs, Fleur Anderson has been around cotton<br />

all her life, and was thrown into the thick of it<br />

during the recent floods that devastated her small<br />

rural community for the second year running. Some<br />

growers lost the lot, twice in the same season, and<br />

as the President of the Theodore Cotton Growers<br />

Association, Fleur stepped up to the plate and supported<br />

her growers and community when it couldn’t<br />

get much tougher.<br />

Fleur and her husband’s family farm was affected<br />

too, but undeterred, she set about gathering data<br />

across the valley that established the scale of the<br />

problem and ultimately helped lead to additional<br />

government assistance.<br />

AgriRisk Innovative Grower of the<br />

Year Winner<br />

Stuart and Maxine Armitage<br />

Cecil Plains, Queensland<br />

By the end of December 2010, Stuart and<br />

Maxine Armitage had received 16 inches (400 mm)<br />

of rain and a good percentage of their 240 hectares<br />

of cotton was under water. And as if that wasn’t bad<br />

enough, they had just picked three cotton modules<br />

Fleur Anderson flanked by Geoff McIntyre and Debbie<br />

Lehman.<br />

Stuart and Maxine Armitage with AgriRisk Managing<br />

Director, John van der Vegt.<br />

12 — <strong>COTTON</strong> <strong>YEARBOOK</strong> <strong>2011</strong>

MAKE EVERY WORKING DAY<br />

MORE PRODUCTIVE<br />

Your Case IH machinery should be ready when you are. So make sure your<br />

equipment is always in peak condition with genuine Case IH parts, filters<br />

and AkcelA lubricants. They’re all designed to work together to make every<br />

working day more productive.<br />

Check with your local Case IH dealer today about genuine Case IH parts<br />

and the correct AkcelA engine oil for your machinery. No worries.<br />

Visit www.caseih.com for the details and<br />

address of your nearest Case IH dealer.<br />

Be Ready.<br />

CNH 1003

• o v e r v i e w B Y S U M I T O M O C H E M I C A L • o v e r v i e w B Y S U M I T O M O C H E M I C A L • o v e r v i e w B Y S U M I T O M O C H E M I C A L •<br />

S E C T I O N 1<br />

OVERVIEW<br />

This section brought to<br />

you in association with<br />

14 — <strong>COTTON</strong> <strong>YEARBOOK</strong> <strong>2011</strong><br />

Monsanto Country Lead Peter O’Keeffe (second from right) with <strong>2011</strong> Monsanto Grower of the Year winners, from l<br />

to r, Bill Willis, Ed Willis and Von Warner, Bullamon Plains.<br />

when another 4½ inches (114 mm) came pouring<br />

down, putting a stop to harvest for over a month.<br />

With serious concerns for the mental health of<br />

some local growers and spirits pretty low in general,<br />

the Armitages faced this difficult issue head<br />

on, organising a number of support services to help<br />

people through. A mental health night was arranged<br />

with a psychologist and respected GP that 90 locals<br />

attended, and a Relax and Revive night hosted by<br />

bush poet Murray Hartin was a great social occasion<br />

with 120 attending.<br />

Monsanto Grower of the Year<br />

Winner<br />

Ed Willis and Von Warner<br />

Thallon, Queensland<br />

Bullamon Plains is an outstanding farm enterprise<br />

including 20,000 hectares of grazing, dryland and<br />

irrigated cropping located at Thallon, about 65 km<br />

south of St George in Queensland. Owned by the<br />

Willis’, the farm has been in the family since 1928,<br />

with four generations of the family currently living<br />

on the property.<br />

In the 2010–11 season, Bullamon Plains grew its<br />

largest ever cotton crop of 1432 hectares, with an<br />

average yield of 11.1 bales per hectare, taking out the<br />

local cotton crop competition for the last three years.<br />

Cotton Australia Service to Industry<br />

Award Winner<br />

Joanne Grainger<br />

Mungindi, Queensland<br />

With almost three decades in the cotton industry,<br />

Joanne Grainger has represented the industry in many<br />

of its major policy forums, donating countless hours<br />

of her own time for the betterment of the industry.<br />

From 2007 to 2010, Joanne was the Chair of<br />

Cotton Australia (she joined the Board in 2002),<br />

where she oversaw the merger of the organisation<br />

with the Australian Cotton Growers Research<br />

Association. This paved the way for a new industry<br />

structure that reduced duplication and streamlined<br />

the advocacy efforts of the industry across all major<br />

policy areas.<br />

Cotton Australia CEO Adam Kay says these<br />

awards recognise people from across the industry,<br />

both those with the youth and vigour to contribute<br />

again and again to their industry in the future, along<br />

with those who have been doing that service for<br />

many years.<br />

“The Australian Cotton Industry Awards are in<br />

their eighth year, and as the resurgent Australian<br />

Cotton Industry looks ahead to another record crop,<br />

our key strength will always remain in the people of<br />

our industry.”<br />

“Cotton Australia thanks everyone involved, all<br />

who nominated and congratulates our finalists and<br />

winners who are leading the way for our industry,”<br />

he said.<br />

The Awards were presented by sponsor representatives<br />

from Cotton Seed Distributors, Bayer<br />

CropScience, AgriRisk, Monsanto and Cotton<br />

Australia.<br />

Joanne Grainger, with Cotton Australia Deputy<br />

Chairman, Lyndon Mulligan.

• o v e r v i e w B Y S U M I T O M O C H E M I C A L • o v e r v i e w B Y S U M I T O M O C H E M I C A L • o v e r v i e w B Y S U M I T O M O C H E M I C A L •<br />

<br />

S E C T I O N 1<br />

OVERVIEW<br />

This section brought to<br />

you in association with<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Australia has world’s highest<br />

cost of cotton production<br />

Research by the International Cotton Advisory<br />

Committee (ICAC) suggests that Australia<br />

has the highest cost of cotton production in<br />

the world, on a per hectare basis. This is probably<br />

due to our very high proportion of irrigated cotton<br />

and the highly technical nature of our industry. In<br />

fact, our costs of production per hectare are more<br />

than twice as high as our north and south American<br />

competitors.<br />

Fortunately, cotton is sold on the basis of<br />

weight, and Australia is much more competetive<br />

when it comes to cost per kilogram of lint produced.<br />

Australian costs are still slightly above the world<br />

average, but well below those in north America and<br />

not that much higher than other major production<br />

areas.<br />

The cost of production is the most critical issue<br />

in determining the net income for a cotton grower.<br />

Prices may be high, as they were in September–<br />

October 2010, but it does not mean anything to a<br />

cotton producer if the cost of production is also high.<br />

The Technical Information Section of the ICAC<br />

updates a cost of production survey every three years.<br />

The survey questionnaire has been designed to cover<br />

all inputs and operations involved in producing,<br />

harvesting and ginning cotton, but there still could<br />

be some operations that are not covered in the survey<br />

questionnaire. Respondents have an option to<br />

include operations/inputs not listed in the questionnaire<br />

under ‘others’, and many countries do so.<br />

The 115-page report ‘Cost of Production of Raw<br />

Figure 1: Cost of production of<br />

cotton by region ($US)<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Cotton’ was published in September 2010 and covered<br />

the 2009–10 season. Thirty-four countries participated<br />

in the survey with 63 entries, including<br />

rainfed and irrigated data and data from different<br />

regions within the same country. These 34 countries<br />

planted 89 per cent of world cotton area.<br />

The net costs reported do not include land rent<br />

in the case of seed cotton, while the value of seed<br />

after ginning and land rent are not included in the<br />

case of the net cost of lint per kg.<br />

Long-term trend<br />

Over the past three years, the average cost of production<br />

of seed cotton increased from US$0.34 per<br />

kg to US$0.43 per kg.<br />

The net cost of lint production increased to $1.22<br />

per kg, a 17 per cent increase. Apparently a significant<br />

portion of the increase in costs of production<br />

came from lower yields in 2009–10. The world yield<br />

at the time of survey in 2006–07 was 770 kg lint per<br />

hectare, but this declined to 724 kg per hectare in<br />

2009–10.<br />

Regional differences<br />

The thirty-four countries that participated in<br />

the survey planted cotton on 26.5 million hectares<br />

in 2009–10. The total cost, excluding land rent,<br />

averaged $1263 in 2009–10 to grow and harvest<br />

one hectare and to gin cotton produced from one<br />

hectare. The largest amount of money, $3282, was<br />

spent in Australia to produce a hectare of cotton. In<br />

Africa, less that 50 per cent of the world average total<br />

cost per hectare is spent to produce and harvest a<br />

hectare of cotton and gin cotton produced from one<br />

hectare. This may be the main reason for lower yields<br />

in Africa.<br />

While the world average net cost of production<br />

of lint per kilogram was $1.22, the cost of production<br />

among regions varied from $0.91 in Other<br />

African countries to $1.96 in North America. In<br />

Asia, where most cotton is now grown, the net cost<br />

of production was $1.15 per kg, almost equivalent to<br />

the average of West African countries. The data from<br />

Francophone/West Africa includes Cameroon, Chad,<br />

Cote d’Ivoire and Togo. Burkina Faso and Mali did<br />

not participate in the survey.<br />

The seed sold after ginning represents income to<br />

the grower.<br />

In most countries, the value of seed is enough<br />

to cover the cost of ginning, but there are countries<br />

where the value of seed is higher than the cost of<br />

ginning. This is particularly true in India, where the<br />

high value of seed after ginning emerged as a major<br />

factor for the lower net cost of production of lint<br />

per kg. The value of seed after ginning averaged at<br />

US$0.22 per kg of seed at the world level, but was<br />

only $0.13 in Australia.<br />

16 — <strong>COTTON</strong> <strong>YEARBOOK</strong> <strong>2011</strong>

• o v e r v i e w B Y S U M I T O M O C H E M I C A L<br />

• o v e r v i e w B Y S U M I T O M O C H E M I C A L • o v e r v i e w B Y S U M I T O M O C H E M I C A L •<br />

Cost of major inputs<br />

The four major inputs, not including field operations,<br />

are planting seed, irrigation, insecticides and<br />

fertilisers. Major operations in addition to input<br />

applications are harvesting and ginning. Data from<br />

all countries showed that on average, a cotton farmer<br />

spends $0.08 on planting seed to produce a kilogram<br />

of lint. Insecticide costs are $0.14 per kilogram of<br />

lint produced, the same as in 2006–07.<br />

Fertiliser costs increased by six cents to $0.28 per<br />

kilogram of lint in 2009–10.<br />

Weed control includes hoeing, thinning, interculturing/weeding<br />

and chemical weed control. Weed<br />

control costs more than doubled in three years to<br />

$0.28 per kilogram of lint in 2009–10.<br />

Taking into account the total expenses on irrigation<br />

and total area planted to cotton in 2009–10, the<br />

cost of irrigation averaged $0.10 per kilogram of lint<br />

produced in the world. The average cost for crops<br />

which are actually grown under irrigation is $0.15<br />

per kilogram.<br />

The two major operations, harvesting and ginning,<br />

cost $0.16 each for every kilogram of lint produced.<br />

In three years, the cost of harvesting increased<br />

by two cents per kilogram, probably due to higher<br />

labor costs. The cost of ginning declined by almost<br />

two cents per kilogram.<br />

Between 2006–07 and 2009–10, the cost of<br />

planting seed, irrigation and ginning declined by<br />

about 10 per cent. The cost of weeding more than<br />

doubled in three years, indicating that the reduced<br />

need to control insects is diverting attention toward<br />

weed control.<br />

Inter-country comparisons<br />

As there are differences between regions, the level<br />

of input use and production practices also affect<br />

the cost of production within regions and within<br />

countries. The cost of producing a kilogram of seed<br />

cotton is as low as 14 cents in the Eastern Region<br />

of Tanzania and 16 cents in Northern Santa Fe in<br />

Argentina, both rainfed.<br />

The net cost of lint (gross cost less land rent and<br />

income from seed sold after ginning) also showed<br />

huge differences among countries. The cost of producing<br />

a kilogram of lint is over $US2 in China,<br />

Colombia and parts of the USA. It is the least expensive<br />

to produce a kilogram of lint in India, whether<br />

irrigated or rainfed. Production costs per kilogram<br />

are lower in India because of recent increases in<br />

yields and high values for the seed after ginning.<br />

Irrigated vs rainfed cotton<br />

The net cost of producing a kilogram of lint<br />

under irrigated conditions is US$1.40 per kilogram,<br />

compared to US$0.93 per kilogram under rainfed<br />

conditions.<br />

S E C T I O N 1<br />

OVERVIEW<br />

This section brought to<br />

you in association with<br />

A D I V I S I O N O F T R I M B L E<br />

Super Strong<br />

Tear Resistance<br />

Chemical & Water<br />

Resistance<br />

Multiple Use<br />

Cost Effective<br />

Valéron® unique manufacturing process produces<br />

super strong cost effective covers that are ideal for<br />

your cotton crop<br />

Lightweight roll 4 metres x 110 metres are available<br />

Easy to handle and attach to cotton modules<br />

For further information contact<br />

Network Marketing<br />

dlynch@networkmarketing.com.au<br />

1300 NETMAR<br />

1300 638 627<br />

HARVEST WITH CUTTING EDGE PRECISION<br />

Laser & Agtech Moree. Contact Fred Nolan, Mobile: 0428 522 430<br />

www.omnistar.com.au | 1800 062 221<br />

<strong>COTTON</strong> <strong>YEARBOOK</strong> <strong>2011</strong> — 17

• o v e r v i e w B Y S U M I T O M O C H E M I C A L • o v e r v i e w B Y S U M I T O M O C H E M I C A L • o v e r v i e w B Y S U M I T O M O C H E M I C A L •<br />

S E C T I O N 1<br />

OVERVIEW<br />

This section brought to<br />

you in association with<br />

Cotton Fibre Expo<br />

Now entering its third decade, the Australian<br />

Cotton Fibre Expo (ACFE) has established<br />

a reputation as an iconic exhibition, bringing<br />

together the skills of some incredibly talented<br />

fashion designers and artists, demonstrating what<br />

can be done with cotton and creativity.<br />

Cotton Australia Chairman Andrew Watson officially<br />

opened the <strong>2011</strong> Australian Cotton Fibre Expo<br />

in Narrabri’s Crossing Theatre.<br />

ACFE President Lixie Killen says the fashions and<br />

designs on display at this year’s ACFE have changed<br />

considerably since the first expo was held in the late<br />

1980s.<br />

“It’s not just the designs that have changed, the<br />

range of cotton materials available and the creative<br />

and advanced techniques now being used by our<br />

talented entrants, clearly demonstrates the important<br />

role this expo has played in driving and advancing<br />

the uses of cotton fibre and fabrics.”<br />

Lixie says with the Australian Cotton industry<br />

currently harvesting the largest crop ever, the ACFE<br />

gives an opportunity for designers and artists both<br />

in Australia and internationally to show the amazing<br />

variety of creative applications for cotton fibre.<br />

Winning the major category for the Acquisitive<br />

Award was Fran Robinson with her work, ‘Red Sun<br />

upon the Seas to Ride’, this magnificent piece of<br />

hand embroidery encompassed mainly stranded cotton<br />

on a canvas base, making a vibrant image in red<br />

and blue.<br />

Lexie Killen says a particular stand-out this year<br />

was the quality of work submitted by young designers,<br />

with Beaujolais Parker winning the student<br />

section for her yellow ‘Tribal Dress’ while Branka<br />

Doncevska secured a highly commended for her blue<br />

‘Tribal Dress’ entry.<br />

Beaujolais Parker’s yellow ‘Tribal Dress’.<br />

Branka Doncevska’s blue ‘Tribal Dress’.<br />

Winner of the Acquisitive Award, Fran Robinson’s with<br />

her work, ‘Red Sun upon the Seas to Ride’,<br />

18 — <strong>COTTON</strong> <strong>YEARBOOK</strong> <strong>2011</strong>

CANOPY.®<br />

THE SIMPLE SOLUTION<br />

TO A COMPLEX PROBLEM.<br />

Concerned about aphids and the disease risk they pose?<br />

Feel that your management options are diminishing<br />

by the day?<br />

At Caltex Precision Spray Oils, we hear you.<br />

“Cotton bunchy top disease is a risk I could do without<br />

so I need to keep aphids under control.”<br />

“I attempted to keep weeds under control in the off<br />

season but I fear a green bridge from over the fence will<br />

bring real early season pressure.”<br />

“I didn’t want to use a seed treatment because I really<br />

don’t want to risk developing further resistance to<br />

neonicotinoids.”<br />

“I can’t risk an early season neonic or carbamate spray for<br />

mirids or aphids because of resistance risk again.”<br />

“I can’t spray with dimethoate because I might flare SWF<br />

later in the season, so I need a soft, early spray option for<br />

aphids and mirids that isn’t a resistance risk.”<br />

Canopy ® is the simple solution.<br />

“Early season aphids and mirids are likely to be<br />

a big problem.”<br />

Visit www.precisionsprayoils.com.au to see how we can work for you or call Stuart Paterson on 0408 682 087.

(Advertorial)<br />

Rotavator – More than a match for stubble trouble<br />

Coughing and sneezing, with a child on his lap and an interim<br />

phone at his ear because the landline has been washed<br />

away for the fifth time this year – and Greg Hutchinson still<br />

wants to talk about how good his Howard Rotavator is.<br />

Greg is part of a large family partnership farming on the<br />

Dawson River near Moura in Central Queensland.<br />

The family has farmed there for half a century and Greg said<br />

they have never seen it as wet as this year.<br />

Soil types vary from sandy loam to heavy black clay and the<br />

terrain is flat. The Hutchinsons grow irrigated cotton and grain<br />

on 1500 hectares with flood irrigation and centre pivots. They<br />

also do dryland farming and graze cattle.<br />

Greg said they wanted to buy a Rotavator because they knew<br />

how much time it would save them with ground preparation and<br />

incorporating crop residues.<br />

“We finally bought our eight-metre RC3825 Rotavator in June<br />

2010 from Vanderfield St George, and it was a great help with<br />

the timing,” he said.<br />

“We’d had no rain since March that year so the ground was<br />

very dry to start with, then the August rains came and then<br />

more rain, so we got to use the machine in a wide range of<br />

conditions and it did a great job.<br />

“Like this year, continuous rain held up the 2010 picking and<br />

the result was the crop grew much heavier and higher, which<br />

meant a lot more residue.<br />

“If we hadn’t had the Rotavator, we wouldn’t have been<br />

able to get the ground prepared and the trash incorporated<br />

with enough time for it to break down before planting. With<br />

conventional tillage equipment, it would have taken much<br />

longer with more passes and there would have been more<br />

interruptions with the rain.<br />

“As it was, we were able to turn it around in double quick time<br />

with the Rotavator which incorporates trash very well and<br />

forms up the beds in a single pass.”<br />

The machine handled 1000ha in 2010 and Greg said it will do<br />

1500 hectares this season with a John Deere 8530 tractor.<br />

“The Rotavator incorporates trash better than anything we’ve<br />

seen and it cuts out a couple of passes over the paddock too.<br />

In the past, we had trouble trying to incorporate irrigated wheat<br />

stubble before planting cotton but we won’t have this problem<br />

with the Rotavator.<br />

“This year, some of the cotton plants are getting on for 1.5m<br />

high after they’ve had the floods over them. There’s going to be<br />

a lot of stubble.<br />

“It will be a late picking and then we’ll put the Rotavator<br />

through to mulch and incorporate the stalks, turning the ground<br />

around and getting a great seed bed ready for planting in<br />

September or October,” he said.<br />

“The effect this machine has on stubble and ground<br />

preparation, and the time it has saved us – it’s well and truly<br />

what we hoped for when we bought it. I wouldn’t hesitate in<br />

recommending the Rotavator.”<br />

20 — <strong>COTTON</strong> <strong>YEARBOOK</strong> <strong>2011</strong>

(Advertorial)<br />

Kronos – just what a contractor needs<br />

Graham Gowar has been contracting in south-west<br />

Queensland for 18 years, 12 of them working with cotton.<br />

He discovered the strength of Howard machinery whilst<br />

farming in South Africa.<br />

“We had two Howard slashers and they took a lot of<br />

punishment from drivers who didn’t know or care about<br />

machinery. Those slashers are rugged machines and they held<br />

up very well, giving us many years of service,” Graham said.<br />

Graham’s business, GMG Contract Farming, is now a family<br />

operation. His son, Bruce, will also mulch cotton this season,<br />

and bought their second Kronos 8000C flail shredder. Graham<br />

bought his first Kronos 8000C shredder three years ago after the<br />

dealers, Vanderfields, demonstrated the machine’s capabilities.<br />

“One of our clients runs a major Queensland cotton station.<br />

They saw the Kronos in action and were very happy with the<br />

results. So were we. We mulched 5000 acres of sorghum with<br />

it in the first season and made enough to pay for the machine.<br />

We’ve been mulching cotton since then, and we also did a trial<br />

run with pigeon peas,” Graham said.<br />

“This year, a client has asked us to mulch 16,000 acres of cotton<br />

in a month. We’re aiming to have 20,000 acres done by end of<br />

the season and we wouldn’t have a hope without the Kronos.<br />

“The shredders are so rugged and reliable. The gearbox is<br />

fantastic. It takes a tremendous load, mulching eight rows of<br />

cotton stalks at once. It’s like feeding wood through it, and to<br />

turn it so quickly, it’s just incredible.<br />

“The hard-faced flails are toughened with a special welding<br />

technique to give them a long life. Sometimes we work in<br />

paddocks with quite a bit of wood lying around and you can’t<br />

always avoid it. I’ve had a flail bend slightly but they just keep<br />

working. I’ve never broken one yet.”<br />

Graham said before they bought their first Kronos, it took at<br />

least four passes to get the work done. “So doing a 10,000-acre<br />

mulch was like doing 40,000 acres in work terms. Getting great<br />

results with one pass is a 75 percent saving on time and labour<br />

for us so we are very happy using the Kronos.”<br />

They use two John Deere 8400 tractors with their Kronos flail<br />

shredders and Graham says if he’s getting 10 km/h, he’s happy.<br />

He learned about machinery growing up on the farm and he<br />

does his own maintenance. They regularly blow down the<br />

machines with a compressor and grease them. “I believe in<br />

preventative maintenance for machinery and for the land too,”<br />

he said.<br />

“The Kronos design is very practical. Maintenance access is<br />

easy and I like the doors at the back. You don’t have to lie in the<br />

dirt to take a look at the machine; you just stand there and open<br />

the doors.<br />

“The only problem we’ve ever had with the Kronos was due to<br />

human error when a driver went too low, cutting into the dirt<br />

and overloading the belts. Apart from that we’ve had no bother<br />

at all. The Kronos just keeps on going, which is exactly what a<br />

contractor needs from a machine.”<br />

<strong>COTTON</strong> <strong>YEARBOOK</strong> <strong>2011</strong> — 21

• o v e r v i e w B Y S U M I T O M O C H E M I C A L • o v e r v i e w B Y S U M I T O M O C H E M I C A L • o v e r v i e w B Y S U M I T O M O C H E M I C A L •<br />

S E C T I O N 1<br />

OVERVIEW<br />

This section brought to<br />

you in association with<br />

Cotton Trade Show <strong>2011</strong><br />

The mood was good at the <strong>2011</strong> Cotton Trade<br />

Show and that was a very pleasant and long<br />

awaited change for all in the industry. With the<br />

harvest about 60 per cent done, the growers were<br />

happy and optimistic – and when the growers are<br />

happy, we’re all happy.<br />

And sticking with this happy theme – we had the<br />

happy coming together of a record harvest, record<br />

prices and record storage levels. Well, ‘record storage<br />

levels’ in the sense that we at least had measurable<br />

levels with the prospect of an allocation going forward.<br />

Excel Agriculture national sales manager Brian Moran,<br />

Toowoomba, shows the features of an Excel Penetrator<br />

to Marc O’Brien, Krui and Glenroy, Mallawa, and John<br />

Ellis, Miralwyn, Carinda.<br />

Andrew Dickson, Warren, Chris Radford, Rowena, Tom<br />

Radford, Bellata, and Tom Quigley, Narromine, catch up<br />

at the trade show.<br />

By Brian O’Connell<br />

The signs were encouraging with the level of<br />

exhibitor interest leading up to the event. Not only<br />

did we have the regular supporters who, along with<br />

the growers, have weathered a few too many difficult<br />

seasons – we had many new faces. In racing parlance<br />

– these included maiden starters and those returning<br />

from a long spell.<br />

This was most noticeable amongst the major<br />

machinery exhibitors – numbers were up by 50 per<br />

cent on what we had seen for at least four trade<br />

shows. And this year most had new products on<br />

display!<br />

The growers and their staff on site also included<br />

a lot of ‘maidens’. Amongst the 1000 or so who<br />

turned up over the two days we had visitors from as<br />

far afield as Western Australia, Victoria, Tasmania,<br />

Far North Queensland and all the more traditional<br />

growing regions.<br />

I’m not sure about the guys from Tassie – they<br />

must have been on the look out for some very short<br />

season varieties and those from up past Cairns are<br />

perhaps keen to do some seed multiplication – they<br />

would have the water and the heat units for four or<br />

five crops a year, surely?<br />

The post-show feedback largely matched the<br />

mood on the day – most were happy. The growers<br />

showed interest in anything new on offer and<br />

all were busy catching up with suppliers and fellow<br />

producers. The ‘newer’ growers – both dryland and<br />

irrigated – from areas like southern NSW and the<br />

Downs were there in numbers and keen to see the<br />

technology. Some expressed disappointment that<br />

there were no pickers on site. Not just the new picker/module<br />

builders, but pickers of any sort.<br />

We would have liked a few too but they were<br />

busy bringing in 4,000,000 plus bales. I’m sure we<br />

could all put up with no pickers on display every<br />

year if it meant that they were always hard at work<br />

on a crop this size!<br />

There were a number of comments about the size<br />

of the crowd. When the Trade Show started over a<br />

decade ago there were a lot more growers, a lot more<br />

suppliers, a lot more consultants, a lot more contractors,<br />

there were a lot more of everything – we’ve all<br />

been rationalised.<br />

All of the people now involved in any way in the<br />

cotton industry could fit in the main pavilion at the<br />

Trade Show – and we would still have room to swing<br />

any number of proverbial cats. But these relatively<br />

few people – most of who were at the Trade Show –<br />

have together delivered the biggest Australian cotton<br />

crop on record. This is now the nature of the industry<br />

and I doubt that we will see it changing much as we<br />

move forward. We have all by necessity become lean<br />

and mean and – just as long as we remain ‘keen’ –<br />

there will be a place for the Trade Show.<br />

22 — <strong>COTTON</strong> <strong>YEARBOOK</strong> <strong>2011</strong>

S e c t i o n 2<br />

THE future<br />

THIS SECTION brought to you in asSociation with<br />

The impact of a carbon price on cotton farming................. 24<br />

Peak phosphorus – a real or perceived issue?...................... 28<br />

Improved growing season predicted for <strong>2011</strong>–12................ 32<br />

23

• T H E F U T U R E B Y S Y N G E N T A • T H E F U T U R E B Y S Y N G E N T A • T H E F U T U R E B Y S Y N G E N T A •<br />

S E C T I O N 2<br />

THE FUTURE<br />

This section brought to<br />

you in association with<br />

The impact of a carbon price<br />

on cotton farming<br />

Based on research conducted by the Australian Farm Institute*<br />

The Government has announced that direct<br />

emissions from agricultural activities will not<br />

incur a cost under the proposed carbon scheme<br />

for the foreseeable future, although the possibility of<br />

imposing a cost on agricultural emissions at some<br />

future time has not been ruled out, and has been<br />

proposed by a number of prominent persons and<br />

groups involved in advising on carbon policy.<br />

While agricultural emissions will not incur a<br />

direct cost under the proposed carbon price mechanism,<br />

major emitters such as electricity generators<br />

will have a cost imposed on their greenhouse emissions,<br />

and other major sources of emission such<br />

as fossil fuels are also likely to be included in the<br />

scheme. This will mean that the proposed carbon<br />

price mechanism will increase the price of energy,<br />

and hence the cost of farm inputs that involve the<br />

use of energy in their production or delivery.<br />

In order to project the impact of the proposed<br />

carbon price mechanism on Australian cotton farm<br />

businesses, the Australian Farm Institute developed<br />

a financial model of a typical cotton farm business,<br />

based on data available from industry sources<br />

The impact of a carbon price mechanism on the<br />

cotton farm was then estimated using formulae that<br />

create a link between the price of carbon, the impact<br />

of that carbon price on fuel and electricity costs, and<br />

the impact of changes in fuel and electricity costs on<br />

the cost of farm business inputs, including upstream<br />

and downstream sectors.<br />

A key issue for cotton farmers is the likely impact<br />

of a carbon price on processing costs. In order to<br />

estimate these cost changes as accurately as possible,<br />

detailed energy use data was obtained for a cotton<br />

gin. This data was used to estimate changes in cotton<br />

ginning costs under the three carbon policy<br />

scenarios, and the three carbon price scenarios under<br />

consideration in this research.<br />

The ‘typical’ cotton farm examined had 400 hectares<br />

of cotton with a yield of 9.24 bales per hectare<br />

and annual farm costs of almost $1.5 million.<br />

Table 1: Projected change in farm business costs and farm cash income, cotton farm<br />

Change in total costs and cash income (agriculture uncovered)<br />

Carbon price scenario Year 5 Year 10 Year 15 Year 20 Year 25 Year 30<br />

Carbon price $23.40 $28.47 $34.63 $42.14 $51.27 $62.37<br />

Cost – processor ($) $6,187 $7,527 $9,158 $11,142 $13,555 $16,492<br />

Low $20<br />

Cost – farm ($) $24,806 $30,014 $36,307 $43,905 $53,068 $64,102<br />

Cost total ($) $30,992 $37,541 $45,465 $55,047 $66,623 $80,594<br />

Cost change (%) 2.1% 2.5% 3.0% 3.7%4 .5% 5.4%<br />

Income change (%) –5.5% –5.2% –5.1% –5.1% –5.3% –5.4%<br />

Carbon price $35.78 $44.34 $53.61 $65.53 $80.35 $97.83$<br />

Cost – processor ($) $9,460 $11,725 $14,174 $17,327 $21,246 $25,869<br />

Med–CO2-5<br />

Cost – farm ($) $37,778 $46,440 $55,716 $67,535 $82,045 $98,931<br />

Cost total ($) $47,237 $58,165 $69,890 $84,863 $103,291 $124,800<br />

Cost change (%) 3.2% 3.9% 4.7% 5.7% 6.9% 8.3%<br />

Income change (%) –8.4% –8.1% –7.9% –7.9% –8.1% –8.4%<br />

Carbon price $50.83 $62.98 $75.60 $91.00 $110.11 $134.07<br />

Cost – processor ($) $13,440 $16,654 $19,991 $24,063 $29,114 $35,451<br />

High–CO2-15<br />

Cost – farm ($) $53,476 $65,562 $77,961 $92,908 $111,200 $133,794<br />

Cost Total ($) $66,916 $82,216 $97,951 $116,971 $140,314 $169,245<br />

Cost change (%) 4.5% 5.5% 6.5% 7.8% 9.4% 11.3%<br />

Income change (%) –11.9% –11.4% –11.0% –10.9% –11.1% –11.4%<br />

Source: Australian Farm Institute, <strong>2011</strong><br />

24 — <strong>COTTON</strong> <strong>YEARBOOK</strong> <strong>2011</strong>

Knock them out with powerful PEGASUS ® without<br />

the knock on effect<br />

Knock out whitefly, aphids, mites and everything else and you could end up with a domino effect. ‘Take out’ the beneficial insects and another pest<br />

problem flares up.<br />

Thankfully, there is a more selective solution. PEGASUS ® , the only Thiourea group insecticide used in cotton, has excellent translaminar, contact<br />

and vapour activity. It knocks down feeding pests hard, yet because of its unique chemistry, is very soft on beneficial species.<br />

PEGASUS also has a short 14 day withholding period, letting you use it up until the end of the season. This makes PEGASUS the perfect partner<br />

in your IPM resistance management program. For more information please call the Syngenta Technical Product Advice Line on 1800 067 108 or visit<br />

www.syngenta.com.au.<br />

® Registered trademarks of a Syngenta Group Company AD11-254 Powerful control. Unique chemistry.

• T H E F U T U R E B Y S Y N G E N T A • T H E F U T U R E B Y S Y N G E N T A • T H E F U T U R E B Y S Y N G E N T A •<br />

S E C T I O N 2<br />

THE FUTURE<br />

This section brought to<br />

you in association with<br />

Scenarios examined<br />

Three carbon price series were used in the analysis,<br />

to provide a picture of the impact of different<br />

carbon prices. The three price series used were as<br />

follows:<br />

• LOW – the carbon price commenced at $20 per<br />

tonne and increased at an average of four per cent<br />

per year.<br />

• MEDIUM – the carbon price was an Australian<br />

Government Treasury carbon price series that<br />

would be required to reduce national emissions<br />

by 5.0 per cent by 2020. This price series commences<br />

at approximately $28 per tonne and<br />

increases by an average of 4.4 per cent per year.<br />

• HIGH – the carbon price required to reduce<br />

national emissions by 15 per cent by 2020. This<br />

price starts at approximately $38 per tonne and<br />

increases by an average of 4.3 per cent per year.<br />

Results<br />

If agriculture is not covered<br />

The following discussion relates to projected<br />

changes from a business-as-usual scenario under<br />

which no carbon cost mechanism is implemented.<br />

So the projections being discussed are relative rather<br />

than absolute changes. Table 1 shows changes in<br />

farm input costs and farm cash income (gross farm<br />

cash revenue minus farm cash costs) arising from<br />

the impact of the carbon price, assuming agriculture<br />

remains an uncovered sector, under the three different<br />

carbon prices under consideration.<br />

Total cotton farm business costs under a carbon<br />

price will increase by between 2.1 per cent and 4.5<br />

per cent by year five of the policy, an increase of<br />

between $30,992 and $66,916 per year. Farm costs<br />

are projected to contribute 80 per cent of the total<br />

Figure 1: Change in farm cash income for a cotton farm<br />

business under a scenario where agriculture becomes<br />

a covered sector after 5 years, and incurs a liability for<br />

10% of emissions, escalating by 1.5% per annum<br />

Source: Australian Farm Institute, <strong>2011</strong><br />

increase in costs, with processing cost increases contributing<br />

20 per cent.<br />

While the percentage increase in input costs<br />

appears relatively minor, in dollar terms the total<br />

change in input costs is quite large. With total<br />

costs of $1,497,046 in the base year, an increase of<br />

$30,992 in total farm costs doesn’t appear significant<br />

in percentage terms, but the dollar increase in costs<br />

may have a significant impact over the long-term on<br />

farm profitability.<br />

The impact of a carbon price on farm businesses<br />

can also be expressed in terms of the changes in farm<br />

cash income (gross farm cash revenue minus farm<br />

cash costs) as the price of carbon changes. Farm cash<br />

income is an important measure for a farm business,<br />

as it reflects the cash surplus generated each year that<br />

is available for owner/operators expenses and/or to<br />

retire debt.<br />

A 2.1 per cent increase in farm input costs, for<br />

example, translates to a 5.5 per cent reduction in<br />

farm cash income under the lowest carbon price scenario<br />

after five years.<br />

At a carbon price of approximately $20 per<br />

tonne, the additional costs are approximately $7.17<br />

per bale of cotton produced.<br />

If agriculture is covered<br />

The Australian Government has stated that agricultural<br />

emissions will not attract a liability under a<br />

carbon price mechanism for the ‘foreseeable future’.<br />

But the New Zealand emissions trading scheme<br />

which has already commenced includes a proposal to<br />

impose a cost on at least some farm emissions from<br />

2015, by making downstream processors and input<br />

suppliers liable for emissions that are generated on<br />

farm. This, in combination with the fact that agriculture<br />

sector emissions will become more prominent<br />

in future in the national inventory as other sectors’<br />

emissions decline (and therefore more likely to<br />

attract the attention of policymakers) suggests that it<br />

is prudent to also examine the implications for farm<br />

businesses of a liability for a proportion of direct<br />

farm emissions.<br />

26 — <strong>COTTON</strong> <strong>YEARBOOK</strong> <strong>2011</strong>

• T H E F U T U R E B Y S Y N G E N T A • T H E F U T U R E B Y S Y N G E N T A • T H E F U T U R E B Y S Y N G E N T A •<br />

A scenario was therefore modelled under which<br />

a carbon price mechanism was introduced in the<br />

economy under the MEDIUM scenario. The agriculture<br />

sector, from year five, was then assumed to<br />

be required to pay a carbon price for 10 per cent of<br />

farm emissions, with the level of liability increasing<br />

by 1.5 per year from year six.<br />

This would mean that a farm business would be<br />

liable to pay a cost for 10 per cent of estimated farm<br />

emissions in year five, 11.5 per cent in year six and<br />

so on. Figure 1 shows projected changes in farm cash<br />

income for the model cotton farm under this scenario,<br />

compared to an equivalent scenario if agriculture<br />

is not covered.<br />

The imposition of a cost for farm emissions from<br />

year five, even at an initial 10 per cent level, would<br />

result in a significant additional decrease in farm<br />

cash incomes for the model farm. By year 30, if agriculture<br />

is excluded from the carbon trading mechanism,<br />

farm cash income is projected to be 8.4 per<br />

cent below business as usual. If agriculture is included,<br />

farm cash income is projected to be 11.4 below<br />

below business as usual.<br />

So even a relatively moderate rate of coverage for<br />

agricultural emissions will have a negative impact on<br />

the profitability of the model cotton farm<br />

No fuel scenario<br />

A carbon price policy scenario that has been the<br />